The part of the house that is most exposed to the external environment is the basement.

It is affected not only by ultraviolet radiation, mechanical stress, temperature fluctuations, but also by heavy rain and snow. The base is reliably strengthened, protected and insulated so that the inside of the house is warm and cozy. That is why high demands on quality and durability are placed on the material for finishing the base part.

The most reliable finishes are considered to be plaster, natural stone, porcelain stoneware or corrugated board.

In this article we will talk about corrugated sheets, its properties, period of operation, how suitable it is for finishing the base, what are its pros and cons.

What is the difference between corrugated sheets and corrugated sheets?

Corrugated sheeting is often confused with corrugated sheets and vice versa. These materials are similar in the manufacturing process. They are produced by cold rolling of steel sheets with a galvanized coating, which reliably protects against corrosion and destruction. The external resemblance is obvious.

Profiled sheet

Corrugated sheet

Main differences:

- rigidity,

- scope of application,

- profile height,

- variety of colors and designs to choose from.

Corrugated sheeting - used most often as a roofing material, has a more pronounced profile, which gives the material additional rigidity. The finishing corrugated sheet has a profile height of less than 3.5 cm. Profiled sheets are presented by manufacturers in various colors, shades, sizes, which cannot be said about corrugated sheeting.

Installation process

The technology itself and the sequence of cladding work will not be difficult.

Next, I will describe the entire technology for installing corrugated sheets:

- Cladding the base begins with preparatory work. The walls should be waterproofed with bitumen mastic. To do this, dilute it with a solvent and apply it to the base.

- After the waterproofing has completely dried, you need to mount a frame on which the corrugated sheets will be fixed. I used a galvanized U-shaped profile, it is not afraid of corrosion and is light weight. Of course, you can use a lathing made of wooden beams, having previously treated it with an antiseptic, but I ruled out this option for myself. I believe that, despite the fact that the bars will be hidden under a corrugated sheet, they will still not be reliably protected from moisture and in the future may suffer from increased humidity

- When the frame is ready, you can begin installing the thermal insulation. A rigid sheet of foam plastic, basalt or glass wool is quite suitable

- I then covered the insulation with layers of vapor barrier. For insulation, cotton wool mats were suitable for me, but they can lose their properties if exposed to moisture, so it was impossible to do without a vapor barrier. You can secure the insulation layers using plastic dowels with a wide head. Such dowels are inserted into holes made using a drill or hammer drill.

What type of material is used?

The base is sheathed with a certain type of corrugated sheet . Any material will not work here. Sheets for finishing the base part are designated “C”. This material has the required strength characteristics and resistance to temperature changes.

If the markings are with the letters “N” or “NS”, then they are not suitable for finishing work on the walls. The sheets are too strong, which leads to higher prices.

The “C” marking is followed by a number indicating the height of the ribs, for example:

- S8,

- C10,

- S20,

- C21.

The higher the height, the greater the strength. Next comes the thickness, the standard value of which is 0.4 ÷ 0.8 mm.

The choice of sheet depends on the purpose of its use . For finishing external walls, installing fences, C8 (budget, with a sheet thickness of up to 0.7 mm) is suitable. If the roof is covered and insulation is added, then C10 is used (up to 0.8 mm).

For finishing the base, C13 is selected, with a thickness of up to 0.7 mm and a ribs height of 1.3 cm.

Cutting corrugated sheets

Finishing the base with corrugated sheets begins with the preparation of all sheets, which must be fully suitable in size. To do this, the first thing you need to think about is how much and how high the layer of corrugated sheeting on the base will be. To cut the material you will need a grinder and scissors for cutting metal.

When working with metal scissors, the cut will be smoother. If you prefer an angle grinder, then you need to choose thinner wheels. It is best if the disk has a carbide coating

After the sheets are cut, it is very important to treat the edges with a paint and varnish composition, otherwise in the future, due to burrs, rust will form on the entire surface of the sheet

Which coating should you choose?

The metal sheets are treated with zinc coating, followed by finishing:

- Polyester – thickness up to 25 microns . It is based on an artificial substitute for tree resin. It prevents cracking, destruction, and burning. The disadvantage is poor protection against mechanical damage, which contributes to the development of corrosion.

- Matte polyester is a thicker coating with a textured pattern that imitates natural material.

- Puralom – high strength, quality, allows the use of profiled sheets in regions with excess humidity.

- Plastisol – the coating imitates wood and stone. It withstands the influence of snow, water, dampness, and mechanical damage.

- PVDF - has increased strength, reliably protecting the entire surface of the material. Operational warranty up to 40 liters.

- Printech coating with a complete imitation of the surface of natural stones, bricks, and wood. It is considered the best coating for corrugated sheets for cladding the basement of houses.

Existing brands

The brand of wall corrugated sheet is chosen depending on the designation. "C" stands for wall material. "NS" is universal. Other designations have increased strength indicators and increased thickness, which makes the use of the material impractical and too expensive. The finishing of the base part and its durability depends on the height of the rib profile.

The most suitable options to prevent the surface from destruction and mechanical damage:

- S8,

- C10,

- S20,

- C21.

Standard sheet sizes:

- width – 1060-1200 mm;

- length from 0.5 to 10 m;

- wave height no more than 15 mm;

- thickness – up to 0.8 mm.

Execution options

The sheet profile differs in wave height, thickness and purpose of the material:

- “N” - load-bearing, has high strength characteristics.

- “C” - wall (suitable for finishing wall surfaces, plinths).

- “NS” - universal (also suitable for the base part).

The choice of color, geometry, wave height, and shape depends on:

- owner's taste

- general house design,

- garden territory.

Sheathing the base with corrugated sheets - advice from professionals

Protecting the area of the building located directly next to the ground and constantly exposed to various environmental influences is an important stage in the construction of a house.

Properly performed waterproofing, blind area and protection of the base will help provide the interior space with comfortable conditions.

Having protected against the penetration of moisture and cold, you can not be afraid of the appearance of mold and fungal infections inside the basement.

What is a plinth and why is finishing needed?

The base is the lower part of the building lying on the foundation. It is the most vulnerable area of the building, as it is constantly exposed to aggressive influences.

Reference. This is the wettest place, especially if the building is located on ground with nearby groundwater. The base is most affected by the difference between internal and external temperatures. The pressure of the walls on the base especially increases in the off-season, when humidity and sudden temperature changes are added.

Builders always pay special attention to protecting the base, since the operation of the entire facility depends on its durability and strength.

Particular attention should be paid to the quality of the materials used. The effectiveness of protection depends on their compatibility with the materials used to manufacture the building.

Attention! The profiled sheet is ideal for these purposes.

Advantages of corrugated sheet cladding

The profile sheet (corrugated sheet or corrugated sheet) has a number of significant advantages that make it a leader among finishing materials used for exterior work.

- It goes perfectly with stone, concrete, brick, wood and other types of building materials.

- It has stiffening ribs that guarantee reliable protection against mechanical pressure.

- Easy to install. It does not require high qualifications to work with it. You can easily do the facing work yourself.

- The use of galvanized steel in the production guarantees the durability and strength of the coating.

- After installation, there is no need to paint it annually, since the surface of the profile sheet is coated with a special compound that is not afraid of changes in temperature, humidity and ultraviolet radiation.

- It has an affordable price, so it can be used by people of any income.

- The contaminated surface can be easily washed with ordinary hygiene products.

- It has a wide color palette, so it can serve as an excellent decorative element.

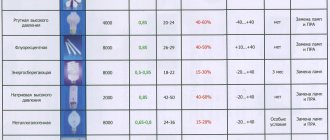

Profile sheet types and characteristics

Trade organizations offer a wide selection of products that can satisfy the most demanding and discerning consumer.

Attention! The quality of corrugated sheeting depends on the thickness of the metal used and the method of applying the protective coating.

The production of different stiffeners gives the sheets not only a different appearance, but also provides the ability to react differently to external influences, guaranteeing high resistance to pressure, impact, twisting and tearing.

You need to pay attention to the markings, since each letter and number carries information about the technical characteristics of the material.

Selecting the color and brand of corrugated sheeting for the base

Help: The appearance of the base plays no less important role in the aesthetic perception of the building than the walls, roof and other architectural elements of the building.

Therefore, when choosing a profiled sheet, in addition to selecting the brand, you need to make sure that the color ideally matches the overall concept of the building’s design project.

In this case, you will not have to spend additional money on painting it. The right color will make the building more elegant and beautiful, emphasizing the architectural features of the building.

When choosing colors for commercial or industrial buildings, you should focus on calmer, neutral shades. Brown, blue or gray are ideal in this case.

Residential buildings can be decorated with bright and catchy colors, but certain standards must be followed so that the contrast is not excessive and does not hurt the eye.

Step-by-step instructions for covering the base with corrugated sheets

In order for the protective coating of the basement of the building to last as long as possible, you need to follow a few simple rules when installing the profile coating.

- We provide reliable protection of the building surface from moisture penetration.

- We install a lattice frame, which will serve as the basis for the installed profile sheet.

- We attach the corrugated sheeting using self-tapping screws to the grille.

Tools and materials used

Before starting work, make sure that the necessary materials and tools are at hand. In this case, the work will move rhythmically and will not take much time.

Having carried out accurate calculations using online calculators, which can be easily found on the Internet, you need to prepare a sufficient amount in advance:

- Corrugated sheeting.

- Laths or profile pipes.

- Fasteners that include various types of screws, dowels and anchor bolts.

- Roulette.

- Level.

- Electric jigsaw.

- Hacksaw and metal scissors.

- Screwdriver.

- Screwdrivers, hammers, tape measure, string.

- Clothing must reliably protect the body from possible damage and cuts from the sharp edge of corrugated sheets. Remember to use safety glasses.

Manufacturing of basement waterproofing

In order to avoid moisture getting into the basement and onto the first floor of the building, care should be taken to ensure high-quality waterproofing of the basement.

After making the foundation, you need to coat its surface with a thick layer of liquid bitumen or special mastic, and glue a layer of roofing felt on top.

Only after this can the basement of the building be erected. If the object is located in an area with groundwater close to the surface, it would not be superfluous to apply several layers of waterproofing.

Important: This protection will prevent excess water from penetrating into the interior of the building. To ensure that the walls always remain strong and are not exposed to moisture, the upper part of the base should also be treated with bitumen and glued with roofing felt. This will prevent liquid from collecting in the walls of the structure.

There are three main methods of waterproofing used when finishing the base:

- Coating is performed using heated bitumen or special mastic. To prevent liquid from penetrating inside the building, it is applied in several layers. Each subsequent layer can be applied only after the previous one has completely dried.

- Pasted waterproofing is a rolled material applied to the wall, made of roofing felt or roofing felt. It is necessary to glue the strips with a slight overlap, and fuse the joints with a gas torch. This guarantees the reliability and durability of the coating.

- The use of membranes made from PVC composition is today the most high-tech solution for protecting a building from moisture. This material is quickly and easily installed, and its structure guarantees reliable protection against any type of liquid.

How to make a frame for installing corrugated sheets on the base of a building

The quality of the protective coating and its durability during operation depend on how well the preparatory work is carried out.

Help: There are opinions that a profile pipe is best suited for the plinth frame, since high humidity can quickly damage wooden blocks.

Tools and materials for sheathing

Before choosing the right material and counting them, it is necessary to take measurements, decide on the overall design and color scheme. You need to choose the option you like, clarify its dimensions and then start making calculations.

Having the necessary tool listed below in the article will not be superfluous. Its purchase is an additional expense.

Before purchasing or choosing materials for construction, you must consult with experts about the parameters of the profiled sheet you like, its service life, reliability, and preservation of appearance.

Don't skimp on quality . The better the material and its processing, the longer it will last while maintaining the characteristics declared by the manufacturer.

Calculation of the required quantity

Calculating the required amount of material is not a difficult, but responsible task. It is necessary to carefully measure the area of the plinth. Calculation procedure:

Calculation of foundation area .

The width and height on each side are measured and their area is found. Next, all areas are summed up. A standard house is a rectangle, which means to find its area you need to multiply the width by the height, and so on on 4 sides.The total area is the sum of the 4 sides of the house. It is most convenient to make calculations in meters, so as not to later get confused in converting units of measurement.

- Purchase of materials . Knowing the dimensions of the base, you can easily select the necessary profiled sheets in a hardware store. Prices for material are indicated in sq.m., which is convenient in calculations.

- Increase for additional expenses . To the resulting amount you should add 10-15% for unforeseen situations, since it will not be possible to take everything into account. This increase will help out in case of force majeure, especially if the house is of non-standard design.

How to sheathe it yourself?

Before starting work, you should prepare the necessary materials, tools, calculate and purchase the required number of profiled sheets. Profiled sheets are mounted on the finished surface of the house. The work can be completed independently, having everything you need available.

Tools:

- Level, roulette.

- Marker for making marks (black, white).

- Self-tapping screws for assembling parts and fastening them.

- Bulgarian.

- Screwdriver, screwdrivers of the required sizes.

How to make cladding with corrugated sheets around the base of a house? Main stages:

- Preparatory. Preparation for finishing implies the presence of waterproofing, the absence of cracks and depressions. Cleaning the surface from dust and dirt.

- Marking . Markings are applied across the entire area of the base, where the frame will go, and the attachment points, depending on the size of the profiled sheet. To do this, use a level, a rope, or a special marker. Perpendicularity and parallelism to the line must be maintained so that the structure looks beautiful and stylish from a design point of view.

- Installation of metal frame structure . Installation of a metal frame, its dimensions depend on whether or not additional waterproofing and foundation insulating materials will be installed. The profile is installed at a certain distance (no more than 40-50 cm) for convenient fastening of profiled sheets.

Installation of insulation, waterproofing materials , if necessary.

If the base needs to be insulated or waterproofed, then this should be taken into account when choosing profiled sheets, calculating areas and installing a metal frame. In order for the profiled sheets not to allow moisture to pass inside, the base must be waterproofed, i.e. The concrete foundation is subject to special treatment.Thermal insulation is ensured by using basalt mineral wool and polystyrene foam, which are mounted from bottom to top. All components must be sealed.

- Fastening the profiled sheets .

Upon completion of the preparatory work, you should proceed to fixing the profiled sheet. Its installation starts from the left corner, moving towards the right. As the sheets are fixed, you need to constantly check the surface with a level for evenness. If even one part is laid unevenly, this will lead to displacement of the entire surface, resulting in a deterioration in the overall appearance. The first corrugated sheet is secured with a roofing screw with a press washer and its surface is leveled using a level. The fastening step is through 1-2 waves to the lower parts. Each subsequent sheet is laid overlapping the previous one, which allows you to achieve the effect of naturalness of the material. The joint area is reinforced with rivets. For one sheet 3 pcs. - The final stage, finishing work . Once all the work is completed, finishing should be carried out to remove unnecessary gaps and irregularities to give the house a spectacular appearance. For this, finishing strips, corners, and ebbs are installed.

If there are chips, scratches, or cracks, they are painted over with a special paint that matches the color of the profiled sheet.

How to install profiled sheets

You can decorate the base yourself with corrugated sheets at the dacha - today such cladding is found everywhere

The corrugated sheet is installed, as mentioned above, using frame technology. That is, first you need to build a frame, and only then apply a profiled sheet to it. The gaps that are observed between the load-bearing parts of the frame are usually insulated - here you can use spraying or use sheet insulation.

Thanks to all this, the thermal insulation characteristics of the lower part of the building will significantly increase, which will benefit the business. The procedure and stages will be discussed below. The first step is to perform waterproofing.

Waterproofing first

It is worth doing waterproofing along with the cladding so that the structure gains reliable protection from the elements

Since the specificity of the base is such that it will absorb water from the ground, condensation will certainly appear on the outside of the building. It is because of this that the insulation can become deformed over time - this happens everywhere.

However, the insulation can be protected from moisture when finishing the base with corrugated sheets. Before starting work, you just need to arrange a waterproofing layer - it will become a reliable obstacle to the moisture that will come from the concrete - any experienced craftsman will confirm this.

Few people know that basement waterproofing can be done in three different ways. Namely: the protection can be adhesive, coating, membrane - all that remains is to choose the option that seems more promising.

- What can you say about adhesive waterproofing for the plinth? Here everything is as follows - this is a rolled material that is applied to the base of the building being finished. This is done using a propane torch - with its help, the necessary heating is created. Such waterproofing will last a very long time, and its quality will never cause any complaints;

- About coating waterproofing: it must be formed from a layer of primer or bitumen mastic. All these substances are first diluted until they become liquid. A solvent will help with this. If the composition is applied to the surface of the base, but moisture continues to accumulate, the waterproofing will have to be strengthened. There are different ways to do this;

- Membrane waterproofing or simply PVC membrane is a solution that currently deserves the status of the most high-tech, if a waterproofing layer is applied when finishing the base with corrugated sheets. Installation of the element is carried out without unnecessary labor costs, in addition, here we can note the presence of a double-sided structure - this gives the base protection from moisture, but the concrete continues to “breathe” without problems. Membrane waterproofing is installed on the base without any problems - you just need to snap the product into place, for which special clamps are provided. Even a novice specialist can cope with the task, not to mention experienced builders or finishers.

Details about frame installation

The corrugated sheet is attached to the frame - it can be either wooden or metal

Average prices for materials and labor costs

Average prices in Russian cities for professional sheets and work:

- Moscow, Moscow region - from 400 rubles/m2 for work, which includes installation of insulation from 90 rubles. per sq.m. Purchasing the material will cost from 200 rubles. per square meter;

- St. Petersburg - from 150 rubles. per sq.m. material, work will cost from 350 rubles;

- Kazan - the material costs from 200 rubles/m2, you will have to pay for the work as in St. Petersburg.

The price for the building materials needed to close the basement is approximately the same across cities, since they can be purchased not only in large hypermarkets, but also ordered online.

The cost of work in big cities is higher, due to high demand and high wages, compared to peripheral regions.

Recommendations from experts

A sheathed base made of corrugated sheets is not a difficult task; even a beginner can cope with it. Therefore, it is important to pay maximum attention not only to the work, but also to the materials. The building materials market offers a wide range of products.

Typically, people choose based on cost. You should choose canvases of the mid-price category; you can even buy them from the manufacturer. The prices there are lower than market prices, and you won’t doubt the quality.

In addition to profiled sheets, you will need slats (an alternative is profile pipes), fasteners (screws, dowels, anchor bolts), tape measure, building level, hacksaw, jigsaw, screwdriver, hammer and screwdriver. To protect your eyes from foreign bodies, use safety glasses and a special suit.

Pros and cons of using

The main advantages of the profiled sheet include:

High strength indicators. The sheets are made by cold rolling, which gives them additional strength.- Long service life. The material is not subject to corrosion or destruction.

- Large selection of colors, geometries, shades. The variety of choices allows you to choose sheets to suit any design of your home or garden.

- Easy installation. Basically, the cladding is done in-house, since the material is easily cut and attached to the surface.

- Availability. The main advantage is that it allows you to get a good appearance of your home at low cost.

Disadvantages include instability to mechanical damage. If the surface protective layer is damaged, the material quickly rusts and collapses.

A variety of options for finishing the basement of a private house are presented in this section.

You will find all the most important, interesting and useful information about finishing the basement in this section.