Dynamic tests of bored piles are carried out to determine the load-bearing and indentation capacity of the presented reinforced concrete products.

The technology used to test the indentation capacity and load-bearing characteristics is regulated by separate provisions of SNiP and GOST 5686-94.

Dynamic testing of load-bearing capacity of piles

To make an accurate assessment of the pressing ability of products, an oscillographic packing analyzer is actively used.

After this, data on the indentation and static load experienced by the piles, in accordance with the requirements of SNiP and GOST 5686-94, are recorded in the relevant documentation. Data regarding soil characteristics is also entered there.

Features and purpose of tests

Dynamic tests for bored piles, as well as assessment of their pressing capacity, are carried out with an orientation towards any type of soil into which driving will be carried out.

Regardless of a number of characteristic features of the soil into which the presented bored reinforced concrete products will be driven, all work is carried out with a clear focus on the requirements of GOST and SNiP.

Dynamic and static testing of piles, as well as soil testing, is carried out during the construction of such objects as:

- Underwater bridge foundations;

- Coastal sites;

- Oil platforms.

Dynamic testing of piles in progress

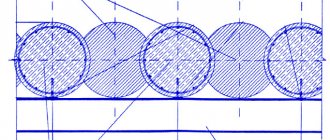

These piles are used for test driving. In this case, the loading device located above the piles is a special hydraulic hammer of the falling or impact type.

If there is no such unit at the construction site with which work on piles is carried out, then the estimate implies the presence of an alternative device for driving.

In this case, the test program for bored reinforced concrete products allows the use of a self-made tubular type hammer.

Based on the requirements of GOST and SNiP, the weight of this hammer for bored piles is 3.2 tons. Its installation is made from elements located between the piles.

Assembly is carried out in accordance with GOST and SNiP regulations, installation is carried out using a crane, in the space between the piles, in the place where soil tests will be carried out in the future.

Dynamic tests of piles are carried out in accordance with the requirements of GOST and SNiP at certain stages of work, the estimate is approved in advance. So, tests of bored piles are carried out:

- In the process of conducting soil surveys;

- Before starting the detailed design processes of a foundation with piles;

- When carrying out test driving of bored piles;

- When accepting completed work.

Dynamic testing of piles

As a result, a dynamic load test report is drawn up for the piles. It is worth noting that dynamic and static tests of bored products and soil studies are carried out:

- In order to determine the level of heterogeneity of soil structures within the construction site.

- To evaluate and compare the bearing capacity and load produced by piles.

- In order to detect load-bearing soil layers and weakened areas of the pile field.

- To obtain accurate and reliable data on the load-bearing capacity of piles after driving them.

GOST and SNiP allow the use of the same equipment during testing as during driving; these provisions clearly indicate the required distance between piles during work.

The final result of testing bored products is presented in the form of the resulting pile failure value. This is the depth to which the pile is immersed with one hammer blow.

Static testing of bored piles

The static method is an imitation of the operation of piles under load. Gives the most correct results, but is more expensive and longer than dynamic tests.

It is important!

We necessarily resort to statics in the following cases:

- when strengthening the foundation, when there is a risk of building collapse;

- on clay soils subject to frost heaving;

- on loess and bulk soils.

To conduct tests, we select an area with the worst soil characteristics throughout the entire site. Process steps:

- Immersion of supports to the design level.

- Acclimatization from three days to three weeks, depending on the structure of the soil (in Moscow on average 6 days). This stage is necessary for the soil to settle and structural connections to be restored.

- Next, we load the pile step by step (in steps). We hold it for some time, measure the draft, and load it again. The duration of the stage is 2-10 days (longest on permafrost).

Load shaping equipment:

- hydraulic jack;

- loading platform (support for jack);

- tared cargo, etc.

GOST recommended “rest” time for piles depending on the soil:

- coarse, coarse sands – 1 day;

- medium and fine low-water sands – 3;

- water-saturated – 10;

- clay and heterogeneous soil – 6.

Features of testing with static loads:

- you can start work only when the concrete has reached at least 75% strength;

- the vertical load must be centered;

- We measure the draft of the steps with hourly type indicators with divisions of 0.01 millimeters;

- We record instrument readings in the test log.

Another method of static testing is for pull-out force, using jacks.

Bored piles using the CFA method (hollow auger)

Calculation of bored piles

Rent of a drilling rig for bored piles

Key Benefits of Dynamic Load Testing

Testing a pile in an operating building before adding a superstructure

The dynamic testing method has a number of irrefutable advantages over the static method. When implementing this method, a high degree of mobility is available, it is quite economical and is applicable to all types of currently existing piles.

The presented method provides a real opportunity to significantly increase the load-bearing capacity of the product. All this is done in accordance with the provisions of SNiP.

Such an increase in the parameter is possible if the pile, during driving, is immersed with its tip into a weak layer, which has greater compressibility.

In clay-type soils, which are distinguished by their homogeneity within the area of the building’s foundation, when piles are driven to the same depth, the magnitude of failures may vary.

Coupled with the short immersion interval, the data provided can be misleading, and therefore an opinion may be formed based on different values of the load-bearing capacity of the products.

In this case, it is recommended to carefully compare the results obtained with those obtained during static surveys. In the process, one general value of the level of resistance of the presented reinforced concrete products will be revealed.

Dynamic testing technology

In most cases, dynamic testing is initiated three times. The first time, all actions are performed on existing products that are selected for work and construction. This happens before action begins with the pile foundation project.

Dynamic load testing of piles

In the process, an indicator of the level of heterogeneity of soil deposits in the place where construction will take place is determined.

The next stage after this is carried out immediately at the moment of driving. In the process, the load-bearing qualities of the product are assessed and the properties of load-bearing soil layers and weakened areas are studied.

After completion of the work, the final stage of testing is carried out. It provides the most reliable data on load-bearing capacity after they have been in the ground for some time.

When driving, in the process of monitoring current changes in failures, it is possible to identify those soil layers that are load-bearing.

This also allows for a comparative assessment of the load-bearing capacity parameters of already clogged products in order to identify possible weakened areas.

In clay-type layers, test driving is carried out using a hammer, which carries out a short series of blows. This allows you to keep the soil structure intact.

All current dynamic tests are carried out with the assistance of the equipment and machinery that was used in performing the main range of work.

Upon completion, the failure value becomes available. It is equal to the degree of immersion of the product into the ground after one blow with a hammer is made on it.

Testing piles with dynamic (impact) load using the ELDI method

The accuracy of the data that will be obtained directly correlates with the height of the hammer and the specific gravity of its striking part.

This also includes the weight parameters of the pile and its cap. Some attention is paid to the level of accuracy of measurements taken during elastic movements of the product in the ground after an impact.

Soil testing

During the construction of a building and its subsequent commissioning, sandy and clayey soils are subject to compaction as a result of the static load affecting them.

Soil testing has a very serious impact on the entire process of building construction. This is due to the fact that the strength and stability characteristics of the entire structure under construction directly depend on the parameters of the bearing capacity of the soil.

This procedure is carried out in order to study in detail the physical and mechanical characteristics of soils, determine the features of their geological structure and identify the conditions that affect the balance of the entire soil mass in a given area. In most cases, two mandatory stages of this type of testing are carried out.

- Laboratory.

- Field.

Strength testing of piles

Laboratory tests make it possible to determine the necessary parameters of the physical and mechanical qualities of soils, and field tests reveal the level of soil resistance in its natural conditions.

The work carried out helps to create the most optimal work schedule and predict the degree of sustainability of the future building.

In addition, this helps to choose the most effective method aimed at strengthening the foundation. These procedures are also carried out in order to avoid the collapse of erected buildings.

Tests can be carried out not only on open construction sites, but also when examining a completed foundation. If construction is carried out on an old foundation, then the soil must undergo a mandatory study procedure.

Static test of piles

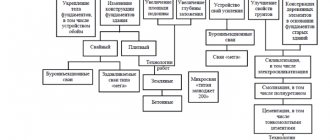

When choosing the equipment that is necessary for correct tests of this kind, the orientation is carried out on the features of the method by which the immersion will be carried out. Currently, the following methods are actively used:

- Laying the required cargo on a platform installed on stilts;

- Use of a tension sleeve or winch;

- Using a hydraulic jack and using its force;

- Using the VCA's own specific gravity.

Testing piles with static load according to GOST 5686-94

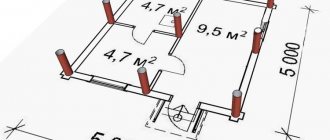

Static testing of piles begins with the identification of the number of existing products and the places where they will be driven further.

After this, test reinforced concrete structures are immersed. All current testing work is carried out with the participation of those structures that lie in areas with the worst ground conditions.

All test work begins by waiting for a period of “rest” for the pile. Those structures that will be immersed using other methods are brought into readiness no earlier than one day before the start of the process.

All work begins only after the product made of concrete hardens to 80% of its strength. All work is carried out evenly without impact and in compliance with the load on the structure. The procedure is established in advance and is displayed in the test program.

When deepening the lower ends of the structure into clastic-type soils, it is allowed to achieve three stages (levels) of load, which amount to 1/5 of all combined loads.

The first test pile must have high strength, due to this it can be ensured that all the necessary characteristics are obtained. If necessary, the pile is reinforced by connecting an external ring.