Photocells with external photoeffect

Photocells with external photoelectric effect consist of a glass cylinder 1, from which air is pumped out:

The cathode in them is a part of the inner surface of the cylinder 2, covered with a photosensitive layer (mainly from alkali metal oxides C s Cs Cs, R b Rb Rb, K K K, N a Na Na), the cathode is illuminated through the transparent part of the cylinder 1. The anode is hemispherical metal spoon 3 placed in the center of the cylinder. The cathode and anode are connected to two pins 4, with the help of which the photocell is connected to the electrical circuit. To increase the photocurrent due to gas ionization, photocells are filled with an inert gas. The figure above shows samples of modern solar cells and their markings: STsV-4 (antimony-cesium vacuum) and TsG-3 (cesium gas-filled). At an operating voltage of 240 V, the sensitivity of the vacuum photocell is 8 × 10-5 A/lm.

Semiconductor photocells

A semiconductor photocell is a device with a rectifying junction for directly converting light energy into electrical energy.

Let's consider the pn junction under illumination at forward voltage (Fig. 6.6). This mode is called the photovoltage generation mode, because generation of charge carriers occurs. An electric field separates them, and as a result of the accumulation of electrons in the n-region and holes in the p-region, an additional potential difference arises - photovoltage.

Photocells are used in the form of solar panels. Typically Si is used for this. In p-Si, the pn junction is created by the diffusion of P or Sb.

Characteristics of photocells:

– the point of intersection of the current-voltage characteristic with the voltage axis corresponds to the photovoltage

or

open circuit voltages

under different illumination (for Si this is 0.5 - 0.55 V);

– the point of intersection with the current axis corresponds to short circuit currents

(for Si this is 20 – 25 mA/cm2);

– light characteristic

– dependence of photovoltage and short-circuit current on luminous flux or illumination;

– spectral response

– dependence of short circuit current on wavelength. The spectral dependence of photocells is similar to the spectral characteristics of photodiodes made from the same semiconductor. The maximum spectral dependence of silicon photocells corresponds to the maximum spectral distribution of solar energy. Therefore, it is Si photocells that are used to create solar cells;

– efficiency

- this is the ratio of the maximum power that can be obtained from a photocell to the total power of the luminous flux incident on the working surface. Efficiency silicon solar cells when converting solar energy does not exceed 12%. It can be increased by using CdTe, GaAs or other materials with a larger bandgap than Si instead of Si, or by using heterojunction solar cells.

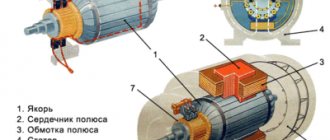

Phototransistors

The structure of a bipolar transistor is shown in Fig. 6.7. The transistor is connected according to a common emitter circuit. The base pin is not connected (IB = 0). Minority charge carriers (holes in the n-base and electrons in the p-collector) are drawn into the collector junction, pass through it and create a photocurrent IФ. The nonequilibrium majority carriers accumulated in the base lower the height of the potential barriers of the emitter and collector junctions. The injection of holes from the emitter into the base increases. The collector current also increases. The additional charge of nonequilibrium majority carriers accumulated in the base provides an increase in the photocurrent. Therefore, a phototransistor can be considered as a photodiode connected to a transistor: the first produces photocurrent IF of the base, and the second provides amplification.

Rice. 6.7. Structure of a bipolar phototransistor

When the base output is connected to an external circuit, some of the nonequilibrium carriers leave the base, which leads to a decrease in the photocurrent. Therefore, the greatest sensitivity to light irradiation of the base region will be when switched on according to a circuit with a common emitter and the base turned off. In this regard, in the first designs of bipolar phototransistors there was no base terminal. Currently, it is made for electrical control of work, to compensate for external influences.

The main parameters of phototransistors are determined similarly to the parameters of photodiodes. For example, the parameters of the germanium transistor FT-1: Urab = 3 V, It = 300 μA, K = 170 – 500 mA/lm, τs = 200 μs, photosensitive area 2 mm2.

IR Sensors

For the IR range of 0.8 - 12 µm, there are many sensors based on PbSe, PbS, InAs, InSb, Ge, as well as pyroelectric detectors. An important area of use of such sensors is detection of people (for example, in burglary protection, etc.). In the spectral composition of IR radiation from the human body at a temperature of about 36 °C (Fig. 6.8), the maximum radiation corresponds to a wavelength of 10 μm.

Rice. 6.8. IR radiation intensity distribution,

emitted by an incandescent lamp and the human body

.

For this spectral range only broadband IR sensors such as pyroelectric detectors

. When a pyroelectric detector is suddenly exposed to infrared radiation, causing it to heat up, the voltage (or current depending on the circuit) changes only briefly and then drops to zero even with continued exposure to radiation.

The nature of the pyroelectric effect is associated with spontaneous polarization P, which is a function of temperature. Spontaneous polarization is the result of a mismatch between the centers of positive and negative charges. Usually, it is not the spontaneous polarization itself that is measured (it is compensated by the fields of free electric charges flowing onto the surface from the inside and outside), but its change ∆P with a rapid change in temperature ∆T. The change in polarization with temperature is determined by the pyroelectric coefficient:

p = dP/dT. (6.6)

If the material is free to expand, as observed in radiation detectors, the effect of expansion on polarization (secondary pyroelectric effect) is included in the P value.

The pyroelectric effect manifests itself in materials whose crystal lattice does not have central symmetry; the direction of polarization is determined by a certain polar axis. This phenomenon is observed in crystals of tourmaline, CdS, CdSe, ZnO, ZnS. For example, in tourmaline, when the temperature changes by 1 K, an electric field E ≈ 400 V/cm arises. A change in polarization in pyroelectrics can also occur under the influence of mechanical stress (piezoelectric effect), but not vice versa - Fig. 6.9. An important group of pyroelectrics are ferroelectrics. The polarization of ferroelectrics disappears above their Curie point. The characteristics of pyroelectric materials are given in table. 6.3. Metrological parameters of pyroelectric radiation detectors: current sensitivity – 0.1 – 10 µA/W; voltage sensitivity – up to 105 V/W; time constant (signal rise time) – 10-9 – 10-7 s; bandwidth – 103 Hz – 102 MHz.

Rice. 6.9. Classification of dielectrics

Table 6.3

Characteristics of pyroelectrics

| Material | Pyroelectric coefficient at 25 °С р, C∙m-2∙K-1 | Curie point, °C |

| Triglycine sulfate (NH2CH2CO2H)3∙H2SO4 | 3∙10-4 | |

| Barium titanate BaTiO3 | 7∙10-4 | |

| Ceramic zirconium lead titanate | (3 – 17)∙10-4 | 215 – 365 |

| Lithium tantalate | 1,8∙10-4 |

Control questions

1. How can you explain the spectral characteristic of a photoresistor?

2. What parameters are the photoresistor characterized by?

3. What are the differences in the properties of photodiodes and photoresistors?

4. Based on what structures can a photodiode be made and what are the main differences in the properties of photodiodes based on various rectifying electrical junctions?

5. How does a photocell directly convert light energy into electrical energy?

6. What is the operating principle of a bipolar phototransistor?

7. What is the nature of the pyroelectric effect?

8. What sensors are used to detect a person?

9. On the basis of what materials can photodetectors be made for the IR region of the spectrum, operating in the “atmospheric window” range of 8 – 14 microns?

HUMIDITY SENSORS

Knowledge of air humidity and other gases is necessary to control physicochemical and biological processes. We list the main areas of use of humidity sensors:

– domestic air conditioning. Relative humidity values corresponding to a feeling of comfort range from 35 to 70%. At lower humidity, respiratory tract irritation occurs and static electricity appears; At very high humidity, skin respiration and sweating are weakened. In addition, when maintaining high humidity, energy costs increase;

– air conditioning in industry. Depending on the type of production, humidity requirements differ greatly: in the textile industry, humidity must be constant, since changes in it lead to changes in fiber tension and affect the operation of machines. In the food industry, the storage conditions of different products require different humidity: for some products a stable temperature (slightly above 0 ° C) with very high humidity is desirable - 85 - 90%, for others - high humidity can lead to mold, and low humidity - to loss mass due to evaporation;

– detection of traces of water vapor. Many technological processes require the absence of traces of water vapor. In microelectronics, the moisture content in integrated circuit packages should not exceed 500 water molecules per million air molecules, during assembly operations - no more than 50 molecules, and during silicon epitaxy - less than one. Relative humidity sensors for measuring ten-thousandths of a percent are required in metallurgy, nuclear energy, heating engineering, and electric power.

Humidity units

Moisture content is measured in units of absolute humidity, partial pressure of water vapor, volumetric moisture content, relative humidity and dew point temperature.

Absolute humidity

measured in grams of water per cubic meter.

Partial pressure

water vapor is measured in hectopascals (104 Pa).

Volumetric moisture content

(volume concentration of water vapor) is defined as the ratio of the volume of water vapor to the total volume of the vapor mixture and is expressed in volume percent or ppm (one part per million) units.

Relative humidity

measured as a percentage and defined as the ratio of the partial vapor pressure of water to the saturated vapor pressure at a given temperature.

Dew point temperature

- this is the temperature at which condensation of water vapor contained in the gas begins during its isobaric cooling. The relationship between different units of humidity at 21 °C is given in the table.

Humidity measurement methods

Methods for measuring moisture in gases and liquids can be divided into direct and indirect. Direct methods are based on the direct release of moisture from the analyzed medium with subsequent determination of its quantity. Indirect methods are based on measuring any physical quantity related to the moisture content of the environment. Humidity sensors (or hygrometers) can be divided into two large groups: temperature-gradient (psychrometric and condensation) and sorption (coulometric, sorption-impedance and piezosorption).

Relationship between different units of humidity

at a temperature of 21 °C

| Dew point in degrees, | Partial pressure of water vapor, Pa | Volumetric vapor concentration, ppm | Relative humidity, % |

| TO | °C | ||

| -72 | 0,1902 | 1,880 | 0,00765 |

| -68 | 0,3471 | 3,43 | 0,0140 |

| -64 | 0,6171 | 6,10 | 0,0248 |

| -60 | 1,0746 | 10,60 | 0,0433 |

| -56 | 1,8354 | 18,20 | 0,0738 |

| -52 | 3,0590 | 30,20 | 0,1260 |

| -48 | 5,0270 | 49,70 | 0,2020 |

| -44 | 8,1000 | 80,10 | 0,3250 |

| -40 | 12,8480 | 127,00 | 0,5160 |

| -36 | 20,0430 | 197,00 | 0,8040 |

| -32 | 30,8290 | 305,00 | 1,2400 |

| -28 | 46,6830 | 462,00 | 1,8800 |

| -24 | 69,9580 | 692,00 | 2,8100 |

| -20 | 103,210 | 1021,00 | 4,1400 |

| -16 | 150,560 | 1489,00 | 6,0600 |

| -12 | 217,060 | 2147,00 | 8,7500 |

| -8 | 314,150 | 3061,00 | 12,8000 |

| -4 | 436,240 | 4316,00 | 17,5000 |

| 609,010 | 6025,00 | 24,1000 | |

| 798,000 | 7895,00 | 32,5000 |

Condensation sensors

The condensation method (dew point method) is based on fixing the condensation temperature of water vapor in the gas phase. For the sensor to operate, it is necessary to control the cooling of the condensing surface with accurate detection of the appearance of condensation and simultaneous measurement of its temperature. The advantages of the method include: measurement of humidity in a wide range of water vapor concentrations, operating range from -70 °C to +100 °C, sensor calibration by temperature and not by humidity (temperature measurement accuracy ±0.2 °C), the ability to measure humidity inside integrated circuit packages.

For cooling, thermoelectric refrigerators (up to -70 °C) and cryogenic liquids are used: liquid nitrogen (77 K), oxygen (20 K), helium (4 K). Thermocouple and thermistors are used to measure temperature. To determine the moment of condensation appearance, measurements of the optical and electrical characteristics of the condensate (surface resistance or capacitance) are used.

To indicate condensation, you can use a piezoquartz resonator included in the generator circuit: at the moment condensation appears, the quality factor of the resonator sharply decreases, and the generation frequency changes (the quartz resonator registers a change in mass of 10-10 - 10-8 g). When optically recording condensate using photodetectors (photodiodes, photoresistors, phototransistors), the intensities of light fluxes reflected from a clean mirror surface and from a surface covered with a layer of condensate are compared. When measuring humidity in IC packages, condensation is detected by changes in surface conductivity or interelectrode capacitance. The simplest surface-condensation type sensor is two metal electrodes (comb-shaped) applied to the surface of a dielectric. The structure of a resistive-capacitive type sensor is shown in Fig. 7.1.

Rice. 7.1. Two-electrode dew point sensor

resistive-capacitive type: 1, 2 – electrodes;

3 – temperature sensor

The surface conductivity of such a structure, when approaching the dew point, increases according to a law close to exponential. The formation of ice on the surface leads to a sharp decrease in the conductivity of condensate.

The main disadvantage of the condensation method is the dependence of the readings on the degree of surface contamination.

Psychrometric sensors

Psychrometric sensors are used to measure the relative humidity of gases (usually air) at temperatures above 0 °C. Their work is based on the dependence of the difference between the readings of dry and wet thermometers on air humidity. The wet thermometer temperature tvl depends on the intensity of evaporation of water vapor from the moistened surface. There is a relationship between the partial pressure of water vapor in the RV at a dry-bulb temperature t and the difference between the temperatures of dry and wet thermometers (t – tvl)

РВ = – A ∙P ∙(t – tvl), (7.1)

where is the saturated vapor pressure of water at the wet-bulb temperature tvl; P – total pressure; A – psychrometric coefficient, depending on the properties of the gas, temperature and design features of the sensor.

The accuracy of the psychrometer readings depends on its design (the speed of the air flow flowing around the wet thermometer, the relative position of the thermometers, the temperature and purity of the water for moistening the wick, etc.).

The sensitivity of a psychrometer depends only on the sensitivity of temperature sensors, which can be thermocouples, resistance thermometers, semiconductor thermistors and thermal diodes. The differential circuitry of temperature sensors provides high sensitivity and good measurement accuracy even near saturation, where the use of most other humidity sensors is limited.

The simplicity and low cost of psychrometers ensures their widespread use in household appliances and air conditioning systems. However, they also have such disadvantages as the need for a wet thermometer, the dependence of readings on the total gas pressure, low-temperature (0 ° C) and high-temperature measurement limits. Psychrometers not designed for a continuous supply of water to wet the wick operate at temperatures up to 40 °C; at higher temperatures, the water to wet the wick may evaporate faster than equilibrium is established. Psychrometers with a continuous supply of water to compensate for evaporation. They are used up to temperatures of 90 – 100 °C, special psychrometers for industrial dryers can operate up to temperatures of 200 – 250 °C, while the wet bulb temperature is 20 – 75 °C. The noted shortcomings lead to the fact that the share of psychrometers in the total production volume of humidity sensors is constantly decreasing.

Valve photocells

Valve photocells

These are devices in which EMF occurs under the influence of light.

The electric field of the barrier layer plays a significant role in this case. Let us recall that the barrier layer appears at the boundary of two semiconductors with different types of conductivity, that is, at a p−n p-n p−n junction. It is the result of the diffusion of holes in the nnn region of the semiconductor and electrons in the p region of the semiconductor; for these reasons, an electric field arises on the barrier layer in the n-p direction.

It is known that when a semiconductor is illuminated (provided that the energy of its photons is greater than the band gap), electron-hole pairs are formed in the latter. If these pairs of current carriers arise near the barrier layer, then under the influence of the electric field of the n−р n-р n−р junction they will separate, which leads to a certain potential difference at the electrodes and creates a current in the circle of the photocell.

Valve photocells have a great future as one of the means of directly converting light energy into electrical energy. Nowadays, silicon solar cells are manufactured with an efficiency of 11-15%; According to theoretical calculations, it can be increased to 22%. Batteries made from such photocells are used in artificial satellites and spacecraft as a power source for radio equipment, in measuring equipment, in automation, etc.

Semiconductor photovoltaic energy converters[ | ]

Photocell based on multicrystalline silicon

The most efficient, from an energy point of view, devices for converting solar energy into electrical energy are semiconductor photovoltaic converters (PVCs), since this is a direct, single-stage energy transition. The efficiency of commercially produced solar cells is on average 16%, with the best samples up to 25%[3]. In laboratory conditions, efficiencies of 43.5%[4], 44.4%[5], 44.7%[6] have already been achieved.

The lack of rectifying diodes and effective antennas for the frequencies of electromagnetic radiation corresponding to light does not yet allow the creation of photoelectric converters that use the properties of a quantum as an electromagnetic wave that induces an alternating emf in a dipole antenna, although, theoretically, this is possible. From such devices one would expect not only better efficiency, but also less temperature dependence and degradation over time.

The physical principle of operation of a photocell[ | ]

Energy conversion in PV cells is based on the photoelectric effect, which occurs in inhomogeneous semiconductor structures when exposed to solar radiation.

The inhomogeneity of the PV structure can be obtained by doping the same semiconductor with different impurities (creating pn junctions) or by connecting different semiconductors with unequal band gaps - the energy of electron removal from the atom (creating heterojunctions), or by changing the chemical composition of the semiconductor, leading to to the appearance of a gradient in the band gap (creation of graded-gap structures). Various combinations of the above methods are also possible.

The conversion efficiency depends on the electrical characteristics of the inhomogeneous semiconductor structure, as well as the optical properties of the photovoltaic cell, among which photoconductivity plays the most important role. It is caused by the phenomena of internal photoelectric effect in semiconductors when irradiated with sunlight.

The main irreversible energy losses in solar cells are associated with:

- reflection of solar radiation from the surface of the converter,

- the passage of part of the radiation through the photovoltaic cell without absorption in it,

- scattering of excess photon energy on thermal vibrations of the lattice,

- recombination of the formed photo-pairs, on the surfaces and in the volume of the photovoltaic cell,

- internal resistance of the converter,

- and some other physical processes.

To reduce all types of energy losses in solar power plants, various measures are being developed and successfully applied. These include:

- the use of semiconductors with optimal band gaps for solar radiation;

- targeted improvement of the properties of the semiconductor structure through its optimal doping and creation of built-in electric fields;

- transition from homogeneous to heterogeneous and graded-gap semiconductor structures;

- optimization of PV design parameters (pn junction depth, base layer thickness, contact grid frequency, etc.);

- the use of multifunctional optical coatings that provide antireflection, thermal regulation and protection of solar cells from cosmic radiation;

- development of solar cells that are transparent in the long-wave region of the solar spectrum beyond the edge of the main absorption band;

- creation of cascade PV cells from semiconductors specially selected for their bandgap width, making it possible to convert in each cascade the radiation that has passed through the previous cascade, etc.;

Also, a significant increase in the efficiency of solar cells was achieved through the creation of converters with double-sided sensitivity (up to +80% of the existing efficiency of one side), the use of luminescent re-emitting structures, Fresnel lenses, and the preliminary decomposition of the solar spectrum into two or more spectral regions using multilayer film beam splitters (dichroic mirrors) with subsequent conversion of each part of the spectrum by a separate photovoltaic cell, etc.