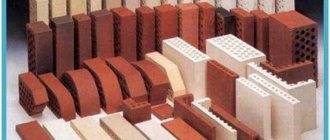

Differences between solid and hollow bricks

The types of bricks that are used in the construction of houses can be divided into solid bricks and hollow bricks.

They differ in the percentage of voids in their mass - for hollow ones they exceed 13%, and solid ones contain voids less than 13%. Typically, solid brick is used when building internal and external walls of buildings, pillars and columns, which are expected to bear a significant load on the remaining structures of the building. Solid brick is also called construction, ordinary or ordinary. Its properties include the ability to withstand bending or compression loads and excellent frost resistance. In addition, such bricks have moisture-absorbing properties that exceed 8%. Walls that are built of solid brick must be additionally insulated, because... they cool down greatly, releasing the accumulated heat. The main brand of solid brick is M-125 brick. The stronger the brick, the higher its grade. Hollow brick is widely used in the construction of walls and partitions, which should not have much weight, i.e. in the construction of lightweight structures. Hollow brick is called differently - hole-shaped, slotted, self-supporting. It is much lighter in weight, but less durable due to through or closed holes of various shapes. When producing this type of brick, less raw materials are consumed, so its price is much lower in contrast to the price of solid brick. Often builders use hollow bricks to reduce the thickness of walls. Contact with water is extremely undesirable for this type of brick; for this reason, it is not used for foundations, basements or basements. One of the main advantages of hollow bricks is its high thermal insulation. The air in the holes retains heat better. Brick manufacturers add peat, sawdust or pieces of coal to the raw material mass. When bricks are fired in a kiln, they burn, creating pores.

What is the difference between solid brick and hollow brick?

How do their properties differ?

They differ in the percentage of voids in their mass - for hollow ones they exceed 13%, while solid ones contain voids of less than 13%. Traditionally, solid brick is used when building internal and external walls of buildings, pillars and columns, which are expected to bear a significant load on the rest of the building's structures. Solid brick is also called construction, ordinary or ordinary.

Hollow brick is widely used in the construction of walls and partitions, which do not have to be heavy, i.e. in the construction of lightweight structures. Hollow brick is called differently - hole-shaped, slotted, self-supporting. It is much lighter in weight, but less strong due to through or closed holes of different shapes.

Solid and hollow - even the words themselves define the qualities of a brick.

Let's start with a solid one, this is a massive brick, it doesn’t matter what material it is made of or what size it is, but it is completely made like a monolith in one solid mass.

There are no voids or niches in it; this brick is very strong and can withstand significant loads.

Walls made of such bricks and high-quality cement become a monolith and cannot be destroyed over the years, since a solid brick has no weak points, but is completely strong over its entire area.

Load-bearing walls are always built from solid bricks.

Hollow bricks have technological niches and voids in their body; this is done to lighten the weight, save material, and also to increase resistance to heat loss and reduce cold permeability.

Such bricks are used exclusively for cladding; they are much less durable than solid bricks, and are also less resistant to wall destruction.

A wall built from hollow bricks can crack right along the brick, tearing them apart, and not at the seams as is the case with solid bricks.

These are the differences and properties of these bricks.

Solid brick is more durable (withstands greater loads both in compression and in fracture), due to the fact that there are no voids.

There is also a difference in price; hollow bricks are cheaper, because due to those same voids, less raw materials are used for its production.

They differ according to the place of application (use).

Foundations (basement) and load-bearing walls are built from solid brick, partitions and non-load-bearing walls are made from solid brick.

Solid brick is also used in multi-story construction, the reason is still the same - its strength.

Hollow brick retains heat better due to the air that is in those same voids.

When laying solid bricks, less masonry mortar is used, because the mortar does not get into the voids, the layer is uniform.

Hollow brick weighs less and, accordingly, the load on the foundation is less.

These are the main differences, but when constructing buildings, both solid and hollow bricks are most often used.

Hollow brick

Everyone undoubtedly knows what a brick is. But what a hollow or slotted brick is, and how it differs from an ordinary one, the average person will not say for sure.

What does a hollow brick look like?

Its manufacturing technology is no different from its main “competitor” - solid brick, with the exception of the slots. They come in different sizes and shapes. The most popular are oblong rectangular slits. And it is thanks to these holes that such a brick is not only lower in cost than a solid brick, but is also faster to manufacture (after all, much less raw materials are spent on it), and is also much better in thermal insulation due to the so-called “stagnation” of dry warm air. The only condition is compliance with the masonry technology, otherwise if cement or other building mixture gets into the cracks, all the “warm” properties will come to naught.

Sound insulation is also an important distinguishing feature of “perforated” bricks. It is achieved as follows: during production, straw, peat, and sawdust are added to the clay mass. When firing brick, all these components burn out and form voids in the thickness of the finished material, which is how porosity is obtained.

Application of hollow bricks

When constructing a building, much attention is paid to reducing the load on the foundation, because the durability and stability of the structure depends on it. That is why lightweight slotted brick is ideally suited for the construction of walls and various partitions. In addition, given the harsh Russian winters, the use of this brick will be more economical, because, unlike solid bricks, its thermal conductivity is much lower, that is, there will be no need to additionally insulate the walls.

Advantages of slotted bricks

1. Cost-effectiveness (lower cost, respectively, lower your construction costs). 2. Lightness (there is no extra load on the foundation, and the building looks more elegant). 3. Availability (you will never face a shortage of building material). 4. Decorative properties (walls made of such bricks look beautiful, they do not require additional cladding).

But it should be noted that when laying stoves, fireplaces, swimming pools, load-bearing walls and laying foundations, hollow brick is not used, since in terms of strength and impact resistance it is still inferior to its solid “brother”. When constructing basement premises, the use of this brick will also be inappropriate: porosity and the presence of voids in the hardness of the brick increase its water permeability. Moisture will enter the voids of the building material and cause gradual destruction.

Types of slotted bricks by size:

— One-and-a-half (or thickened) 250x120x88

— Double (ceramic stone) 250x120x140

Secrets of the right choice

First of all, look at the slots in the brick. Ideally, they should be of medium size, non-through, so that the building mixture fills them evenly, leaving small air gaps - this will provide excellent protection from noise and prevent the room from cooling.

Then carefully inspect the ceramic bar itself. Preference should be given to those specimens that have an even dark red, even slightly brown color. It is these bricks that will delight you with strength and durability, and will also not lose their noise and heat insulation properties, and, importantly, will be resistant to moisture.

It is not recommended to purchase bricks if the middle of the block is lighter than the rest of the mass. Such material did not undergo proper heat treatment and was not fired sufficiently. Walls made of unfired bricks have reduced frost and moisture resistance; they collapse quite quickly when temperature changes occur.

Burnt brick has a dark core and is quite suitable for construction. All useful properties are preserved if the block is of the correct shape, without chips or cracks. By the way, burnt bricks are in no way inferior in strength to fired bricks according to GOST; their main drawback is their low decorative properties.

Often blurry white spots can be seen on the brickwork, which disfigure the façade of the building. This plaque is called efflorescence. They arise due to the interaction of the brick itself, the mortar and the environment. This salty coating appears especially often at high humidity. In dry weather, the liquid evaporates from the surface and the salt crystallizes, forming unsightly white spots. In addition, efflorescence gradually destroys the integrity of the brick, and cracks may appear. Removing salt deposits is quite difficult; acids (hydrochloric, acetic) and alcohol, such as ammonia, give the best effect.

Salting out of brickwork can also be a sign of a violation of brick manufacturing technology. Therefore, it is very important to purchase building materials only from trusted suppliers, such as the ROSTAL company. Our specialists will be happy to tell you about the features and help you buy hollow bricks with delivery to your site.

How to choose and buy solid building bricks

Brick is a common building material. It is made in different ways from natural mineral raw materials. A distinctive feature of any type of this building stone is its regular rectangular shape, although the structure of the product may differ.

Which brick to buy: solid or hollow

Depending on the structure, there are two types of bricks:

- full-bodied (regular, ordinary);

- hollow (slit, hole, economical).

Solid building bricks are divided into:

- by size (single, one and a half, double);

- by production technology (ceramic, silicate and hyper-pressed);

- according to technical characteristics (facing and ordinary);

- by brand for strength (M50, M100, M200, etc.). The number means the load in kilograms that 1 cm² of the surface of the product can withstand.

In terms of price, a solid brick and its hollow counterpart are practically the same. Hollow brick has voids in its structure, which can amount to up to 45% of its volume. The presence of voids changes the physical properties of the building material:

- The weight of the product is reduced. This allows you to reduce the load on the foundation;

- Thermal insulation characteristics are improved.

Hollow products are used in the construction of walls and partitions of low buildings. It is unsuitable for the construction of multi-story structures and laying foundations. For this purpose, it is better to buy a solid brick.

The main types of facing hollow bricks.

Facade hollow facing bricks differ in several ways: size, color, texture, number of rows of voids, shape of bars, area of application, type of raw materials used:

- ceramic hollow bricks are made of fusible clay with special additives, suitable for masonry and cladding of buildings;

- clinker based on refractory clay with the addition of mineral additives, has high density and low porosity, excellent frost resistance, minimal moisture absorption, good decorative properties, a wide selection of colors;

- hyperpressed bricks are obtained without firing, by pressing under high pressure, low water absorption, high frost resistance, high-quality mechanical strength.

There are several types of facade hollow bricks on the construction market:

- textured, used for finishing window openings, arches, have various geometric shapes and facial relief imitations of the surface (tree bark, grass);

- two-layer with engobe (coating of liquid clay with tinting), white clay with the addition of dyes is applied to the base;

- glazed clinker brick is covered with glazed fusible glass to increase frost resistance;

- The private has a strict rectangular shape with a smooth surface.

Which brick is better, hollow or solid?

The popularity of brick in the construction of houses and cottages is largely due to its excellent characteristics and presentable appearance. There are two types of bricks: hollow and solid. In this article we will look at the advantages and disadvantages of both types and answer the question - “which Togliatti brick is better to buy?”

Solid brick Solid brick in Togliatti is a building material with a high level of strength and durability. Therefore, it is most often used in the construction of areas with increased load. For example, Tolyatti plinth brick is excellent for foundations, plinths or load-bearing walls.

The main advantage of solid brick is its strength. It is able to withstand loads from 75 to 300 kg/cm2. The advantages of this material also include:

• Frost resistance. Since a solid brick will not collapse even after 100-150 cycles of freezing and heating; • Fire resistance. Solid brick does not burn and can withstand temperatures up to 1000 degrees Celsius; • Wide scope of application. Can be used both in the construction of a private house and a multi-storey one.

Selling bricks from Tolyatti assumes that solid bricks have shortcomings. For example, its low thermal protection and high weight. So, in order to reduce heat loss, well masonry and insulation are used.

Hollow brick For a brick to be called hollow, 45% of the holes of different shapes (square, round, rectangular, etc.) are made in its body. This makes the product much lighter in weight, so it is not recommended to use it for areas with increased load. However, for the construction of partitions and hollow bricks that do not support the structure, the price of Togliatti is perfect.

The weaknesses of hollow brick include poor tolerance of sudden temperature changes and incompatibility with moisture. This means that this material is not suitable for the construction of stoves and chimneys, as well as for the construction of foundations in basements.

- Buy brick

- Brick catalog

- Brick prices

- Where to buy brick

2015 NIKA-BRICK - buy bricks in Togliatti. Website development by KwebeK.

Why do you need hollow and solid bricks?

Despite technological progress and the emergence of innovative building materials, brick does not lose popularity. The reason lies in the excellent characteristics of artificial stone. Competition pushes manufacturers to create new and improved types of products. For example, shaped brick, textured, porous. Colors and shades allow you to build masterpieces of design and architecture. To understand the assortment of construction supermarkets, you need to start with the basics - hollow and solid bricks.

When erecting brick structures, most people are guided by practicality and rationality. Different types of brick products differ significantly in price, although a cheaper product can give a better effect than an expensive one.

Visually, hollow and solid bricks cannot be confused, at least if you pick them up. The main difference is the presence of holes of different shapes and numbers. Both types are manufactured using general technology, the shape and dimensions are made according to the standards set out in GOST.

Solid and hollow brick

Depending on the raw material base, variety and purpose, all bricks are divided according to their structure into two types: solid and hollow. Hollowness affects the technical characteristics of the brick, scope of application and cost, and therefore is an important factor when choosing this classic masonry material.

Definitions

Solid is a solid brick in which there are no through technical voids, and the total volume of air inclusions is no more than 13%. It can be produced as a monolithic briquette or with small recesses for better adhesion to the solution.

Hollow is a brick that has through or one-sided technical voids of various diameters and geometries, which can amount to up to 50% of the volume. Previously, mainly hollow bricks were produced, with round, cone-shaped, one-sided recesses; modern bricks are most often slotted - with flat through voids.

Characteristics

The structure of the brick indirectly affects strength and directly affects thermal conductivity.

Strength

Both solid and hollow bricks meet standard strength grades. If solid and hollow bricks have M-150, it means that they are equally strong in compression and bending and will withstand the same load. The difference is that for hollow bricks the maximum strength grade is M-150, while solid bricks can be up to M-300, and solid clinker bricks can be up to M-500.

Thermal conductivity

Dense solid brick has virtually no air pores or voids, so heated air escapes through it unhindered. This explains its high thermal conductivity - up to 0.7 W/(m°C). Hollow brick, due to large volumes of air, conducts heat much weaker, and has a coefficient in the range of 0.34 - 0.50 W/(m°C). The minimum thermal conductivity of hollow porous ceramics is from 0.2 W/(m°C).

Frost resistance

This indicator practically does not depend on the structure of the brick; it is much more influenced by the raw materials and production method. As a rule, manufacturers produce both types of bricks with the same frost resistance, within the limits of the type. Ceramics, clinker and hyperpress are designed for a greater number of freezing cycles than silicate.

Application

Solid brick is intended for laying foundations, plinths and load-bearing structures with heavy loads. Basements, drainage pits, steps and columns are laid out of it. Solid bricks over M-200 are used for the construction of high-rise buildings. A special, heat-resistant variety of solid brick is used for laying fireplaces, stoves, barbecues and chimney systems. Ceramic solid brick belongs to a type of construction, ordinary brick, but silicate or hyper-pressed solid brick is often a facing, facade material.

Solid and hollow sand-lime bricks and their detailed characteristics

Sand-lime brick does not lose its popularity due to its strength characteristics: buildings of different heights can be built from sand-lime brick. Well, popularity is determined by the variety of materials. The basis of the classification here is division according to the density of the product.

According to GOST, both silicate stones and bricks can be hollow. A distinctive feature of the latter is the presence of holes.

Concept and features

Regulates the properties of both solid and hollow SK GOST 379-95. The brick is made in the form of a parallelepiped; the holes are assumed to be non-through and should be located perpendicular to the bed. The wall thickness must be at least 10 mm. However, by agreement with the customer, the number and shape of holes can be changed if this does not contradict established standards.

Hollow brick is characterized by the following features:

- less weight - voids make it possible to lighten the product without a large loss in strength, which is very important when constructing storey buildings;

- lower thermal conductivity - voids filled with air increase the thermal insulation properties of the product. Thermal conductivity is 0.56–0.81 W/(m*C);

- ease of installation due to the lighter material;

- The density of the product is lower - 1450–1550 kg/cubic. m. In general, hollow concrete is used in the construction of lower buildings;

- however, thanks to the voids, the water absorption of the brick also increases to 8–11%, which means less frost resistance.

The following video is dedicated to the features and concept of solid sand-lime brick:

GOST allows for different hollowness of the product. The classification is as follows:

- the degree of hollowness is 28–31%, that is, there are 14 holes in the brick measuring 30–32 mm;

- the degree of hollowness reaches 22–25% - the product has 11 cells with a diameter of 27–31 mm;

- 15% - implies 3 cells measuring 52 mm.

The dimensions of the SK, like any other brick, are strictly standardized: otherwise construction as such would be impossible. Several types are available with different thicknesses, while the length and width remain the same: length - 250 mm, width - 120 mm.

The thickness of different types is as follows:

- single sand-lime hollow brick – 65 mm. These sizes are called standard. This briquette weighs 3.2 kg;

- thickened or one-and-a-half silicate hollow brick has a thickness of 88 mm. Weight of one block – 3.7 kg;

- double - according to GOST it is called silicate stone. Its thickness is 138 mm, weight reaches 5.4 kg

Front and private SK

Material is produced for ordinary wall masonry, where some other finishing layer is expected, and material that creates a fairly attractive surface that does not need cladding. Accordingly, the products are called ordinary and facial.

Their requirements for appearance differ, but otherwise their characteristics are completely identical.

- The facial SC has a relatively smooth outer surface and very precise geometric parameters. The surface may be painted or unpainted. In any case, the shade must match the template, and color spots or color changes are not allowed. In the case of facial KS, this is considered a serious defect.

- Products according to GOST must have two front planes - a splice and a spoon. However, with the customer’s consent, bricks with one front surface can be produced. Rounding of ribs no more than 6 mm is allowed.

- Cracks, dull ribs, chips, as well as swelling, peeling or fine cracks are not allowed.

The requirements for ordinary products are much lower. However, here too there are very specific standards: defects in any case should not affect the strength characteristics.

- An ordinary SC can change color, and in a very wide range. Swelling and peeling are acceptable.

- Cracks up to 40 mm long are allowed - no more than 1, chips at corners up to 15 mm - no more than 3, broken edges up to 15 mm - up to 3.

- There should be no fractures or inclusions of other materials with a diameter of more than 5 mm.

We talk about the application and prices of hollow silicate bricks of different sizes below.

Application and cost of material

- SK is used in multi-story construction, since the strength of sand-lime brick allows pressure up to 2.5 MPa. However, other properties of the product somewhat limit its use.

- The thermal conductivity of hollow SC is lower than usual. However, it is by no means a thermal insulation material. Its use is based precisely on the greater lightness of the blocks.

- Load-bearing, self-supporting walls, interior partitions, unloaded structures, and so on are erected from SF.

Is the brick solid or hollow?

- Solid or hollow brick: expert opinion on the choice

- Hollow or solid: questions and answers

Solid or hollow brick: expert opinion on the choice

In the modern construction industry, the widest range of masonry materials is used. However, despite the constant replenishment of their ranks with new types, brick remains the most common and popular for a long time. In our review we will try to give a detailed answer to one of the most popular questions related to this material. We are talking, of course, about which brick is better, solid or hollow, and how to make the right choice between the two varieties.

To obtain the most reliable information, we will use the recommendations of experienced specialists in the field of construction and design. This will allow you not only to make the most correct choice between solid and hollow bricks, but also to generally evaluate all the advantages of using one type or another, which may be useful during construction work in the future.

Hollow or solid: questions and answers

For ease of perception of all the information presented in our review, we will consider the main differences between solid and hollow bricks in the format of questions and answers provided by experts.

What is the difference between hollow and solid bricks in terms of product structure?

This indicator is illustrated by the very names of each species. Thus, a solid brick does not have internal voids, while a hollow brick, accordingly, does.

An exception may be when manufacturers create voids of a technical nature in a solid material. They are necessary to relieve increased stress during firing.

Moreover, the sizes of such voids are extremely small, and they have virtually no effect on the manifestation of the basic physical and technical properties of the material.

What is the difference in strength between solid and hollow bricks?

To give an accurate answer to this question, you will need to take into account a number of indicators inherent in each type.

We are talking about brand, density and other parameters. Therefore, if, with completely identical characteristics, a solid structure has higher strength, then a brand such as, for example, solid brick M-150 will not be as strong as hollow brick M-200. However, returning to what was said earlier, we note that if we are talking about the construction of a plinth, foundation and other load-bearing structures, then when the question arises of which brick to choose, solid or hollow, preference should be given to the first.

Which brick is warmer, hollow or solid?

First of all, it is necessary to amend the wording of the question itself. Of course, we are not talking about the temperature of the material itself, but about such an indicator as thermal conductivity. The higher this parameter, the less effective the structures will be in terms of heat conservation. For this parameter, it is much preferable to choose hollow marks. It is these that experts recommend for laying internal and external walls, as well as interior partitions.

Which brick to choose for building basements, hollow or solid?

The presence of voids in the structure of the material increases such an indicator as moisture permeability. As the outside temperature drops, the water may freeze and its volume will increase. Such an impact can lead to destruction of the material from the inside. It is not difficult to guess that according to this parameter, hollow brick is inferior to solid brick. Therefore, it is not recommended for use in the construction of basements and other unheated facilities exposed to external temperatures.

Here are just some recommendations on which brick is better, hollow or solid, for use in a given situation. By contacting the services of the specialists of the Vector Group of Companies, you will definitely receive any additional information of this kind. Moreover, our experienced managers will definitely select the optimal type of solid or hollow brick for you, help you calculate the amount of material required for your facility and resolve all organizational issues related to the purchase.

Which brick is better

Which brick is better

Brick is used to build dachas and cottages, residential buildings and industrial buildings, erect internal partitions, foundations, fences, lay chimneys, barbecues, stoves and fireplaces, use them for interior and exterior decoration of buildings, pave sidewalks and paths. There are many other building materials, but brick remains popular today. The construction market offers a large number of bricks of various colors and quality.

Many people are concerned about the question - which brick is better?

? We will try to talk about the types of bricks and the rules for choosing them in order to choose the good brick that you really need.

Which brick is better?

You need to have a complete understanding of the different types of bricks and their properties.

The most popular types of bricks:

Silicate (white) - consists of quartz sand, lime and additives. Used for the construction of walls.

Ceramic (red) - made from clay, water and additives. The mixture is mixed, bricks are formed, then dried and fired. When you hit a good brick, it makes a ringing sound. Products must have a quality certificate. Suitable for all types of buildings.

Hyper-pressed - contains rock crushing screenings, cement, water and dye. Used for decoration (cladding) of buildings.

Clinker - made from refractory types of clay and fired until completely baked. They are used for finishing facades, for interior decoration; they are used to lay fences, columns, bay windows, sidewalks, steps, etc.

Fireclay (fireproof) - the basis is baked fireclay clay. Used for fireplaces and stoves.

People often ask which brick is better - silicate or ceramic.

For different construction work, different types of white or red bricks are used, which differ in certain properties. There are restrictions on the use of silicate (white) bricks.

White brick is not recommended for use where there is constant contact with water and at high temperatures. Therefore, when building foundations, cellars and basement structures, laying stoves, baths, and chimneys, certain brands of red brick are used. When asked which brick is better - white or red, the answer is that they can be neither better nor worse. Each type of brick is good in its field of application, in accordance with its technical characteristics. If you choose based on price, which one is better, then definitely white. It is much cheaper than red. For each type of brick, there are GOST standards for the basic properties.

Which red brick is better? The brick has its own marking according to its tensile strength (which can withstand a load per 1 cm2). For single-story buildings, bricks M100 and M125 are used, for multi-story buildings - from M150 to a maximum of M300. We also look at the frost resistance index - F, which indicates the number of freezing and thawing cycles. The lowest value is F25, and the most frost-resistant are F200 and F300. Depending on the climate, choose the required brand of brick.

Which sand-lime brick is better?

Like red brick, sand-lime brick has a tensile strength grade. M100 is used for low-rise construction (1-3 floors). For multi-story construction, choose M150 or M200.

A high-quality brick must have the correct geometric shape, without chips.

Solid and hollow brick. Which brick is better, solid or hollow?

Solid bricks are produced without holes or may have no more than 13% of them. This product has quite a lot of weight, high strength, but it does not hold heat well. Suitable for load-bearing structures and foundations.

Hollow bricks are produced with holes. Due to the voids, it retains heat well. When asked which brick holds heat better, the clear answer is hollow. This product is lightweight and reduces the load on the foundation. Such bricks are used for internal partitions and cladding of facades (their insulation).

As a result, the choice of a certain type of brick depends on the characteristics of the object being built.

Single, double and one-and-a-half bricks.

The following questions often arise: which brick is better, single or one-and-a-half, and which double ceramic brick is better.

A single brick has dimensions

— L 250 mm, B 120 mm, H 65 mm.

One and a half brick with dimensions

: L 250 mm, B 120 mm, H 88 mm. Used for lightweight masonry. They are produced hollow, perforated and porous.

Double brick has dimensions

- L 250 mm, B 120 mm, and H 138 mm. They are produced with holes (slits) and are used in lightweight masonry. Double brick has different properties, which depend on the additives and type of clay, and is available in various shapes and textures. The choice depends on what you are going to build - a foundation or a building.

In 1 m of masonry in height there are 13 rows of single, 10 rows of one and a half and 6.5 rows of double bricks. Stronger masonry made from taller bricks.

From an economic point of view, the higher the brick, the lower the cost and the higher the laying speed. But in general, it all depends on your preferences and the main thing is that it fits the characteristics.

Construction and facing bricks.

Construction (ordinary) brick is used for the construction of foundations, walls and partitions. Walls require protection and insulation. The facing brick has precise geometric dimensions and a beautiful appearance. It is used for finishing facades, plinths, interior and exterior decoration

Which brick is better to buy? The choice depends on the design of the building, the terrain and climate. Pay attention to density, strength (M), porosity, thermal conductivity, frost resistance (F), fire resistance and moisture resistance.

Which factory's brick is better? In the Samara region, in Tolyatti, at the Mattone plant, you can buy facade textured and facing bricks of the correct geometry, different sizes and a wide range of colors. There are 350 types of high-quality and durable products for you.

Build practically and beautifully with MATTONE bricks.

Which brick is better for building a house?

Man has been building his houses from wooden logs since time immemorial, and from bricks for many hundreds of years, ever since he managed to burn clay on fire and realized that the resulting material is durable, beautiful and convenient for building the walls of a home.

In ancient Egypt there were already buildings made of baked brick, and various structures made of raw brick date back to earlier eras. Of course, the technology for making modern bricks is strikingly different from the ancient ones, but the popularity of this building material remains high. Those who are accustomed to the depressing monotony that reigned on the building materials market during the Soviet era will most likely be pleasantly surprised and even delighted to see how many varieties of bricks are offered to a potential buyer today to choose from. The information provided in this article will help you not to drown in this sea of colors and shapes; in it we will try to determine which brick is best to use for building a house.