DC motor. Connection diagrams and characteristics of DPT

The DC motor has found wide application in various fields of human activity.

Starting from the use of traction drives used in trams and trolleybuses, ending with the drive of rolling mills and lifting mechanisms, where maintaining high precision of rotation speed is required. The main positive features that distinguish a DPT from an asynchronous motor:

| — flexible starting and adjustment characteristics; |

| — two-zone regulation, which allows you to achieve rotation speeds of more than 3000 rpm. |

Negative features:

| - difficulty in manufacturing and high cost; |

| — during operation, constant maintenance is necessary, since the collector and current-collecting brushes have a short service life. |

A DC motor is used only when the use of an AC motor is impossible or extremely impractical. On average, for every 70 AC motors there is only 1 DC motor.

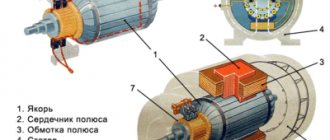

DPT design

The DC motor consists of:

| — inductor (stator); |

| - armature (rotor); |

| — collector; |

| — current collection brushes; |

| — structural elements. |

The armature and the inductor are separated by an air gap. The inductor is a frame that serves to secure the main and additional poles of the motor’s magnetic system. The main poles have excitation windings, and the additional poles have special windings that help improve switching.

The collector supplies direct current to the working winding, which is placed in the slots of the rotor. The collector has the form of a cylinder and consists of plates isolated from each other; it is mounted on the engine shaft. The brushes are used to remove current from the commutator; they are mounted in brush holders to ensure the correct position and reliable pressure on the surface of the commutator.

Figure 1 – DC motor design

DC motors are classified according to the stator magnetic system:

1) DFC with permanent magnets;

2) DFC with electromagnets:

| — DPT with independent excitation; |

| — DBT with sequential excitation; |

| — DPT with parallel excitation; |

| — DBT with mixed arousal. |

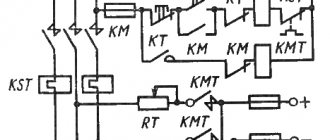

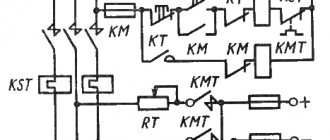

Figure 2 – DC motor connection diagrams

The connection diagram of the stator windings significantly affects the electrical and traction characteristics of the drive.

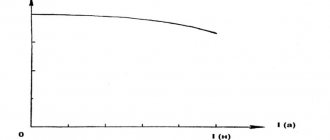

Starting a DC Motor

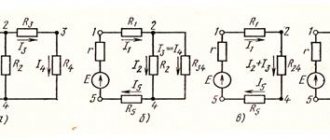

The DC motor is started using starting rheostats, which are active resistances connected to the armature circuit. Rheostatic starting is performed for two reasons:

| — if necessary, smooth acceleration of the electric motor; |

| - at the initial moment of time, the starting current Iп = U / Rя is very large, which causes overheating of the armature winding (which has low resistance). |

Only DFCs with a power of up to 1 kW are allowed to start without starting rheostats, the so-called “direct start”.

Figure 3 – Rheostatic engine starting with 3 stages

At the beginning of the start-up, all resistances are connected to the rotor circuit, and as the speed increases, they are removed in steps.

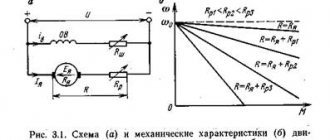

Rotation speed regulation

The rotational speed of a DC motor is expressed by the formula:

This expression is also called the electromechanical characteristic of the DPT, in which:

| U – supply voltage; |

| Iа – current in the armature winding; |

| Rya – anchor chain resistance; |

| k – motor design coefficient; |

| Ф – magnetic flux of the motor. |

Engine torque formula:

Substituting the electromechanical characteristics into the formula, we get:

Thus, based on the above formulas, we conclude that the rotation speed of the DC motor can be adjusted by changing the armature resistance, supply voltage and magnetic flux.

Story.

The principle of converting electrical energy into mechanical energy by an electromagnetic field was demonstrated by British scientist Michael Faraday in 1821 and consisted of a free-hanging wire dipped into a pool of mercury. A permanent magnet was installed in the middle of a pool of mercury. When current was passed through the wire, the wire rotated around the magnet, showing that the current caused a cyclic magnetic field around the wire. This engine is often demonstrated in school physics classes, using brine instead of toxic mercury. This is the simplest type of electric motor. A subsequent improvement is the Barlov Wheel. It was a demonstration device, unsuitable for practical applications due to limited power.

Three-phase brushless DC motor

This type of motor has excellent characteristics, especially when controlled by position sensors. If the resistive torque varies or is completely unknown, or if it is necessary to achieve a higher starting torque, sensor control is used. If the sensor is not used (usually in fans), the control allows you to do without wired communication.

Features of controlling a three-phase brushless motor without a position sensor:

- the rotor location is determined using a differential ADC (analog-to-digital converter);

- current overload is also determined using an ADC (analog-to-digital converter) or an analog comparator;

- speed adjustment is performed using PWM channels connected to the lower drivers;

- AT90PWM3 and ATmega64 are considered recommended microcontrollers;

- The supported communication interfaces (communication interfaces) are UART, SPI and TWI.

Features of controlling a three-phase brushless motor with a position sensor using the example of a Hall sensor:

- speed adjustment is performed using PWM channels connected to the lower drivers;

- the output of each of the Hall sensors is connected to the corresponding I/O line of the microcontroller, configured to generate interrupts when the state changes;

- supported communication interfaces (communication interfaces) are UART, SPI and TWI;

- current overload is determined using an ADC (analog-to-digital converter) or an analog comparator.

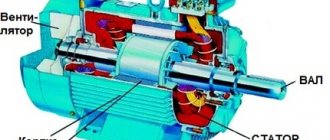

Electric motor device

The main elements that make up a typical three-phase motor are:

- A housing having legs with which it is attached to the foundation;

- A stator whose structure resembles a simple transformer. It has a core and a winding. When current is applied, a vortex electromagnetic field is created.

- Rotor. Main rotating part.

- The shaft on which the rotor is rigidly mounted. The front part extends outward and has a keyway for gears or a pulley. An impeller for cooling and airflow is mounted on the rear part, extending beyond the body.

- Bearings located in the niches of the front and rear covers.

- Sealed terminal box.

Classification of MPT according to the method of powering the inductor and armature windings

Based on this feature, MPTs are divided into 4 types.

With independent excitation

The inductor and armature windings have no electrical connection. In generators of this type, the excitation winding is powered by a direct current network, a battery, or a generator specially designed for this purpose - an exciter. The power of the latter is several hundredths of the power of the main generator.

Scope of application of generators with independent excitation:

- systems of significant power, where the voltage on the excitation winding differs significantly from the generated one;

- systems for regulating the rotation speed of engines powered by generators.

For motors with independent excitation, the armature winding is also energized. Basically these are also high-power units.

The independence of the inductor winding makes it more convenient and economical to regulate the excitation current. Another feature of such motors is the constancy of the excitation magnetic flux under any load on the shaft.

With parallel excitation

The inductor and armature windings are connected in one circuit parallel to each other. Generators of this type are usually used for medium power. In a parallel connection, the voltage generated by the device is applied to the excitation winding. When the inductor and armature windings are connected into one circuit, they speak of a self-excited generator.

In terms of their characteristics, they are identical to motors with independent excitation and have the following features:

- when the load changes, the rotation speed is practically not transformed: the deceleration is no more than 8% when transferring from idle to rated load;

- it is possible to regulate the rotation speed with minimal losses, and within a wide range - 2 times, and for specially designed motors, 6 times.

The inductor of a rotating parallel-wound motor cannot be disconnected from the armature circuit, even if it is already disconnected. This will lead to the induction of a significant EMF in the excitation winding with subsequent failure of the motor. Personnel nearby may be injured.

With sequential excitation

The windings are connected in series to each other. The armature current flows through the field winding. Generators of this type are almost never used, since the process of self-excitation occurs quite rapidly and the device is not able to provide the constant voltage required by most consumers. They are used only in special installations.

Series excitation circuit

Motors of this type are widely used as traction motors (electric locomotives, trolleybuses, cranes, etc.): compared with parallel excitation analogues, when loaded they produce a higher torque with a simultaneous decrease in rotation speed. The starting torque is also high.

Starting the engine with a load below 25% of the rated load, and even more so at idle, is unacceptable: the rotation speed will be too high and the unit will fail.

With parallel-series (mixed) excitation

There are two types of scheme:

- the main winding of the inductor is connected in parallel with the armature winding, the auxiliary winding is connected in series;

- The main winding of the inductor is connected in series with the armature winding, the auxiliary winding is connected in parallel.

Schemes of MPT excitation systems

Connecting a parallel winding before a series winding is called a “short shunt”, and after a series winding - a “long shunt”. Generators of this type are used extremely rarely.

The engines combine the advantages of analogues with parallel and series excitation: they are able to operate at idle speed and at the same time develop significant traction force. But they are almost never used today.

How does a synchronous electric motor work?

Synchronous machines are often used as generators. It operates synchronously with the mains frequency, so it, with an inverter and rotor position sensor, is an electronic analogue of a DC commutator motor.

Structure of a synchronous electric motor

Properties

These engines are not self-starting mechanisms, but require external influence in order to gain speed. They have found application in compressors, pumps, rolling machines and similar equipment, the operating speed of which does not exceed five hundred revolutions per minute, but an increase in power is required. They are quite large in size, have a “decent” weight and a high price.

There are several ways to start a synchronous electric motor:

- Using an external power source.

- Start is asynchronous.

In the first case, using an auxiliary motor, which can be a DC electric motor or a three-phase induction motor. Initially, no direct current is supplied to the motor. It begins to rotate, reaching close to synchronous speed. At this moment, direct current is supplied. After the magnetic field closes, the connection with the auxiliary motor is broken.

In the second option, it is necessary to install an additional short-circuited winding in the pole pieces of the rotor, crossing which the magnetic rotating field induces currents in it. They, interacting with the stator field, rotate the rotor. Until it reaches synchronous speed. From this moment, the torque and EMF decrease, the magnetic field closes, reducing the torque to zero.

These electric motors are less sensitive than asynchronous motors to voltage fluctuations, have a high overload capacity, and maintain a constant speed under any load on the shaft.

Pros - cons

The technical characteristics of asynchronous electric motors with a squirrel-cage rotor are so superior to those of synchronous ones that most drives are made on their basis.

The advantages of such devices are:

- Reliability, simplicity of design, durability;

- No difficulties in repair and maintenance;

- By switching 2 phases, you can make the shaft rotate in the opposite direction;

- Application as a generator.

There are also disadvantages or disadvantages:

- If the phasing is incorrect, the shaft can rotate in the wrong direction and jam other mechanics (gears);

- Inrush current up to five times the rated current;

- Acceleration and braking speed. Some devices with high inertia require higher power motors.

- If a phase is broken, the motor may burn out if the voltage supply is not turned off in a timely manner.

Connection to single-phase and three-phase power supplies

According to the type of supply network, AC electric motors are classified into single- and three-phase.

Connecting asynchronous single-phase motors is very easy - to do this, just connect the phase and neutral wires of a single-phase 220V network to the two outputs on the housing. Synchronous motors can also be powered from this type of network, but the connection is a little more complicated - it is necessary to connect the rotor and stator windings so that their single-pole magnetization contacts are located opposite each other.

Connecting to a three-phase network seems a little more complicated

First of all, you should pay attention that the terminal box contains 6 pins - a pair for each of the three windings. Secondly, this makes it possible to use one of two connection methods (“star” and “delta”)

Incorrect connection can damage the motor by melting the stator windings.

The main functional difference between “star” and “triangle” is the different power consumption, which is done to enable the machine to be connected to three-phase networks with different line voltages - 380V or 660V. In the first case, the windings should be connected in a “triangle” pattern, and in the second case, in a “star” pattern. This switching rule allows in both cases to have a voltage of 380V on the windings of each phase.

On the connection panel, the winding terminals are located in such a way that the jumpers used for switching on do not cross each other. If the motor terminal box contains only three terminals, then it is designed to operate on one voltage, which is indicated in the technical documentation, and the windings are interconnected inside the device.

Advantages and disadvantages of brushless electric motors

Unlike those described, the moving part of these electric motors is a stator with a permanent magnet (housing), and the rotor with a three-phase winding is stationary.

The disadvantages of these DC motors include less smooth adjustment of the shaft rotation speed, but they are capable of reaching maximum speed in a fraction of a second.

The brushless motor is housed in a closed housing, so it is more reliable under adverse operating conditions, i.e. he is not afraid of dust and moisture. In addition, its reliability increases due to the absence of brushes, as does the speed at which the shaft rotates. At the same time, the design of the motor is more complex, therefore, it cannot be cheap. Its cost in comparison with the collector is twice as high.

Thus, a commutator motor operating on alternating and direct current is universal, reliable, but more expensive. It is both lighter and smaller than an AC motor of the same power.

Since AC electric motors powered from 50 Hz (industrial power supply) do not allow high frequencies (above 3000 rpm), if necessary, use a commutator motor.

Meanwhile, its service life is lower than that of asynchronous AC motors, which depends on the condition of the bearings and winding insulation.

Current Applications and Prospects

There are many devices for which increasing uptime is critical. In such equipment, the use of BDKP is always justified, despite their relatively high cost. These can be water and fuel pumps, cooling turbines for air conditioners and engines, etc. Brushless motors are used in many models of electric vehicles

Currently, the automotive industry is seriously paying attention to brushless motors.

BDKPs are ideal for small drives operating in difficult conditions or with high precision: feeders and belt conveyors, industrial robots, positioning systems. There are areas in which brushless motors dominate without alternative: hard drives, pumps, silent fans, small household appliances, CD/DVD drives. The low weight and high power output have also made the BDKP the basis for the production of modern cordless hand tools.

AC motors

They are in higher demand than DC motors. They are often used in everyday life and in industry. Their production is much cheaper, the design is simpler and more reliable, and operation is quite simple. Almost all household appliances are equipped with AC motors. They are used in washing machines, kitchen hoods, etc. In large industries, they are used to drive machine tools, winches for moving heavy loads, compressors, hydraulic and pneumatic pumps and industrial fans.

Principle of operation

The operation of the engine is that the controller switches a certain number of stator windings in such a way that the vector of the magnetic fields of the rotor and stator are orthogonal. Using PWM (pulse width modulation), the controller controls the current flowing through the motor and regulates the torque exerted on the rotor. The direction of this acting moment is determined by the mark of the angle between the vectors. Electrical degrees are used in calculations.

In such a situation, the resulting vector shifts and becomes stationary with respect to the rotor flow, which, in turn, creates the necessary torque on the electric motor shaft.

Classification

All three-phase electric motors can be divided into two groups:

Synchronous. They rotate at the speed of a constant magnetic field. To increase power, the rotor is made according to the principle of a transformer - it has windings and a core. Voltage is supplied through carbon brushes to the commutator rings (contacts) mounted on the shaft, and only then to the rotor coils.

Asynchronous, with a squirrel-cage rotor. The rotational impulse comes from the excitation of the stator coils. The short-circuited turns are made in the form of a squirrel wheel. The rotor rotates at a speed lower than the electromagnetic field of the stator. Hence its name.

Classification of electric motors

- DC motor

DC motor; DC brushed motors. Varieties: Excited by permanent magnets; - With parallel connection of field and armature windings;

- With series connection of field and armature windings;

- With a mixed connection of field and armature windings;

- AC motor

- an electric motor powered by alternating current, has two varieties: Synchronous electric motor - an alternating current electric motor, the rotor of which rotates synchronously with the magnetic field of the supply voltage; - An asynchronous electric motor is an alternating current electric motor in which the rotor speed differs from the frequency of the rotating magnetic field created by the supply voltage.

- Single-phase - manually started, or have a starting winding, or have a phase-shifting circuit

- Polyphase

- Stepper motors are electric motors that have a finite number of rotor positions. The specified position of the rotor is fixed by supplying power to the corresponding windings. The transition to another position is carried out by removing the supply voltage from some windings and transferring it to others.

- Valve motors - Electric motors made in the form of a closed system using a rotor position sensor (RPS), a control system (coordinate converter) and a power semiconductor converter (inverter).

- A universal commutator motor (UCM) is a commutator electric motor that can operate on both direct current and alternating current.

Due to the connection with the low network frequency (50 Hertz), asynchronous and synchronous motors have greater weight and size than a brushed DC motor and a universal brushed motor of the same power. When using a rectifier and inverter with a frequency significantly higher than 50 Hz, the weight and dimensions of asynchronous and synchronous motors approach the weight and dimensions of a brushed DC motor and a universal brushed motor of the same power.

A synchronous motor with a rotor position sensor and an inverter is an electronic analogue of a brushed DC motor.

Energy conversion principle

The operating principle of any type of electric motor is to use electromagnetic induction that occurs inside the device after being connected to the network. In order to understand how this induction is created and sets the engine elements in motion, you should turn to a school physics course that explains the behavior of conductors in an electromagnetic field.

So, if we immerse a conductor in the form of a winding, along which electric charges move, into a magnetic field, it will begin to rotate around its axis. This is due to the fact that the charges are under the influence of a mechanical force that changes their position on a plane perpendicular to the magnetic field lines. We can say that the same force acts on the entire conductor.

The diagram below shows a current-carrying loop that is energized and two magnetic poles that give it rotational motion.

The picture is clickable.

It is this pattern of interaction between the magnetic field and the current-carrying circuit with the creation of electromotive force that underlies the functioning of electric motors of all types. To create similar conditions, the device design includes:

- Rotor (winding) is a moving part of the machine, mounted on a core and rotation bearings. It plays the role of a current-conducting rotational circuit.

- The stator is a stationary element that creates a magnetic field that affects the electric charges of the rotor.

- Stator housing. Equipped with mounting sockets with cages for rotor bearings. The rotor is placed inside the stator.

To represent the design of an electric motor, you can create a circuit diagram based on the previous illustration:

After connecting this device to the network, a current begins to flow through the rotor windings, which, under the influence of the magnetic field arising on the stator, gives the rotor rotation, which is transmitted to the rotating shaft. Rotation speed, power and other performance indicators depend on the design of the specific motor and the parameters of the electrical network.

Collector machines

However, synchronous and asynchronous electric motors have one insurmountable drawback - the frequency of the supply voltage. It determines the speed of rotation of the magnetic field and shaft in these motors. With no design changes in them, at a given frequency of the supply voltage, it is possible to obtain a shaft rotation frequency greater than the frequency of the supply voltage. If a higher number of revolutions is required, commutator electric motors are used.

In these engines, the rotor windings are constantly switched by the commutator. Each winding is essentially a frame with current, which, as is known from Faraday’s experiments, rotates in a magnetic field. But one frame will turn and stop. Therefore, there are several frames - windings - and each of them corresponds to a pair of plates in the collector. Current is supplied through brushes sliding along the commutator.

The design of such an electric motor allows it to operate from a source of either direct or alternating voltage, which provides current in both the stator and rotor. With alternating voltage, the direction of the current in the stator and rotor changes simultaneously and therefore the direction of the force rotating the rotor is maintained. The frequency of the supply voltage does not affect the rotor speed in any way. It depends only on the voltage supplying the electric motor. The sliding contact of the brush with the commutator limits the capabilities of these electric motors in terms of service life and place of application, since sparking in the brushes quickly destroys the sliding contact and is unacceptable in conditions of increased explosion hazard.

Types of engines and their design

AC electric motors have a different design, thanks to which it is possible to create machines with the same rotor speed relative to the stator magnetic field, and machines where the rotor “lags behind” the rotating field. According to this principle, these motors are divided into corresponding types: synchronous and asynchronous.

Asynchronous

The design of an asynchronous electric motor is based on a couple of important functional parts:

- The stator is a cylindrical block made of steel sheets with grooves for laying conductive windings, the axes of which are located at an angle of 120˚ relative to each other. The poles of the windings go to the terminal box, where they are connected in different ways, depending on the required operating parameters of the electric motor.

- Rotor. In the design of asynchronous electric motors, two types of rotors are used:

- Short-circuited. So called because it is made from several aluminum or copper rods short-circuited using end rings. This design, which is a current-carrying rotor winding, is called a “squirrel cage” in electromechanics.

- Phase. On rotors of this type, a three-phase winding is installed, similar to the stator winding. Most often, the ends of its conductors go to the terminal pad, where they are connected in a star, and the free ends are connected to slip rings. The phase rotor allows you to use brushes to add an additional resistor to the winding circuit, which allows you to change the resistance to reduce inrush currents.

In addition to the described key elements of an asynchronous electric motor, its design also includes a fan for cooling the windings, a terminal box and a shaft that transmits the generated rotation to the working mechanisms of the equipment whose operation is provided by this motor.

The operation of asynchronous electric motors is based on the law of electromagnetic induction, which states that electromotive force can only arise under conditions of a difference in the speed of rotation of the rotor and the magnetic field of the stator. Thus, if these speeds were equal, the EMF could not appear, but the influence on the shaft of such “braking” factors as load and bearing friction always creates conditions sufficient for operation.

Synchronous

The design of synchronous AC electric motors is somewhat different from the design of asynchronous analogues. In these machines, the rotor rotates around its axis at a speed equal to the rotation speed of the stator's magnetic field. The rotor or armature of these devices is also equipped with windings, which are connected at one end to each other and at the other to a rotating collector. The contact pads on the commutator are mounted in such a way that at a certain point in time it is possible to supply power through the graphite brushes to only two opposite contacts.

Operating principle of synchronous electric motors:

- When the magnetic flux in the stator winding interacts with the rotor current, a torque arises.

- The direction of movement of the magnetic flux changes simultaneously with the direction of the alternating current, due to which the rotation of the output shaft is maintained in one direction.

- The desired rotation speed is adjusted by adjusting the input voltage. Most often, in high-speed equipment, such as rotary hammers and vacuum cleaners, this function is performed by a rheostat.

The most common reasons for failure of synchronous electric motors are:

- wear of the graphite brushes or weakening of the pressure spring;

- wear of shaft bearings;

- collector contamination (clean with sandpaper or alcohol).

Three Phase Alternator

Links

Wikimedia Foundation. 2010.

See what “AC electric motor” is in other dictionaries:

- AC motor

— — [A.S. Goldberg. English-Russian energy dictionary. 2006] Topics: energy in general EN ac motor ...

Rice. 1 The design of the simplest commutator DC motor with a two-pole stator and a two-pole rotor. DC motor is an electric machine, ma ... Wikipedia

An alternating current machine designed to operate in motor mode (see Alternating current machine). P. t. e. divided into synchronous and asynchronous. Synchronous electric motors (See Synchronous electric motor) are used in... ...

An electrical machine used to produce alternating current (generator) or to convert electrical energy into mechanical energy (motor) or into electrical energy of another voltage or frequency (converter) P. t. m.... ... Great Soviet Encyclopedia

AC machine current, intended for operation in engine mode. P. t. e. divided into synchronous and asynchronous. Synchronous electric motors are used in electric drives mainly. when constant angular velocity is required. From asynchronous... ... Big Encyclopedic Polytechnic Dictionary

AC electric drive

— direct [alternating] current electric drive An electric drive containing a direct [alternating] current electric motor. [GOST R 50369 92] Topics: electric drive EN ac drivealternating current drive DE Wechselstromantrieb ... Technical Translator's Guide

DC (AC) electric drive

— 3.1.3 direct (alternating) current electric drive: A drive containing a direct (alternating) current electric motor and a gearbox;

The phenomenon of electromagnetic induction became the basis for the emergence and development of all electrical machines. The discoverer of this phenomenon at the end of the 19th century was Michael Faraday, an English scientist and experimenter. He conducted experiments with the first electric machines. Now it is impossible to imagine our life without them. Electric motors have become one of the most common electrical machines.

To operate an electric motor, voltage is required, the properties of which determine its design. The following electric motors operate on alternating voltage and current:

operate at constant voltage and current:

- collector;

- unipolar;

- stepper.

Brushless DC motor. General information and device design

Motor controllers of this type are often powered by constant voltage, which is where they get their name. In English technical literature, a valve motor is called PMSM or BLDC.

The brushless motor was created primarily to optimize any DC motor in general. Very high demands were placed on the actuator of such a device (especially the high-speed microdrive with precise positioning).

This, perhaps, led to the use of such specific direct current devices, brushless three-phase motors, also called BLDC motors. In their design, they are almost identical to synchronous AC motors, where the rotation of the magnetic rotor occurs in a conventional laminated stator in the presence of three-phase windings, and the number of revolutions depends on the voltage and load of the stator. Based on certain coordinates of the rotor, different stator windings are switched.

stator windings serve as a fixing element

If one of the windings is turned off, the signal that was induced will be measured and further processed, however, this operating principle is impossible without a signal processing professor. But to reverse or brake such an electric motor, a bridge circuit is not needed - it will be enough to supply control pulses in reverse sequence to the stator windings.

In a VD (switched motor) an inductor in the form of a permanent magnet is located on the rotor, and the armature winding is on the stator. Based on the position of the rotor, the supply voltage for all windings of the electric motor is generated. When a collector is used in such designs, its function will be performed by a semiconductor switch in a switch motor.

The main difference between synchronous and valve motors is the self-synchronization of the latter using the DPR, which determines the proportional rotation speed of the rotor and the field.

Most often, brushless DC motors are used in the following areas:

- freezing or refrigeration equipment (compressors);

- electric drive;

- air heating, air conditioning or ventilation systems.

Stator

This device has a classic design and resembles the same device of an asynchronous machine. The composition includes a core of copper winding (laid around the perimeter in grooves), which determines the number of phases, and a housing. Usually the sine and cosine phases are sufficient for rotation and self-starting, however, the valve motor is often created as a three-phase or even four-phase one.

Electric motors with reverse electromotive force are divided into two types based on the type of winding on the stator winding:

- sinusoidal shape;

- trapezoidal shape.

In the corresponding types of motor, the electric phase current also changes according to the supply method, sinusoidally or trapezoidally.

Rotor

Ferrite magnets are considered the most common and cheapest for making a rotor, but their disadvantage is the low level of magnetic induction, so such materials are now being replaced by devices made from alloys of various rare earth elements, since they can provide a high level of magnetic induction, which, in turn, allows the rotor size to be reduced.

DPR

A rotor position sensor provides feedback. Based on the principle of operation, the device is divided into the following subtypes:

- inductive;

- photoelectric;

- Hall effect sensor.

The latter type has gained the greatest popularity due to its almost absolute inertia-free properties and the ability to get rid of delays in feedback channels based on the rotor position.

Control system

The control system consists of power switches, sometimes also of thyristors or power transistors, including an insulated gate, leading to a current inverter or voltage inverter assembly. The process of controlling these keys is most often implemented by using a microcontroller, which requires a huge number of computational operations to control the motor.

Features and design of DPT

A DPT is a rotating electrical machine powered by direct current. Depending on the direction of power flow, a distinction is made between an engine (an electric motor with electrical and mechanical power) and a generator (an electrical generator supplied with mechanical power as well as electrical energy). DCTs can be started under load and their speed can be easily changed. In generator mode, the DPT converts the AC voltage supplied by the rotor into a pulsating DC voltage.

History of invention

Based on the development of the first voltaic cells in the first half of the 19th century, the first electromechanical energy converters were direct current machines. The original form of the electric motor was developed in 1829, and in 1832 the Frenchman Hippolyte Pixie built the first generator. Antonio Pacinotti built a DC electric motor with a multi-component commutator in 1860. Friedrich von Hefner-Alteneck developed the drum anchor in 1872, which opened up the possibility of industrial use in the field of large-scale engineering.

In subsequent decades, such machines, due to the development of three-phase alternating current, lost their importance in large-scale mechanical engineering. Synchronous machines and low maintenance induction motor systems have replaced them in many applications.

Engine design

To understand the principle of operation of a DCT, you must first study its design features, one of which is that a rotating conductive circuit is installed in the magnetic field of a permanent magnet.

Simplifying this structure, we can say that the engine consists of two main components:

- The main magnet (permanent magnet) that is attached to the stator. A magnetic field can also be electrically generated. The stator contains the so-called exciting windings (coils).

- A conductive loop (reinforcement) on the armature core, usually consisting of laminated metal sheets.

Both designs are called externally excited DC motors. The electrodynamic law indicates that a current-carrying loop of a conductor in a magnetic field represents a force [F], depending on the current [I] and the magnetic field strength [B]. A current-carrying conductor is surrounded by a circular magnetic field. If you combine the magnetic field of a magnetic field with the magnetic field of a conducting loop, you can find a superposition of the two fields, as well as a resulting force effect.

The armature winding consists of two halves of the coil. If a DC voltage is applied to the two ends of the armature winding, moving charge carriers can be imagined to enter the lower half of the coil from the upper half of the coil.

Each current-carrying coil develops its own magnetic field, and the magnetic field of the permanent magnet is superimposed on the magnetic field of the lower half of the coil and the field of the upper half of the coil. The field lines of a permanent magnetic field are always in the same direction , they always point from north to south pole. In contrast, the fields of the two halves of the coil have opposite directions.

On the left side of the field half of the coil, the field lines of the exciter field and the coil field have the same direction. Due to this force effect, a torque is created in the opposite direction at the lower and upper ends of the reinforcement, which causes a rotational movement of the armature.

The anchor is a so-called I-beam anchor. This design got its name because of its shape, which resembles two compound “Ts”. The armature coils are connected to the commutator (collector) boards. The supply of current to the armature winding is usually through carbon brushes, which provide sliding contact with the rotating commutator and supply electricity to the coils. The brushes are made from self-lubricating graphite, partly mixed with copper powder for small motors.

Symbols for DC motors of the P series.

P X1 X2 X3 M P – DC machine; X1 – version according to the degree of protection and cooling method. Without a letter - splash-proof with self-ventilation size 1-6. B – closed version with natural cooling, size 1-4; X2 – dimensions of the electric machine. 1-1 dimensions, 2-2 dimensions, 3-3 dimensions, 4-4 dimensions, 5-5 dimensions, 6-6 dimensions; X3 – nominal length of the armature core. 1 – first length, 2 – second length; M – marine version;

According to the installation method, DC electric motors have a design - IM1001, IM2101, IM2111, IM2131, IM3601, IM3631, IM3611. DC motors can be manufactured with an attached tachogenerator.

Operating conditions for DC electric motors P51, P52.

- DC motors P51, P52 are manufactured for operation at ambient temperatures from -40°C to +40°C.

- At an ambient temperature of 20° ± 5°C% relative humidity 95°±3°C%.

- Withstands vibration, shock, long-term tilting of the axis of a DC electric motor from 45° in any direction and when rolling up to 45° with a rolling period of 7-9 s.

Excitation of a DC motor is serial, parallel, mixed, independent. The heat resistance class of DC electric motor insulation is N. The general level of vibration of electric motors and the level of airborne noise intensity comply with all accepted standards.

Overall and connecting dimensions of DC motors P51, P52, PB51, PB52

| Type of DC motors | Dimensions, mm | Weight, kg for IM2101, IM2102, IM3601, IM2103, IM2104, IM3611, IM3631 | Weight, kg for IM1001, IM1004 | ||||||

| b10 | d1 | d20 | d30 | l10 | l30 | h | |||

| P51U4 | 264 | 35 | 255 | 352 | 225 | 606 | 180 | 122 | 115 |

| PB51U2 | 638 | 127 | 120 | ||||||

| P52U4 | 264 | 35 | 255 | 352 | 265 | 646 | 180 | 142 | 135 |

| PB52U2 | 678 | 147 | 140 |

Main technical characteristics of DC motors P51, P52

| Type | power, kWt | Voltage V | Mains current A | Rotation speed, rpm | Efficiency % |

| P51M | 2,7 | 110 | 33 | 750/1500 | 71 |

| 2,7 | 220 | 17,2 | 750/1500 | 74 | |

| 4,2 | 110 | 52,2 | 1000/2000 | 73 | |

| 4,2 | 220 | 25,6 | 1000/2000 | 74,5 | |

| 7,4 | 110 | 83,6 | 1500/2250 | 79,5 | |

| 7,4 | 220 | 41,8 | 1500/2250 | 80 | |

| 14,5 | 110 | 153 | 3000/3300 | 85 | |

| 14,5 | 220 | 77,3 | 3000/3300 | 85 | |

| P52M | 3,4 | 220 | 20,8 | 750/1500 | 74,5 |

| 5 | 110 | 58,5 | 1000/2000 | 77 | |

| 5 | 220 | 29,2 | 1000/2000 | 77 | |

| 8,8 | 110 | 97,8 | 1500/2250 | 81,5 | |

| 8,8 | 220 | 48 | 1500/2250 | 82,5 | |

| 16 | 220 | 84,5 | 2800 | 86 | |

| 20 | 220 | 104 | 3000/3300 | 87 |

DC electric motors of the P series 1, 2, 3, 4 dimensionsDC electric motors of the P51, P52 seriesDC electric motors of the P61, P62 seriesDC motors of the 2P series (2PO132 - 2PO200, 2PF132 - 2PF200)DC electric motors 2PN, 2PBElectric DC machines of the 4PD series DC motors current DP-112, DK-112, DKU-112MR permanent magnet motors

MTA motors on permanent magnetsPI, PC, 3PI motors on permanent magnetsMX, MVN, MVO motors on permanent magnetsDC electric motors of the DE seriesDC electric motors DPMEDC electric motors DPURDC electric motors PBS, PBSTDC electric motors DK-309M