Types of linoleum

Manufacturers offer two types of this flooring: natural - marmoleum (made from plant fibers and linseed oil, resin or wood flour) and artificial - linoleum.

Artificial turf has its advantages:

- Easy to install by yourself.

- Easy to maintain (wash).

- There is no need to apply an additional protective coating (unlike parquet).

- Good thermal insulation characteristics.

- Variety of patterns and colors.

Depending on the composition, linoleum can be:

- Rubber-based (for finishing children's and sports grounds).

- Colloxylin (with increased elasticity).

- Glyphthalic (from alkyd resins).

- PVC (the most common type, used in all types of premises).

PVC coating comes in several varieties:

- baseless (single-layer),

- multilayer (based on foamed fiber),

- reinforced (usually fiberglass, characterized by high tensile strength).

A single-layer coating is called homogeneous, it is less durable, the service life is about 6 years. Multilayer linoleum is heterogeneous, consists of several layers (including protective ones) and lasts about 10 years.

The main disadvantage of linoleum is the dents from heavy furniture that remain on the surface over the years.

What are the features, how to choose the type of linoleum

Before starting work, choose the type of coating according to the project and wishes.

Depending on the area of application, coatings are divided into household, semi-commercial and commercial. The last two types are used for industrial buildings, water and railway transport, in places where there is increased load (including transport, for example, in warehouses).

Conventional coating is intended for flooring in residential buildings, apartments, office and commercial premises, where the load on it is not so significant. In terms of quality, this linoleum is the most fragile. Even when used in an apartment, it can quickly wear out and lose its qualities.

It is very difficult to lay commercial flooring yourself without hiring hired workers. You can lay household linoleum with your own hands.

To choose a coating suitable for a specific room, you must rely on the technical characteristics of the material:

- Antistatic.

- Density.

- Sound and heat insulation.

- Water resistance.

- Chemical resistance.

- Strength (rate of abrasion and punching).

- Flammability.

When choosing a material, you need to pay attention to how it smells. After laying linoleum on a concrete floor, the strong and pungent odor will be difficult to remove from the room.

The packaging indicates the marking of the material, including its class. The higher it is, the stronger the linoleum and, accordingly, more expensive. The first digit of the class indicates the type of room in which it is recommended to use this coating (1 - minimum traffic, 2 - living rooms, 3 - offices, 4 - industrial premises). The second digit characterizes the permissible load intensity as it increases from 1 to 4.

Before purchasing a coating, you need to check its quality: the surface should be smooth, the layers should not move away from each other.

Do you need a backing for linoleum?

There is no clear expert opinion on the need to use a substrate, so each situation is considered.

Substrates are:

- Cork (universal, environmentally friendly, durable, expensive).

- Jute (inexpensive, hold their shape well, moisture resistant, durable).

- Linen (eco-friendly, cheap, available in different thicknesses, breathable).

- PET (cheap, affordable, short service life, non-breathable).

- Combined (consist of wool, flax and jute, combining all the advantages of substrates made from these materials).

- Conifers (consist of fibers and resin, prevent the formation of fungus).

- Composite (granules between two layers of PET, good thermal insulation).

- Chipboards (plywood, fiberboard, OSB; swells when in contact with moisture).

The underlay is used in case of a damp floor: if the room is on the ground floor or above an unheated space (basement, arch), the underlay will help avoid moisture and insulate the floor.

If you purchased thin and inexpensive linoleum, then it is also better to lay a substrate under it.

High-end multilayer heterogeneous material is already produced with a substrate and does not require additions.

Another case of using the underlay is an uneven subfloor. If it cannot be corrected with a screed, then the substrate can correct the situation, but only slightly.

How to prepare a concrete floor for laying

Before laying linoleum on a concrete floor, you need to prepare the subfloor. The better this is done, the longer the final floor covering will last. The choice of method for preparing a concrete floor for laying linoleum depends on the budget, technical characteristics of the room, and the skills of the craftsman who performs the construction work.

The main preparation of the floor for linoleum flooring is to make the surface smooth, even, clean and dry.

Wet screed

Floor screed using the wet method is made from a cement-sand mixture. It is the cheapest and easiest to manufacture. The solution is subject to shrinkage, and in cases of improper care during hardening, cracking. Therefore, this type of screed is most often additionally reinforced with mesh.

The surface is prepared for leveling: debris and elements of old finishing are removed, and dust is removed. Then mix the cement mortar or buy ready-made.

Waterproofing is done around the perimeter of the room, joints are sealed, large cracks and cavities are sealed with concrete or foam. Beacons are placed for even pouring of the solution. Lay the reinforcing mesh.

They start pouring the solution from the far wall and spread it throughout the room. The height of the screed is determined by SNiPs and depends on the overall height difference in the room, the installation of heated floors, and the need for additional heat or sound insulation. Usually a 3 cm thick screed is sufficient.

The leveled cement mixture is left to gain strength. The surface must be additionally moistened or covered with polyethylene. This will avoid the formation of cracks.

A wet screed dries completely in 1-1.5 months. You cannot lay linoleum before this date: it will begin to get wet and rot.

Dry screed

This method of preparing the subfloor reduces repair time, since there is no need to wait for the screed to harden.

Beacons are installed on the cleaned floor with waterproofed joints. Dry insulating material is poured between them: it can be expanded clay, polystyrene or quartz sand. The height of the beacons should not exceed the height of the backfill layer. The backfill is leveled using a long rule and left for a day.

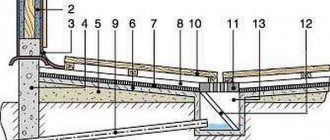

Sheets of screed are laid on top of the mixture and beacons: plasterboard, plywood or gypsum fiber board. The edges of the sheets are coated with construction adhesive and laid in two layers so that the joints of one row do not coincide with the joints of another. The joints are sealed with putty.

Self-leveling mixture

The floor is cleaned of debris and dust, waterproofing is organized, and a damper tape is attached around the perimeter of the room at floor level to compensate for the shrinkage of materials. Beacons are installed.

The prepared solution is poured onto the floor. Due to its plasticity and liquid consistency, it spreads evenly over the entire area of the room. There is no need to level the mixture as a rule; a wide spatula is sufficient.

Use a spiked roller to roll the surface that has not yet hardened to remove air bubbles and avoid the formation of cavities.

You can walk on such a floor within two days, but lay linoleum only after complete drying, the duration of which depends on the thickness of the layer.

Work technology

As mentioned earlier, laying linoleum on a concrete floor with your own hands is not difficult. After reading some recommendations, it is not difficult to lay such a covering without outside help.

Selection of materials and tools

The concrete field itself is quite cold, so when choosing a covering, pay attention to multi-layer linoleum on a felt basis. This coating is more expensive, but the price fully corresponds to the properties. Based on the size of the room, you should not take the material exactly as measured - it is better to take a few centimeters of stock. If the pattern is large, and one piece will not be enough to cover the entire room, take the material taking into account the fact that you will have to select a pattern.

You don’t need any special tools for DIY installation – just have a brush and rollers on hand. Only at the cutting stage you will need a knife (stationery or construction knife, depending on the thickness of the coating), a square and a ruler for accurately marking the lines.

Having unrolled the linoleum roll, transfer the floor plan onto it with chalk.

When purchasing linoleum, you can ask for it to be cut right in the store, but there is still a chance that you will have to cut it during installation. Cutting is not a difficult process; all errors and uneven edges will be hidden by the baseboards. If there are protrusions, columns, or pipes in the room, it becomes necessary to cut out some sections of linoleum in shapes. For such work, you need to prepare cardboard templates - then errors and irregularities will be minimal.

Before laying, linoleum with an exact pattern must be laid face up, the borders should be joined to ensure the correct placement of the pattern, and fixed with a heavy object to prevent the knife from slipping along the linoleum while cutting the material.

Actually, we have reached the main stage of work. There are several options for DIY installation - for example, in a low-traffic room with an area of up to 20 square meters. m do not require additional fasteners at all - just secure the linoleum with a plinth. For other cases when it is necessary to lay linoleum on a concrete floor, there are three most common, simple methods.

On a concrete screed

Craftsmen recommend making a concrete screed before laying the covering - this will level the base and the linoleum will lie more tightly. Before pouring the screed, there should be no debris or any debris on the concrete floor that could spoil the smooth surface. Pour the cement mixture, level it over the area of the room and wait until it dries completely. Next, it is recommended to carefully clean the surface with a brush and lay the linoleum, which has previously been left unrolled for several days.

We recommend: Flooring in an apartment

Gluing with tape

This method is best used if you need to lay linoleum on a concrete floor, but the coating is not too rough. First, double-sided tape is glued to the prepared, cleaned and degreased floor, without removing the protective film on the other side. The strips of adhesive tape should form a kind of grid - this way the linoleum will hold more firmly. We spread the covering, fold one half and remove the protective film from the tape. Carefully unfold the canvas, then you need to level it, simultaneously pressing it to the floor - with your hands or with a roller. We do the same with the other half of the linoleum.

Using construction adhesives and mastics

It is best to buy adhesives in the same store where you buy linoleum - a consultant can tell you which product is best suited for this type of coating.

There are two types of adhesives, they are divided depending on the gluing method: for continuous and for fixation. The costs of the second are much lower, and application is less labor-intensive. Manufacturers offer the following types of adhesives:

- water-dispersed;

- one-component;

- two-component;

- on a solvent;

- polyurethane;

- for fixation.

When laying linoleum, glue is applied with a notched trowel, roller or brush.

The glue is applied over the entire floor area or pointwise around the perimeter of the room (adhesive for fixation). Due to the properties of moisture resistance and high strength, bitumen mastics are often used when laying linoleum. If the work takes place in a room with a large area, then the use of mastic is a must. In addition, with the help of this material you can isolate the floor from the harmful effects of moisture, level out minor defects and unevenness after concrete screed.

Before applying mastic, the floor must be well primed, the composition is applied to the floor and linoleum - a layer of about half a millimeter for a thin coating, for a coarser one - up to 0.9 mm. When choosing mastic, give preference to well-known manufacturers - their products are of high quality and reliability.

Welding joints

Exactly following the technique of laying linoleum with your own hands is not enough for a good result. Incorrect joining of the panels can ruin the entire appearance of the floor. There are two welding methods for joining linoleum sheets - cold and hot.

The advantage of this type is that it requires a minimum of time and effort. In fact, it is not much different from ordinary gluing. Tape is applied to the joints and cut along the joining line. Glue is poured into the resulting gap; after it dries, the adhesive tape is removed.

Hot welding of a freshly laid coating is not recommended.

Hot welding requires more time and precision when working, but this is justified by the result. The seams become almost invisible, the life of the linoleum is noticeably extended.

For hot welding, you must have welding equipment and a special fastening polymer cord. The work can be divided into two stages:

- Place the cord in the welding machine, heat to 350 degrees Celsius. The side from which the paintings will be fastened does not matter, but is carried out exclusively in the direction of the middle of the room. The melted cord is poured exactly into the gaps, after the product has hardened, the excess is cut off using a sickle-shaped knife (you can also use other types of sharp cutting tools).

- The equipment is transferred to the other side, and the polymer begins to be poured. The center seam should lie on top of what was just applied; after application, repeat the procedure for removing excess with a crescent knife.

It is more difficult to align joints on linoleum with a large pattern - make sure that the pattern matches correctly. And most importantly, this process cannot be rushed.

Description of installation, step-by-step description of the process

Before laying linoleum, a number of preparations are made:

- Check the concrete base for cracks, defects, and unevenness. The floor is vacuumed and all small debris is removed.

- Warm floors, if any, are turned off 72 hours before installation.

- Linoleum is left spread out in the room for a day.

- The room should be dry and warm (not hotter than +25o)

The following tools are prepared for the work:

- Roulette.

- Level.

- Spatula (preferably metal).

- Knife.

- Lapping board (to squeeze out excess air from under the coating).

- Glue.

- Rollers for different types of work.

- Masking tape.

After completing all preparations, proceed to laying the covering:

- The material is laid so that it lies close to one or two walls, making a slight overlap on the wall (no more than 5 cm). Leave for several hours.

- The material is cut with a utility knife to the size of the room, not missing the cutouts for the pipes.

How to install with and without glue

There are several options for attaching linoleum to the floor. The order of work depends on their choice. Not only glue is used as a connecting composition, but also a variety of mastics (moisture-resistant material, can be used as waterproofing).

If linoleum is attached with glue:

- Prepare the adhesive composition: the type of glue or mastic is chosen depending on the type of linoleum. As a rule, recommendations for adhesive are indicated on the packaging of the floor covering.

- The glue is applied to the floor surface with a notched trowel, and the mastic is applied with a plastic tool.

- Work is carried out sequentially in small areas. Until the adhesive has set, it is necessary to expel excess air from under the coating with a special roller. You need to roll from the center to the edges. If you don't have a roller, you can use a padded board.

- The drying time of the glue is indicated on the packaging.

The second way to attach the finishing coating is with double-sided tape:

- Adhesive tape is glued around the perimeter of the room on the floor and inside every 45-50 cm.

- The linoleum is rolled out from above, ironed with a roller or board to ensure uniform gluing and remove excess air.

This method is much easier and faster. It allows, if necessary, to quickly remove the linoleum and reuse it. But it is not recommended to lay linoleum on tape in rooms with a large area.

How to properly lay linoleum on a concrete floor: instructions and video

The use of linoleum as a flooring goes back to Soviet and early post-Soviet times, however, with the constant development of technology, production capacity and design, modern linoleum should not be considered a relic of the past - both the quality and visual characteristics of this material have increased. Linoleum is very popular in many office spaces due to its resistance to wear and relatively low susceptibility to mechanical damage; it can and is successfully used in apartments and houses.

Typically, linoleum is laid in rooms with high humidity - kitchens, hallways, balconies and loggias, but due to the variety of patterns it can also be used in living rooms.

Visually, using linoleum you can imitate a stone, tile, laminate or parquet coating, but it is much cheaper and easier to install yourself than any of the listed coating options.

We recommend: Polymer flooring device technology