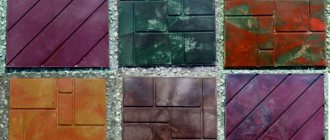

Brick paving slabs have a simple design, but they can be used to lay out many types of patterns. This type of paving stone is highly decorative. The simplicity of laying paving slabs of this type allows you to carry out the installation work yourself.

In addition, this decorative material is characterized by high performance characteristics and a long service life. You can purchase this product not only in Moscow, but also in other large cities.

Dimensions and installation details

Paving slabs, paving stones and bricks have a regular rectangular shape, but it is difficult to confuse them with the material for building walls due to the difference in size. Standard paving stones of this shape have dimensions of 20x10 cm and a width of 5-8 cm. Non-standard paving stones are also produced. Its height can reach 7 cm. Dimensions can be 21x7, 18x8.8 and 24x16 cm.

Patterns for laying paving slabs and bricks require the use of additional elements, which are produced separately. Most often, additional elements in the form of a cube with dimensions of 8.8x8.8 and 10x10 cm are sold along with full-size paving stones.

On rectangular tiles, there are 2-3 shaped protrusions on the long side, and only 1 on the end side. On additional elements, there is only 1 protrusion on each side. These protrusions are necessary to facilitate laying and seam formation.

On winding areas, not all types of tiles can be laid with high quality; paving stones and bricks are well suited for decorating such paths and areas. At the same time, it is possible to preserve the intended ornament and shape of the seams. When forming complex patterns of paving slabs, wedge-shaped seams are allowed.

When planning the use of decorative coating, you should draw up a plan for laying out the paving slabs in advance. There are many schemes for installing such paving stones. You can combine 2 or more colors of the coating.

What sizes are paving slabs?

The huge variety of paving slabs literally dazzles buyers' eyes. Square, rectangular, wavy, broken - for every taste and budget. But do not forget that when choosing, you need to pay attention to the size of the paving slabs. Why? Let's talk about this in detail.

Paving slabs are a durable piece product designed for finishing road and pedestrian surfaces. Available in the following materials:

1. Concrete mortar based on cement and quartz sand. To obtain different shades, pigments are added to the raw material before molding. The surface is matte, smooth or embossed depending on the decor. Strength and applications are determined by thickness.

2. Mixtures of several types of clays, fillers and additives. The front side is smooth, uniform, the glossy effect is achieved by glazing.

3. Composite composition based on mineral fillers and binder resins. It is inferior in strength to concrete, but looks much more presentable.

Since concrete products are the most common, we will consider this type of tile, its sizes and designs.

Cement-sand paving stones are available in two types:

1. Vibrocast for garden and pedestrian areas, playgrounds and the like. The form with the mixture is placed on a vibrating table for 10-30 minutes, depending on the size of the container. The material is obtained with smooth edges and surface, but its strength is low.

2. Vibrocompressed. It is stamped at enterprises using special sophisticated equipment - molds operating at pressures of up to 35 atmospheres. This paving stone has good technical and performance characteristics and is used in all areas - from garden paths to road paving.

Where exactly it will be laid depends on the size and shape of the bridge stone. The most common sizes are:

- Paving stones 10x10 cm.

A popular type, since such tiles are incredibly convenient for installing straight and curved paths, smooth turns, landscape design, laying out mosaic panels on the central streets and squares of the city.

The thickness varies from 3 to 10 cm, the shape is square with rounded edges, rectangular, round. Products with a cross section of up to 6 cm are used for pedestrian areas, and above - for roadways. Weight – up to 3 kg/piece. Very easy to install products: geometric (square, brick, diamond, coil), figured (lace, honeycomb, clover, scales), broken (zipper, maple leaf, wave). The surface of the paving stones is smooth or embossed, the thickness is from 3 to 8 cm. The dimensions of complex shapes are determined by the extreme points. Most often used for pedestrian and garden areas, they are very popular in landscape design. It’s not easy to lay out curved paths, but experienced pavers can do it.

- Paving tiles 30x30.

Similar to the previous size, it is interesting because in some designs you need to use 2 or 4 pieces for a complete decoration. These are Cobweb square or diamond, Clover embossed, Grid and others. Weight – about 4 kg.

- Pavement paving stones 40x40.

This size is convenient for introducing new designs: 8 bricks, Flower, California, wood and others. In addition, it is enough to lay out two paths from these tiles to get a width of 1 meter together with the curb stone. The thickness of the products is from 3 to 8 cm, weight – up to 10 kg. But it is very difficult to make curved roads, smooth bends and turns.

Preparatory stage

Despite the fact that there are many ways to lay brick paving slabs, there is only one preparatory stage.

First you should purchase all the necessary materials and tools:

- rule;

- building level;

- grinder with discs for cutting stone;

- roulette;

- pegs;

- cord;

- shovel;

- rake and hoe;

- protective glasses;

- gloves;

- rubber hammer;

- sand;

- crushed stone;

- cement, etc.

The area should be cleared of grass, leaves, turf and debris. After this, a drawing and marking of the site is carried out. The boundaries of the site where the coating will be installed are marked with pegs. A cord is pulled over them. When marking paths with regular geometric shapes, you can use metal slats.

After marking is completed, it is necessary to begin forming a trench for the tile base. Its depth should be at least 20-25 cm. When forming a pit, it is important to ensure that the bottom is as level as possible. It is advisable to check it with a building level. This will further reduce material consumption and simplify the installation of the coating.

Along the perimeter of the site, curbs should be installed, which are fixed together with cement mortar. After this, a cushion of crushed stone is formed. First, a layer of washed river sand is poured. Its thickness should be at least 5 cm.

This layer is carefully leveled and compacted. After this, a 10 cm layer of crushed stone is filled in. It should also be compacted well. The last layer of the pillow should be sand. Its thickness should be approximately 5-7 cm. This layer should be thoroughly compacted.

It is necessary to spill all layers with water and wait for the substrate to dry. If necessary, add sand in places where it falls through. The surface is carefully leveled using the rule. Lastly, a layer of dry cement-sand mixture is poured. Its thickness should be 3-5 cm. This layer is carefully compacted and leveled according to the rule. After this, you can begin installing the tiles.

Popular layout schemes

There are many options for laying brick paving slabs. The installation process is facilitated by diagrams developed by specialists. Using them, even non-professionals can lay tiles efficiently. All installation options can be divided into 3 categories.

The first includes options when only 1 color tile is used. They are the easiest to implement. The second category includes options that use paving stones of 2 or more colors. This is a more complex installation method.

The third category includes radius patterns. This installation is difficult to perform and often requires cutting a large number of additional elements, which increases material consumption.

Plain

The simplest option is the linear installation of masonry. In this case, all the bricks with the long side should be oriented along the line of the path. The seams must match. With this type of masonry, it is important to properly arrange and secure the borders. They will hold the paving stones.

In addition, you can lay the tiles in a brickwork pattern. In this case, the direction of the paving stones is maintained, but an offset of ½ tile in adjacent rows is added.

In addition, brick tiles can be laid in a herringbone pattern. In this case, each element is laid at right angles to each other. This is a fairly simple option. The orientation of the Christmas tree can be either along the path or directed towards its side.

The block paving option looks beautiful, in which 2 tiles are adjacent to each other with their long sides, and another 1 element is located perpendicularly. The orientation of such an ornament can be any.

Two or more colors

The simplest version of two-color masonry is “chessboard”. In this case, blocks consisting of 2 tiles are laid out sequentially. In this case, it is important to ensure that tiles of the same color are turned lengthwise in one direction, and tiles of another color in the other direction. This way, the seams will be better visible, which will create the desired effect.

When covering large areas, paving stones can be laid out to create a pattern. The design can be of any complexity and include more than 3 colors of material. To obtain a high-quality result, it is important to make a drawing of the location of the tiles in advance and calculate the dimensions of the pattern on the ground.

Radius patterns

Radius patterns are the most difficult to execute, so if you don’t have the skills to create them, it’s better to choose an easier option. In this case, if you plan to lay a winding path, first lay the first row along its entire length. The orientation of the paving stones should be along the path. The second row begins with a square additional element. This will create a shift that resembles a brickwork pattern. This fills the entire surface of the track.

In addition, moving from a small radius to a large one, you can lay the tiles in semicircles. It is recommended to use elements of different colors. Before starting masonry, you must make a drawing of the design and calculate the amount of material required.

How much do paving slabs weigh?

It would seem that the question of how much paving slabs weigh should not greatly bother a customer who wants to see a path or platform on his or her personal plot. But in fact, everyone who knows about the intricacies of styling knows that too much depends on the weight indicator to ignore it. This includes the strength of the product, the installation technology, and the correct choice of base. If you don’t ask this question and let everything take its course, such a coating is unlikely to last long, and if it can’t withstand the weight, the base can easily sag. Next, we will tell you everything you wanted to know about the weight of vibro-pressed or vibro-cast paving slabs. We recommend vibration casting tiles.

| Name | Dimensions, mm | Weight, pcs./kg |

| Paving stones | 200x200x60 | 5,3 |

| Brick | 200x100x60 | 2.6 |

| Paving stones | 200x100x100 | 5,0 |

| 30x30x6 | 300x300x60 | 12,0 |

| Square | 400x400x60 | 21,0 |

| Square | 500x500x70 | 38,0 |

| Square | 500x500x60 | 34 |

| 8 bricks | 400x400x40 | 18.3 |

| Cloud, parquet, wave pattern | 300x300x30 | 4,8 |

| Coil | 225x136x60 | 3.3 |

| Wave | 240x120x60 | 4,0 |

| Old city | 1182x944x60 | 154,0 |

| Lawn grate | 600x400x80 | 27,0 |

| Sidewalk curb | 500x210x70 | 15.4 |

What determines the weight of paving slabs?

Today it is difficult to imagine a street without encountering a covering that would be made of paving stones. This is the most practical and not the most expensive way to improve not only a public place, but also your own private territory. At the same time, depending on the intended use, you should choose the product itself. The shape, size, thickness, and weight of paving slabs change. The latter will depend on a number of factors:

- Manufacturing technology. The vibrocompressed product will be much heavier, but at the same time stronger;

- Thickness and dimensions. It is not surprising that conventional slabs for paving the roadway will be noticeably heavier than the paving stones that are used for paths in the country;

- Compound. Paving stones differ not only in size and technology, but also in the composition itself. Actually, it is regulated according to GOST, which means you can always make preliminary calculations.

What is all this for? To determine what level of maximum load can be placed on a product. Also, do not forget about ground pressure. For example, if you are using vibration-pressed paving slabs with the appropriate thickness, it is advisable to use a concrete base, but for lighter solutions a sand cushion is also suitable.

Weight of 1 paving slab using specific examples

Of course, professionals try in advance, before they receive the material for further installation, to calculate the work process down to the smallest detail. That is why it is necessary to clarify the weight of 1 paving slab according to GOST. In addition, there is also a comparison table for such purposes. Moreover, knowing all the characteristics, you can also calculate the specific gravity. To do this, you need to have information about the mass of products and the construction area. independently delivers products to its client, but sometimes it is important for the buyer to know which transport is suitable for transportation. This point must also be taken into account. To give you an idea of the mass of one paving stone, here are comparative examples:

- Wave – 2.1 kg;

- Honeycombs – 2.4 kg;

- California - 5.8 kg;

- Brick – 2.7 kg;

- Spider web – 16 kg.

These are small examples where standardized sizes are used. To make it easier for you to understand, the weight is 1 pc. paving slabs "Volna" are based on dimensions 210x110x45. Our heaviest example is “Cobweb” 400x400x45, and the lightest is 30 mm paving stones.

As you can see, even if you thoroughly know GOST paving slabs, it will be very difficult to calculate the mass. That is why it is best to contact the manufacturer for detailed advice.

How can I find out the mass of Rentek tiles?

Nothing could be simpler. Firstly, we often indicate all the necessary characteristics in the catalog. But even if you couldn’t find what you were looking for there, it doesn’t matter, just call or write to us. We will tell you exactly how much paving slabs of a particular sample weigh and answer other questions that may arise.

Dimensions: 240x120x40mm Quantity: 32 pcs/sq.m

Paving nuances

Laying paving stones in the form of bricks has its own subtleties. Installation should begin from the lowest point of the site. The coverage area must be limited to storm drainage gutters or a curb, so these elements are installed first and securely fixed with cement mortar. Without these limiters, the integrity of the masonry may be compromised during operation.

If the coating will be subjected to heavy loads in the future, it is recommended to use geotextiles or dornite for the base. To reduce labor costs, you should lay the paving stones in front of you, while moving along the already formed surface.

When arranging a parking lot or parking lot, it is better to use tiles with a thickness of at least 6-8 cm, while for sidewalks products with a thickness of 4-5 cm are suitable. To increase the resistance of the tile to environmental factors, after the formation of the coating, it is recommended that it be treated with special hydrophobic compounds.