Prefabricated strip foundation remains a fairly common type of supporting part of a house. Factory-made blocks allow you to reduce construction time, since there is no need to wait a month for concrete to harden. Before purchasing products, it is worth understanding what types of foundation blocks there are and what each of them is intended for.

Types of blocks

According to GOST 13579-78, concrete products for the construction of basement and underground walls are made of three types:

- FBS;

- FBV;

- FBP.

All types can be made of heavy, silicate concrete or expanded clay concrete, the density of which is not lower than 1800 kg/m3.

FBS marking means solid products. Most often they are made of cement concrete. The strength characteristics of such products are higher compared to others. Only this type according to GOST can be used for foundations for buildings.

Drawings of series 1.116-1 “Concrete blocks for basement walls”, which are used in the manufacture of elements, do not imply reinforcement. According to this document, metal is used only for the manufacture of mounting loops. But sometimes in factories when producing FBS blocks of large sizes (width and length), longitudinal reinforcement rods are laid.

FBS - a; FBP - b

FBV brand blocks differ from solid ones in that they have a longitudinal cutout intended for laying utility lines. They are manufactured according to the same series as FBS (GOST is also general). They are used very rarely in construction, so such products cannot be found in factory catalogs. If necessary, you need to make a custom order.

The FBP brand is hollow concrete products. Manufactured according to the same series 1.116-1 and GOST 13579-78. Lightweight blocks have square voids open downwards. Available in different widths and heights, but only one length 2.4 m (2380 mm). FBP elements are suitable for constructing internal basement walls or as foundations for industrial equipment.

What are FBS foundation blocks?

FBS block (decoding) - foundation wall blocks or basement wall blocks (also used in the construction of basements). Such products have a rectangular shape and do an excellent job of supporting the entire building, since their composition is mainly determined by heavy concrete (reinforced).

The ends of the blocks have recesses, which makes the process of pouring a vertical seam in the masonry easier.

It will not be possible to fill such blocks yourself, since their production uses vibration-compression technologies and it is possible to compress a massive product only in a factory setting.

There are no more durable and economical alternatives to laying the foundation for the construction of a specific building, with the exception of monolithic casting of formwork.

What kind of concrete is used

A strip foundation is a building structure that works primarily in compression (with the exception of foundation pads). There is no need to use high grades and classes of concrete. According to GOST 13579-78:

- maximum compressive strength class B15 (or grade M200);

- minimum class for products made of expanded clay concrete or heavy concrete B3.5 (or grade M50);

- minimum class for elements made of silicate concrete B12.5 (grade M150).

Most often, heavy cement concrete B7.5 is used for foundations for blocks in the FBS and FBV series. For weakened FBP, the more durable material B12.5 is used.

Prefabricated strip foundation.

Quick foundation laying using concrete blocks

As mentioned above, when laying a strip foundation, solid FBS foundation concrete blocks are used. They are convenient in many ways:

- it is very easy to calculate the number of blocks for the required base area of the house;

- identical dimensions allow you to build a level foundation;

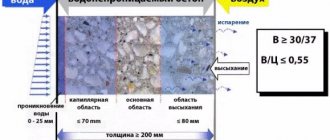

- the blocks can withstand large temperature changes and exposure to precipitation;

- FBS is distinguished by high moisture resistance;

- the strength of the concrete used in their composition allows them to withstand heavy loads from the building structures and provides a reliable foundation for the building. Heavy

It is for this reason that builders choose the strip type of foundation and concrete foundation blocks as the building material. Prefabricated block strip foundations will be a good solution for buildings with walls made of brick or any other heavy building material. They perfectly withstand the weight of the walls and distribute their entire load over the ground.

Marking

Before purchasing, it is important to study the sizes of the blocks, their characteristics and what concrete they are made of. All this information is contained in the labeling. A detailed explanation can be seen in GOST 13579-78 in paragraph 1.3. The structure looks like this:

FBS.ХХ.Х.Х - Х.

Some factories use a dash instead of a dot to separate numbers. But this does not change the decoding.

In the first position there is a number indicating the length of the block manufactured according to the series. The value is indicated in rounded decimeters. To calculate the exact value you need to subtract 20 mm (2 cm, 0.2 dm).

Advice! Also 2 cm is subtracted to find the exact height. This value falls on the seam between adjacent products. When constructing foundation layouts, it is not taken into account (rounded dimensions are taken, for example, height 600 mm, length 2400 mm, etc.).

The number in the second position shows the exact width of the product, and in the third the rounded height. All dimensions are given in decimeters. The last position indicates a letter indicating the type of concrete used for production (T, P or C).

Examples of notation:

- FBS.12.6.3-T - made of heavy cement concrete, having exact dimensions of 1180x600x280 mm (length, width and height, respectively);

- FBS.9.4.6-P - expanded clay concrete (material on porous aggregates) 880x400x580 mm;

- FBS.24.5.6-S - made of dense silicate concrete 2380x500x580 mm.

Standard product sizes.

Marking by series and GOST will be required when ordering products from the factory. It is important not to make a mistake with this question and not to confuse the sizes (the easiest way is to swap the height and width).

Advice! To prevent mistakes, it is worth remembering that foundation blocks are produced only in heights of 600 and 300 mm (rounded), but there are more width options.

What are FBS blocks?

FBS literally stands for “foundation wall blocks.” These are reinforced concrete products of various shapes and sizes with high performance and strength characteristics. Thanks to these properties, concrete blocks are widely used today in the construction of heavy-duty foundations.

The main materials for the manufacture of FBS blocks are concrete grades M150, M200, expanded clay concrete, silicate concrete and class A-III reinforcement. As a result, different types of FBS blocks have their own specific characteristics. For severe operating conditions, preference is given to blocks made of concrete grade M200.

Types of FBS blocks and their sizes

The main function of FBS blocks is to hold huge loads. Not every reinforced concrete product can cope with this task equally well. Therefore, concrete blocks are usually divided into three main types: FBP, FBS and FBV.

- FBS are solid reinforced concrete blocks with maximum strength characteristics. It is this type of FBS blocks that is used for laying foundations.

- FBV - concrete blocks of this type are not much different from the previous one, with the exception of a special cutout, which is intended for communications.

- FBP is a brand of hollow block up to 2.4 meters long. Blocks of this type have a lightweight design, which allows them to be used for the construction of walls.

| FBS BLOCKS • DIMENSIONS | WIDTH mm | HEIGHT mm | LENGTHmm | Weight, kg |

| FBS 24.6.6 | 800 | 580 | 2380 | 1960 |

| FBS 24.5.6 | 500 | 580 | 2380 | 1630 |

| FBS 24.4.6 | 400 | 580 | 2380 | 1300 |

| FBS 24.3.6 | 300 | 580 | 2380 | 970 |

| FBS 12.6.6 | 600 | 580 | 1180 | 960 |

| FBS 12.5.6 | 500 | 580 | 1180 | 790 |

| FBS 12.4.6 | 400 | 580 | 1180 | 640 |

| FBS 12.3.6 | 300 | 580 | 1180 | 460 |

| FBS 12.6.3 | 600 | 280 | 1180 | 460 |

| FBS 12.5.3 | 500 | 280 | 1180 | 390 |

| FBS 12.4.3 | 400 | 280 | 1180 | 310 |

| FBS 9.6.6 | 600 | 580 | 880 | 700 |

| FBS 9.5.6 | 500 | 580 | 880 | 590 |

| FBS 9.4.6 | 400 | 580 | 880 | 470 |

| FBS 9.3.6 | 300 | 580 | 880 | 350 |

The existing GOST FBS blocks defines up to 15 standard sizes of these products

At the same time, an important distinguishing characteristic of concrete blocks is their standard width, which varies from 300 to 600 mm. The length of FBS blocks is: 880, 1180, 2380 mm, and their height can be 280 or 580 mm

Dimensional characteristics of solid foundation blocks

One of the main parameters of FBS blocks is their dimensions. The specified structural units are classified according to a given length, width and height. These values are especially taken into account when choosing these elements. After all, they must perfectly fit a specific structure, fulfilling their main purpose - to evenly distribute the mechanical loads of the entire building falling on its base.

FBS block sizes.

It is the calculated load of the object on the foundation that determines what size blocks need to be selected. Moreover, the exact correspondence of their dimensions to the total mass of the structure is extremely important. For example, the use of blocks smaller than those required by the calculated standard risks the fact that in the future a building built on such a foundation will most likely be very difficult to operate normally and safely.

Today, the following parameters are considered the main standard sizes of FBS blocks:

- block length – 900 mm, 1200 mm, 2400 mm;

- block width – 300 mm, 400 mm, 500 mm, 600 mm;

- block height – 600 mm (some manufacturers offer corresponding products with a height of 300 mm).

Application of FBS blocks for strip foundations

Today, almost every second cottage is built on a strip foundation, which has a long service life, is durable and has good characteristics.

In most cases, the strip foundation is poured with monolithic concrete. However, if you need to create a foundation in the shortest possible time, then FBS blocks are used.

The structure can be made in a few days, and the solution, which is used to glue the materials together, dries in a few hours. If you compare FBS blocks with ordinary concrete, the blocks not only dry faster, but are also more practical.

It is worth considering that if you use blocks for the foundation, then you will need to use heavier equipment to build the structure.

The main features of a strip foundation made of FBS blocks

Special foundation blocks are rectangular-shaped products that are strengthened with reinforcement. To make it easier to create a seam from the blocks, there are small pits on their sides.

In FBS production, blocks are made from light and heavy concrete.

In addition, they are created from concrete, which contains expanded clay. In addition, products are divided into several types. It all depends on what kind of reinforcement they will be fastened with - regular or hardened.

The advantages of a strip foundation using FBS blocks include:

- Such blocks can withstand even the heaviest loads, which can never be compared with a monolith. They are resistant to climate changes, as well as the environment. Thanks to minimal porosity, there will never be mold on the floor.