Electrical resistance

The electrical resistance of a conductor, which is denoted by the Latin letter r, is the property of a body or medium to convert electrical energy into thermal energy when an electric current passes through it.

In the diagrams, electrical resistance is indicated as shown in Figure 1, a.

| Figure 1. Symbol for electrical resistance |

Variable electrical resistance that serves to change the current in a circuit is called rheostat . In the diagrams, rheostats are designated as shown in Figure 1, b. In general, a rheostat is made of a wire of one resistance or another, wound on an insulating base. The slider or rheostat lever is placed in a certain position, as a result of which the required resistance is introduced into the circuit.

A long conductor with a small cross-section creates a large resistance to current. Short conductors with a large cross-section offer little resistance to current.

If you take two conductors from different materials, but the same length and cross-section, then the conductors will conduct current differently. This shows that the resistance of a conductor depends on the material of the conductor itself.

The temperature of the conductor also affects its resistance. As temperature increases, the resistance of metals increases, and the resistance of liquids and coal decreases. Only some special metal alloys (manganin, constantan, nickel and others) hardly change their resistance with increasing temperature.

So, we see that the electrical resistance of a conductor depends on: 1) the length of the conductor, 2) the cross-section of the conductor, 3) the material of the conductor, 4) the temperature of the conductor.

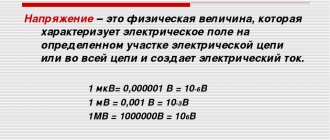

The unit of resistance is one ohm. Om is often represented by the Greek capital letter Ω (omega). Therefore, instead of writing “The resistance of the conductor is 15 ohms,” you can simply write: r = 15 Ω. 1,000 Ohms is called 1 kiloohm (1kOhm, or 1kΩ), 1,000,000 Ohms is called 1 megaohm (1mOhm, or 1MΩ).

When comparing the resistance of conductors from different materials, it is necessary to take a certain length and cross-section for each sample. Then we will be able to judge which material conducts electric current better or worse.

Video 1. Conductor resistance

Electrical conductivity of metals

The classical theory of electrical conductivity of metals originated at the beginning of the twentieth century. Its founder was the German physicist Karl Rikke. He experimentally established that the passage of a charge through a metal does not involve the transfer of conductor atoms, unlike liquid electrolytes. However, this discovery did not explain what exactly is the carrier of electrical impulses in the metal structure.

The experiments of scientists Stewart and Tolman, conducted in 1916, allowed us to answer this question. They were able to establish that the smallest charged particles - electrons - are responsible for the transfer of electricity in metals.

This discovery formed the basis of the classical electronic theory of electrical conductivity of metals. From this moment on, a new era of research into metal conductors began.

Thanks to the results obtained, today we have the opportunity to use household appliances, production equipment, machines and many other devices.

How does the electrical conductivity of different metals differ?

The electronic theory of electrical conductivity of metals was developed in the research of Paul Drude. He was able to discover such a property as resistance, which is observed when electric current passes through a conductor.

In the future, this will make it possible to classify different substances according to their conductivity level. From the results obtained, it is easy to understand which metal is suitable for the manufacture of a particular cable.

This is a very important point, since incorrectly selected material can cause a fire as a result of overheating from the passage of excess voltage current.

Silver metal has the highest electrical conductivity. At a temperature of +20 degrees Celsius, it is 63.3 * 104 centimeters-1. But making wiring from silver is very expensive, since it is a rather rare metal, which is used mainly for the production of jewelry and decorative items or bullion coins.

The metal with the highest electrical conductivity among all elements of the base group is copper. Its indicator is 57*104 centimeters-1 at a temperature of +20 degrees Celsius. Copper is one of the most common conductors used for household and industrial purposes. It withstands constant electrical loads well, is durable and reliable. The high melting point allows you to work for a long time in a heated state without problems.

In terms of abundance, only aluminum can compete with copper, which ranks fourth in electrical conductivity after gold. It is used in networks with low voltage, as it has almost half the melting point of copper and is not able to withstand extreme loads. The further distribution of places can be found by looking at the table of electrical conductivity of metals.

Electrical resistivity

The resistance in ohms of a conductor 1 m long, with a cross-section of 1 mm² is called resistivity and is denoted by the Greek letter ρ (rho).

Table 1 shows the resistivities of some conductors.

Resistivities of various conductors

| Conductor material | Specific resistance ρ in |

| Silver Copper Aluminum Tungsten Iron Lead Nickelin (alloy of copper, nickel and zinc) Manganin (alloy of copper, nickel and manganese) Constantan (alloy of copper, nickel and aluminum) Mercury Nichrome (alloy of nickel, chromium, iron and manganese) | 0,016 0,0175 0,03 0,05 0,13 0,2 0,42 0,43 0,5 0,94 1,1 |

The table shows that an iron wire with a length of 1 m and a cross-section of 1 mm² has a resistance of 0.13 Ohm. To get 1 Ohm of resistance you need to take 7.7 m of such wire. Silver has the lowest resistivity. 1 Ohm of resistance can be obtained by taking 62.5 m of silver wire with a cross section of 1 mm². Silver is the best conductor, but the cost of silver excludes the possibility of its mass use. After silver in the table comes copper: 1 m of copper wire with a cross section of 1 mm² has a resistance of 0.0175 Ohm. To get a resistance of 1 ohm, you need to take 57 m of such wire.

Chemically pure copper, obtained by refining, has found widespread use in electrical engineering for the manufacture of wires, cables, windings of electrical machines and devices. Aluminum and iron are also widely used as conductors.

The conductor resistance can be determined by the formula:

where r is the conductor resistance in ohms; ρ – conductor resistivity; l – conductor length in m; S – conductor cross-section in mm².

Example 1. Determine the resistance of 200 m of iron wire with a cross section of 5 mm².

Read also: How to remove rivets from clothes

Example 2. Calculate the resistance of 2 km of aluminum wire with a cross section of 2.5 mm².

From the resistance formula you can easily determine the length, resistivity and cross-section of the conductor.

Example 3. For a radio receiver, it is necessary to wind a 30 Ohm resistor from nickel wire with a cross section of 0.21 mm². Determine the required wire length.

Example 4. Determine the cross-section of 20 m of nichrome wire if its resistance is 25 Ohms.

Example 5. A wire with a cross section of 0.5 mm² and a length of 40 m has a resistance of 16 Ohms. Determine the wire material.

The material of the conductor characterizes its resistivity.

Based on the resistivity table, we find that lead has this resistance.

It was stated above that the resistance of conductors depends on temperature. Let's do the following experiment. Let's wind several meters of thin metal wire in the form of a spiral and connect this spiral to the battery circuit. To measure current, we connect an ammeter to the circuit. When the coil is heated in the burner flame, you will notice that the ammeter readings will decrease. This shows that the resistance of a metal wire increases with heating.

For some metals, when heated by 100°, the resistance increases by 40–50%. There are alloys that change their resistance slightly with heating. Some special alloys show virtually no change in resistance when temperature changes. The resistance of metal conductors increases with increasing temperature, while the resistance of electrolytes (liquid conductors), coal and some solids, on the contrary, decreases.

The ability of metals to change their resistance with changes in temperature is used to construct resistance thermometers. This thermometer is a platinum wire wound on a mica frame. By placing a thermometer, for example, in a furnace and measuring the resistance of the platinum wire before and after heating, the temperature in the furnace can be determined.

The change in the resistance of a conductor when it is heated, per 1 ohm of initial resistance and per 1° temperature, is called the temperature coefficient of resistance and is denoted by the letter α.

If at temperature t the resistance of the conductor is equal to r, and at temperature t is equal to rt, then the temperature coefficient of resistance

Note. Calculation using this formula can only be done in a certain temperature range (up to approximately 200°C).

We present the values of the temperature coefficient of resistance α for some metals (Table 2).

Temperature coefficient values for some metals

| Metal | α |

From the formula for the temperature coefficient of resistance we determine rt:

Example 6. Determine the resistance of an iron wire heated to 200°C, if its resistance at 0°C was 100 Ohms.

Example 7. A resistance thermometer made of platinum wire in a room with a temperature of 15°C had a resistance of 20 ohms. The thermometer was placed in the oven and after some time its resistance was measured. It turned out to be equal to 29.6 Ohms. Determine the temperature in the oven.

The most electrically conductive metal in the world

The value of metals is directly determined by their chemical and physical properties. In the case of an indicator such as electrical conductivity, this relationship is not so straightforward. The most electrically conductive metal, if measured at room temperature (+20 °C), is silver.

But high cost limits the use of silver parts in electrical engineering and microelectronics. Silver elements in such devices are used only if economically feasible.

Physical meaning of conductivity

The use of metal conductors has a long history. Scientists and engineers working in fields of science and technology that use electricity have long decided on materials for wires, terminals, contacts, printed circuit boards, etc. A physical quantity called electrical conductivity helps determine the most electrically conductive metal in the world.

The concept of conductivity is the inverse of electrical resistance. The quantification of conductivity is related to the unit of resistance, which is measured in Ohms in the International System of Units (SI). The SI unit of electrical conductivity is siemens. The Russian designation for this unit is Cm, the international designation is S. An electrical conductivity of 1 Cm has a section of an electrical network with a resistance of 1 Ohm.

Conductivity

The measure of a substance's ability to conduct electric current is called electrical conductivity. The most electrically conductive metal has the highest similar indicator. This characteristic can be determined for any substance or environment instrumentally and has a numerical expression. The specific electrical conductivity of a cylindrical conductor of unit length and unit cross-sectional area is related to the resistivity of this conductor.

The system unit for conductivity is siemens per meter – S/m. To find out which metal is the most electrically conductive metal in the world, it is enough to compare their experimentally determined conductivities. You can determine the resistivity using a special device - a microohmmeter. These characteristics are inversely dependent.

Conductivity of metals

The very concept of electric current as a directed flow of charged particles seems more harmonious for substances based on crystal lattices characteristic of metals. Charge carriers when an electric current occurs in metals are free electrons, and not ions, as is the case in liquid media. It has been experimentally established that when a current occurs in metals, there is no transfer of particles of matter between the conductors.

Metallic substances differ from others by having looser bonds at the atomic level. The internal structure of metals is characterized by the presence of a large number of “lonely” electrons. which, at the slightest influence of electromagnetic forces, form a directed flow. Therefore, it is not for nothing that metals are the best conductors of electric current, and it is precisely such molecular interactions that distinguish the most electrically conductive metal. Another specific property of metals, high thermal conductivity, is based on the structural features of the crystal lattice of metals.

Top best metal conductors

4 metals that are of practical importance for their use as electrical conductors are distributed in the following order relative to the value of specific conductivity, measured in S/m:

- Silver 62,500,000.

- Copper – 59,500,000.

- Gold – 45,500,000.

- Aluminum 38,000,000.

It can be seen that the most electrically conductive metal is silver. But like gold, it is used to organize the electrical network only in special specific cases. The reason is high cost.

But copper and aluminum are the most common option for electrical appliances and cable products due to their low resistance to electric current and affordability. Other metals are rarely used as conductors.

Factors affecting the conductivity of metals

Even the most electrically conductive metal reduces its conductivity if it contains other additives and impurities. Alloys have a different crystal lattice structure than “pure” metals. It is characterized by a violation of symmetry, cracks and other defects. Conductivity also decreases with increasing ambient temperature.

The increased resistance inherent in alloys is used in heating elements. It is no coincidence that nichrome, fechral and other alloys are used to manufacture working elements of electric furnaces and heaters.

The most electrically conductive metal is precious silver, mostly used by jewelers, for minting coins, etc. But its special chemical and physical properties are also widely used in technology and instrument making. For example, in addition to being used in components and assemblies with reduced resistance, silver plating protects contact groups from oxidation. The unique properties of silver and alloys based on it often make its use justified, despite its high cost.

autogear.ru

Electrical conductivity

So far, we have considered the resistance of a conductor as the obstacle that the conductor provides to the electric current. But still, current flows through the conductor. Therefore, in addition to resistance (obstacle), the conductor also has the ability to conduct electric current, that is, conductivity.

The more resistance a conductor has, the less conductivity it has, the worse it conducts electric current, and, conversely, the lower the resistance of a conductor, the more conductivity it has, the easier it is for current to pass through the conductor. Therefore, the resistance and conductivity of a conductor are reciprocal quantities.

From mathematics we know that the reciprocal of 5 is 1/5 and, conversely, the reciprocal of 1/7 is 7. Therefore, if the resistance of a conductor is denoted by the letter r, then the conductivity is defined as 1/r. Conductivity is usually symbolized by the letter g.

Electrical conductivity is measured in (1/Ohm) or in siemens.

Example 8. The conductor resistance is 20 ohms. Determine its conductivity.

If r = 20 Ohm, then

Example 9. The conductivity of the conductor is 0.1 (1/Ohm). Determine its resistance

If g = 0.1 (1/Ohm), then r = 1 / 0.1 = 10 (Ohm)

Source: Kuznetsov M.I., “Fundamentals of Electrical Engineering” - 9th edition, revised - Moscow: Higher School, 1964 - 560 p.

2QM.ru: The most electrically conductive metal in the world

The value of metals is directly determined by their chemical and physical properties. In the case of an indicator such as electrical conductivity, this relationship is not so straightforward. The most electrically conductive metal, when measured at room temperature (+20 °C), is silver.

But high cost limits the use of silver parts in electrical engineering and microelectronics. Silver elements in such devices are used only if economically feasible.

The content of the article

Physical meaning of conductivity

The use of metal conductors has a long history. Scientists and engineers working in fields of science and technology that use electricity have long decided on materials for wires, terminals, contacts, printed circuit boards, etc. A physical quantity called electrical conductivity helps determine the most electrically conductive metal in the world.

The concept of conductivity is the inverse of electrical resistance. The quantification of conductivity is related to the unit of resistance, which is measured in Ohms in the International System of Units (SI). The SI unit of electrical conductivity is siemens. The Russian designation for this unit is Cm, the international designation is S. An electrical conductivity of 1 Cm has a section of an electrical network with a resistance of 1 Ohm.

Conductivity

The measure of a substance's ability to conduct electric current is called electrical conductivity. The most electrically conductive metal has the highest similar indicator. This characteristic can be determined for any substance or environment instrumentally and has a numerical expression. The specific electrical conductivity of a cylindrical conductor of unit length and unit cross-sectional area is related to the resistivity of this conductor.

The system unit for conductivity is siemens per meter – S/m. To find out which metal is the most electrically conductive metal in the world, it is enough to compare their experimentally determined conductivities. You can determine the resistivity using a special device - a microohmmeter. These characteristics are inversely dependent.

Conductivity of metals

The very concept of electric current as a directed flow of charged particles seems more harmonious for substances based on crystal lattices characteristic of metals. Charge carriers when an electric current occurs in metals are free electrons, and not ions, as is the case in liquid media. It has been experimentally established that when a current occurs in metals, there is no transfer of particles of matter between the conductors.

Metallic substances differ from others by having looser bonds at the atomic level. The internal structure of metals is characterized by the presence of a large number of “lonely” electrons. which, at the slightest influence of electromagnetic forces, form a directed flow. Therefore, it is not for nothing that metals are the best conductors of electric current, and it is precisely such molecular interactions that distinguish the most electrically conductive metal. Another specific property of metals—high thermal conductivity—is based on the structural features of the crystal lattice of metals.

Top best conductors - metals

4 metals that are of practical importance for their use as electrical conductors are distributed in the following order relative to the value of specific conductivity, measured in S/m:

- Silver - 62,500,000.

- Copper – 59,500,000.

- Gold – 45,500,000.

- Aluminum - 38,000,000.

It can be seen that the most electrically conductive metal is silver. But like gold, it is used to organize the electrical network only in special specific cases. The reason is high cost.

But copper and aluminum are the most common option for electrical appliances and cable products due to their low resistance to electric current and affordability. Other metals are rarely used as conductors.

Factors affecting the conductivity of metals

Even the most electrically conductive metal reduces its conductivity if it contains other additives and impurities. Alloys have a different crystal lattice structure than “pure” metals. It is characterized by a violation of symmetry, cracks and other defects. Conductivity also decreases with increasing ambient temperature.

The increased resistance inherent in alloys is used in heating elements. It is no coincidence that nichrome, fechral and other alloys are used to manufacture working elements of electric furnaces and heaters.

The most electrically conductive metal is precious silver, mostly used by jewelers, for minting coins, etc. But its special chemical and physical properties are also widely used in technology and instrument making. For example, in addition to being used in components and assemblies with reduced resistance, silver plating protects contact groups from oxidation. The unique properties of silver and alloys based on it often make its use justified, despite its high cost.

2qm.ru

2.1.1. Physical nature of electrical conductivity of metals

Metals have a crystalline structure: at the nodes of the crystal lattice there are positively charged ions surrounded by itinerant electrons (electron gas).

Modern ideas about the electronic structure of metals, the distribution of electrons over energy states, their interaction with other elementary particles and the crystal lattice are given by quantum theory, the foundations of which were developed by the Soviet scientist Ya.I. Frenkel and the German physicist A. Sommerfeld.

Read also: Pipes for bored piles

Free electrons move chaotically throughout the crystal with an average thermal speed u = 10 5 m/s. In an electric field of strength E, electrons receive an additional speed of ordered movement v - drift speed, due to which an electric current arises. The current density depends on the drift speed, the electron charge e and the concentration of free electrons n.

The drift speed in real conditions is significantly less than the speed of thermal motion of electrons vu. So, in the copper industry

in a water carrier at a current density j = 1 A/mm 2 the drift speed is v = 1. 10 -4 m/s.

During the time τ between collisions with nodes of the crystal lattice at the mean free path l, electrons moving with acceleration

rhenium a = e E , acquire drift speed: me

Equating the analytical expression of Ohm's law (1.1) with expression (2.1) taking into account (2.2), we obtain the formula for specific conductivity

Let's express the product me. and through the concentration of free electrons, using quantum statistics based on the Pauli principle, according to which there can be only one electron in each energy state, and no more than two (with antiparallel spins) in each energy level. Then, at absolute zero temperature (T = 0 K), half of the total number of free electrons in the crystal (n/2) will occupy the lowest energy levels.

In quantum theory, the probability of electrons filling energy states with level energy E is determined by the Fermi function

where E F is the Fermi energy, i.e. the maximum energy that an electron in a metal can have at absolute zero temperature.

From formula (2.4) it follows that when E = E F, the probability of filling the Fermi level with electrons is 0.5. The Fermi energy for most metals ranges from 3 to 15 eV. Levels located below the Fermi level (E E F) are filled with electrons with probability >0.5, and levels located above the Fermi level (E > E F) are free of electrons with the same probability.

In accordance with Fermi-Dirac quantum statistics, the concentration of free electrons in a metal is determined by integrating

rirovanii over all filled energy states, which gives the following expression

Expressing from this relation the value of the Fermi energy in terms of the electron concentration and taking into account that E F = me and 2 2, we obtain

Substituting me and into formula (2.3), we find an expression for

conductivity of metals

The concentration of free electrons in pure metals, the nature of their energy distribution, and the Fermi energy remain almost unchanged with increasing temperature. For example, when silver is heated from 0 to 1000 K, the Fermi energy decreases by only 0.2%. Such small changes over a wide temperature range can be ignored. Therefore, formula (2.6) is valid at any temperature. Therefore, the electrical conductivity of a metal is determined mainly by the mean free path of electrons, which depends on the electronic structure of the atoms and the type of crystal lattice. The free path length for some metals is given in table. 1.

Electron mean free path in some metals at 0 °C

The longest free path is observed in metals with a face-centered cubic crystal lattice (Ag, Cu, Au), which are the best conductors.

Transition metals (Fe, Ni, Co, Cr, Mn, V, Zr, Nb, Mo, W, Hf, Ta, Re, Pt, etc.) have lower electrical conductivity, which is due to their specific electronic structure. In these elements, the inner d - or f -shells are not completely filled with electrons. In an electric field, some of the valence electrons from the outer s shell move to free levels of the inner shells, which leads to a decrease in the number of free electrons participating in conduction.

The peculiarities of the electronic structure of transition metals are the reason for many of their specific properties: thermal, magnetic, tendency to polymorphism, variable valence, etc.

And finally, in pure metals, when heated, the average electron energy remains practically unchanged, which indicates the low heat capacity of the electron gas.

Conduction theories

In 1900, P. Drude, based on the principles of molecular kinetic theory, and considering electrons in a metal as an ideal gas, created the classical electronic theory of conductivity of metals. Initially, this theory did not take into account the distribution of electron velocities; this distribution was taken into account in 1904 by H. Lorentz.

The Drude-Lorentz theory was able to explain Ohm's, Joule-Lenz's laws, the mechanism of conductivity and the dependence of resistance on temperature. However, over time, more and more data began to appear that were inexplicable within the framework of the classical theory. In particular, there were discrepancies in the temperature coefficient of resistance and in heat capacity values. And the phenomenon of overproduction, discovered in 1911, was completely inexplicable.

All these discrepancies are of a quantum nature, and therefore are explained within the framework of a more advanced quantum theory of conductivity of solids (band theory of conductivity).

Rice. 3. Band theory of conductivity.

2.1.2. Temperature dependence of resistivity of metals

Let us consider the movement of free electrons in the form of plane electron waves, the length of which λ is determined by the de Broglie relation (1.3). Such an electron wave propagates in a strictly periodic potential field without energy dissipation. This means that in an ideal crystal the mean free path of electrons is infinity, and the resistance to electric current is zero.

The reasons for the scattering of electrons in real metals, creating electrical resistance, are:

• thermal vibrations of crystal lattice nodes (ρ t – thermal component of electrical resistance);

• impurities and structural defects (ρres – component of ρ caused by non-thermal factors).

It is known that effective dissipation of electron energy occurs if the size of scattering centers (defects) exceeds 1/4 of the wavelength. In metals, electron energy

conductivity is 3...15 eV, this energy corresponds to the electron wavelength λ = 0.3...0.7 nm. Therefore, any microinhomogeneities and imperfections in the crystal structure cause a decrease in conductivity.

Read also: What you can make from an iron with your own hands

So, the resistivity of real metals is the sum of two components:

The relative change in the resistivity of metals with a change in temperature characterizes the temperature co-

The resistivity of metals is a measure of their ability to resist the passage of electric current. This value is expressed in Ohm-meter (Ohm⋅m).

The symbol for resistivity is the Greek letter ρ (rho). High resistivity means the material is a poor conductor of electrical charge.

The most electrically conductive metal in the world

The value of metals is directly determined by their chemical and physical properties. In the case of an indicator such as electrical conductivity, this relationship is not so straightforward. The most electrically conductive metal, when measured at room temperature (+20 °C), is silver.

But high cost limits the use of silver parts in electrical engineering and microelectronics. Silver elements in such devices are used only if economically feasible.

Physical meaning of conductivity

The use of metal conductors has a long history. Scientists and engineers working in fields of science and technology that use electricity have long decided on materials for wires, terminals, contacts, printed circuit boards, etc. A physical quantity called electrical conductivity helps determine the most electrically conductive metal in the world.

The concept of conductivity is the inverse of electrical resistance. The quantification of conductivity is related to the unit of resistance, which is measured in Ohms in the International System of Units (SI). The SI unit of electrical conductivity is siemens. The Russian designation for this unit is Cm, the international designation is S. An electrical conductivity of 1 Cm has a section of an electrical network with a resistance of 1 Ohm.

Conductivity

The measure of a substance's ability to conduct electric current is called electrical conductivity. The most electrically conductive metal has the highest similar indicator. This characteristic can be determined for any substance or environment instrumentally and has a numerical expression. The specific electrical conductivity of a cylindrical conductor of unit length and unit cross-sectional area is related to the resistivity of this conductor.

The system unit for conductivity is siemens per meter – S/m. To find out which metal is the most electrically conductive metal in the world, it is enough to compare their experimentally determined conductivities. You can determine the resistivity using a special device - a microohmmeter. These characteristics are inversely dependent.

Conductivity of metals

The very concept of electric current as a directed flow of charged particles seems more harmonious for substances based on crystal lattices characteristic of metals. Charge carriers when an electric current occurs in metals are free electrons, and not ions, as is the case in liquid media. It has been experimentally established that when a current occurs in metals, there is no transfer of particles of matter between the conductors.

Metallic substances differ from others by having looser bonds at the atomic level. The internal structure of metals is characterized by the presence of a large number of “lonely” electrons. which, at the slightest influence of electromagnetic forces, form a directed flow. Therefore, it is not for nothing that metals are the best conductors of electric current, and it is precisely such molecular interactions that distinguish the most electrically conductive metal. Another specific property of metals—high thermal conductivity—is based on the structural features of the crystal lattice of metals.

Top best conductors - metals

4 metals that are of practical importance for their use as electrical conductors are distributed in the following order relative to the value of specific conductivity, measured in S/m:

- Silver - 62,500,000.

- Copper – 59,500,000.

- Gold – 45,500,000.

- Aluminum - 38,000,000.

It can be seen that the most electrically conductive metal is silver. But like gold, it is used to organize the electrical network only in special specific cases. The reason is high cost.

But copper and aluminum are the most common option for electrical appliances and cable products due to their low resistance to electric current and affordability. Other metals are rarely used as conductors.

Factors affecting the conductivity of metals

Even the most electrically conductive metal reduces its conductivity if it contains other additives and impurities. Alloys have a different crystal lattice structure than “pure” metals. It is characterized by a violation of symmetry, cracks and other defects. Conductivity also decreases with increasing ambient temperature.

The increased resistance inherent in alloys is used in heating elements. It is no coincidence that nichrome, fechral and other alloys are used to manufacture working elements of electric furnaces and heaters.

The most electrically conductive metal is precious silver, mostly used by jewelers, for minting coins, etc. But its special chemical and physical properties are also widely used in technology and instrument making. For example, in addition to being used in components and assemblies with reduced resistance, silver plating protects contact groups from oxidation. The unique properties of silver and alloys based on it often make its use justified, despite its high cost.

4u-pro.ru

Resistivity

Electrical resistivity is defined as the ratio between the electric field strength inside a metal and the current density within it:

where: ρ is the resistivity of the metal (Ohm⋅m), E is the electric field strength (V/m), J is the value of the electric current density in the metal (A/m2)

If the electric field strength (E) in a metal is very high and the current density (J) is very small, this means that the metal has high resistivity.

The reciprocal of resistivity is electrical conductivity, which indicates how well a material conducts electric current:

σ is the conductivity of the material, expressed in siemens per meter (S/m).

Conductivity of metals

The very concept of electric current as a directed flow of charged particles seems more harmonious for substances based on crystal lattices characteristic of metals. Charge carriers when an electric current occurs in metals are free electrons, and not ions, as is the case in liquid media. It has been experimentally established that when a current occurs in metals, there is no transfer of particles of matter between the conductors.

Metallic substances differ from others by having looser bonds at the atomic level. The internal structure of metals is characterized by the presence of a large number of “lonely” electrons. which, at the slightest influence of electromagnetic forces, form a directed flow. Therefore, it is not for nothing that metals are the best conductors of electric current, and it is precisely such molecular interactions that distinguish the most electrically conductive metal. Another specific property of metals—high thermal conductivity—is based on the structural features of the crystal lattice of metals.

Electrical resistance

Electrical resistance, one of the components of Ohm's law, is expressed in ohms (Ohms). It should be noted that electrical resistance and resistivity are not the same thing. Resistivity is a property of a material, while electrical resistance is a property of an object.

The electrical resistance of a resistor is determined by a combination of its shape and the resistivity of the material from which it is made.

For example, a wirewound resistor made from a long, thin wire has a higher resistance than a resistor made from a short, thick wire of the same metal.

At the same time, a wirewound resistor made of a high resistivity material has greater electrical resistance than a resistor made of a low resistivity material. And all this despite the fact that both resistors are made of wire of the same length and diameter.

To illustrate this, we can draw an analogy with a hydraulic system, where water is pumped through pipes.

- The longer and thinner the pipe, the greater the resistance to water.

- A pipe filled with sand will resist water more than a pipe without sand.

Wire resistance

The amount of wire resistance depends on three parameters: the resistivity of the metal, the length and diameter of the wire itself. Formula for calculating wire resistance:

where: R - wire resistance (Ohm) ρ - metal resistivity (Ohm.m) L - wire length (m) A - cross-sectional area of the wire (m2)

As an example, consider a nichrome wirewound resistor with a resistivity of 1.10×10-6 Ohm.m. The wire has a length of 1500 mm and a diameter of 0.5 mm. Based on these three parameters, we calculate the resistance of the nichrome wire:

R=1.1*10 -6 *(1.5/0.000000196) = 8.4 Ohm

Nichrome and constantan are often used as resistance materials. Below in the table you can see the resistivity of some of the most commonly used metals.

Surface resistance

The surface resistance value is calculated in the same way as the wire resistance. In this case, the cross-sectional area can be represented as the product of w and t: For some materials, such as thin films, the relationship between resistivity and film thickness is called the surface resistance of the layer RS:

where RS is measured in ohms. For this calculation, the film thickness must be constant.

Often, resistor manufacturers cut tracks into the film to increase resistance to increase the path for electrical current.

Properties of resistive materials

The resistivity of a metal depends on temperature. Their values are usually given for room temperature (20°C). The change in resistivity as a result of a change in temperature is characterized by a temperature coefficient.

For example, thermistors (thermistors) use this property to measure temperature. On the other hand, in precision electronics, this is a rather undesirable effect. Metal film resistors have excellent temperature stability properties. This is achieved not only due to the low resistivity of the material, but also due to the mechanical design of the resistor itself.

Many different materials and alloys are used in the manufacture of resistors. Nichrome (an alloy of nickel and chromium), due to its high resistivity and resistance to oxidation at high temperatures, is often used as a material for making wirewound resistors. Its disadvantage is that it cannot be soldered. Constantan, another popular material, is easy to solder and has a lower temperature coefficient.