Which floor insulation for linoleum to choose and how to install it

Linoleum is the most commonly used flooring. It has gained such popularity due to its remarkable qualities, such as strength, long service life, ease of installation, and a large selection of colors. Despite all these advantages, it has one significant drawback: the material itself is not warm and if the base for the floor is concrete, the floor will be very cold. Therefore, insulation for the floor under linoleum is necessary.

How to insulate a floor

Installation of insulation on the floor under linoleum can be done in several ways:

In the classic version, adhesive mastic is used. It is applied using a metal spatula. It is allowed to coat well only the joints.

Of course, before laying it is necessary to prepare the base and tools. To work you will need:

- Knife for cutting the required length of material;

- Masking tape for fastening;

- Polyethylene film;

- Scissors;

- Fasteners (screws, bolts).

If there are no differences on the wooden or concrete floor, then you can safely begin the work. If they are present, it is recommended to walk over the base several times with a primer.

Leveling the floor with chipboard sheets

If there is a damp room under the floor, waterproofing is recommended. In other options, its installation is not required. Small recesses in the concrete floor are filled with putty. If the defects are significant, it is recommended to use a concrete screed.

- Rigid insulation.

Laying rigid insulation

Kawabanga! Emaco repair mixture

The bars are secured to the base using dowels. The insulation is inserted very tightly into the cells. The top of the structure is covered with plywood. By the way, any material can be laid in this way.

Selection of insulation material

They consist of components of natural and artificial origin. Even when purchasing linoleum with insulation, when laying it on a concrete floor, in most cases it is necessary to additionally place a suitable substrate. Foam plastic (expanded polystyrene) is a good option as an insulation material, and its improved analogues, for example, penoplex and extruded polystyrene foam, have recently appeared on the market. They are great for further installation of linoleum on an uneven base.

Among modern solutions, we can highlight liquid thermal insulation, which not only acts as an insulating material, but also provides protection against corrosion of elements made of metal. It has a long service life, does not emit components harmful to health and eliminates the formation of condensation on the surface. Liquid thermal insulation is an excellent option for insulating the flooring in a children's room.

Also, heated floors are becoming more and more in demand, which makes it possible to create a favorable environment in the room with an optimal temperature. During its operation, low-quality linoleum can undergo deformation or become soft, which usually does not happen with high-quality linoleum. It is best to choose natural or vinyl material with a foam base for heated floors.

When selecting a substrate, it is also necessary to take into account its thickness, since if it is more than 0.5 cm, the height of the floor will noticeably increase, which can become an obstacle when opening doors.

How to insulate?

In addition to the substrates listed above, which can keep the floor in the apartment warm, there are other insulation materials for linoleum on concrete floors.

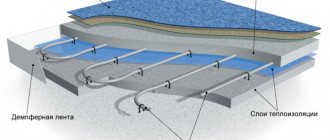

Floor insulation with a warm floor system is an innovation in the construction market. This system assumes that insulation or a special heating element is placed under the linoleum. There are several types of heated floors:

- heating mats or thermomats are a fabric in the form of a fiberglass mesh with heating cables attached to it. Unlike the previous type, it can be mounted without a screed;

- a water heated floor involves the use of a pipe system through which coolant circulates. Due to the large number of pipes, this type of insulation is most suitable for installation in a private home. It is unlikely that it will be possible to officially install such a heating system in an apartment in an old house, but in many new buildings they began to provide a warm water floor at the stage of building the house.

Kawabanga! Characteristics of epoxy putty for concrete

Linoleum structure

In addition, the structure of the material can be of several types:

- Linoleum without base. Such a coating can have a thickness of no more than 2 mm and its price is minimal. The pattern runs through the entire thickness, so abrasion will not affect the aesthetic properties of the coating. This type lasts up to 5-7 years. Very capricious in terms of surface preparation.

- Linoleum based. This 5-6 mm coating is quite elastic, easy to install and does not require particularly careful surface preparation. Has some thermal insulation properties. The basis can be foamed polyvinyl chloride compounds, jute, polyester or felt.

- Heat and sound insulating linoleum. A pre-installed material most suitable for cold concrete and wood floors. The most expensive type of material. The lining is made of a special heat insulator, which we will discuss below.

This is an environmentally friendly, warm, lightweight, practical and moisture-repellent material. An accessible installation method and attractive performance characteristics are the main advantages of cork.

It can be laid directly on a concrete base. However, some are confused by the high price of the material.

Several layers of heat-insulating paint will allow you to satisfactorily insulate a concrete floor

How to lay linoleum on a concrete floor

When the base or rough coating is ready, you can begin the flooring. It’s not difficult to do this yourself, the main thing is to follow the rules.

The temperature in the room should not be less than 15 degrees with a relative humidity of at least 30% and not more than 60%. Otherwise, waves and swelling may appear.

Before laying the product on a concrete floor, allow it to “rest” in a straightened form for a couple of days so that the canvas is leveled. There are several types of laying linoleum: the simplest - without the use of adhesives, with double-sided tape, with mastic or glue. The choice of method depends, first of all, on the room itself.

Let's look at each method in more detail.

Simple flooring

To work you will need scissors, a knife, a ruler and a simple pencil. After the linoleum has “rested”, it is cut off along the perimeter of the room. And then the plinth is installed. The main danger of this method is that subsequently, under the influence of loads, including furniture, the flooring may become deformed.

The process is shown in more detail in the video:

Using adhesive

After the linoleum has been leveled, you can begin flooring.

First stage

- First you need to cut the material around the perimeter of the room, not missing entrances, pipes and spaces under windows. On the first adjustment, you can leave allowances of about 5 cm.

- Next, the allowances are reduced to 10 mm. They start with the outer corners, then work with the inner ones, the last work is cutting out the pipes.

- After adjusting the coating, give it more time to straighten and settle. For household linoleum, one or two days are enough.

Second phase

At this stage you need to prepare the glue. It is applied to the base with a metal notched trowel, and mastic is applied using a plastic tool.

- Linoleum is glued in small parts. The adhesion time of the glue to the surface should be indicated on the packaging of the product.

- While the glue is still plastic, you need to “expel” the air in the direction from the center to the edges. If there is no professional skating rink, you can use a board with soft upholstery, but you will have to put in more effort.

Chipboards

Insulating a concrete floor using pressed slabs is a three-layer “pie” consisting of waterproofing, chipboard and a finishing coating. Please note that the insulation is installed exclusively on a dry, clean surface covered with plastic film (waterproofing).

A small gap (1.5 cm) must be left between the wall and the slabs. This will help maintain the integrity of the structure during linear expansion of the material, because chipboard boards change their dimensions with temperature changes.

The insulation is attached to the base of the floor with dowels, and the joining seams are glued with a special construction mesh, which is coated with a composition of sawdust and parquet varnish in a 1:1 ratio. At the final stage, the decorative covering is laid and the plinth is attached.

Types of thermal insulation materials

Insulation of a concrete floor begins with preparation for the process and selection of a suitable material. Nowadays there is a wide variety of similar products on the market:

- Mineral and basalt wool. Such insulation materials are very popular due to their low density and thermal conductivity, and good sound insulation. But construction wool also has negative properties: it is not environmentally friendly and absorbs moisture. Therefore, it is recommended to use it only in homes with low humidity.

- Polystyrene foam (expanded polystyrene). Despite the fact that polystyrene foam is quite fragile and not environmentally friendly, it has good moisture resistance and thermal insulation.

- Extruded polystyrene foam. It is characterized by strength and durability.

- Polyurethane foam. It has remarkable characteristics of moisture resistance, thermal conductivity and resistance to sudden temperature changes. In addition, polyurethane foam tolerates mechanical loads well and is part of the group of durable insulation materials. But, like most insulation materials, it has one big drawback - it is not environmentally friendly.

Insulation for concrete base: 1 - Mineral wool, 2 - Extruded polystyrene foam, 3 - Polyurethane foam

- Expanded clay. It is mainly used instead of crushed stone. Expanded clay is environmentally friendly and has a low level of thermal conductivity, but a very thick layer of insulation is required, and it also has strong moisture absorption.

- Foam glass. It does not absorb moisture, is environmentally friendly and durable, has a low degree of thermal conductivity and specific gravity. But due to its fragility, it is better not to use it in homes where there is a high probability of mechanical stress.

- Cork. It is completely natural and insulates a concrete floor well in a private home, but is more suitable as insulation for a finishing coating.

- Perlite. Its properties are similar to expanded clay, but some characteristics are superior to it.

Bulk and 100% environmentally friendly insulation - expanded clay and perlite

How to install insulation yourself

plywood - a method tested for decades

Plywood is laid in a checkerboard pattern

Kawabanga! Characteristics of epoxy impregnation for concrete

the optimal solution is cork insulation

Undoubtedly, the big advantage of cork insulation is its resistance to moisture and combustion. Insulation made from cork oak bark has good hypoallergenic properties.

Cork insulation is produced in the form of rolled tape and sheet panels.

“Loose laying” is used for cork insulation. Tapes or sheets of cork are applied tightly to each other and secured with construction tape.

universal polystyrene foam

Expanded polystyrene insulation can withstand significant loads and is not subject to deformation during long-term operation. It has a porous structure and a low water absorption coefficient.

Before installation, it is recommended to unpack and lay out the boards for smoothing and leveling. This method of insulation can be applied to all types of floors and does not require additional fastening or gluing.

The insulation boards are cut to the required sizes, and the joints are glued together with special tape. Sheets of plywood are laid on top. Plywood creates additional structural rigidity.

thorough insulation with polystyrene foam

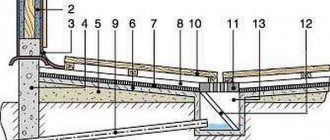

Fastening plywood onto joists, between which there is polystyrene foam insulation, is a fairly effective way to insulate the floor in a private house or apartment with high ceilings.

This design creates maximum heat and sound insulating effect. The plywood is attached to the joists with self-tapping screws. They need to be deepened somewhat to create a smooth surface. Holes from self-tapping screws and joints must be carefully puttied and sanded.