All parts of building structures lose strength during operation. Floor panels and support beams are no exception. As a result of increased load on the floors, as well as partial destruction of the slab reinforcement, cracks appear on the surface of prefabricated slabs, as well as inside the concrete mass of monolithic floors. To increase the load capacity and increase the service life, the floors are reinforced. The choice of the optimal method of strengthening the panels is determined by their design features.

Strengthening floors is a necessary measure

The need to carry out restoration work aimed at increasing the strength of floors arises quite often:

- when performing planned repairs of an ordinary apartment located in a multi-storey building;

- when carrying out repair work inside industrial or warehouse premises;

- in the process of restoration of architectural monuments and restoration of interfloor structures of old buildings;

- when carrying out repair activities associated with serious redevelopment of various types of premises.

The technical condition of these structural elements is one of the main factors that determine the need for reconstruction of civil and residential buildings.

The reasons for the destruction of load-bearing structures are various:

- non-compliance with technology requirements when performing construction work;

- use of low-quality building materials;

- a significant increase in load on load-bearing walls and ceilings;

- reinforcement corrosion associated with damage to the protective layer.

In addition, sometimes there is a need to strengthen interfloor panels, the condition of which is quite satisfactory. This situation is associated with a change in the functional purpose of the premises. After all, new building owners quite often place massive equipment, carry out significant reconstruction, and also increase the number of floors of the building.

Depending on the characteristic features of the destruction, repair work includes:

- removal of collapsing elements and their local replacement with new ones;

- restoration of the concrete mass or increasing the thickness of the slabs;

- reinforcement of panels with steel mesh or additional reinforcement bars;

- installation of steel plates and powerful clamps in the areas where beams join.

The choice of the optimal reinforcement method is determined by the builders depending on the material of the overlapping structures. The following materials are used as flooring materials:

- wood;

- metal profile;

- reinforced concrete.

These works include a whole range of measures that are aimed at restoring the load-bearing capacity of the ceiling and individual parts.

In some cases, concrete reinforced with steel reinforcement is used to increase the load capacity, in others, supporting elements are installed or metal clamps are used. It is allowed to install support posts made of rolled metal or wooden beams in the problem area. When carrying out restoration measures and installing floors, you should adhere to the requirements of the technology and use high-quality raw materials.

Following these recommendations will allow you to avoid problematic situations during the operation of the building.

Strengthening floor slabs

Strengthening slabs is an event that may be required in any type of structure. The unsatisfactory condition of the structure and a sudden increase in load, as a rule, become the main reasons for the demand for ordering this service. As a rule, the choice of slab reinforcement technique depends on the type of structure, number of floors, material used and other factors.

Strengthening reinforced concrete floor slabs is practiced quite often in the construction industry. The main reasons for the need for such an event are considered to be the poor technical condition of this element, its satisfactory load-bearing capacity, and failure to comply with certain requirements during the operation of the building.

Reinforcing the floor slab - common types of panels

Reinforcement of reinforced concrete floors is carried out using various methods depending on the design features of the slabs. The following types of plates are used:

- compound. They are widely used in reinforced concrete floors of residential, industrial and commercial buildings. Prefabricated concrete panels rest on load-bearing walls, as well as longitudinally located transom beams or reinforced concrete trusses;

- whole. They are formed by continuously pouring graded concrete into pre-installed formwork with reinforcement cage. The monolithic structure is also assembled from standard reinforced concrete elements, which, after installing the floor slabs, are filled with a thick layer of concrete mortar.

Various types of panels are used for the construction of floors:

- full-bodied. They have no internal cavities. Solid slabs are mainly used for the lower floors of buildings, as well as at production facilities. Typical types of solid panels are ribbed, coffered, and beamless slabs. Ribbed slabs are easily distinguished by their trapezoidal cross-section and the presence of longitudinally located ribs. The length of the elements reaches 12 m, which allows them to be used to form floors at various construction sites;

- hollow. They are distinguished by the presence of six longitudinally located channels of round or oval cross-section. The length of hollow-core slabs ranges from 3 to 6 m. Hollow-core products with reduced weight are in demand in the construction of residential and administrative multi-storey buildings. The design features of the panels, associated with the presence of internal cavities, negatively affect the strength properties. To increase the reliability of building structures, products need to be strengthened.

Restoration and strengthening may involve identifying safety margins.

Along with the indicated types of floors, the following structures are used:

- formed by a frame of wooden beams;

- made of metal beams of I-section.

Building structures made from wood and steel beams were used in buildings constructed in the 19th and 20th centuries. The free space between horizontally located elements made of wood and metal was reinforced and filled with concrete. As a result, a monolithic surface was formed. Floors based on wooden and metal beams have been well preserved to this day, but require additional reinforcement.

Features of strengthening floor slabs

In the construction of buildings and structures, various types of floor slabs are used: hollow-core, monolithic and ribbed. Depending on the type of slab, operating conditions and nature of destruction, the civil engineer decides which type or types of reinforcement to use. The decision is made in each specific case, a strength calculation of the reinforcement of the floor slab is made, and a technical design is drawn up and agreed upon.

At this point in time, the designer has the following technologies for strengthening a damaged floor slab in his arsenal: strengthening floor slabs with carbon fiber, strengthening floor slabs with metal beams, as well as strengthening the floor slab from above or below by building up reinforcement and a layer of concrete. Let's consider technologies for restoring the load-bearing capacity of floor slabs in more detail.

Strengthening hollow core slabs

The technology for strengthening and repairing hollow-core floor slabs is one of the simplest and most cost-effective. The essence of the technology is to release the slab from all mechanical loads (equipment, furniture, etc.). Next, mechanical opening of the voids is carried out, installation of reinforcement and forced, under pressure, filling of the voids with high-strength concrete mortar.

Strengthening monolithic floor slabs

The type of reinforcement of reinforced concrete products of this type is accepted by the designer on the basis of an examination of a competitive structure and calculation of the magnitude of mechanical loads. In the vast majority of cases, a decision is made to strengthen the floor slab from below, in the area of bending loads. Two technologies for strengthening a monolithic slab from below have been developed and are used.

In both options, there is an additional reinforcing belt, onto which additional concrete material is “thrown” using the gunite method. The difference is that in the first option, an additional reinforcing belt is attached to the reinforced slab through special bends welded to the exposed reinforcement of the reinforced slab. And in the second case, the armored belt is attached to a steel strip mounted on through anchor bolts.

In some cases, top reinforcement technology is used with the installation of reinforced concrete dowels, top extension in the form of an additional monolithic reinforced slab and other technologies. In any case, when strengthening a monolithic slab, the following problems are solved:

- Effective fastening of the reinforcing belt to the surface being repaired.

- Installation of formwork.

- Pouring concrete mortar and maintaining the poured structure.

Strengthening ribbed floor slabs

Repair of ribbed floor slabs involves the use of three technologies. Additional reinforcement and concreting as in the case of monolithic slabs. Installation of supporting columns and strengthening the load-bearing capacity of the slab using truss reinforcement.

Truss reinforcement is arranged along the diagonals of the reinforced structure and forming mutually intersecting planes (stiffening ribs) provide the necessary reinforcement and rigidity of the reinforced floor slab

Strengthening U-shaped floor slabs

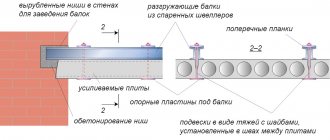

Work to increase the load-bearing capacity of U-shaped floor slabs can be carried out either by building up a new mass of reinforced concrete, as in previous cases, or by strengthening the floor slabs with a channel. In this option, the bending loads on the slab will be redistributed to the channel beams and load-bearing walls. Due to the unesthetic appearance of reinforcement, this method is used for the repair and reconstruction of production workshops and warehouses.

A similar effect is obtained when monolithic floor slabs are reinforced on top with metal beams. This technology binds the emergency slab with a kind of “corset” of welded channels or I-beams and prevents its destruction.

Strengthening reinforced concrete floor slabs with carbon fiber

This is the most modern technology that allows you to significantly increase the load-bearing capacity of floor tiles of any type and type of structure. The essence and technical meaning of the technology lies in gluing carbon tape and lamellas to the upper or lower surfaces of the slab.

Carbon fibers act as additional reinforcement and increase the load-bearing capacity of the structure. Considering the low relative strength of carbon fiber, we can say that using this method it is impossible to radically increase the load-bearing capacity of floor slabs.

What factors indicate the need for strengthening

The need to strengthen the slabs is mainly due to temporary factors:

- during long-term operation, the ability of floors to absorb loads decreases;

- with prolonged use of floors, their technical condition deteriorates;

- When the integrity of the roof is gradually compromised and moisture penetrates into the room, corrosion of the reinforcement occurs.

It is not always possible to detect weakened areas of the ceiling. Damaged areas located in the lower part of a monolithic or prefabricated floor can be difficult to visually identify. Quite often they are located under a layer of decorative plaster, under a suspended ceiling or covered with a layer of paint.

Strengthening floor slabs may involve increasing the cross-section of structural elements

When examining, it is important to pay attention to the following points:

- peeling of concrete from the top or bottom surface of the panels;

- deep and superficial cracks on the surface of slabs;

- peeling of the cement screed from the reinforced concrete base;

- violation of the integrity of the floor covering;

- corrosion destruction of the reinforcement frame;

- the appearance of light or dark spots on the concrete surface;

- formation of rusty stains on the surface of the slabs;

- destruction of the protective layer of concrete and exposure of reinforcement;

- increased deflection of floor elements;

- uneven cross-section of supporting structural elements;

- significant destruction of wooden and reinforced concrete floor beams.

Depending on the type of defects, specialists decide to reinforce the floor slab from below or strengthen the surface with a new reinforcement cage and concrete on top.

Strengthening hollow-core floor slabs

Content

The main characteristic of hollow core floor slabs is their load-bearing capacity, a decrease in which can have irreparable consequences. When using floor slabs, like any other product, it is subject to physical wear and tear, and its performance can also be affected by fires, earthquakes, and more. In fact, the only way to repair the slab is to strengthen it.

Strengthening floors - preparatory activities

The correct approach to carrying out repair activities affects the reliability and durability of the structures being restored.

Repair work requires preparation and is carried out in the following sequence:

- Vulnerable areas are identified.

- The scope of construction work is determined.

- Design documentation is being developed to strengthen the floor.

- The calculations necessary for restoration work are carried out.

- A suitable recovery method is selected.

- Construction tools are being prepared.

- Construction materials provided for by the project are purchased.

Let us dwell on the features of performing individual stages.

Strengthening floor slabs is sometimes accompanied by the inclusion of new elements in the work

To assess the actual condition of the reinforced concrete floor and determine its actual load capacity, an examination is carried out using one of the following methods:

- by visual inspection, the correctness of the geometry, the integrity of the reinforcement, the degree of exposure to increased loads from technological equipment, and the presence of local defects in the concrete mass are determined;

- The method of instrumental control determines the strength factor of concrete, the cross-sectional size of reinforcing bars, the width and thickness of cracks, the amount of deflection of floor panels, the thickness of the cement screed or protective layer of concrete.

Having completed the survey activities, they determine the methodology for performing the work, which involves solving the following tasks:

- restoration of the load capacity of reinforced concrete slabs;

- carrying out work to additionally strengthen the panels;

- elimination of factors that caused defects in the reinforced concrete base.

Regardless of the type of ceiling, the following work is performed before starting restoration activities:

- vertically located supports made of steel pipes or wooden logs are installed under the structure to be strengthened. Fixation of supporting elements intended for redistribution of forces is carried out using spacers or linings;

- remove remnants of old paint, a layer of plaster and whitewash. It is important to remove concrete delaminations, as well as thoroughly clean the reinforcement frame elements from corrosion using a wire brush;

- clean the surface of the floor covering and old screed, and also dismantle the technological equipment located in the room.

In areas where local restoration is planned, dust should be removed and the surface of the concrete mass and reinforcement should be degreased.

Sometimes additional supports may be installed

Reinforcement of floors

Repair, strengthening and replacement of floors

The functionality of the ceiling can be restored by repair, strengthening or replacement (full or partial - selective). The choice of method depends on the material and design of the floor, as well as the degree of its wear. In old buildings, where wood is often used as a flooring material, their wear exceeds the wear of load-bearing walls. The service life of reinforced concrete floors and floors supported by load-bearing metal beams is comparable to the service life of walls. Therefore, the question of what to do with the floors must be decided in each individual case, depending on the specific conditions. In this case, it is necessary to be guided by the following principle: the end of the service life of the restored structures must coincide with the end of the service life of the load-bearing walls.

Repairing, strengthening or replacing floors is an expensive and labor-intensive process, since it is almost impossible to ensure a high degree of mechanization, the work is carried out in cramped conditions, a large amount of preparatory work is required, performed manually, solutions that differ from the design ones are often used, etc. .

Strengthening monolithic reinforced concrete floors can be done by strengthening the floor slab, floor beams, or both at the same time. When strengthening a slab of monolithic reinforced concrete floors, an additional slab with a thickness of at least 3 cm is placed on top of the existing slab, which is reinforced with one mesh. In this case, reliable adhesion of the new concrete to the old must be ensured by cleaning the slab and making notches on its surface. If this cannot be done due to deep contamination, then the thickness of the additional slab is increased to 5 cm.

To strengthen reinforced concrete beams, additional reinforcement is installed in their tension zone, which is welded to the cleaned reinforcement of the reinforced beam. Welding is carried out using keyed seams directly to the reinforcement bars or to gaskets in the form of short pieces of round steel. In places of welding, a protective layer of concrete is beaten off with holes 8-10 cm in diameter with a distance between sections of 30-50 cm. The rods are welded on both sides with a seam 6-8 cm long. The bottom layer in this case is shotcrete. The thickness of the simultaneously applied shotcrete layer is taken from 7 to 20 mm. If it is necessary to increase the thickness of the reinforced structure, shotcrete is carried out in several layers, with each subsequent layer being applied after the previous one has set. Before applying a new layer after a long break, the old surface is washed. All layers of shotcrete except the last are applied and left without grouting. Structures are shotcrete at a temperature not lower than 5°C. The shotcrete layer may have deviations from the design thickness of up to 5 mm.

For prefabricated reinforced concrete floors, repairs usually come down to grinding the surface, but sometimes there is a need to strengthen the floors. In various series of standard designs for prefabricated houses, mainly three types of floors are used: solid and double-shell room-sized slabs and hollow-core slabs and decking.

Main floor defects:

hairline cracks in the protective layer;

· the occurrence of freezing zones in places where the slabs adjoin the walls due to the destruction of the insulating package;

· excess deflections;

· loss of mortar from seams (rusts) between floorings, etc.

In case of excess deflection of the ceiling panel, various design solutions are used in repair practice to strengthen the ceiling slabs. For example, by installing a metal beam from a steel angle along the outer wall with preliminary lifting of the panel with a jack. Or various options for securing and tensioning additional reinforcement in the stretched zone of the slab, followed by plastering or shotcrete.

Precast concrete hollow core slabs can be strengthened using voids. To do this, a shelf is punched from above in the area where the channel is located and a reinforcement frame is installed. When strengthening only the supporting part of the slab, the frames are located on part of its span, and, if necessary, along the entire length of the slab. After this, the channel is filled with plastic concrete on fine crushed stone. Simultaneously with the installation of an additional frame, the slab can also be strengthened by extending it from above (Fig. 4.14).

Two methods of finishing a reinforcing structure are recommended: plastering with cement mortar over a grid with embedding the structure in the mortar, which increases the cross-sectional area of the slab itself, increases its load-bearing capacity and rigidity, and significantly reduces the sound conductivity of the floor; filing of sheet material (asbestos plywood, particle boards, dry plaster, etc.) on wooden blocks, which are attached to anchors with additional reinforcement and to the slab itself, which eliminates wet processes for strengthening and finishing slabs (this finishing method can be carried out without eviction of tenants).

Rice. 4.14. Reinforcement of a hollow core slab: 1 - reinforced slab; 2 – additional reinforcement cage; 3 – additional reinforcing mesh; 4 – concrete reinforcement

The total height of the reinforcing structure and its finishing layer should not exceed 50 mm.

After strengthening the slab, the ceilings are finished or new floors are installed (depending on the method of strengthening).

In order to protect the reinforcement reinforcement from corrosion (in the case of ceiling cladding with sheet material), the reinforcement rods are coated with an anti-corrosion compound.

Reinforcement of wooden floors is carried out if the load-bearing walls have significant wear and tear and the building is subject to demolition in the near future. Reinforcement can be done by replacing part of the joist, replacing or strengthening the ends of wooden beams, installing a new floor while preserving the old one, or replacing floor structures on part of the floor area.

To strengthen the ends of wooden beams, the installation of wooden, metal or reinforced concrete “prostheses” is used, as well as side linings with the supply of support beams (Fig. 4.15). If beams are damaged in the span, they are strengthened using wooden overlays, a technology similar to that of strengthening the ends of beams.

Rice. 4.15. Strengthening wooden beams: A – wooden prostheses (top view); B – side linings (view

above); B – support beam (side view); 1 – beam; 2 – wall;

3 - wooden prosthesis; 4 – gasket; 5 – bolts; 6 – nails;

7 — side pads; 8 - support beam

After strengthening the beam, roll-up panels are laid, which, as a rule, are made of two layers. The cladding is nailed to the bottom of the shield. The width of the roll shield depends on the distance between the load-bearing beams, and the length is taken to be 1, 1.5 and 2 m. The thickness of the roll shield is usually determined by the thickness of the skull block; the shield laid on the cranial bars, its lower surface should be in the same plane with the lower surface of the beams. A layer of sound and heat insulating material is laid on the roll-up shields. In interfloor ceilings, a layer of waterproofing material is laid on top of the shield. This is prohibited in attic floors, since moisture vapor from warm rooms will condense on the cold lower surface of the insulation: as a result, the floor will be systematically moistened, creating conditions for its rotting and the development of fungus.

Reinforcement of metal floor beams is carried out by increasing the cross-section, and it is necessary to unload them by at least 60% or install temporary additional supports. When designing reinforcement, it is necessary to adhere to the following technological rules: the volume of welding should be minimal, welds should be located in convenient accessible places, ceiling welding should be avoided, the lower chord must be strengthened first, and then the upper, which eliminates the deflection of the beam at the time of strengthening. The simplest method of reinforcement is with symmetrical overlays (Fig. 4.16).

Replacement of floors.

During major renovations of buildings, instead of dismantled floors, durable floors are installed from reinforced concrete elements or from reinforced concrete elements on metal beams.

As a rule, wooden floors have to be replaced so that the service life (capacity) of all load-bearing elements of the building is comparable. New floors installed to replace existing ones can be made of:

— reinforced concrete elements of various sizes and weights;

— metal beams filled with reinforced concrete slabs;

— reinforced concrete or metal beams with monolithic filling (prefabricated monolithic floors);

— monolithic reinforced concrete.

Rice. 4.16. Strengthening steel beams with symmetrical

overlays made of: a – strip steel; b – corners;

c – square; g – round steel; d – pipes;

e – rental combination

Reinforced concrete elements for replacing floors of reconstructed buildings are divided into large-size ones weighing more than 600 kg (for example, hollow-core decks with outlet ribs), medium-size ones weighing from 200 to 600 kg (beam structures with liners) and small-size ones weighing up to 200 kg. When completely replacing floors in a building, large-sized prefabricated reinforced concrete elements installed by cranes are most often used. When selectively replacing floors, medium- and small-sized reinforced concrete elements are most common. When reconstructing buildings with a complex configuration, the use of prefabricated structures is impractical due to the abundance of standard sizes.

Furrows and nests are punched with grips 3-4 floors long; subsequent preparation of the work front for installation of the decking is carried out after anchoring and embedding of their supporting ends.

Prefabricated floors on reinforced concrete or metal beams are mounted in a certain sequence. To do this, nests are marked and punched for inserting reinforced concrete beams; prepare the bases in the sockets for supporting the beams; lay the beams in the design position with alignment; lay the anchors of the beams and seal the nests with bricks and mortar; lay liners/infill slabs between the beams.

To install prefabricated monolithic floors, the locations are marked and slots are punched for beams of partial cross-section; lay the beams in the design position, as well as the elements of interblock filling; the beams are monolied to their full cross-section.

Preparation of the supporting surface of the nests and grooves consists of cleaning it from dust and rubble and leveling the layers of cement mortar to the mark of the ends of the beams or floorings. To evenly distribute the load from prefabricated floor structures, concrete tiles are placed under the ends of the beams, and unloading metal beams or rails are inserted into the grooves so that the elevation of their top corresponds to the design elevation of the supporting part of the floor elements.

New floors can be installed without transferring load to existing walls. Then there is a need to construct an internal load-bearing frame of the building. Load-bearing frames are installed after dismantling structures, repositioning, strengthening or repairing individual sections of foundations. After excavating the pits and installing the foundation, reinforced concrete cushion blocks are installed in the design position, the seams between which are filled with sand or mortar. A reinforcing mesh is spread on the horizontal plane of two pillows and a formwork template is installed (in the form of a bottomless box), after which a monolithic seam is concreted. Marks are applied to the surface of the reinforced joint, leveled with cement mortar, indicating the location of the reinforced concrete cup, which is then installed, checking that its position corresponds to the design.

Upon completion of the installation of the foundation, nests are marked and punched in the brick walls to support the ends of the purlins, beams or flooring.

Common schemes for strengthening monolithic floors

Professional builders use various schemes for strengthening floors:

- additional reinforcement of the damaged area followed by concreting;

- increasing the thickness of the slabs due to the formation of an additional layer of reinforced concrete;

- shotcreting the surface of a reinforced concrete base with branded concrete mortar.

The choice of the optimal strengthening scheme is made individually depending on the design features of the floor.

Difficulties in strengthening monolithic floors

Strengthening reinforced concrete floor beams is a complex engineering and technical problem, in the process of solving which it is often necessary to use both standard (reinforcement, extension, use of mesh) and non-traditional restoration methods. At the same time, a personal project plan is developed for each specific building, taking into account the requirements not only for strength, but also for aesthetics.

There are two fundamentally different ways of strengthening a monolithic floor:

- transferring the entire load or part of it to the reinforcement being built;

- increasing the load-bearing capacity of an existing load-bearing structure.

In the process of strengthening reinforced concrete floor beams, we often encounter the following problems:

- impossibility of using all available mechanization means;

- obviously limited conditions (cramped environment, insufficient free space, etc.);

- the need to carry out complex preparatory and additional labor-intensive work.

Professional skills allow us to guarantee the quality of service delivery, regardless of the difficulties encountered.

Method of strengthening the floor of a hollow-core structure

To strengthen the structure of hollow-core panels, various construction techniques are used:

- the formation of an additional layer of concrete on the surface, reinforced with steel reinforcement;

- strengthening slabs on the lower side of the reinforced concrete mass using steel reinforcement and concreting;

- local reinforcement of damaged areas and filling cavities with concrete mortar;

- strengthening reinforced concrete panels with reinforcement and concrete at points of contact with the surface of the walls.

Experts decide which method to choose for a particular situation.

Basic methods of strengthening floor slabs

The choice of method depends on the reason why reinforcement of structures is required.

The first is the risk of pushing through due to insufficient support area of the floor slabs on the columns. It can be eliminated by increasing the area of the upper end of the column or by completely extending the column throughout its entire volume. Very precise calculations of reinforcement and concrete composition are required to ensure that new and existing volumes of reinforced concrete work as a single unit. Additionally, strengthening of the foundations under the columns is required. For large spans, it is practiced to install additional lower and upper unloading beams. Which will definitely require strengthening the foundations under the load-bearing structures.

The second is an increase in the load-bearing capacity of the slab in cases where there are no deformation changes in it, but the load on the floor is assumed to be greater than that taken into account when developing the project. Here you can consider two options: how to strengthen a hollow-core floor slab and a solid-section slab.

For multi-hollow slabs, it is practiced to create additional reinforced ribs in the voids. This is the installation of flat frames followed by concreting so that the new frame works in conjunction with the reinforcement of the lower part of the slab. In this case, simultaneously with the reinforcement, an additional layer of concrete is added along the top of the slab. Reinforcing hollow-core slabs with only a layer of concrete is ineffective, since with a thin top flange it is also necessary to install fastening pins. And here it is necessary to recalculate the loads on the supporting structures, since the weight of the slab increases.

For solid slabs, concrete is used on top or bottom with reinforced concrete dowels or bolts. A reinforced concrete key is a recess in the body of an existing slab into which reinforcement is placed, followed by pouring concrete. This is necessary to create a single volume of the slab with concrete.

We will consider the third reason and how to strengthen a floor slab with cracks in concrete separately.

Strengthening floor slabs with damaged concrete

A small network of cracks that appears on the ceiling can be the same small, easily eliminated defect, or it can also be a signal that more significant destruction has begun. In order to eliminate any possibility of such defects, it is necessary to purchase only high-quality hollow core floor slabs from the manufacturer. This will avoid the creation of additional stresses and loads in concrete during numerous unloading, loading and storage.

Before starting reconstruction, it is necessary to assess not only the degree of damage to the concrete, but also the condition of the reinforcement, since the depth of the cracks cannot be visually determined. This task is especially relevant when choosing a method of strengthening a hollow-core floor slab, because the thickness of the concrete layer above the reinforcement is very small. Modern devices allow you to perform a full scan without stripping the concrete down to the reinforcing mesh.

If the depth of the cracks is insignificant, reconstruction will only require applying a layer of concrete, polymer mortar or gluing fiberglass. In case of significant damage, complete clearing is carried out down to the reinforcement. Then anti-corrosion treatment of the steel, application of concrete mortar with a layer of concrete and the already discussed fastening methods.

How to increase the load-bearing capacity of a monolithic floor

To increase the load capacity of a solid reinforced concrete floor, various methods are used:

- construct support structures in problem areas for strengthening. This allows you to redistribute the existing loads;

- increase the load-bearing characteristics of the existing building structure. To do this, a complete replacement of the outdated ceiling or its partial restoration is carried out.

Installing additional supports under problem areas will ensure the immobility of structures.

The principle of reinforcing a floor slab with carbon fiber

Monolithic and hollow-core floor slabs experience bending load: at the bottom (ceiling) in tension, at the top (floor) in compression. For concrete and reinforced concrete structures, the maximum compressive load is tens of times greater than the maximum tensile load. But there are methods for creating pre-stress to reduce the compression force, which leads to an increase in the efficiency of measures to strengthen the slab from below in tension. To do this, use a bidirectional fabric (for example, CarbonWrap Fabric 450/1200), which is located along the long side of the slab with a certain step of several layers. After laying the web on top and “setting” the reinforcing layer, similar work is carried out from below, where a unidirectional web can be used (for example, CarbonWrap Tape-230/600).

Strengthening ribbed slabs using the extension method

This method is used when you need to significantly increase the load-bearing capacity and strength of floors. To do this, you need to thicken the slab with an additional layer of concrete.

This type of amplification requires some preparatory work. So, to improve the adhesion of the ceiling and the new concrete solution, it is necessary to first clean its surface from any contaminants.

Next, a reinforced sheathing is laid on the surface of the slab - for maximum convenience of work on imparting the required rigidity to the reinforcing concrete layer. And the resulting mixture is poured into the prepared structure using a shotcrete machine.

Strengthening slabs

If the power is large enough, you have to dismantle part of the existing monolithic floor and then make a new one. The designer makes a design for strengthening concrete structures depending on the planned capacity for the ceiling . Steel beams act as load-bearing components of the new structure. The size, quantity and cross-section depend on the magnitude of the load. Between the beams it is possible to design a Klein slab (a brick filling that is reinforced with rods, and they rest on the shelves) or a reinforced concrete slab.