Purpose

The prepared concrete solution, despite thorough mixing, remains heterogeneous, which reduces the characteristics of the monolith. In addition to cement laitance, crushed stone and sand, it contains water and air bubbles.

If concrete is simply poured into the formwork, the result will be a structure that is heterogeneous in structure. The use of a vibration compactor for concrete increases the fluidity of the mixture without additional additives, due to the movement of its components. Air inclusions are pushed onto the surface of the monolith, and the fillers are evenly distributed throughout the volume.

After vibration compaction, the volume of concrete poured into the formwork is reduced by 30%. This effect occurs due to getting rid of air-filled voids and more dense packing of sand and crushed stone. As a result, the strength of the massive structure reaches its maximum value and high density for a given grade of concrete.

Principle of operation

In private and industrial construction, a submersible vibrator is more often used; other models have similar operating principles. The design is based on a unit that creates vibration vibrations of a frequency sufficient to squeeze out air bubbles and foreign inclusions and compact the fillers.

In the design of vibrators, the main unit is a shaft with an eccentric, which is immersed in concrete. Rotates from a drive connected to a gasoline, diesel, electric or pneumatic motor. The rotation is transmitted through a strong but flexible steel cable. The shaft itself is located in a vibrating tip or mace - a steel cylinder and is attached to the end of a rotating cable covered with a sheath.

The source is a single or three-phase electric motor of 220 V or 42 V. There are portable models with rechargeable batteries. For large volumes of concrete, it is better to work with gasoline internal combustion engines. The most productive devices are connected to diesel engines; they are designed for compacting large masses of concrete.

Device: 1 - mace (vibrating tip), 2 - flexible shaft, 3 - drive

Types and characteristics

There are 3 types of concrete vibrators, differing in design:

- A deep vibrator immersed in a freshly poured solution. It is used in construction, when concreting large monoliths and foundations of buildings and structures.

- Platform vibratory compactors are used when pouring floors and roads. A surface vibrator is an oscillating plate or strip. By acting on the top layer, the slab compacts the entire monolith.

- External type vibrators are fixed to the formwork. They are often used in the construction of columns with dense reinforcement.

Vibrators differ in drive type:

- Electric - have a relatively small mass and work in any conditions. 220 volt vibrators have the lowest power, three-phase options are massive and require special conditions to provide power.

- With internal combustion engines - high-power petrol and diesel models. They are quite bulky and require professional maintenance, but can work on sites without electricity. Their high power makes it possible to compact large monoliths.

- Pneumatic models operate from a compressor, the force is transmitted through a high-pressure hose, and are used in reinforced concrete factories; they are not widely used in construction.

Based on power, portable vibrators are distinguished with motors up to 2 kW. They are inexpensive, do not require professional training to operate, and are suitable for private construction. Professional vibrators have a power of up to 4 kW, can operate for a long time, and are used in industrial construction, in the construction of monoliths and in the production of reinforced concrete structures.

In addition, vibrators are classified according to shaft rotation speed:

- Low-frequency models with shaft speeds up to 3500 rpm provide a large amplitude of the vibrating shaft. They are used for concrete with coarse-grained fillers that have low mobility.

- Mid-frequency devices up to 10,000 rpm, the most popular option with universal characteristics, are used to work with mixtures of varying degrees of mobility.

- High-frequency vibrating tools, a frequency of more than 10 thousand revolutions per minute, with a small amplitude, are suitable for moving mixtures with fine grain fillers. Ultrasonic models have a similar area of application.

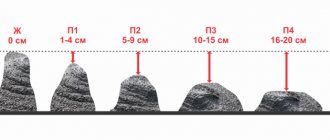

These devices differ in shaft length, which can vary from 0.5 to 20 meters. This makes it possible to process volumetric monoliths, column foundations, and reinforced concrete structures. Submersible models come with a club diameter from 25 to 110 mm.

The thicker the reinforcement, the smaller the diameter of the club used.

Assembling a vibrator with your own hands from a drill

If you need an internal vibrator, you can simply assemble it from an electric drill.

Before making a homemade vibrator for concrete, you need to understand what the operating principle of the device is based on.

An ordinary drill can be found in almost every home. The main driving force of such a device will be the transformation of rotational motion into oscillatory motion.

The main driving force of the device will be the most ordinary drill

Selecting material for vibrator assembly

To assemble such a device from a drill, any tool with a power of 1 kW or more is suitable. You will need an eccentric nozzle and a durable stainless steel tip. In addition, the following must be available:

- stainless steel tube 55 cm long and Ø 4 cm;

- metal rod Ø 15 mm;

- a piece of rectangular metal rod;

- two high-quality bearings and a bushing;

- bendable reinforced hose with waterproofing or durable rubber tube;

- internal rod for the tube (you can take the speedometer cable).

Assembly tools

To assemble a vibrator you need to have a set of the following tools:

- set of metal drills;

- electric or gas welding;

- hacksaw;

- rectangular rod.

Stages of manufacturing a deep vibrator

The structure is assembled in the following order:

- We select a stainless steel tube about 40–60 cm long and Ø 3–4 cm. To construct the internal rod, you need to take a metal rod Ø 12–15 mm. It will shift the entire mechanism system in a certain direction and provide vibration vibrations. Since concrete is a very aggressive environment, stainless steel is the only suitable metal for making a vibrator.

- We make the central part and prepare the metal tube, and then combine them with each other. First, we drill a hole through one end of the rod through which we will attach the drive to the device.

- In order for the core to “walk” easily and freely without friction, you need to take several high-quality bearings, in the middle of which the rounded part of the end of the rod will be installed. Then it must be threaded inside the tube, and the bearings must be hammered in on both sides until they stop.

- If the end of the rod protrudes too forward from the side of the bow, then it must be cut to a length of 5 or 10 mm. Also, the bearings must be reliably protected on both sides with a homemade metal cover from the penetration of dust and dirt into them, otherwise the device will stop rotating and it will be impossible to operate it. Bearings must be of high quality, since they bear the heaviest load on the vibrator.

- We put a sleeve on the second end of the flexible rod that will tightly cover the rotating element of the vibrator.

- We prepare a tube made of thick rubber or bendable plastic and a movable rod for assembling the internal device, which can bend freely. From these elements we make an eccentric shaft, which is designed to connect an electric drill with an attachment that creates vibration vibrations.

- We put a tube on the shaft so that there is 4–5 cm of margin left on both sides of the shaft. The rotational movement of the rod creates a certain vibration, which is necessary for the operation of the entire device.

- Next, on one side we thread a special bushing into the rod. We rest against the core rod where the hole was made and connect them together. We stuff the bushing so that it fits tightly into the bearing and well hides the connecting “seam”.

- Then we pull the hose onto the sleeve and fasten it tightly with a clamp, and also make a protective cover for the tip from some dense material.

- The result is a concrete vibrator made from a drill.

An electric drill is the optimal tool if you need to make a submersible concrete vibrator

How to choose?

At the first stage, the type of vibrating tool is selected - for screeds and other extended structures of small thickness, a surface type device is selected. The deep vibrator is widely used in construction work, when pouring foundations and other structures. External vibrators are used in the production of paving slabs; they are also necessary for compacting screeds and floors of relatively small thickness and large areas.

Another selection criterion is the power of the equipment, on which the time of its continuous operation depends. In private construction, the most popular are deep portable vibrators with a power of 0.8 to 1.5 kW. At dachas and other facilities where there is no centralized power supply, battery models can be used. In industrial construction, in the production of structures, devices for compacting reinforced concrete from 3 to 4 kW are more often used.

To obtain optimal mixture quality, the rotation speed must be taken into account. For concrete with coarse fillers, a low-frequency tool with a large vibration amplitude is used. If you use other models, the composition will separate and the quality will decrease. For private construction, it is better to choose a mid-frequency vibration compactor with a wide range of settings, suitable for solutions with different fractions of fillers. The high-frequency tool has a narrow specialization and is used for fine-grained concrete.

An important parameter is the weight of the equipment. For construction work on a personal plot, power tools weighing up to 6 kg are often purchased. Installations with higher power weigh up to 18-20 kg; this is semi-professional equipment used by private teams. The powerful professional tool weighs 90-100 kg and requires several people with special training to operate it.

When selecting a submersible vibrator, pay attention to the diameter of the tip (club), driven by a flexible shaft. Densely reinforced structures require vibrating tips with a diameter of 15 mm, options up to 50 mm are allowed. To compact a conventional unreinforced monolith, large diameters of up to 110 millimeters are used.

The choice also depends on the depth of the formwork. To use the vibratory compactor effectively, the drive tube must be 1 meter longer than this depth. This will leave freedom of maneuver, which is taken into account in the manufacture of vibration equipment.

How to make a vibrator from a hammer drill?

Drill based assembly

There are two options for achieving the desired result: connecting the tool with purchased ready-made factory attachments or making your own vibrating mace. The technology in the second case is more complex; for assembly you will need:

Alternative schemes

In addition to the drill and hammer drill, other construction and household tools with an engine of the required power are used for self-assembly. They can be done:

When selecting the frequency and amplitude of vibrations for self-assembled internal vibrators, you should focus on the instructions for electrical appliances, the type and expected mobility of concrete.

In what cases is it easier to buy than to make?

For one-time processing of small structures, homemade products are more than enough; for regular and professional use, a factory model is required. It is not advisable to specifically buy a drill or hammer drill.

Kawabanga! Types and purpose of concrete breakers

DIY concrete vibrator

It’s easy to make a reliable and functional vibrator with your own hands; all you need is a suitable power tool with variable speed control. Its drive must be reliable so that the bearing can withstand the eccentric runout.

From a drill

To make an internal vibrator with your own hands, you can use a regular drill. The easiest way is to purchase a ready-made nozzle with a mace. Such drives that transmit force to the shaft can be found in stores that sell ready-made equipment.

Most models have a hexagon on the shaft. If not, an adapter is made that is clamped into the chuck. The protective casing is a tube with several holes into which bolts are screwed. They tighten, resting against the body, which is quite enough.

You can also make a mace yourself. To do this, take a metal cylinder on which the bearings are fixed. A steel rod is passed through them, onto which a weight is welded in the part located inside the cylinder, providing an eccentric. When working with shallow-depth monoliths, the flexible drive that transmits force to the vibrating tip can be replaced with a steel rod.

It is important to ensure the tightness of the structure.

From a hammer drill

This is the easiest way to make a deep concrete vibrator. Several rods are added to a regular lance to increase the processing area, and it must work with impact to create oscillatory movements. Such a vibrator is convenient in private construction, but it is difficult to use in reinforced massifs.

Using a scoop or trowel, you can make a surface vibrator for compacting concrete from a regular hammer drill. It is enough to place the rod on a scoop or trowel in impact mode and place them on the solution. After switching on, the top layer will begin to compact.

Surface vibrator

For a homemade vibrator for concrete screeds and other large surfaces, you can take any motor and attach an eccentric weight to the output axis. This design is mounted on a flat plank, maybe even a wooden one, to which a handle is attached. The bar is installed on the solution, and the vibrator is turned on, vibrations are transmitted from the upper layers to the bottom of the structure.

Operating principle of a deep vibrator

You don’t even have to compare the efforts that are expended when carrying out construction activities using “human” traction and using a submersible vibrator - the work time is reduced enormously. A device that starts working by starting a three-phase electric motor with a short-circuit base in the rotor is very effective when working with concrete.

The structure of the device’s operation is quite simple: mechanical rotation is imparted to the hose, then the transition occurs towards the vibrating head. When it comes to choosing the optimal length of a flexible shaft, it usually helps to compare the severity of the monolithic work to be carried out.

You should stock up on vibrating pins of different diameters, because you may have to work with different types of formwork. The electric vibrator creates an abundant wave that vibrates in the deepest layers of concrete. So it is best to have vibrators of several diameters.

Deep vibrator device