How is the hardness of a concrete mixture measured?

Stiffness refers to the ability of a mixture to remain homogeneous and not undergo separation during transportation. During compaction, heavy fractions sink, and small fractions rise to the top. These processes negatively affect the strength of concrete. To prevent this, you need to correctly calculate the percentage of fine fractions, use plasticizers and a minimum amount of water.

The time until the solution is compacted to a homogeneous mass determines its hardness. The faster it becomes smooth, the more workable it is considered.

Hardness measuring device

The hardness index is determined using a special device with a cylindrical vessel. Before starting to determine the indicators, prepare instruments and equipment, paying attention to the work site:

- the laboratory device for determining hardness and additional devices are cleaned of dust and other contaminants;

- Use a damp cloth to wipe all surfaces that come into contact with cement;

- firmly fix the equipment on the vibrating platform;

- the cone for supplying the mixture is inserted into the installation ring and securely fixed.

After preparation, they begin to directly study and determine the rigidity of the concrete mixture. To do this, it is poured into a cone. Then the tripod is deployed, removing the steel mold. The metal disk is then placed against the surface of the molded cone. At the same time, turn on the stopwatch and create vibration, observing the compaction of the solution.

The vibration continues until cement flows from at least two holes of a metal disk having six holes. As soon as this moment comes, the operation of the equipment is stopped and the time of its stop is recorded. The time spent on the test in seconds allows you to calculate the stiffness of the concrete.

Determination of mobility and rigidity of concrete mixture

According to GOST 10181.1-81

The workability of concrete mixtures is determined by indicators of mobility and rigidity.

For plastic concrete mixtures laid under the influence of their own weight or with the application of small mechanical forces, the mobility indicator is determined, and for low-plastic mixtures that require significant effort during installation, the rigidity indicator is determined.

The mobility of the concrete mixture is characterized by the amount of sediment of the cone OK (cm) formed from the concrete mixture being tested.

Equipment.

A device in the shape of a truncated hollow cone, made of sheet steel, with open upper and lower bases, a smooth inner surface (for concrete mixtures with aggregate size up to 40 mm inclusive, a cone with a height of 300 mm is used, for a size of 70 mm or more - a height of 450 mm ), a steel rod with a diameter of 16 and a length of 600 mm with rounded ends, a steel ruler with a length of at least 700 mm, a steel ruler with divisions with a length of 200 - 500 mm, a trowel, a metal sheet with a size of at least 700X700 mm.

Trial.

Weighted sand is poured onto the striker, then cement is mixed thoroughly with trowels, crushed stone (gravel) is added and mixed until the composition is homogeneous. The firing pin is wiped with a damp cloth before kneading. The mixed dry mixture is placed in an oblong ridge, a depression is made in the middle and approximately half of the measured water is poured out, making sure that it does not flow out through the edges of the depression. After 30 seconds, the mixture is thoroughly mixed with a trowel dipped in water, and the rest of the water is gradually poured out. Shovel the mixture until completely homogeneous for 5 minutes.

Before testing, the cone and all other devices are cleaned and wiped with a damp cloth. The cone is placed on a smooth metal sheet and filled with concrete mixture through a funnel in three layers of equal height. Each layer is compacted by bayoneting with a metal rod in a regular cone 25 times, in an enlarged one - 56 times. The cone must be pressed tightly against the sheet during filling. After compacting the concrete mixture, the funnel is removed and the excess mixture is cut off flush with the upper edges of the cone. Then the cone is smoothly lifted vertically upward and placed next to the cone of compacted concrete mixture. The cone rise time is 3-7 s. The settlement of the concrete mixture cone OK (Fig. 40) is determined by placing a metal ruler with its edge on the top of the cone and measuring the distance from the bottom edge of the ruler to the top of the concrete mixture with an accuracy of 0.5 cm. The OK value determined in an enlarged cone is given by the OK value in a regular cone by multiplying it by a factor of 0.67. The cone slump of a concrete mixture sample is determined twice, and the test time from the beginning of filling the cone during the first determination and until the moment of measuring the cone slump during the second determination should not exceed 10 minutes.

If, after removing the cone, the concrete mixture is severely deformed (falls apart) or takes on a shape that makes it difficult; determining its shrinkage, the measurement is not performed, but the test is repeated on a new portion of the concrete mixture.

The slump of the concrete mixture cone is calculated as the arithmetic mean of the results of two determinations with rounding to 1 cm. The discrepancies between parallel determinations should not be more than 1 cm for OK ≤ 4 cm, 2 cm for OK = (5÷9) cm and 3 cm for OK > 10 cm. If there are large discrepancies in the results, the tests are repeated on a new sample. If the cone settlement is equal to zero, then the mixture is considered hard and is characterized by a hardness index.

The rigidity of the concrete mixture is characterized by the vibration time (in seconds) required to level and compact the preformed cone of the concrete mixture in a standard technical viscometer (Fig. 41).

Equipment. Metal cone with a height of 300 mm, a cube shape with dimensions of 200X200X200 mm, a vibrating platform, a stopwatch, a steel rod with a diameter of 16 and a length of 600 mm with rounded ends, a trowel.

Trial. Before testing, cylindrical ring 1 is rigidly fixed on a vibration platform with a vibration frequency of 2800 - 3000 per minute and an amplitude of (0.5 ± 0.01) mm. Check the total mass of the moving part of the disk 8, rod 5 and washer 7. It should be equal to (2750±50) g. The internal surface of the device is wiped with a damp cloth. I

A cone is inserted and secured into ring 1, after which it is filled with a concrete mixture in the same way as when determining mobility (in three layers with each layer bayoneted 25 times). Then the cone is removed from the mold, disk 8 is installed above the molded concrete mixture by rotating stand 9 and freely lowered onto it. The tripod is secured in the fixing sleeve 10 with a clamping screw.

Then the stopwatch and the vibration platform are turned on simultaneously. Vibration is carried out until the release of cement paste from at least two holes of the disk begins. At this moment, turn off the stopwatch and vibrator. The resulting time in seconds characterizes the hardness of the concrete mixture.

The hardness of the concrete mixture sample is determined twice. The total test time from the beginning of the first determination to the end of the second should not exceed 15 minutes.

The hardness of a concrete mixture is determined as the arithmetic mean of the results of two determinations from one sample of the mixture, differing from each other by no more than 20%. If the discrepancy is greater, the determination is repeated on a new sample.

The hardness of a concrete mixture is determined in a simplified way as follows. A form with dimensions of 200X200X200 mm is installed and secured on the vibrating platform. A hollow cone from a technical viscometer is inserted into it, which is filled with concrete mixture. Then the cone is carefully removed and the vibrating platform is turned on simultaneously with the stopwatch. Vibration is carried out until the concrete mixture fills all the corners of the form and its surface becomes horizontal. The time required to level the surface of the concrete mixture in the mold, multiplied by a factor of 1.5, characterizes the hardness of the concrete mixture.

The mobility and rigidity of the concrete mixture must be within the limits specified in the table. 23.

Table 23

| Types of mechanisms for compacting concrete mixture | Mobility (cone draft), cm, no more | Hardness according to a standard viscometer, s, not less | |

| Sealing and finishing | Concrete placing machines | 2 | 15 |

| Area vibrators and vibrating screeds | 4 | 10 | |

| Compaction of bases for improved permanent covering | 2 | 25 | |

How is the determination made?

During testing, non-integer values may be obtained; the stiffness indicator is rounded to one second. The test is carried out at least twice, so the average value of two values is taken as the technical characteristic. If the test results do not agree by more than 20%, they are carried out again using a different concrete mixture.

One of the characteristics of concrete mortar is cohesion, which means maintaining the homogeneity of the composition and the absence of delamination during transportation and laying. As a result of compacting the mixture, the particles are compacted, and the remaining water is squeezed into the upper layers of the solution. In this case, cavities are formed under the grains of the bulk filler. If the filler has a high density, then its particles settle. Otherwise, particles of the porous sealant rise to the surface. This deteriorates the structure of concrete, resulting in increased water resistance and decreased frost resistance. To increase cohesion and prevent separation, correctly calculate the quantitative amount of fine aggregate in the concrete mixture and reduce water consumption by mixing plasticizing additives.

In laboratories they use a simple method for determining this value using the technology of B.G. Skramtaev. An ordinary cone is placed in a cubic metal mold. It is freed from supports and the lower diameter is made smaller so that it can easily fit inside the cubic shape.

Such a cone is filled with three layers of the composition. After removing the metal cone, the concrete mixture is examined on a vibrating platform. Vibration is maintained until all corners of the cube are filled with concrete. After the mixture fills the mold and is distributed absolutely horizontally and evenly, the vibration is turned off and the hardness value begins to be determined.

The time during which vibration is maintained depends on the mobility of the solution, the size of the object being formed, the presence of reinforcement, the frequency and amplitude of movement of the vibrating device. The smaller the size of the product and the rigidity of the cement mortar, the less time is needed to completely compact the composition.

Numerous studies show that the stiffness index obtained when using a device with a cylindrical vessel is almost two times less than the index obtained using B.G. Skramtaev’s method.

Determining the hardness of a concrete mixture

The stiffness index of the concrete mixture is determined using a special device, which consists of a cylindrical vessel 1 200 mm high with an internal diameter of 240 mm with a device 9 attached to it for measuring the slump of the concrete mixture in the form of a guide stand 8, a rod 5 and a metal disk 6 4 mm thick with six holes 7 (Fig. 12).

The device is installed on a standard laboratory vibration platform, which provides vertically directed vibrations with a frequency of 45...50 s-1 (2800...3000 counts/min) and amplitude (0.5±0.01) mm, and is tightly attached to it. Then a metal cone mold 3 with a nozzle 4 is placed into the vessel to be filled with concrete mixture.

The dimensions of the cone form are the same as when determining the mobility of a concrete mixture, i.e. height ─ 300 mm, lower diameter ─ 200 mm, upper diameter ─ 100 mm. The cone shape is fixed in the device using a special holder ring 2 and filled with three layers of concrete mixture, compacting it by bayoneting (25 times each layer). Then the cone mold is removed, the tripod is rotated, a disc is placed on the surface of the concrete mixture and the vibrating platform is turned on. Vibration at a frequency of (2900±100) counts/min and an amplitude of (0.5±0.01) mm is continued until the release of cement paste from two holes of the disk begins. The resulting vibration time is an indicator of the hardness of the concrete mixture.

Rice. 12. Standard device for determining the hardness of a concrete mixture

The hardness of the concrete mixture is determined twice. The total test time from the beginning of the first determination to the end of the second should not exceed 15 minutes.

The stiffness of a concrete mixture is calculated, rounded to the nearest 1c, as the arithmetic mean of the results of two determinations that differ by no more than 20%. If there is a greater discrepancy between the results, the determination is repeated on a new sample.

Laboratories sometimes use a simplified method for determining the hardness of a concrete mixture, proposed by B.G. Skramtaev. According to this method, the test is carried out as follows. A standard cone is inserted into a regular metal mold for preparing cubes measuring 20x20x20 cm. First, remove the stops from it and slightly reduce the lower diameter so that the cone fits inside the cube (Fig. 13).

The cone is also filled in three layers. After removing the metal cone, the concrete mixture is subjected to vibration in the laboratory area.

The vibration lasts until the concrete mixture fills all the corners of the cube and its surface becomes horizontal.

As experiments have shown, the stiffness index determined on a standard device is approximately 1.5-2 times less than the index obtained using the method of B. G. Skramtaev.

Rice. 13. Determination of the hardness of a concrete mixture in a simplified way

Control questions

1. How is concrete mix different from concrete?

2. What indicators characterize the workability of a concrete mixture?

3. What groups and grades are concrete mixtures divided into according to workability?

4. How is the mobility of a concrete mixture determined?

5. For which concrete mixtures and how is hardness determined?

6. How is the hardness of a concrete mixture determined in a simplified way and how, in this case, does the hardness indicator correlate with the indicator determined on a standard device?

7. In what units are the workability indicators of a concrete mixture expressed?

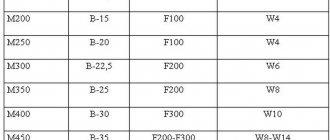

Brands and varieties of concrete mixture according to hardness according to GOST

Workability is an indicator of the following properties of a solution:

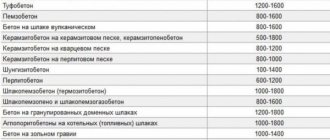

Depending on workability, all concrete mixtures are divided into rigid, super-rigid and flexible.

Hard mixtures

They contain a small amount of liquid, so the cement is strong. In another way, such raw materials are called rammed concrete, used for the construction of structures subject to high loads.

To obtain high-density material, it is carefully compacted. During the shrinkage process, a small amount of liquid appears on the surface of the composition. After squeezing the mixture in your fist, a plastic piece is formed that does not leave marks on your hands.

Rigid mixtures have strong adhesion to reinforcement and form perfectly smooth surfaces. The technology for their production is complex and expensive. Therefore, such material is used for the construction of buildings and structures that will be subject to loads during use.

Ultra-hard concrete

Produced by hydrothermal treatment of the working solution. After combining the compositions, they are compacted and converted into a solid metal state. When producing super-rigid concrete, there is no stage of liquefaction of the composition. In industry, such raw materials are used in rare cases.

The use of plasticizers is one of the effective ways to increase the workability of concrete mixtures. Conducted studies have proven that the plasticizing additive LST reduces the mixture’s need for water from 10 to 30%. The effectiveness of additives is reduced in the composition of rigid concrete.

Source

Necessary additives in concrete

It is impossible to dispute the fact that concrete is the most used material in construction. Requirements for concrete by designers and work performers often lead to the use of modifiers (chemical additives). Many additives are also successfully used in cement-sand mortars to change and improve their characteristics.

Plasticizers for concrete mixtures, depending on their effect on the mixture, are divided into: superplasticizers, highly plasticizing, medium-plasticizing and low-plasticizing additives.

Ideal concrete mixtures for builders would be those that have high mobility, slow and gradual setting, rapid strength development, the ability to be transported for a long time, with subsequent easy pouring into molded structures, and obtaining a pouring result that does not require waterproofing work.

But we must not forget that the main task is to impart durability and strength to the concrete structure, that is, ensuring for a long time the ability to withstand both mechanical loads and physical and chemical influences of the environment. Therefore, the use of additives in modern construction is vital.

Plasticizers, which allow the mixture to be liquefied for further convenient use, are the most common modifiers used in construction. Of course, the same result can be obtained by adding an additional volume of water, but in this case the strength of the concrete, its density are lost, shrinkage cracks are possible and the future structure will take longer to dry.

Plasticizers are quite versatile in use: with their help, you can increase the strength of concrete, increase density, that is, water resistance, reducing the amount of water by up to 30%, while maintaining the mobility of the mixture, reducing the amount of cement and water, thereby obtaining concrete with low shrinkage.