General information about the strength of bricks

The strength of a brick is indicated by the letter “M” and a number indicating the load per 1 square meter. cm can withstand the product. The brick is marked in strict accordance with GOST. To do this, several copies of brick are taken from each batch of finished products, which are subsequently tested for compression and bending. During the research, a stone grade is established from M 75 to M 300. The established marking corresponds to all types of material, for example: solid face brick M 150, has the same strength as hollow brick. But each brand of product has a different purpose, determined by technical characteristics and properties.

Among the variety of materials, the most common is M 125 building brick, which, due to its reliability and strength, is used for the construction of the upper floors of multi-story buildings, internal and load-bearing walls, pillars and columns, partitions and other things. The price of M 125 brick is quite affordable and depends on the type of product. But in order to make the right choice, it is necessary to more carefully study the properties and characteristics of the product.

Where and what ceramic material is best used?

Ceramic brick and its technical characteristics make it possible to use it for the construction of almost any object. In this matter, it is important to simply choose the right type and brand of material. After all, its price is quite different and you shouldn’t overpay.

- For making a foundation, simple ceramic bricks, but just solid ones, are best suited. For example, to make a fireplace or to install a barbecue, grade 75 is quite enough. But if it is a large stove, or a large building, then you need to take ceramic brick grade 100 or ceramic brick grade 125;

- For a multi-story building, it is worth using ceramic brick of grade 150, and if the load is very large, then you will need to use M200. You can determine the weight of the structure using a masonry calculator;

- Hollow material is quite suitable for partitions. It is not very heavy and this will reduce the load on the supporting structures. Also, the hollow material retains heat well and has good sound insulation;

Attention: Facing bricks are used for facing masonry. There are also different types and their price is not small. Therefore, here the choice must also be approached from a practical point of view. And choose the right solution.

Product description M 125

Ceramic brick M 125 is an environmentally friendly and completely harmless material, in the manufacture of which the following ingredients are used: clay, water, plasticizers. The use of different types of clay and additives that improve the properties of bricks affects the variety of shades available on the market for the product.

When buying building material, you should figure out what the brand of brick M 125 means. The next number after “M” indicates that a load reaching 125 kg per 1 sq. m. cm surface will not lead to destruction or deformation of the product.

The high density of the product makes it almost universal. Brick is used for the construction of any structures and is used in various conditions.

It is important to know! Taking M 125 brick as the basis for construction, it is impossible to erect a building higher than three floors. If this condition is not met, the load exerted by the structure on the lower rows of bricks will be higher than the maximum permissible value, which will lead to the destruction of the structure.

Product Specifications

The manufacturing technology for M 125 bricks can be different: semi-dry pressing or plastic molding. But in any case, according to GOST, the product is fired in a kiln at high temperatures. There are various modifications of the product. There are:

The choice depends on the purpose of the material.

Facing brick M 125

Hollow brick M 125 has a textured surface, and is usually used as a facing material for the external and internal walls of buildings of various heights. They are used to decorate surfaces that have high aesthetic requirements.

Technical characteristics of facing bricks:

- size – 250x120x65 mm;

- weight – from 2.2 kg to 2.5 kg;

- water absorption – up to 8%;

- thermal conductivity - from 0.2 to 0.26 W/m.deg.C.

The even color of the product indicates its high quality. Experts recommend buying bricks for finishing from one batch. The facing brick has ideal proportions, so when laid it looks very neat and aesthetically pleasing.

Solid brick M125

Solid brick M 125 has a relatively small volume of voids, the value of which does not always reach 13%, therefore it is used for the construction of residential buildings, industrial and administrative buildings, columns, garages, outbuildings and outbuildings, warehouses.

The advantage is the ability to operate the material in different climatic conditions. The product has a rough, rough surface, so during the construction of buildings it is recommended to additionally plaster the walls. The use of the product for the construction of load-bearing structures of buildings gave it the following names: ordinary, construction, ordinary brick M 125.

Technical characteristics of solid brick M 125 correspond to GOST 530-2007, and have the following values:

- brick dimensions M 125 – 250x120x65 mm;

- bending and compressive strength - 1.4-1.6 MPa;

- weight of brick M 125 – 3.4-3.5 kg;

- water absorption – from 6% to 8%;

- frost resistance – from F50 to F75;

- thermal conductivity – 0.513 W/m.deg.S.

The porosity of a brick affects its thermal conductivity, water absorption and the quality of the resulting adhesion to the mortar. Judging by the characteristics given, brick M 125 has low thermal insulation properties, so walls built from this material must be additionally insulated.

Additional marking characteristics

Red brick must also meet the requirements of GOST and differ from ordinary concrete. The first characteristic, frost resistance, in the marking is indicated by the Latin letter F. The table allows you to see more detailed characteristics:

| Marking | Decoding |

| F25 | Low rate |

| Suitable for interior use only | |

| F35 | Means average |

| Used for the construction of buildings that are not constantly exposed to cold | |

| F50 | This means the level is above average |

| Demanded for facing work | |

| F75 | Indicates high criterion |

| Often used for the construction of high-rise buildings | |

| F100 - F300 | Can be used for the construction of any buildings exposed to low temperatures |

| The differences between them are small |

An important part of the labeling is the average density class of the product, as shown in the table:

| Product groups by thermal characteristics | Index |

| High efficiency | 0,7—0,8 |

| Increased thermal efficiency | 1,0 |

| Effective | 1,2 |

| Conditionally effective | 1,4 |

| Ordinary thermal effect | 2,0 |

| Minimum efficiency | 2,4 |

Material advantages

The popularity of red brick M 125 is due to its strength and quality characteristics.

The buildings erected with its help are distinguished by their reliability, durability and neat appearance. The material breathes, which eliminates the appearance of fungus and mold on the surface of the walls. Brick is produced in various sizes:

The weight of the structure and the load it will put on the foundation depend on what type of material, solid or hollow, is used during construction. When constructing walls, solid bricks are usually used, and hollow or facing bricks are used for finishing. Such masonry will add originality and neatness to the structure. If you want to save on cladding, you can use silicate stone, which looks very impressive in combination with red brick.

When purchasing material, you should pay attention to the price of M 125 brick, which is an important factor when choosing. It may vary depending on the type of product, delivery region, and the wishes of the seller. Therefore, it is worth looking for the best deals.

- Using M 125 brick, you should lay a wall whose thickness will be at least 2.5 bricks. This will eliminate unnecessary heat transfer.

- The core of a quality stone has a more saturated color than its edges.

- The ringing sound produced by the product upon impact indicates its high quality. A dull sound and a light brown color of the product indicate non-compliance with GOST.

- When purchasing a brick, you must require a certified copy of the accompanying document: a quality certificate or passport. If you do not have the necessary papers, it is better to refuse such an acquisition.

- It is advisable to familiarize yourself with the entire batch of goods. The presence of minor defects, chips, and cracks is not acceptable.

Strength of different types of bricks

In modern construction, the entire range of brick products is used, which are preferred for masonry, paving, cladding, and creating decorative interior elements. Depending on the type of material, the strength of the brick may vary.

- Sand-lime brick is made using a mixture of sand and lime through steam exposure in an autoclave. Its production does not take much time and is relatively inexpensive, and the strength of the resulting material is M200.

- Ceramic bricks are created from a clay mixture during the firing process and in the end a strong product is obtained, the strength of which is slightly higher than that of silicate bricks, M 300.

- Hyper-pressed brick is grade M 350 and contains cement, shell rock, limestone and additives.

- Clinker bricks have high strength indicators and among representatives of this type of material you can find those that have the M 1000 grade, which allows the material to be used for paving in areas where it will be subject to constant mechanical stress.

BRICK BRAND

The brand of brick determines the compressive strength of the brick. It is designated by the letter “M” and a number indicating how much load 1 square meter can withstand. see structures. The most popular bricks are brands M-75, M-100, M-125, M-150, M-175, M-200, M-250, M-300. M 75 and M100 are quite suitable for the walls of a 2-3 storey building, M 125 and above - for erecting walls of multi-storey buildings, M 150 and above - for laying foundations and plinths. M 200 - 300 are an indispensable material for the construction of high-rise foundations. The compressive strength of masonry depends not only on the brand of brick, but also on the brand of mortar, as well as on the quality of the masonry (thickness and density of the joints). https://www.stroykirpich.ru/harakteristiki/marka.php

The brand of a brick is an indicator of strength, showing how much load (in kg) per 1 cm2 a brick can withstand. In Ukraine, bricks are divided into grades: 75, 100, 125, 150, 200, 250, 300. Grade 100 (M-100) means that the brick is guaranteed to withstand a load of 100 kg per 1 cm2. Brand 150 - respectively 150 kg per 1 cm2.

The most popular brands (M): 100,125,150,175,200.

What is the abbreviation “F” or frost resistance? This is frost resistance - the ability of a water-saturated brick material to withstand repeated alternating freezing and thawing without visible signs of destruction and without a significant decrease in strength. Frost resistance is measured by the number of freezing and thawing cycles carried out under laboratory conditions. Frost resistance (indicated by “Mrz.” or F). According to frost resistance: brick is divided into grades F-15, F-25, F-35, F-50, F-100 and more. In the Central region, it is not recommended to use bricks with frost resistance below 25 cycles. The lower the frost resistance, the cheaper the brick. Frost resistance is determined during testing - the brick is immersed in water for 8 hours, then placed in the freezer for 8 hours (this is one cycle). And so on until the brick begins to change its characteristics (weight, strength, etc.). Then the tests are stopped and a conclusion is made about the frost resistance of the brick.

Strength is the main characteristic of brick - the ability of the material to resist internal stresses and deformations without collapsing.

The brand of brick is an indicator of strength, designated “M” with a digital value. The numbers show what load per 1 sq.cm. can withstand brick. For example, grade 100 (M100) means that the brick is guaranteed to withstand a load of 100 kg per 1 sq.cm. The brick can have a grade from 75 to 300. The most common bricks on sale are M100, 125, 150, 175.

How to find out what brand of brick you need? For example, for the construction of multi-storey buildings, bricks of at least M150 are used. But for a cottage of 2–3 floors, “one hundred square meters” (that is, M100) is enough.

Frost resistance is the ability of a material to withstand alternate freezing and thawing in a water-saturated state.

Water not only wears away stone, but also brick. And the frost adds.

Frost resistance (denoted “Mrz”) is measured in cycles. During standard tests, a brick is immersed in water for 8 hours, then placed in a freezer for 8 hours (this is one cycle). And so on until the brick begins to change its characteristics (weight, strength, etc.). Then the tests are stopped and a conclusion is made about the frost resistance of the brick.

For Moscow construction projects, you need to use bricks with frost resistance of at least 35 cycles. Therefore, large factories try not to produce bricks with frost resistance below 35 cycles. But on the market you can still find bricks with frost resistance of 25 and even 15 cycles (usually brought from warm regions). It has a low price, which attracts buyers (and sellers try not to talk about “features”).

In general, the brand of brick for the future home should be determined by a specialist.

Brick is an indispensable building material. Having appeared thousands of years ago, it still does not lose its popularity. The evolution of brick included many stages, and if in ancient times it was just a piece of clay and straw dried in the sun, today brick is the brainchild of modern technology and chemistry.

Resistance of (brands) of bricks to frost.

The ability of any material to withstand freezing and thawing in a water-saturated state is called “frost resistance.”

Based on frost resistance, bricks are also divided into certain brands only with a different designation: F15, F25, F35, F50. The resistance of bricks to frost is measured according to certain cycles. When testing, the product is saturated with water (kept in water for 8 hours), then the product is placed in the freezer for 8 hours - this is counted as one cycle. This process is repeated until the brick begins to change its characteristics in terms of strength, etc. When this happens, the test is stopped and conclusions are drawn about the frost resistance of the brick.

For buildings in Moscow, it is better to use bricks with frost resistance of at least 35 cycles. That is why large factories try to produce bricks with frost resistance below 35 cycles as little as possible. But in the markets you can find bricks with a low frost resistance; they are brought from warm regions. These bricks have a low price, which attracts customers. To ensure that there are no incidents after the construction of the house, it is best to have a specialist determine the brand of brick for the future construction.

Our advice: you should not buy bricks at low prices, which have a frost resistance rating of 25, or even 15 cycles. For construction in the Moscow region, it is better to use brick grades F35, or even F50.

Brick M100, M125 and M150 - what is the difference?

The most popular “artificial stone” these days can be called bricks of the M100, M125 and M150 series. They differ from each other in terms of strength and resistance to all kinds of climatic changes. M100 brick is excellent for the construction of private suburban dwellings - be it houses or cottages, as well as other civil buildings of one or two floors. However, M100 should not be used in the construction of multi-story buildings and foundation laying, as this can lead to the collapse of the building.

The most resistant to deformation from all kinds of external and internal factors is M125 brick. It is commonly used to construct walls and upper floors of buildings. They are also often used to line the internal and external walls of buildings, stoves and fireplaces. In combination with M150 brick, which is usually used to build load-bearing walls and foundations, as well as the main floors of high-rise buildings, M125 brick allows you to reduce construction costs, as well as lighten the load on the support of the structure being erected.

Description of features and characterizing characteristics

Despite the diversity, the most popular building material remains ceramic brick made from fired clay. The shape is a rectangular parallelepiped, dihedral, with a smooth or relief (textured) surface. The color of the product matches the color of the raw materials. For example, if the clay is yellow, then without adding dye the finished block will be the same. Ordinary brick is usually red, but each batch differs from the other in tone. This point should be taken into account if the material is used for the facade wall.

Benefits

- affordable price;

- ease of use (single multiple of 1 meter);

- durability;

- strength;

- environmental friendliness;

- resistance to moisture and temperature changes;

- refractory;

- good sound insulation;

- a wall made of solid brick does not require additional insulation;

- high performance (buildings do not require repairs for a long time).

The M150 brick, manufactured in compliance with the rules and regulations, produces a ringing sound when struck.

Brick construction

Design

Full-bodied

Hollow

Solid brick - having no voids (through holes) or with a voidness of no more than 13%.

Hollow brick (slotted or perforated) - having through holes (voids) of various shapes and sizes, due to which it has less weight and greater thermal insulation ability.

Hollow brick is cheaper to produce. The use of hollow ordinary bricks reduces the load on the foundation. The difference in thermal conductivity is not very significant when comparing the thermal conductivity of finished masonry. Fastening some types of facade finishing to slotted bricks may be unreliable. Solid brick can better withstand loads (vertical and pull-out of fasteners).

Frost resistance of bricks

The resistance of brick to changes in temperature and humidity is determined by such a quality as frost resistance - the ability of the material to withstand alternating thawing and freezing in a water-saturated state. Frost resistance is designated by the letter “F” with a numerical value and is measured in cycles: F-15 brick, F-35 brick, F-50 brick, etc.

It is important to understand that brick is saturated with moisture in cold climates not from outside, but from inside the premises. In our practice, we see how, in combination with improper finishing, brick is actively destroyed by the freezing of moisture in it - this is a serious danger of operation.

The frost resistance grade of bricks for construction is selected in accordance with regulatory documentation, depending on the climatic characteristics of the region; The lower the frost resistance index, the cheaper the brick. This indicator must be checked before purchasing the material.

Forming methods

Brick is produced by several molding methods:

Plastic molding is the most common option for producing bricks. Brick obtained in this way can be used without restrictions. The finished mixture in the mold is subject to pressure testing with high pressure. After drying and firing at a temperature of 800 to 1000 degrees, the brick is ready.

Semi-dry pressing involves subsequent firing of the product. Drying is not used in this production method. The result of this molding is the porous structure of the brick, which does not allow its use in the construction of load-bearing walls and fences.

Brick produced by semi-dry molding has found application in the construction of internal walls and ceilings. Its main advantage is a smooth and even surface combined with an ideal geometric shape. Walls made of such bricks do not require subsequent leveling, which significantly speeds up construction.

Dimensions and specifications

The dimensions of the M 150 brick are nominal. A single block is 250 mm long, 120 mm wide, 65 mm high, a one-and-a-half block measures 250*120*88 mm, and a double block measures 250*120*138 mm. There are also non-standard sizes: quadruple, eighth, restoration, European. The weight of one single block is from 3.6 to 4.5 kg.

The main distinctive characteristics of the building material are strength and frost resistance. Strength is considered the ability of a material to resist internal stress and external changes in shape. Conventional letter designation M (brand) and a number indicating the load that the block can withstand per 1 cm2. Brick brand M 150 is durable, capable of withstanding significant loads - 150 kg in compression and bending. Products with grades lower or higher are also produced, for example, M75 or M200. Frost resistance is indicated by the letters Мрз, is calculated in cycles and means the ability of a product to withstand loads of freezing and thawing at time intervals.

Types of blocks

According to their intended purpose, KR bricks are divided into ordinary (also known as construction or ordinary) and facing (facing). Depending on the filling density, it can be solid or hollow. The solid product is durable, voids account for less than 13% of the total volume. There is also a separate type of porous red brick, which is also made from clay by extrusion with the addition of various fillers, which form pores (chambers). Thanks to the air holes of the porous block, its thermal properties are higher and the weight is significantly less.

Sand-lime brick has largely similar characteristics. It is also durable, resistant to temperatures, but is susceptible to moisture. The raw material for production is a mixture of 85-90% lime and sand. Hence its color from white to ivory. Silicate brick of the SORPo M150 brand is used for finishing facades. Painted white, smooth in texture, highly durable.

Types of ceramic bricks

According to application, a distinction is made between ordinary solid brick and facing brick . The second type is divided into textured for finishing the walls of buildings, and shaped , which is used when laying complex sections of the facade around openings. Shaped is used for window sills, curly fences, arched structures, non-standard pillars, gazebos.

Shaped

Full-bodied

Textured

Based on strength they are divided into types:

- ordinary private M100 - M300 , the number after the letter M means how many kilograms 1 cm2 can withstand without destruction;

- clinker bricks are produced in grades M300 – M1000 ;

- stones with horizontal voids - M25 - M100 .

Bricks are made using different methods. Plastic molding involves the creation of elements by pressing from a raw material mass with a moisture content in the range of 15 – 21% . The semi-dry method involves production from a clay mixture with a moisture content of 8–14% .

Special varieties

Ceramic building materials are used for the construction of various structures and structures, therefore, types with enhanced characteristics have been developed and created for work in critical conditions. There are bricks with increased resistance to moisture and destructive loads - these are used for finishing paths and sidewalks.

Refractory bricks are used for laying furnaces; there are different types:

- quartz for the structure of the furnace body, arches that reflect infrared waves;

- fireclay is used in the masonry of fireplaces and household stoves; this is the most used red brick;

- the main one is produced with the addition of lime and magnesia, it is used in smelting furnaces in the metallurgical field;

- carbon is used in the construction of blast furnaces and mines; it contains pressed graphite.

Refractory material retains thermal energy. Stoves in a residential building accumulate heat and gradually release it. Brick is distinguished by high thermal inertia (it heats up and cools down slowly) and high heat capacity (it gets very hot).

Brands of ceramic bricks by density and strength

Density is a parameter that determines the weight of a material of a certain volume. For facing products it reaches values from 1.3 to 1.45 tons per cubic centimeter. In this case, the porosity rate can reach up to 14 percent (minimum 6 percent). As for strength, it shows how much load (in kilograms) one square centimeter of brick surface can bear.

Strength is indicated by brands, where after the letter “M” there is this indicator. There are seven brands of ceramic facing bricks: from M75 to M300. But for cladding, as a rule, very high grades are not required - after all, the material does not experience the same loads as, say, ordinary brick when laying a foundation. Or load-bearing walls. Therefore, facing products of the M300 brand are not produced at all.

Ceramic bricks used for facing work mostly have voids inside. This way you can solve two problems at once: make its laying simpler and more convenient, and also improve the heat conservation of walls lined with this material. But hollowness does not affect the tensile strength. We decided not to present ceramic brick brands by strength in the form of a table, limiting ourselves to a brief description of the advantages of each of them.

This video will tell you more about the types and brands of red brick:

Frost resistance characteristics

This characteristic shows how many times the moistened material can withstand freezing and thawing (the temperature during freezing should be minus 18 degrees Celsius with an error of up to 2 degrees). This indicator appears in the brand designation after the letter “F”. There are the following main brands for this parameter: F100, F75, F50, F 35, F30, F25, F15.

It is worth knowing that brick tests are carried out in extreme laboratory conditions. So, let’s say, Brand F50 can actually withstand not fifty freeze-thaw cycles, but much more. Moreover, winter varies from winter to winter; some are quite warm.

According to DSTU B V.2.7-61-97, the brick used for cladding must have a grade that is not lower than F25. Therefore, you should especially pay attention to the fact that for facing bricks, unlike ordinary bricks, the F15 brand does not exist.

This video will tell you how red brick is tested for strength:

Scope of application

Solid one-and-a-half brick is a strong and stable material. It is used as a working building brick in the construction of load-bearing internal walls and partitions, external walls. Good adhesion to the mortar allows the use of M 150-200 blocks in laying foundations, chimneys, decorative fireplaces, and stoves. Widely used as plinth brick. Ceramic products of these brands are used for the construction of load-bearing and high-rise (more than 2 floors) walls in the construction of residential and industrial facilities, to seal the walls and increase stability.

To lay the plinth, you should choose a red single block that can withstand increased loads, temperature changes, and exposure to moisture, and has a quality certificate.

Brick M 100

M-100 brick is the most common building material. It is used in the construction of up to 3 floors, as well as in the construction of partitions in high-rise buildings.

Building brick brand M100:

Solid brick m-100 is a building material in which there are no voids (GOST 530-2007). This brick is used for:

- masonry of internal and external walls,

- creating columns and pillars,

- construction of various structures, which, in addition to their own weight, usually also carry an additional firing load.

M-100 brick is used for the construction of load-bearing walls and partitions, which are subsequently planned to be faced, plastered, and painted. Since the M100 brick is hidden behind a decorative layer, the GOST requirements for its appearance are minimal:

- Roughness of the front surface is allowed,

- roughness,

- lack of uniform color,

- curvilinearity,

- chips up to 1 cm (no more than 3 per product).

It is extremely important that the load-bearing capacity of the M 100 brick is sufficient. To improve adhesion to masonry mortar, bricks can be embossed on the sides.

Construction brick M-100 must comply with GOST 530-2012. It can be either solid or slotted. Thanks to its special physical and mechanical parameters and durability, m-100 brick is widespread in the modern construction industry. It is widely used for masonry:

- building walls,

- foundations,

- chimneys,

- designs.

Hollow building brick M-100 cannot be used in laying foundations, basements and plinths, where it will come into contact with water. Typically, building bricks are used with protective and decorative layers (cladding materials). You can buy M100 brand brick with delivery by calling us at 8-499-340-35-47.

State standards (grades) of bricks.

In construction, as in any other field, many new materials, technologies, developments and standards are appearing nowadays. And not all of these new products are absolutely simple and safe to use. In order to streamline the set of all these innovations, a state standard (or GOST) was invented. These standards spell out all the rules and methods for working with certain materials. GOST is, so to speak, a sign of quality and compliance with all necessary standards and requirements. Every industry has its own state standards, and construction is no exception. Below we will present you a list of GOSTs that apply specifically to bricks:

• GOST 530-2007 Ceramic bricks and stones; • GOST 530-95 Ceramic bricks and stones; • GOST 7484-78 Facing ceramic bricks and stones; • GOST 379-95 Brick and silicate stones.

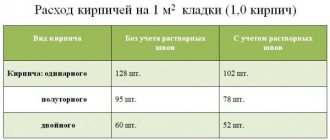

How to determine material consumption?

The initial calculation of the required amount of material for construction can be performed by a specialist who has the appropriate education and skills. The calculation is based on such characteristics as the type and purpose of the future structure and the required thickness of the masonry. When making calculations yourself, you can use an example calculation.

| Example of basic flow calculation | |||

| Unit measurements | Size | Excluding seams, pcs. | Including seams, pcs. |

| 1 m3 masonry | Single | 512 | 394 |

| One and a half | 378 | 302 | |

| Double | 242 | 200 | |

The assortment of the construction market consists of both traditional types of red and white bricks, as well as new varieties. When choosing between silicate, red ceramic or porous blocks, you should clearly define the purpose of the future structure, take into account the climatic features of the chosen location for construction, and the expected budget.

Source