Terminology

To use a humidity sensor to be useful, you need to understand its design and operation. Many users do not understand its effectiveness and the principle of the device, which is where difficulties arise.

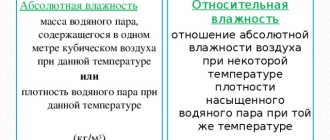

Air humidity is conventionally divided into absolute and relative. Absolute corresponds to the measurement of the volume of water in an air mass. There is a saturation threshold that corresponds to 100%. From this indicator the next process begins, called condensation.

Often, devices are assembled with an additional temperature sensor, which determines the relationship between the temperature of the environment and the amount of moisture in the air.

Relative humidity is measured by the ratio of moisture capacity to absolute humidity. The higher the relative humidity, the higher the “dew point”, correspondingly closer to the actual air temperature.

The process of improving humidity sensors

In both domestic and foreign production of humidity sensors, an effective direction of development is visible - the development of innovative moisture-sensitive compositions. In general, this industry is characterized by the following features:

- the inevitable transition to group planar microelectronic production technology (both thin-film and thick-film are used);

- creation of multitasking devices, for example, integrated temperature and humidity meters. The operation of such sensors not only helps to increase the accuracy of the measurements taken, but also leads to a simplification of the process of their calibration;

- bringing to a unified design system of humidity sensors, as well as signal processing facilities against the backdrop of the widespread use of microprocessors.

The existence of a wide variety of models of humidity sensors can be explained by the fact that none of them is universal. Each type of sensor has its own specifics, has advantages and disadvantages, which means the choice of device should take into account the characteristics of its application.

Description and purpose

Humidity sensor is a device designed to measure and convert relative humidity into a digital signal, as well as into a standard voltage signal.

Protective coatings of the sensor allow the device to be used in various environmental conditions and tasks, as well as in controlling the moisture content indicator: for building automation, for drying control in chemical production, in agriculture.

Methods for measuring humidity are conventionally divided into direct and indirect. In direct methods, the test material is distributed specifically into dry matter and moisture. Indirect methods measure physical quantities that are related to the moisture content of the material.

In rooms with high humidity, it is customary to install a fan that has a hydrostat - a humidity sensor that analyzes the saturation of the air in the bathroom with water vapor. Such a device will turn on only when the humidity level is exceeded.

For high-quality air exchange in the bathroom, instead of a ventilation grille, a fan with a built-in humidity sensor is installed.

Hygrometer calibration in practice.

And now an example from my practice of testing the Chinese hygrometer CX-201A. In a room with 37% humidity, the hygrometer showed 16%. In a room with 47% humidity, the hygrometer showed 29%.

After soldering the trimmer resistor to the R1 contacts, the hygrometer displayed a humidity of 50% and under no conditions did the readings change by more than 1 percent. Changing the parameters of other elements also did not bring the desired results. In the end, it was decided to leave everything as it was initially and judge the humidity in the room offhand.

Types and their operating principles

Capacitive

The capacitive sensor is the simplest and consists of capacitors with air between two plates. When dry, air does not conduct electricity. Capacitance is determined by the ability to store an electrical charge and changes when the structure of the sensor changes.

The second type is a capacitive dielectric sensor, which is significantly more sensitive to a humid environment than an air sensor. The capacitor is connected to the generator, and the object is located between the plates. The frequency of the oscillation circuit is measured and the capacitance is calculated.

The third version of the capacitive sensor is a substrate with two electrodes in the form of a comb. They act as covers. To compensate the temperature, 1 thermocouple is included in 1 sensor.

Sensors with an analog output create an electromagnetic field in the sensor response section, which is triggered by the approach or removal of metallic substances from the active surface and converts this distance into an analog signal in terms of current or voltage with a linear dependence.

Resistive

Resistive sensors monitor changes in the electrical resistance of the medium. Their design uses a ceramic coating to prevent the merging of environmental conditions during the formation of condensation. The sensors are constructed from a substrate, on the surface of which there is a conducting electrolyte, with electrodes deposited on it. They are placed in plastic protection.

The connecting material is ceramic powder suspended in a liquid medium. Once coated and dried, the sensors are exposed to high temperatures. This creates a thick film coating that does not dissolve in water and completely prevents the formation of condensation.

Resistive sensors have bifilar winding. Once coated with a hygroscopic polymer, their resistance is inversely proportional to humidity.

Thermistor

This type of sensor is based on thermistors. They determine humidity by fluctuations in the thermal conductivity of gases. These sensors are made from two very small thermistors held together with very thin wires to reduce heat loss by conduction through the housing.

The resistance of a thermistor changes greatly with a small change in temperature. In the sensor, one thermistor is built into a sealed chamber with dry air, and the other has direct contact with the environment. Moisture vapor partially condenses and evaporates when it hits the second thermistor. At the same time, its temperature and resistance change. Comparing the resistance of two thermistors gives an idea of the degree of air humidity.

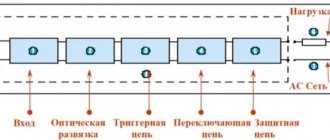

Optic

The greatest accuracy in monitoring environmental humidity is shown by optical sensors. The price of such a sensor is higher than other types, but accurate diagnostics are guaranteed.

In addition to the high cost, you need to know that there is a high probability of contamination of the optical glass. And besides, a significant amount of electricity is consumed.

Most humidity sensors have poor repeatability and do not provide accurate measurements. Based on this property, indirect methods for determining humidity are used, the most effective of which is the calculation of absolute and relative humidity at the temperature of thermodynamic equilibrium of liquid and gas in the air.

The dew point temperature corresponds to a certain value of saturated vapor pressure. Therefore, by measuring the dew point temperature at a known pressure value, absolute humidity can be determined.

Electronic sensor

The sensor is triggered when the electrolyte with which the insulating material is coated changes. There are devices with automatic heating that maintain the dew point temperature.

The principle of operation of the sensor is the reaction of a lithium chloride solution, which is very sensitive to even slight fluctuations in humidity. The dew point is measured over this solution. For the hygrometer to be most effective, a thermometer is attached to it, which makes it work with increased accuracy. Moreover, a minor error cannot be completely excluded. It can measure humidity at any ambient temperature.

Recently, digital electronic sensors have found application, which are high-precision devices with indoor climate control functions. The touch screen determines temperature and humidity percentage. In case of deviation from the specified parameters, it informs the owner, usually with a sound or light signal. This allows you to quickly configure the required parameter.

The most common are conventional electronic hygrometers with two electrodes. Two electrodes are placed in the ground. The degree of current conductivity determines humidity.

Duct

The duct sensor is used to determine the humidity of a non-aggressive environment. The air should not be loaded with dusty masses, otherwise there will be a large error and the inability to cope with its function.

A digital humidity sensor detects relative humidity. It is also capable of triggering based on configured ranges of indicators.

Sensor connection or installation

The process of connecting system elements to the control unit (CU) is not particularly difficult. Despite the fact that the operating instructions contain a description of the installation procedure, we have prepared for you a more detailed and detailed template of actions for installing the system.

You may be interested in: Rating of the TOP 7 best electric kebab makers for the home: review of popular models, reviews

First, you need to determine the places of probable leakage, these usually include sections of pipes with a large number of connections, places where water taps and household appliances are installed, such as a dishwasher and washing machine. It is better to attach the sensors to the base so that they are parallel to the floor plane. If possible, you can fasten it using a small self-tapping screw directly to the base; if a self-tapping screw cannot be used, you can drill a hole for the dowel and secure it with it.

According to the instructions, first of all you need to connect the built-in battery; it is responsible for the operation of the system in the event of a 220V network disconnection. To do this, you need to unscrew two screws from the back of the controller and connect the contacts of the battery and the controller.

According to the instructions, you need to connect all wires to the controller. All connection points are marked and this procedure does not cause any difficulties. We would like to draw your attention to the fact that the wires from the taps can be combined to the controller - connect only three, not six. The system is also designed to connect a grounding wire, so if there is one, it’s better to connect it.

After installing the system, you need to check its functionality; to do this, you need to wet the sensor. As soon as the sensor senses moisture, the controller sends a signal to the wires and the ball valves automatically close. At the same time, a sound and light signal is heard.

Please note that there are different types of sensors, we only told you about the model that comes with cables. Regardless of the type of your model, be sure to read the instructions - everything is explained in detail and clearly shown in the most accessible way.

Review of popular devices

HIG-2

The SOLER&PALAU HIG-2 humidity sensor reacts at a humidity of 60-90%, temperature from 0 to 40°C. A humidistat is used to automatically turn fans on and off based on a set relative humidity level.

After reaching the set humidity level, the sensor turns off and the shutdown delay timer is triggered.

After running on the timer, the fan automatically turns off and the sensor goes into standby mode. Electrical safety is ensured

DHT11 and DHT22

Temperature and humidity sensors DHT11 and DHT22 belong to the group of inexpensive and simple ones. DHT sensors are assembled from two parts: a capacitive humidity sensor and a thermistor.

A simple chip is built into the sensor body to change the analog signal into a digital one. Reading the digital output signal is absolutely simple - using any controller.

Having studied all the technical indicators, we can conclude that DHT22 is more accurate and has a larger scale of measured values. Both sensors have one digital output. Requests to them can be sent no more than once per second or two.

Xiaomi

Xiaomi produces a wide range of inexpensive equipment, but it has characteristics that are distinctive from other manufacturers, having its own advantages and disadvantages.

So in the model range there are also temperature and humidity sensors. It is a tiny device that responds to changes in specified indicators. Management is carried out through an application and a special program.

The sensor is designed quite primitively, it is mounted on a surface, uses a battery, and there is a button on top of the device that lights up the moment it is turned on for the first time. The gadget only works in conjunction with the main device.

The operating temperatures of the sensor vary from -20 to 60ºС. Humidity – from 0 to 100%, Temperature and humidity are measured continuously.

The device gives a signal (flashing light or sound) of danger if the sensor readings go beyond the established norm. You can connect several sensors to the main device and control the humidity in different rooms.

IVIT-M

The Ivit-M temperature and humidity measuring device is designed to control air humidity and non-aggressive gases in industry, housing and communal services and rural activities.

IVIT-M devices use high-quality capacitive-type sensors with time and temperature stability of parameters. Technical indicators and accuracy class of the device divide sensors into types. All IVIT-M devices have high measurement accuracy.

The IVIT-M air humidity sensor has protection against moisture condensation on the sensitive element. If the value increases by 90%, the microheater of the sensor is immediately activated, causing the temperature to increase by 5°C above the ambient temperature. Moreover, the relative humidity around the sensitive element is reduced and the likelihood of moisture condensation is eliminated.

Hygrometer calibration options, theory.

A mechanical dial hygrometer is easy to calibrate. For example, you used the salt test method when the humidity is 75%. Just turn its arrow on the axis, fixing it at 75% reading. Time is of decisive importance during calibration - you need to do it in a maximum of a minute before the instrument readings change. You can remove the glass covering the pointer with the scale in advance before placing it in a wet container, because you simply may not have time to do this in such a short time.

With electronic hygrometers it is more difficult. If the hygrometer or weather station is under warranty, have it set up for free at a service center. If there is no guarantee, then calibration is unlikely. While an expensive device may also have a trimmer, calibration is not provided for in cheap hygrometers. You won't find a diagram on them either. However, there are a couple of options to improve the accuracy of your humidity readings.

To set up an electronic hygrometer yourself, you first need to disassemble it. The cases of small-sized models are often held on with latches. You can open them by inserting a knife into the side, and insert an unnecessary bank card into the resulting gap, then swiping it around the perimeter of the case.

In my hygrometer, it was necessary to unscrew the screws by first tearing off the front decorative panel under which they were hidden.

You should not tear the screen away from the electronic board - disconnected contacts often cannot be restored after this. Also, you should not touch, much less wipe, the humidity sensor, because... it has a very sensitive and unreliable coating. The electronic circuits of various hygrometers are identical. The board contains an open-frame microcircuit, a dozen capacitors (sand-colored), heels of resistors (black), a quartz resonator (metal cylinder), a temperature sensor (a black drop on legs), a humidity sensor (a white square on legs).

The hygrometer was initially designed without the possibility of repair or adjustment. You can't find schematics for any model on the Internet. What’s interesting is that thermometers, as a rule, work accurately, but when measuring humidity, the error breaks all possible and impossible records. Using an oscilloscope, I found out that the humidity sensor receives a signal in the form of a meander with a frequency of 1 kHz. But this information gives us little.

There are several ways to change the accuracy of your humidity readings.

a) Replace the HR202L humidity sensor. They are sold both on Aliexpress and in radio stores. b) If the displayed humidity is always low (10%), you can try applying a thin layer of hygroscopic fluid , such as brake fluid, to the surface of the sensor. As an option, you can apply soap gel - laundry soap + polyamide imide + polyethylene glycol 50x50. c) If the displayed humidity is always too high, then from the humidity sensor on the “snake” side, in its corner from the surface, you need to scrape off the moisture-sensitive coating . The more coating you remove, the lower the humidity reading will be. d) You can also adjust the humidity R1 (sometimes R2) located next to the humidity sensor with trimming resistor. e) Solder a trim resistor in parallel (sometimes in series) with the humidity sensor and adjust the readings by adjusting its resistance.

Connection features

Many sensors connect to the system without special requirements. Having previously opened the cover of the device, it is necessary to stretch the cables of external signals and connect them to the network.

When the sensor is initially connected to the network, it comes with factory settings that can be adjusted at your discretion. Moreover, it is possible to program the settings via the interface or through other transmission channels, such as the Internet or USB.

Operating rules

Operating rules imply compliance with safety requirements and necessary measures to increase the service life. Therefore, moisture must not get into the internal electrical and radio elements of the device. It is not allowed to operate the device in chemically aggressive environments containing acids and alkalis.

It is dangerous for a person to touch the working surface of the element with his hands. Prolonged exposure of the instrument to high relative humidity can lead to drift in its performance and deterioration of measurement accuracy.

Applications for humidity sensors

Measuring humidity indicators is necessary in such areas of activity as:

- chemical production;

- fuel transportation;

- pharmaceuticals;

- polymerization;

- livestock farming;

- product storage;

- maintenance of refrigerators and freezers;

- timber processing industry;

- work of food shops;

- agricultural industry, etc.