Where is it used?

Where can we put it?

Our sensor is suitable for use in:

- shopping and entertainment establishments;

- production workshops;

- apartment buildings, private residential buildings, dormitories;

- open areas;

- educational institutions;

- large warehouses.

The fire heat detector (IP) is indispensable in large open areas,

and also where a fire generates a large amount of heat.

They are also not suitable in the presence of radioactive radiation and alkaline materials in the protected area.

All this leads to false alarms or destruction of the detector structure.

Heat point detectors

Table 2 shows the radii of the control zone of a heat point detector for different heights of the controlled room (clause 6.6.15). The radius values are determined in such a way that it remains possible to place detectors at the distances defined in SP5.13130.2009 [4]. For example, for thermal point detectors in rooms with a height of up to 3.5 m inclusive, the radius R = 3.55 m. Based on this value, when placing detectors on a square grid according to formula (1), the maximum distance between detectors is L= √ 2R=5 .02 m, distance from the wall 2.51 m (Fig. 11).

Table 2. Radius of the heat detector control zone

| Room height, m | R, m | L, m |

| Up to 3.5 incl. | 3,55 | 5,02 |

| St. 3.5 to 6.0 inclusive. | 3,20 | 4,52 |

| St. 6.0 to 9.0 inclusive. | 2,85 | 4,03 |

Rice.

11. Arrangement of heat detectors on a square grid In rooms with large areas, an arrangement on a triangular grid can also be used with distances between detectors in a row equal to √ 3R, between rows - 1.5R with a shift of rows by half a step, distance from the wall R/2. With a radius of 3.55 m, the distances between detectors in a row are 6.15 m, between rows are 5.32 m, and the distances from the wall are 1.77 m (Fig. 12).

Rice. 12. Arrangement of heat detectors along a triangular grid

Advantages and disadvantages

Depending on the type, detectors can detect the presence of smoke, flame or heat. Each type has its own advantages and disadvantages. Smoke ionization units are criticized more often than other options. These devices show good performance with smoke consisting of fine suspensions. The emission of charged substances inherent in an ionization device causes radioactive radiation. Installation of devices is not permitted in areas where people are constantly present. Optical smoke devices will not “see” the combustion of gases. They also do not react to the action of solvents or organic liquids, since the substances do not produce smoke.

Thermal fire appliances are installed in structures more often than others. The main advantage is the low cost of the devices. The operating principle of instances can be regulated relative to a certain specified norm. The value of this value can be maximum or differential.

Differential thermal units are considered the most tactile. They often generate false alarms, which can occur due to temperature changes or process actions. Heat units are recommended where it is impossible to install smoke devices or those that react to flame. Such devices are not suitable for rooms with high ceilings. The devices only react to a flared flame.

Flame detectors will sound in the infrared or ultraviolet range. They are the ones that appear when there is a fire. The advantages of the device are noted when it is actively triggered when a flame appears. If the fire starts with smoldering, the effectiveness of these specimens decreases. There are no units with ideal characteristics. Therefore, experts often recommend using devices in combination. Different types of fire systems will respond to different external influences.

Distance to building structures and lamps

Similar to BS 5839-1, clause 6.6.36 states the requirement: “The minimum distance from the IP to building structures or utility equipment protruding 0.25 m or less from the floor must be at least two times the height of these building structures or equipment. The distance from the IP to walls (partitions), as well as other building structures and to engineering equipment protruding from the ceiling at a distance of more than 0.25 m, must be at least 0.50 m” (Fig. 14). Thus, the distance to non-protruding lamps is not regulated.

Rice. 14. Distance of the detector to the beam

Clause 6.6.37 states that the distance between the detector and an object that prevents the spread of smoke and heat flows in the room (beams, protrusions, equipment of engineering systems, protruding lamps, ventilation openings, etc.) should be measured along the shortest path from the center detector to the nearest point of the object.

Classification

A thermal fire detector is an indispensable device that can determine the value of the natural temperature in a room and the rate at which it changes upward, which indicates the occurrence of a fire. This definition is ideal for threshold detectors, which independently determine the possibility of fire, assess the situation and sound an alarm. These are the models that are popular when installing a fire safety system.

Modern models of heat detectors are divided according to several classification criteria, listed below.

In the manufacture of individual temperature sensor models, various materials are used.

Heat fire detectors differ in the way they scan the monitored area.

In this classification, heat fire detectors are divided into two types.

According to the nature of the controlled sign of fire

Based on the method of temperature control, fire detectors are divided into several types.

- Maximum thermal detectors. The sensor is triggered when the room temperature changes according to the specified detector parameters.

- Differential specimens and thermal detectors with a differential component. They are sensitive to the rate of increase in temperature in the room. Thermal elements of the presented type are equipped with two ultra-sensitive inserts. A fire safety alarm is generated when the maximum difference in temperature detector readings is reached.

- Combined differential-maximum temperature sensor. The presented variety includes the features and capabilities of the first two types of detectors.

By inertia

The classification of device inertia is a time characteristic that can determine the delay before an alarm signal is sent when the maximum temperature of the set value is reached. In modern models of fire detectors with a built-in electronic system, the inertial indicator must be set independently.

By food type

Thermal fire detectors are divided according to the method of connecting to power.

Autonomous, also called radio channel. This device is powered by charging regular batteries. Autonomous units are equipped with a module responsible for redirecting the incoming signal from one radio communication point.

What does a fire alarm include?

This is a set of devices that detect signs of fire and inform people about the location of their occurrence.

The system includes:

- Fire detectors

- Receiving equipment

- Light and sound devices

- Communication lines

- Power supplies

Sensors are available for manual and automatic signal generation. They react to:

- Smoke

- Warm

- Gas

- Flame

Receiving devices receive a signal from the detector, control sound and light fire alarms, transmitting the signal to the fire department.

There are three types of alarm systems:

- Threshold (regular) - the cheapest and most common model, used on small objects

- Addressable - a later version, allows you to accurately determine the location of the fire

- Addressable analogue - the latest development in this area, guarantees not only an accurate determination of the location of the fire, but also the possibility of registering it at a very early stage

Types of detectors

The choice of a specific type of detector for each object is based on the average air temperature in the room during normal operation. To eliminate false alarms, the alarm cutoff is set to exceed 20℃ from the maximum temperature during normal operation of the room.

Contact

Based on the use of contacts made of low-melting metals. Under the influence of increased temperature, the contacts are deformed, which leads to the contacts opening. A signal about this is sent to the control panel. Due to the need to heat a specific small part, these sensors have a limited range. It is advisable to use for small areas.

Electronic

A signal that a fire has started is a change in resistance on a part of the semiconductor. The thermistor detects the difference and reports to the fire alarm control panel (hereinafter - PS). Ambient electronic noise can affect the accuracy of the sensors. The maximum distance of the sensor from the receiving console of the PS is up to 2500 meters.

Optical

Fire safety control occurs by laying a fiber optic cable. A laser beam passes through the entire length.

When heated, the optical fiber changes its structure, which prevents the passage of the laser. A special controller accurately determines the area where the reflection occurred, as well as the current temperature.

Such sensors operate in any weather and electromagnetic conditions. In the event of a breakdown, it is possible to replace only the damaged area. Signal transmission distance is up to 8 km.

Mechanical

The body of such a sensor contains a metal flask containing gas, which expands when heated. The design is one of the first used for fire protection of objects. At the moment, it is considered too difficult to manufacture (the need to control the tightness of the flasks and the quality of the gas mixture) and is used in exceptional cases where other types of detectors are not suitable.

Autonomous

Autonomous fire detectors

Detectors powered by a battery pack or a pair of household batteries. The activation signal is transmitted via a radio channel to a transmitter connected to a constant power supply. The main problem is the loss of signal range indoors.

Explosion-proof

Necessary for determining the start of a fire in premises where a fire can start with an explosion, as a result of which other sensors will be destroyed and will not be able to sound an alarm. There are 2 common TPI models in Russia: MAK-1 in version 11 IB and IP 103-1V. The sensors are manufactured by NPP Spetsinformatika-SI and NPC Etalon, respectively. This category of detectors is connected via intrinsically safe cables.

Addressable analog

They are computerized integrated solutions for providing fire alarms at the facility. One device can monitor signals from 100 different sensors.

Linear

Designed for installation in hard-to-reach places or aggressive environmental conditions. To detect fire, linear detectors use 3 types of sensors:

- An optical cable that responds to changes in temperature, reducing its transparency. A decrease in light flux is detected by the analyzer and indicates where changes occur.

- The sensor cable consists of sensors along its entire length, which change their resistance when heated, which is issued by the system to the control panel in the form of an alarm signal.

- A twisted pair cable whose cores are coated with a heat-sensitive compound. When heated, the wires come into contact, forming a short circuit. The location of the fire is recognized as a fire and transmitted to the control panel.

This type is ideal for large fire alarm systems. The response temperature can be set separately for each zone.

Multipoint

They use a network of several sensors in their work. All information is transmitted via connecting cables. Fire detection, unlike linear detection, is possible only at the point where the sensor is installed, and not along the entire length of the connection loop.

The principle of operation of fire alarm sensors, connection diagram and installation features of devices

Reading time: 5 minutes(s) One of the most pressing problems of modern man is security. Modern living spaces are equipped with various appliances, flammable furniture, and other utensils that can catch fire at any time. To prevent fire and protect against the outbreak of a fire, there are fire safety sensors.

Before installing such a system, you need to know how it works. After all, there are a huge number of fire detectors. Moreover, each of them reacts differently to the source of ignition. And so as not to regret the purchase later, let’s look at everything in more detail.

Why are they needed and where are they used?

The fire system protects a certain area of the premises from ignition sources. The entire circuit consists of one or more sensors that send a signal to the system control unit. At the same time, different fire sensors (or as they are also called detectors, detectors) react differently to the source of ignition.

How does a fire alarm sensor work: device and principle of operation

During combustion, many chemical processes occur, as a result of which the environment begins to change. The detectors react to this change and send a signal to the control unit. But each sensor reacts differently to the source of ignition.

Temperature change. In the area of the sensor, if the temperature changes, then signals will be sent through the detector to the power supply and an alarm will sound.

Change in smoke concentration in the air. This system usually responds to increased smoke density (commonly called a smoke alarm). This system is popular in businesses where there is an increased risk of fire without fire.

Reaction to certain radiation. Fire has its own unique radiation. Sensors that respond to this radiation are considered the most effective. But the price matches the result.

Smoke detectors

This fire protection system is considered one of the most common in the world. In this case, the sensors themselves can be either photoelectric or ionizing.

The photoelectric detector emits a beam that scans the smoke density level.

They are conveniently located in enterprises where there is always a certain amount of gases in the air.

But at home, these sensors are absolutely useless, since the air from the ventilation will confuse them.

An ionization detector ionizes the room with a special radioactive isotope (Americum 241). Inside there are two electrodes, between which there is a free flow of electrons under the influence of the isotope. But when smoke gets inside, the electrons stop moving and an impulse is sent to the control unit, which triggers an alarm.

Sensors are generally protected from insects, shock, dust, dirt and water. They ventilate the air well, and some of them even have explosion protection.

An optical sensor is one of the types of smoke detectors. But, unlike them, the optical analogue does not react to cigarette smoke or the smell from a gas stove. This type of detector has a range of 100 m, allowing you to scan large rooms.

Aspirating smoke detectors take a sample from the smoke and analyze its composition. This allows you to separate the same cigarette smoke from a starting fire.

The video smoke detection system is a new invention. The product appeared on the market quite recently. The operating principle of the fire alarm sensor is as follows. There is a camera mounted inside the sensor that monitors the movement of smoke. As soon as this happens.

Gas detectors can detect carbon monoxide, which cannot be seen or smelled. But at the same time you can suffocate from it. Therefore, such sensors detect carbon monoxide.

Heat detectors

Such a sensor responds to changes in ambient temperature. That is, when a fire occurs, the detector begins to respond to an abnormal increase in temperature (for example, when gasoline or fuel oil ignites). But such systems are prohibited from being installed in administrative buildings and residential premises.

If there are heating devices in the room, it is necessary to place the sensor as far as possible from the artificial heat source.

Flame detectors

The principle of operation of such sensors is to respond to an open fire or a smoldering fire source. This system allows you to install detectors in rooms where there is artificial heating (for example, air heaters, etc.).

Multi-touch sensors

There are ready-made sensors that have several different detectors built into them. For example, a smoke and heat detector. This approach reduces the risk of false positives. Such systems are included in the “smart home” project. They can be mounted on the ceiling or hidden in baseboards or behind walls.

Signal transmission and reception channels

When a general plan for installing the sensors is drawn up, and each wire is connected to loops. The loops, in turn, are connected to a control unit, which transmits a signal to a control device in the security service.

In order for the devices to work properly, it is necessary to choose cables with copper conductors. In addition, special requirements are imposed on such things (SNIP and GOST) so that they are protected from mechanical damage and run separately from other cables.

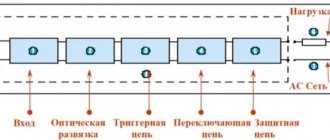

Fire alarm sensor connection diagram

Fire system diagram

The sensors are connected to each other using wires. True, there are some types of detectors that send a signal to the control unit without wires.

Once the required number of detectors has been determined and the fire protection system has been ordered, the next step is to install the detectors themselves. But before that, you need to decide where the manual fire call points, control unit and warning system will be installed. To do this, you need to look for places with open access. That is, in the event of a fire, nothing should interfere with reaching, for example, a manual fire call point.

Detectors are most often attached to the ceiling. They can be hidden under baseboards or installed behind walls. But at the same time take into account how effective they will work in these places.

All sensors are connected to a control unit (also called a control panel).

Recommendations for installing devices

Before you begin installing sensors, you need to estimate the area of the room where the devices will be placed. To do this, you need to know what distance the detectors should cover. You can do this yourself, but it is better to consult a specialist.

Detectors must be installed in such a way that their operation is not interfered with by false stimuli. For example, some smoke detectors detect strong odors coming from the kitchen. It is better to place thermal sensors away from sources of artificial heat.

The LED “Exit” sign should shine brightly so that in the event of a fire, people know where to exit.

To improve the performance of devices, it is best to use multi-touch sensors. Especially if they are installed in a large multi-storey building. Or combine several sensors that will “communicate” with each other via radio control.

The fire alarm system must be installed in such a way that all people in the room can hear the announcement during an alarm.

But the most important recommendation is the maintenance of devices. This must be monitored carefully. To do this, they need to be checked periodically and the settings adjusted.

Some devices are protected against dust, insects, etc. But this does not mean that they do not need to be periodically wiped from dust.

When purchasing a device, there are instructions everywhere. And the instructions contain clear instructions on how to use the product. If you follow these instructions, then the device will serve for a very long time. And during a real fire it will help save lives and also avoid false alarms of the system.

Fire alarm sensors have repeatedly proven themselves to be a reliable means of fire prevention. Now these devices can be found all over the world. Not a single enterprise, office space, or residential building can do without them. Especially considering that a fire can happen anywhere - at any time. But choosing a sensor is not an easy matter. Therefore, it is better to invite a specialist who will not only estimate the number of sensors, but will also install the entire system and connect it to the common security service base. So think about what is more important - the money spent or your life?

Did this article help you? We would be grateful for your rating:

1 1

Other classifications of fire sensors

- Addressable - has several trigger presets (“fire”, “fault”, “dust”, etc.).

- Non-addressable - operates in two states (“fire” and “no fire”).

- Single-mode - active only when a fire occurs. This is not very good, especially if there are infrequently people in the room who can, on occasion, detect a fire and transmit a danger signal. That is, if this device suddenly fails, no one will know about it, unless regular checks of the devices are carried out to assess their performance.

- Dual-mode - in addition to the alarm signal, it periodically sends the “No fire” message, which allows you to timely detect a detector breakdown (in the event of a long-term absence of a signal).

- Multi-mode - to all of the above, a signal about a malfunction is also added.

- Wired - transmits information through a wire system.

- Wireless - communicates with the base using Wi-Fi or GSM.

We recommend to buy

Linear smoke detectors

For linear smoke detectors, the width of the protected zone is defined as in SP 5.13130.2009 equal to 9 m without changes (clause 6.6.18). The maximum height of the protected room also remains equal to 21 m, but the requirement to place linear smoke detectors in two tiers with a room height of more than 12 m is excluded. The need to confirm by calculation the possibility of placing linear smoke detectors below 0.6 m from the ceiling is also excluded. In this case, the distance between the optical axes of the detectors should be no more than 25% of the height of the detectors and from the wall - no more than 12.5% (Fig. 4) [BS 5839-1]. Thus, in a room 21 m high, linear detectors can be placed below the trusses at a height of, say, 18 m, with distances between detectors of 18 x 0.25 = 4.5 m. That is with a double number of detectors, as with two tiers, but without confirmation by any calculation. At the same time, it is prohibited to install linear smoke detectors on sandwich panels.

Rice. 4. Arrangement of linear smoke detectors at the lower level

This arrangement of linear smoke detectors is determined based on the model of smoke propagation from the source shown in Fig. 5. Smoke from the fireplace rises upward due to convection, the angle of the smoke propagation cone is assumed to be 22°. Accordingly, at height H, the radius of the area filled with smoke will be equal to 0.2H, respectively, the diameter will be equal to 0.4H. Thus, the axes of linear smoke detectors are located at distances less than the diameter of the smoke spread at height H, which guarantees the detection of an upward flow of smoke.

Rice. 5. Spread of smoke indoors

Symbols of fire detectors

For combined fire detectors:

Element X1 - indicates a controlled sign of fire.

Instead of X1, one of the following digital designations is given:

- 1 - thermal;

- 2 - smoke;

- 3 - flame;

- 4 - gas;

- 5 - manual;

- 6-8 - reserve;

- 9 - when controlling other fire factors.

Element X2X3 denotes the operating principle of the IP. Instead of Х2ХЗ one of the following digital designations is given:

- 01 - using the dependence of the electrical resistance of the elements on temperature;

- 02 - using thermo-EMF;

- 03 - using linear expansion;

- 04 - using fusible or combustible inserts;

- 05 - using the dependence of magnetic induction on temperature;

- 06 - using the Hall effect;

- 07 - using volumetric expansion (liquid, gas);

- 08 - using ferroelectrics;

- 09 - using the dependence of the elastic modulus on temperature;

- 10 - using resonant-acoustic methods of temperature control;

- 11 - radioisotope;

- 12 — optical-electronic;

- 13 - electrical induction;

- 14 - using the “shape memory” effect;

- 15 - ionization;

- 16 - using electrochemical cells;

- 17 - using semiconductor gas sensors;

- 18 — using metal oxide sensors;

- 19...27 - reserve;

- 28 - visible spectrum;

- 29 - ultraviolet;

- 30 - infrared;

- 31 — thermobarometric;

- 32 - using materials that change optical conductivity depending on temperature;

- 33 — aeroionic;

- 34 - thermal noise;

- 35 - when using other principles of fire detector operation.

Element X4 indicates the serial number of the development of a fire detector of this type.

Element X5 indicates the class of fire detector (for IPT, IPDA, IPP, IPR).

Example - The symbol for IPT has the form “IP 101-8-A1”, where 1 is thermal; 01 - using the dependence of electrical resistance on temperature; 8 — serial number of development; A1 - IPT class.

The fire detector may additionally have a code name and/or commercial name.

Point smoke detectors

The radii of the control zone of a smoke point detector for different heights of the controlled room are given in Table 1. The values of the radii are determined in such a way that it remains possible to place detectors at the distances specified in SP5.13130.2009 [4]. The distance between detectors L when arranged on a square grid based on the radius of the control zone R is calculated by the formula: L= √ 2*R

The results of calculations of the value L are given in Table 1. For example, for smoke point detectors in rooms up to 3.5 m high, based on a radius R = 6.4 m, the maximum distance between detectors is L = 9.05 m (Fig. 2), and not 9 m.

Table 1. Smoke detector control zone radius

| Room height, m | R, m | L, m |

| Up to 3.5 incl. | 6,40 | 9,05 |

| St. 3.5 to 6.0 incl. | 6,05 | 8,55 |

| St. 6.0 to 10.0 incl. | 5,70 | 8,08 |

| St. 10.0 to 12.0 incl. | 5,35 | 7,56 |

Rice.

2. Arrangement of smoke detectors on a square grid Obviously, an arbitrary arrangement of detectors can be used; the most interesting arrangement is on a triangular grid. With a control zone radius of 6.4 m, the distances between detectors in a row increase to 11.08 m, the distances between rows - up to 9.6 m (Fig. 3). From the theory of laying and coatings it follows that for the two-dimensional case, circles whose centers form a lattice in the form of equilateral triangles provide the maximum coating density [9]. Those. To protect a given area when detectors are arranged in a triangular grid, a minimum number of detectors is required. Indeed, if, when arranged on a square grid, each detector has a square measuring 9.05 m x 9.05 m, the area of which is 81.9 m2, then when detectors are arranged on a triangular grid, each detector has a hexagon with an area of 106.4 m2 , which is 1.3 times more. In the general case, for a triangular array, the distances between detectors in a row are √3R, between rows are 1.5R with the rows shifted by half a step, the distance from the wall is R/2.

Rice. 3. Arrangement of smoke detectors in a triangular grid

Classification

A fire detector allows you to monitor changes in a room by reacting to signs of fire. The devices are characterized by simple installation and long service life.

By type of transmitted signal

This parameter for units can be single-mode or multi-mode. The first option requires sufficient exposure to an external factor. For example, the temperature must rise several positions before the sensor switches to reporting mode.

The multi-mode option operates in two modes: “Fire”, “No fire”. The second parameter shows the serviceability of the device, which is convenient for security services, because you can find out how single-mode broadcasters react only during an inspection, and no one will do it every day. Such options are used throughout the fire protection system today, and they show good performance results.

There are also multi-mode automatic devices that report a system malfunction to the remote control. This quality was assessed at large facilities, where it is not possible to check every detector. The technicians recognize the nature of the reported malfunction and can immediately take with them the necessary spare parts and tools.

An analogue type fire sensor monitors both the external conversion and the parameter value. When changes are detected, these species respond with an audible signal. The command transmission type can be:

- wired;

- wireless.

By localization

According to this parameter, products are:

- point;

- multipoint;

- linear.

Detectors with a single sensor are usually assembled together. These are most often targeted or household options. Multipoint devices incorporate several different types of sensors. Linear devices track the territory along a certain line. Devices can be paired or single. The pair may contain a photocell that detects smoke.

By type of parameter change tracking

The most popular are gas sensors that respond to carbon dioxide or carbon monoxide in the air. The devices are often chosen for a private home or apartment; they are almost never used in production. Combined types of detectors are a hybrid unit, the housing of which contains systems that complement each other. Basically, thermal and smoke devices are compared with each other.

The optical detector is equipped with a relay output. When the relay is active, the device performs a self-test, indicated by a light or sound indication. The test button with indicator is located on the top cover, so the device can be activated by not very thick smoke. Normal operation is indicated by short blinking indicators.

By sensor type

According to this parameter, devices are divided into:

- thermal;

- smoke;

- flame sensors.

Smoke and thermal models are rarely suitable for industrial premises, so flame sensors are more often installed in enterprises. Smoke and temperature indicators in workshops are almost always higher than normal.

Flame sensors are not suitable for installation in residential buildings or offices. Where there is a crowd of people, it is recommended to install combined devices. Otherwise, the system will issue an alarm signal regularly.

Flame sensors are either ultraviolet or infrared. The latter are not suitable for rooms where electric heaters are constantly operating. The first are considered an equivalent replacement for the second option. An alternative choice if it is impossible to install both options would be a magnetic emitter. It responds to the source of fire due to a special magnetic field.

Types of APS maintenance

Maintenance is a set of activities that will maintain the condition of the automatic fire alarm. A modern level of service will provide the opportunity to promptly eliminate any defects and eliminate a malfunction during a fire. There are several types of maintenance: unscheduled and planned.

The first is carried out through random alarm activation. In addition, there may be several reasons: exposure to any external factors or equipment breakdown. Unscheduled maintenance must be recorded. An unscheduled inspection occurs as a result of any complaints regarding the operation of the equipment.

The second is a procedure that is performed once a month. The process is recorded in a special journal. Alarm maintenance is carried out as a mandatory procedure. After the company carries out the installation process, it is mandatory to provide detailed instructions regarding operation.

Coordination of power supply

Typically, a contract for the provision of services is signed with the company that provides the service. At the same time, the customer can contact another organization as needed. The main condition is that this company has a license from the Ministry of Emergency Situations. A license is obtained by those companies that provide a guarantee regarding the quality of their work.

Electrical design

The design of automatic fire alarms falls into category 1 of electrical receivers. In this case, the presence of a source is provided, which is a backup and ensures operation of the system during the day without the use of an external power supply.

Power supply design

The alarm activation during power backup must be carried out for at least 3 hours. Cables used for security alarms are usually laid using separate boxes. They are not placed near electrical wiring whose voltage is 60 V.

Electric installation work

Electrical installation work is carried out by assembling and installing devices that are electrical. The organization and performance of electrical installation work involves compliance with the necessary requirements and the use of the necessary documents.

Network engineering

Fire alarm engineering networks

Absolutely all work regarding technical approval for the placement of automatic fire alarms is carried out in accordance with the regulations, which, in turn, are normative. During the occurrence of an automatic alarm, the smoke removal system and ventilation units are activated.

Conclusion

The decision to place a fire alarm is an important component in the design of any premises. A huge number of factors are used to develop a project. Installation is carried out exclusively with the help of experienced people and in accordance with a pre-developed plan.

Free information

The main task of the fire alarm system is to recognize sources of fire as soon as possible and transmit a danger signal either to the detector itself or to the fire station.

Some detector models can be equipped with additional functions - activation of fire extinguishing means, transmission of information to backup control points - and much more.

This system will work smoothly and accurately only if it contains all the points that ensure uninterrupted functioning at any stage:

- the fire sensors themselves, which recognize a fire (their types will be discussed in more detail below);

- communication channel through which the detector transmits a signal about a fire;

- a point for receiving information about an emergency and its further transmission or a control panel (there are professional/semi-professional, used in industry, multi-beam - for private households, as well as apartment - the simplest types for use in apartments);

- prompt response (this can be either a fire brigade or an automatic fire extinguishing system in the building).

Linear heat detectors

For linear heat detectors, the control zone is defined as equal to two radii of point detectors (clause 6.6.5). If, according to SP 5.13130.2009, in rooms with a height of up to 3.5 m, the maximum distance between point and between linear heat detectors was 5.0 m, now with a radius of the protected zone of 3.55 m, the maximum distance between linear heat detectors is 3.55 m x 2 = 7.1 m (Fig. 13), i.e. increases by 1.42 times. Naturally, this provision does not apply to multipoint linear heat detectors, the protected zone of which is a set of control zones of point detectors.

Rice. 13. Linear heat detector control area