When carrying out activities for the construction of buildings or repairs of previously erected buildings, it is important to reliably insulate the walls of the building. To reduce the amount of heat loss and reduce the cost of maintaining a comfortable temperature, it is important to take a responsible approach to the selection of thermal insulation materials and performance of thermal calculations. When solving problems related to ensuring the energy efficiency of concrete buildings, it is necessary to take into account the thermal conductivity of concrete. This indicator characterizes the ability to conduct heat and is one of the most important characteristics.

Thermal conductivity of concrete mass

How does the thermal conductivity of concrete affect the indoor microclimate?

Of the many building materials used to construct buildings, one of the most common is concrete. Among the main performance characteristics of the material, the thermal conductivity coefficient of concrete stands out. At the design stage, it is necessary to provide for the use of thermal insulation materials during the construction process, which will allow turning the erected reinforced concrete structure into a residential building. After all, it is important to erect not only a sustainable, environmentally friendly and original building, but also to create favorable conditions for living.

Knowing the thermal conductivity of a concrete mass and choosing the right thermal insulation materials, you can achieve significant results:

- significantly reduce heat losses;

- reduce space heating costs;

- provide a comfortable microclimate inside the building.

The influence of the level of thermal conductivity on the internal microclimate is expressed by a simple relationship:

- as the coefficient increases, the intensity of heat transfer increases, and a structure built from a material with such characteristics cools faster and, accordingly, heats up at an accelerated pace;

- reducing the ability of the concrete mass to transfer heat allows for an increased period of time to maintain a comfortable temperature inside the room, with a corresponding reduction in heat losses.

Knowing the thermal conductivity of the concrete mass, it is possible to ensure a comfortable microclimate inside the building.

To summarize, the degree of thermal conductivity of concrete is the determining factor affecting the comfort of the home. Different types of concrete differ in the structure of the mass, the properties of the filler used and, accordingly, the degree of thermal conductivity. It is important to use such grades of concrete together with insulation materials to ensure that the concrete mass reliably retains heat in the room. The choice of materials used for construction is made at the design stage.

Thermal conductivity of reinforced concrete and thermal resistance - getting acquainted with the concepts

When deciding whether to use a certain brand of concrete or other building material for the construction of a building, you should pay attention to the following characteristics that ensure the energy efficiency of the building:

- thermal conductivity coefficient of reinforced concrete or concrete. This is a special indicator that characterizes the amount of thermal energy that can pass through various building materials over a certain period of time. When the coefficient value decreases, the material’s ability to conduct heat decreases, and when the coefficient increases, the rate of heat removal increases;

- thermal resistance of building structures. This parameter characterizes the properties of building materials to prevent thermal energy loss. Thermal resistance is the opposite of thermal conductivity. With an increased value of the thermal resistance index, the building material can be used for thermal insulation purposes, and with a decreased value, for accelerated heat removal.

When developing a project for a future building and performing thermal calculations, it is necessary to take into account these indicators.

Thermal conductivity coefficient of materials

Thermal conductivity coefficient of concrete for various types of monolith

When deciding on the type of concrete that will be used to build a residential building, you should evaluate how the thermal conductivity of the monolith changes for the varieties of this building material. A table that covers the characteristics of all types of concrete will help you compare the thermal conductivity of concrete. Let's consider how the level of thermal conductivity of a concrete mass changes, which is expressed in W/m2x ºC for the most common types of material.

The lowest coefficient value is for concrete composites with a cellular structure:

- for dry foam concrete and gas-filled concrete, the value of the indicator is small compared to other types. It increases with increasing material density. With a specific gravity of 0.6 t/m3, the coefficient is 0.14, and with a density of 1 t/m3 it is already 0.31. At base humidity the values increase from 0.22 to 0.48, and at increased humidity from 0.26 to 0.55;

- Expanded clay-filled concrete, depending on the density of the mass, also has a different coefficient value, which changes in proportion to the increase in specific gravity. Thus, expanded clay concrete with a density of 0.5 t/m3 has a low coefficient of 0.14, and when the density increases to 1.8 t/m3, the thermal conductivity parameter increases to 0.66.

The value of the coefficient is also determined by the filler used to prepare the concrete mixture:

- for heavy concrete with a density of 2.4 t/m3 containing crushed stone filler, the figure is 1.51;

- concrete, where slag is used as a filler, is characterized by a reduced thermal conductivity value of 0.3–0.7;

- Expanded clay concrete containing quartz or perlite sand has a density of 0.8–1 and, accordingly, a thermal conductivity level of 0.22–0.41.

The thermal conductivity coefficient of concrete

reliably insulates the structure being built.

When constructing building walls from concrete, which has a porous structure and a low level of thermal conductivity, a thin layer of thermal insulation is required. The use of heavy grades of concrete requires enhanced insulation of the structure. To do this, a thick layer of heat insulation is laid. When selecting a material, it should be taken into account that with increasing density, the thermal conductivity of the concrete mass increases.

Thermal conductivity of heavy concrete: indicators

Such materials are also divided into two main groups. Concrete can be used in construction:

- heavy;

- especially heavy.

In the production of the second type of material, fillers such as metal scrap, hematite, magnetite, and barite are used. Extra-heavy concrete is usually used only in the construction of facilities whose main purpose is radiation protection. This group includes materials with a density of 2500 kg/m3.

Conventional heavy concrete is made using types of filler such as granite, diabase or limestone, made from crushed rock. In the construction of buildings and structures, a similar material with a density of 1600-2500 kg/m3 is used.

What could be the thermal conductivity of concrete in this case?

The table below shows the indicators characteristic of different types of heavy material. Thermal conductivity of heavy concrete

| Type of concrete | Extra heavy | Heavy for reinforced concrete structures | On the sand |

| Thermal conductivity index W/(m°C) | 1,28-1,74 | At a density of 2500 kg/m3 - 1.7 | At a density of 1800-2500 kg/m3 - 0.7 |

What factors influence the thermal conductivity coefficient of reinforced concrete

The level of thermal conductivity of concrete, regardless of its grade and the presence of steel reinforcement in the mass, depends on a set of factors. Let's consider the indicators, each of which has a certain impact on this characteristic:

- structure of the concrete mass. When creating air cavities inside the monolith, the process of heat transfer through the cellular array is carried out at low speed and with minimal losses. To summarize, the increased concentration of cells reduces heat loss;

- specific gravity of the material. The density of the concrete mass affects its structure and, accordingly, the intensity of the heat transfer process. As the density of the material increases, the degree of heat transfer increases and the volume of heat losses increases;

- moisture concentration in concrete walls. The concrete mass, which has a porous structure, is hygroscopic. Moisture particles that seep deep into the concrete through capillaries fill the air pores and thereby accelerate the heat transfer process.

When performing calculations, it is necessary to take into account that as the moisture content of the material decreases, the degree of thermal conductivity decreases and less heat is lost. The use of porous filler can reduce heat loss and provide a comfortable microclimate in the room. It is advisable to use building materials with low thermal conductivity for thermal insulation purposes. Knowing the dependence of the thermal conductivity of concrete on its characteristics, you can choose the optimal type of material for building walls.

Thermal conductivity coefficient of reinforced concrete

Thermal conductivity of concrete and insulation of buildings

The decision on thermal insulation of the walls of buildings under construction is made depending on what types of concrete the walls are constructed from. Concrete products are divided into the following types:

- structural, used for capital walls. They are distinguished by increased load capacity, increased density, as well as the ability to conduct heat at an accelerated pace;

- thermal insulation, used in unloaded structures. They are characterized by a reduced specific gravity and a cellular structure, due to which the thermal conductivity of the walls is reduced.

Table of thermal conductivity of building materials: coefficients

To maintain a comfortable temperature in the room, you can build walls from various types of concrete. In this case, the thickness of the walls will change significantly. The same level of thermal conductivity of main walls is ensured with the following thickness:

- foam concrete – 25 cm;

- expanded clay concrete – 50 cm;

- brickwork – 65 cm.

To maintain a favorable microclimate, as part of energy saving measures, thermal insulation of building structures is carried out. At the project development stage, specialists determine possible ways of heat loss and select the optimal insulation option.

Comparative graph of thermal conductivity coefficients of some building materials and insulation materials

The main volume of heat losses occurs due to insufficiently effective thermal insulation of the following parts of the building:

- floor surfaces;

- capital walls;

- roofing structure;

- window and door openings.

With a professional approach and choosing effective insulation materials, you can make your home more comfortable and also save a significant amount of money on heating.

Thermal conductivity coefficient of the material. Thermal conductivity of building materials: table

The concept of thermal conductivity

Factors affecting thermal conductivity

The thermal conductivity coefficient of a material depends on several factors:

When choosing a material for insulating rooms, it is also important to take into account the conditions in which it will be used.

The concept of thermal conductivity in practice

Particular attention should be paid to the insulation of the roof, window and door openings, and floors. The most heat is lost through these elements. This can be seen visually in the photograph at the beginning of the article.

Structural materials and their indicators

For the construction of buildings, materials with a low thermal conductivity coefficient are used. The most popular are:

Another popular building material is brick. Depending on its composition, it has the following characteristics:

- adobe (made from clay): 0.1-0.4 W/m*K;

- ceramic (made by firing): 0.35-0.81 W/m*K;

- silicate (from sand with the addition of lime): 0.82-0.88 W/m*K.

Concrete materials with the addition of porous aggregates

The thermal conductivity coefficient of the material allows it to be used for the construction of garages, sheds, summer houses, bathhouses and other structures. This group includes:

Indicators of thermal insulation materials

Thermal conductivity coefficient of thermal insulation materials, the most popular in our time:

Indicator table

How is the calculation made taking into account the thermal conductivity coefficient of concrete

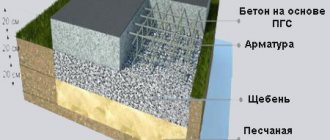

To maintain a comfortable temperature and reduce heat loss, the load-bearing walls of modern buildings are multi-layered and include permanent structures, thermal insulation materials, and finishing coatings. Each layer of the sandwich has a certain thickness.

When solving the problem of calculating the thickness of a heat insulator, it is necessary to use the formula for calculating thermal resistance - R=p/k, which is deciphered as follows:

- R – temperature resistance value;

- p – layer thickness value, indicated in meters;

- k is the thermal conductivity coefficient of reinforced concrete, concrete or other material from which the walls are made.

Using this dependence, you can perform the calculation yourself using a regular calculator. To do this, it is necessary to divide the thickness of the building structure by the thermal conductivity coefficient of concrete or other material. Let's consider an example calculation for walls 0.3 meters thick, built from aerated concrete with a specific gravity of 1000 t/m3 and a degree of thermal conductivity equal to 0.31.

Calculation algorithm:

- Calculate the thermal resistance by dividing the wall thickness by the thermal conductivity coefficient - 0.3:0.31=0.96.

- Subtract the result obtained from the maximum permissible for a certain climatic zone - 3.28-0.96 = 2.32.

By multiplying the thermal conductivity coefficient of the insulation by the value of thermal resistance, we obtain the required layer size as a result. For example, the thickness of sheet foam with a thermal conductivity coefficient of 0.037 will be 0.037x2.32=0.08 m.

How is thermal conductivity coefficient calculated?

This indicator is determined for different materials, including concrete, using special formulas. A total of two methods can be used. The thermal conductivity of concrete is determined by the Kaufman formula. It looks like this:

- 0.0935x(m) 0.5x2.28m + 0.025, where m is the mass of the solution.

For wet (more than 3%) solutions, the Nekrasov formula is used: (0.196 + 0.22 m2) 0.5 – 0.14.

Expanded clay concrete with a density of 1000 kg/m3 has a mass of 1 kg. Accordingly, for example, according to Kaufman in this case the coefficient will be 0.238. The thermal conductivity of concrete is determined at a mixture temperature of +25 C. For cold and heated materials, its indicators may vary slightly.