Diesel generator malfunctions

Have you discovered that your diesel generator is malfunctioning or has stopped starting altogether? First of all, it is necessary to inspect the equipment for visible problems. In this article we will look at the main types of malfunctions of diesel generator sets (diesel generator sets), their causes, and also tell you how to eliminate them.

The generator does not start

There could be several reasons:

- The fuel pump is broken: this is indicated by low or uneven fuel supply.

- The cold start device is broken. This is most likely due to waxing of the fuel, which usually occurs in cold temperatures. To prevent this from happening to your equipment, use seasonal fuel and do not use the device in cold weather.

- Fuel is of low quality or contaminated. To avoid this, use only proven, clean, undiluted fuel: saving on it can lead to serious repair costs.

- The starter has failed, resulting in insufficient rotation speed. There are two reasons: a) the use of low quality oil, b) a weak battery.

When should you contact the workshop?

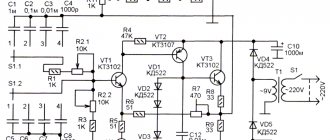

A number of malfunctions, alas, are quite difficult to fix with your own hands without sufficient qualifications: for example, a faulty inverter converter or voltage regulator can be repaired only with a good understanding of the operating principle and circuitry of such devices. Not every owner of a gas generator will undertake to overhaul the engine, although this is not as difficult as it might seem.

In this case, you should contact a specialized repair shop. You can find out the coordinates of workshops in your city on the Internet or in stores selling gas-powered tools.

| City | Workshop | Coordinates |

| Moscow | "Electrical petroleum engineering" | 13 centers in Moscow and 18 in Moscow Region |

| "Southeast" | Maryino, Stavropolsky proezd. possession 199 (499) 390-93-49 | |

| Saint Petersburg | "Lenremont" | 7 workshops |

| "Benzomix" | st. Uchitelskaya, 23, ATOLL business center, office 154 (812) 385-54-30 | |

| Nizhny Novgorod | "Machines" | st. Rodionova, 24 (831) 412-92-48 |

| Novosibirsk | "RemCity" | st. Topolevaya, 3 |

| Vladivostok | "Gasoline unit" | st. Dorovolsky (4232) 273-273-9 |

The video shows the repair of a Chinese-made gas generator

A loud knocking sound is heard while the engine is running

Most often, knocking indicates wear or breakdown of the following parts:

- injectors

- valve springs

- piston rings

- cylinder-piston group

- crankshaft bearing

- camshaft

If the listed parts are in order, check the valve clearance adjustment, timing mechanism and injection timing setting. Is that normal too? Then the problem is the presence of air in the fuel system or poor quality fuel.

Most common faults

If you arrange the possible malfunctions of a gas generator in a kind of rating, you will get the following list:

- Failure or contamination of the spark plug: difficult or impossible starting, unstable operation.

- Carburetor clogged: difficult starting, excessive fuel consumption, unstable operation under constant load.

- Ignition coil failure: no spark, unable to start.

- Starter breakdowns: breakage, cable snagging, ratchet destruction.

- Violation of valve clearances: difficult starting, increased noise during operation.

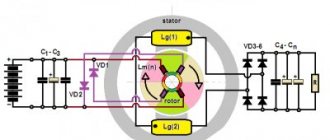

- Brush wear (on synchronous generators) – lack of output voltage.

- Faulty speed controller: floating engine speed, dips when the load changes.

- Wear of the crankshaft bearings and generator rotor - increased operating noise and oil leakage.

- Wear of the cylinder, piston rings - difficulty starting a cold engine, excessive oil consumption.

This does not take into account breakdowns that result from a gross violation of the operating rules of the generator: for example, scuffing on the crankshaft journal due to insufficient oil level, burnout of the windings of the generator or voltage converter (on inverter gas generators) due to frequent overloads.

Difficulty starting the generator, which appears suddenly and is not accompanied by an increase in engine noise, is a clear sign of either abnormalities in the carburetor (too lean or rich mixture) or a faulty ignition system (weak or intermittent spark formation). Since the diagnostics of the state of these systems is interconnected, it is combined into one section.

Remove the spark plug and inspect the carbon deposits on its electrodes.

- Dense and dry black carbon deposits are a sign of a rich mixture (the carburetor is faulty, the air filter is clogged);

- Oily black soot is a sign of severe wear of the piston rings; oil enters the combustion chamber;

- White carbon deposits are a sign of running on a lean mixture; you need to check the carburetor.

- Brick-brown soot is normal for carburetor engines.

- Red, green-red soot is a consequence of working on low-quality fuel.

It is easy to check the functionality of the ignition system itself because of its extreme simplicity: turn on the ignition, insert a known good spark plug into the spark plug cap and, placing its skirt on the nearest metal part of the engine, sharply turn the recoil starter. If there is no spark, disconnect the ignition switch and oil level sensor in turn from the ignition coil: if, after disconnecting both elements, there is still no spark, replace the ignition coil.

If the spark is present and has sufficient strength (white or white-blue color), remove the spark plug after several starting attempts. A spark plug filled with gasoline is a sign of over-enrichment of the mixture; a dry spark plug is a sign of a lack of fuel.

The most common malfunction of the carburetor is its contamination. Dirt getting into the air channels leads to over-enrichment of the mixture, and into the fuel jets - to depletion. Dirt on the float shut-off needle leads to loss of tightness and overfilling of the float chamber, which will be immediately noticeable by fuel leaking from the carburetor.

Let's look at servicing a carburetor using the example of one installed on Honda GX engines - its design is typical for a gasoline generator.

- Remove the float chamber cover (4). Wash it in gasoline or aerosol carburetor cleaner - dirt and deposits accumulate at the bottom.

- Do the same with the gas tap sump (22).

- Check whether the gas valve is ventilated in the “open” position.

- Remove the float shaft (3), remove the float and locking needle (2). Blow out the channel with air.

- Blow out the fuel nozzle (25), emulsion tube (11) and all carburetor channels with an aerosol cleaner or compressed air.

- Turn out the adjusting screw (5) and blow out its channel. Then screw it all the way and loosen it by 2 (foam rubber, paper filters) - 2.5 turns (cyclone filters), depending on the type of air filter.

- Assemble the carburetor.

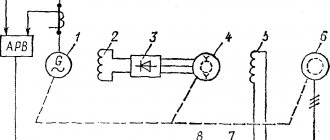

The electrical system of gas generators is quite reliable. Most often, you may encounter two problems: lack of battery charging on electric-start generators or lack of voltage at the generator output.

- Lack of battery charging is a consequence of a failure of the rectifier or low-voltage winding. It’s easy to check this system with your own hands: connect a 12-volt light bulb in parallel with the low-voltage winding of the generator and start it. A burning light means that the generator itself is working properly and the rectifier needs to be replaced.

- The lack of voltage at the generator output is most often a consequence of brush wear. Remove them and assess the degree of wear, replace if necessary. If your generator is of the inverter type, check whether voltage is coming to the input of the converter by connecting a low-power 220 V lamp in parallel with it.

Video about step-by-step repair of a gas generator

One of the routine works provided for in the operating instructions for gasoline generators is monitoring and adjusting, if necessary, the clearances of the valve mechanism. Increasing the gaps beyond the norm will lead to a decrease in engine power and increased noise during operation. Reducing the gap is the most dangerous, since it is not audible during operation, but pinched valves, especially exhaust valves, begin to quickly burn out. As a result, the engine begins to operate unstably and when the plate burns out, it stops starting.

The procedure for adjusting the valves is quite simple:

- Remove all components that interfere with removing the engine valve cover.

- Remove the spark plug.

- Remove the valve cover.

- Align the crankshaft to the top dead center of the compression stroke using the mark on the flywheel (if there is one) or by monitoring the movement of the piston through the spark plug hole. Do not confuse compression TDC (both valves are closed) with exhaust TDC (exhaust valve closes, intake valve opens).

- Loosen the locknuts of the adjusting screws and use a flat feeler gauge inserted between the rocker arm and the end of the valve to set the gaps by rotating the screw. Typically, a gap of 0.2 mm is accepted for the exhaust valve, and 0.15 for the intake valve (check the operating instructions).

- Tighten the locknuts and rotate the crankshaft twice, bringing it to TDC. If everything is done correctly, at the next dead center both gaps will go away, and after another turn they will take the set value. The gaps that have increased after the first revolution are a sign that they were adjusted at TDC of the exhaust stroke.

- Assemble the generator.

Recoil starter malfunctions are perhaps the most common mechanical problem. Either the cable breaks, or the starter refuses to reel it in due to a broken return spring, or the ratchet does not turn the crankshaft.

Remove the starter by unscrewing the bolts around the perimeter of its casing. By unscrewing the screw (1), you can remove the ratchet mechanism. Check its cams (4) and return springs (5). Then carefully remove the pulley along with the spring (7). Replace the broken cable or broken spring, depending on what caused the repair.

When assembling the starter, you need to ensure that the spring remains engaged with the housing and pulley while it is being installed in place. The cable must be completely wound around the pulley. After replacing the ratchet mechanism, check the cable movement and how the starter returns to its original position.

Review and repair of the Einhell STE800 gas generator

Strange color of exhaust gases

Pay attention to the color of the diesel generator exhaust gases: black or white-blue color indicates a problem. Most often, they are caused by a dirty air filter. If you change the filter and the emissions continue, the following options are possible:

- malfunction, wear or breakdown of the following parts: injectors, injection pump (high pressure fuel pump), glow plugs or relays of these plugs (in this case, smoke occurs only at startup), piston rings, cylinder-piston group, block gasket

- presence of additional resistance in the intake system

- not adjusted: valve clearance, gas distribution mechanism, injection timing

- insufficient compression or turbo pressure

- low-quality oil or oil that does not meet the manufacturer’s (engine) requirements

Diesel generator stalls shortly after starting or during operation

Why does a diesel generator stall?

- too little fuel;

- air bubbles have entered the fuel;

- the air filter is dirty;

- nozzles are broken;

- idle speed is set incorrectly;

- the presence of additional resistance in the fuel supply systems, draining excess fuel, intake and exhaust systems.

Some of these faults can be dealt with on your own, while for others it is better to contact a service center for the repair of diesel generators and power plants.

Repair of equipment

Remember that careful and correct use of the generator will extend its service life.

If you find faults that you cannot fix yourself, call us at this number or leave a request on the website, and we will call you back within 20 minutes. Our specialists will help you identify the cause of the problem and advise you on repairing the diesel generator set.

Please also note that our catalog contains a large selection of new generator models.

- Model: 2000 E-SERIES S with ATS

- Power: 1600 kW

- RUB 47,172,125

- Model: BD 250 B in container

- Power: 200 kW

- RUB 3,079,679

- Model: LDG 3600 CL

- Power: 2.97 kW

- 42,000 rub.

When you read this article, you will know: how to inspect a diesel generator before starting it, and how to independently identify and eliminate the main types of diesel generator faults.

Leave your phone number and our specialist will call you back within 15 minutes.

Source

Diesel generator does not produce voltage? Review of diesel generator faults

A diesel generator is a complex unit with a rather complex structure. Therefore, it is not surprising that various types of malfunctions periodically appear. Most often they are associated with severe wear of some structural elements, incorrect or untimely maintenance, severe overloads and improper placement and storage conditions of the device. Sometimes breakdowns are the result of a manufacturing defect or the inattention of people working with the unit.

Diesel generator does not produce current

Three-phase French SDMO DX 6000 TE is available. It served faithfully for a long time, but it broke down. On all phases it produces from 4 to 6V. The windings seem intact. The brushes are also ok. No smell, no blackening. I tried to find a circuit diagram on the Internet, but I couldn’t find it. I'm sinning with this incomprehensible device. Like Conder. I couldn't find anything like this on the Internet. There are no markings on it. There are similar ones, but with two or three outputs. This one has five. He is not a ringer in any way. In all directions. Although that may not be the issue. Are there any generator specialists? Who has any thoughts? Thank you in advance

Thanks for the answer. The problem turned out to be more serious than I thought. A piece of aluminum fell on the winding and shorted it. Where he came from, the devil only knows. I thought it had broken off from the body. Everything seems to be intact. Moreover, it didn’t penetrate the body. Well, in general, the stator rewinding is shining

220v That's where the conclusions come from

12V, they go to a simple rectifier (in the panel) of 4 diodes and to +/-12V terminals. And there is a 35 mF capacitor, (it is called with an ohmmeter as expected) for it two wires come out of the stator winding. I'm just shocked. How does THIS work and how is it regulated?

Diesel generator (power plant) does not work: starts and stalls

Diesel power plants are often used to provide electricity to a country house, construction or industrial facility. This is a convenient solution that will allow you to use electrical appliances even in remote places where there is no electricity supply system. Since a diesel generator set (diesel generator set) is a rather complex technical device, it can break down. The reasons may be different, it is important to identify the malfunction and find the right solution.

Main signs of generator failure

If the generator starts and immediately stalls, produces low voltage or does not function, there is a breakdown. The causes of malfunctions are:

- incorrectly selected unit power and load;

- non-compliance with recommendations when operating the installation;

- inappropriate place to place the device;

- manufacturing defects.

In the latter case, if a production error is identified, you should use the warranty passport, which allows you to correct problems in the diesel power plant free of charge. Standard warranty provided:

- for 12 months from the start of operation;

- for 3 thousand engine hours (depending on what comes first)

The main malfunctions of the generator, possible breakdowns of the engine, control cabinet, batteries and methods for eliminating them are described in detail in the operational documentation for them. Each manufacturer carefully checks the product’s resistance to external influences, draws up rules for using the unit and describes in detail how to operate the device so that it works for a long time and properly.

After identifying a malfunction, it is necessary to find out what is the cause of the breakdown.

Key Causes of Generator Failure

Each power plant is equipped with a control cabinet of the required degree of automation; it can be made on the basis of analog devices, but in most projects the cabinet is equipped with a microprocessor Russian controller. If a failure occurs that does not correspond to the specified parameters, the controller indicates the presence of a malfunction on the screen. It is not recommended to undertake repairs yourself unless you have special skills and knowledge. If the device detects a breakdown, it is recommended to call the supplier from whom the station was purchased so that experts can advise on further actions.

Possible malfunctions in the systems and electrical equipment of the electric unit and methods for eliminating them are given in the table below:

| Name of the breakdown, external and other signs of manifestation | Possible reason that caused the malfunction | Way to solve the problem |

| 1. Diesel engine does not start | Air ingress into the connecting elements of the fuel supply system. | Checking the tightness of connecting components. Bleeding the entire system with a special pump. |

| 2. Devices for measuring and monitoring engine operation do not display data | 1. A break occurs in the electrical wiring of the measuring devices. 2. Technical breakdown of devices designed to measure power plant operating parameters. 3. A malfunction occurs in the functioning of the sensors. | 1. Checking electrical circuits and solving the problem. 2. Replacement of a non-working device. 3. Replacement of broken sensors. |

| 3. Increasing the temperature of the cooling fluid and lubricant | 1. Cooling and lubrication fluid level is too low. 2. Clogged oil cooler or water radiator. | 1. Checking the level and, if necessary, additional filling 2. Rinsing and cleaning the system radiator. |

| 4. Excessive gas release in the room | Gases are passed through flanged connections in the exhaust system. | Checking bolt fastenings and their degree of tightening. If the problem persists, the gaskets need to be replaced. |

| 5. The drive that controls the diesel engine governor is not functioning. | 1. Engine failure. 2. Clutch slippage. | 1. Replace the engine with a working one. 2. Adjust the clutch or get rid of increased friction in the gearbox. |

| 6. The control and measuring devices of the power circuits are faulty | 1. Burning fuses. 2. The occurrence of a wire break in instrument circuits. 3. Problems with the devices themselves. | 1. Replacing fuses that have burned out. 2. Checking circuits and troubleshooting. 3. Replacement of broken measuring and control instruments. |

| 7. The temperature of the power supply is increased, which leads to burning or oxidation of contact and insulating surfaces | 1. The load exceeded the permissible limit due to the breakdown of energy-consuming equipment. 2. Poor reliability of contact between parts of the power source through which current passes. The cause may be burning or oxidation of the contact or insulating surface. | 1. Elimination of the cause that led to the overload. 2. Checking contact connections and eliminating damage. |

Voltage problems - causes of voltage drop on a diesel generator under load

Most of the problems are usually associated not with the fact that the diesel generator does not start, but with the fact that when the engine is operating in normal mode, the equipment does not produce the declared power or the voltage level is too low. The following types of faults are typical for the electrical part of the equipment:

Loss of contact at the wire connection points, wear of the generator brushes.

The reason for the drop from 380 to 330 V in a three-phase unit may be due to insufficient voltage supply to the excitation circuit; in addition, phase imbalance during an uneven load can also play a role.

If the diesel generator produces high voltage, the problem should be looked for in the operation of the AVR device (voltage regulator).

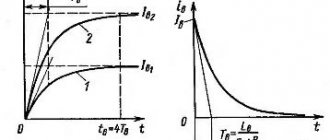

In cases where the diesel generator does not produce voltage at all, you should pay attention to the circuit breaker or fuses, which may fail due to current overload or short circuit in the circuit. In situations where the diesel generator set operates underexcitation, the current lags behind the voltage in phase by 90 degrees, that is, it becomes inductive relative to the network

Long-term operation of the installation in this mode is unacceptable.

In situations where the diesel generator set operates with underexcitation, the current lags behind the voltage in phase by 90 degrees, that is, it becomes inductive relative to the network. Long-term operation of the installation in this mode is unacceptable.

Counter voltage during DGS operation poses a particular danger. The cause of this malfunction is due to damage to the switch or ATS, in which power is supplied from the main network and the generator itself.

For the connected load, the increased voltage at the output of the diesel generator set is considered especially dangerous. The causes of overvoltage in a diesel generator may vary, but in any case it can cause the equipment and devices being serviced to fail.

When operating units of this class, you should adhere to a simple rule - starting a diesel engine with a faulty generator is prohibited. This can cause failure of the stator and rotor windings; repairs in this case will be expensive; in some cases it will be cheaper to buy a new diesel generator set.