Brick pallet weight

The sale and transportation of bricks to the construction site is carried out, as a rule, in pallets. This not only facilitates transportation, but also minimizes losses. Although brick is a strong and hard material, during transportation, if it is stacked one on top of the other, it breaks and deteriorates. Pallets allow you to avoid this. The laying method is determined by the type of blocks being transported. Solid bricks are usually folded in a herringbone pattern, while hollow bricks are folded in a cross-link pattern. Additional protective measures include packaging in durable bags. It does not allow moisture and dirt to settle on the bricks and reduce the declared qualities of the building material. And in order to correctly formulate a cost estimate for the construction of a brick structure, you need to know exactly how much a pallet of bricks weighs. This value is of decisive importance for the carrier; it determines the number of trips made by the vehicle to its destination.

Weight of a pallet with bricks

It represents the total mass of both the container and the brick itself. To calculate how much a “clean” building material weighs, you need to know the mass of one and the total number of blocks, multiply these values and subtract the mass of the pallet. The weight must be clarified with the supplier and checked in accordance with GOST, taking into account the type, density, and purpose of the block. Solid and single ones can be transported in 200-400 blocks. Considering that the mass of each is 3.3-3.6 kg, the pallets can weigh either 660 or 1440 kg. The weight of one and a half is less variable, since one block has a mass of 4 kg. No more than 200 bricks can be stacked on one container at a time, and, therefore, the weight is 800 kg.

This value applies when ordering a truck for transporting packages. The weight of the package has

impact on the number of flights, and therefore the cost of delivery. One silicate single brick weighs 3700 g, and one and a half - 5000 g. A hollow one and a half brick has a mass of 4000 g, and a double brick - 5200 g. Ceramic bricks (250 × 120 × 65 mm) have a mass of: 2600 g (hollow), 3600 g ( full-bodied) and 2100 g (short).

Characteristics

Ceramic brick obtained by firing clay using additives is distinguished by its high strength, level of frost resistance and moisture resistance. Ceramic products are environmentally friendly. A minor drawback is the cost and weight of this building material.

Slit stone has technological holes that can occupy up to 45% of the total volume. This structural type significantly reduces the weight of red hollow bricks as opposed to solid stones.

The main characteristic properties of ceramic products include:

- water absorption from 6 to 16%;

- strength grade M50–300;

- frost resistance index – F25–100.

Voids in building materials can be varied, that is, horizontal or longitudinal, round and slotted. Such voids allow you to create additional insulation in the room from external noise.

Number of bricks in a pallet

The brick can be single, one and a half, double. Almost all companies sell bricks in pallets, because it is very convenient when talking about large quantities.

Therefore, it will be useful to know that:

- in a pallet 770x1030 mm - 420 pieces of single brick, 200 pieces of double brick;

- in a pallet 520x1030 mm - 200 pieces of single brick.

Since ceramic cladding comes in different sizes, the resulting amount of bricks in the pallet will also be different:

- hollow single - 480 pieces;

- hollow one and a half - 352 pieces.

Sand-lime facing bricks are slightly heavier than ceramic ones, so the amount of bricks in the pallet will differ:

- single - 400 pieces;

- one and a half - 280 pieces.

How much does a pallet of red solid brick weigh?

When building houses and outbuildings, red solid brick is most often used. It has high performance characteristics and provides buildings with durability. Before you start building with this material, you need to know not only its properties, but also be able to correctly calculate weight parameters and consumption.

How much does one brick weigh?

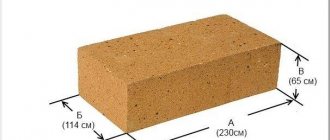

Solid red brick is a bulk building material that is made using a special technology from high-grade refractory clay. It has a minimum of voids inside, their equivalent is usually 10-15%. To determine the weight of one piece of red solid brick, it is important to consider that it can be produced in three types:

- single;

- one and a half;

- double.

The average weight of a single block is 3.5 kg, a one-and-a-half block is 4.2 kg, and a double block is 7 kg. At the same time, for the construction of houses, the material most often chosen is standard sizes 250x120x65 mm, its weight is 3.510 kg. Buildings are faced with special single blocks; in this case, one brick weighs 1.5 kg. For the construction of fireplaces and stoves, it is recommended to use material marked M150; it has excellent thermal stability and, with standard sizes, the weight of one stove block can be from 3.1 to 4 kg.

In addition, ordinary brick of the M100 brand is used for exterior decoration; it is frost-resistant, provides the building with good sound insulation and protects it from moisture penetration. The weight of one such block is 3.5-4 kg. If you plan to build multi-story buildings, then you need to purchase material with a strength class of at least 200. Bricks marked M200 have an increased level of strength, are characterized by excellent thermal insulation and weigh on average 3.7 kg.

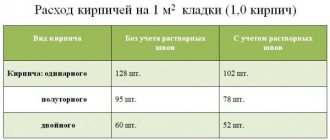

Calculation of the total mass of building materials

In order for the constructed building to reliably serve for a long time, the quality of the brickwork plays a huge role in its construction. Therefore, in order for the material to withstand the optimal and maximum load, it is necessary to correctly calculate the mass of the material per 1 m3 of masonry. For this, craftsmen use a simple formula: the specific gravity of red solid brick is multiplied by its quantity in the installation. At the same time, we must not forget about the mass of the cement mortar, and also take into account the number of rows, seams and wall thickness.

The obtained value is approximate as it may have minor deviations. In order to avoid mistakes during construction, when creating a project, it is necessary to decide in advance on the brand of brick, the method of laying and correctly calculate the weight and width of the walls.

You can also simplify the calculation of the total mass of the material by calculating individual areas.

1 pallet

Before purchasing building materials, you also need to know its consumption. Bricks are transported in special pallets, where the blocks are placed at an angle of 45, in the form of a “herringbone”. One such pallet usually holds from 300 to 500 units of fragments. It is easy to calculate the total weight of the material yourself if you know the number of blocks in the pallet and the weight of one unit. Typically, wooden pallets weighing up to 40 kg are used for transportation; their load capacity can be 900 kg.

To simplify the calculations, the buyer and seller must also take into account the fact that a single red solid brick weighs up to 3.6 kg, one and a half 4.3 kg, and double up to 7.2 kg. Based on this, it turns out that on average, from 200 to 380 bricks are placed on one wooden substrate. After performing simple calculations, the approximate mass of material on the pallet is determined; it will be from 660 to 1200 kg. If you add the tare weight, you will end up with the desired value.

What does weight depend on?

The weight of a brick on a pallet often does not comply with government regulations, according to which it cannot be more than 850 kg. As a rule, this is due to the fact that manufacturers or sellers ignore the requirements, pursuing their own benefit due to material or time costs. According to GOST rules, brick blocks can be laid using cross-banding using several methods: on an “edge”, “Christmas tree”, “die”, securing them with a special tape or film. And the pallets themselves are prohibited from being placed higher than 2 tiers. Violation of the acceptable methodology for laying brick blocks on a pallet causes an increase in their total mass.

What is a pallet?

Pallet (pallet) is a specific device designed for transporting ceramic materials, in particular brick products. It allows you to safely deliver brick blocks to any location with minimal risk of damaging or deteriorating them along the way. Pallets are a special shield made from individual boards. They are:

- Depending on the materials used: wooden;

- metal;

- wood-metal.

- on supports;

With the help of a pallet, not only the transportation of brick products is carried out, but also its storage and loading. In addition, the pallet plays the role of packaging (a kind of pack), and its cost is paid separately by the customer of the building materials. Accordingly, the more expensive the materials from which the container is made, the higher its price. Wooden products are the most popular, since they are the cheapest and, unlike wood and metal products, can be transported by all major modes of transport: water, rail and road.

Despite the unsightly appearance of the pallet, it must be manufactured in compliance with certain standards regulated by GOST. The following rules must be observed:

- full technical equipment of the production line;

- proper manufacturing control;

- compliance with all necessary technical standards and parameters;

- checking the quality of the finished product;

- familiarizing buyers or persons who will use it with the operating rules.

Return to contents

Pallet stacking norm

How many brick products on a large pallet:

- single (standard brick size 250 x 120 x 65 mm) - about 420 pieces;

- one and a half (250 x 120 x 88 mm) - approximately 390 pieces;

- double (250 x 120 x 138 mm) – about 200 pieces;

- double corrugated – 192 pieces;

- tortoiseshell M150 – 280 pieces;

- with torn edge (single) – 308 pieces;

- with a torn edge (angular) - 352 pieces;

- basement - 478 pieces.

If the size of the facing brick is 250 x 90 x 65 (short), then up to 360 pieces can be placed on a large board. The small pallet holds a smaller number of single bricks - 275 pieces.

How many pallets fit in a truck?

If you need to load bricks into a long length, and the pallet size is, say, 1130x520, then their number will be 32. If loading is carried out in KamAZ, then with euro-sized pallets their number will be 10-12 pieces. When transporting material in a truck, their number reaches 32-33.

Brick is a very popular building material, which today is actively used for various purposes. But today the process of transporting this product occurs in special pallets. Thanks to them, it is possible to ensure simplicity and ease of transportation. In addition, this facilitates the process of recalculation for the seller, which is carried out by the sale of the specified product. Choose only high-quality products, and then your building will serve you for a long time. Read our article about how many bricks are in 1 m2.

How much does a pallet of bricks weigh and how many pieces are in a pallet?

Today, construction stores have a huge number of materials, each of which has its own properties. But to this day, brick competes with all modern materials. This is what is often used in building houses and laying walls. In order to calculate the amount of material required, it is necessary to take into account the number of bricks in the pallet.

Standard number of pieces in one pallet

Red brick

When building a private house, red is often used. For its production, various types of clay are used, which is subjected to a firing process. The result is a very durable product. The weight of a red solid brick will be 3.6 kg, and a hollow one - 2.5 kg. Red perfectly resists precipitation.