Features of plywood

Plywood is a universal sheet building material designed for leveling any surface: walls, ceiling, floor, etc. We are talking not only about the simplest thin material made of pressed veneer, but also about such varieties as chipboard, OSB and others.

In our case, we should consider plywood as a material for leveling floors. Naturally, it will not be required if the screed was previously made using a self-leveling mixture or ordinary cement-sand mortar. In fact, a perfectly smooth coating is very rare, which means that before laying linoleum, you should take care of leveling the floor under the linoleum. The advantage is that plywood under linoleum on a concrete floor can be laid regardless of the number of defects in the subfloor.

At the same time, many owners in their homes have wooden floors that are not of the best quality. In this case, plywood for linoleum on a wooden floor will come in handy (for more details: “Laying plywood on a wooden floor - which one to choose and how to lay it”). The owners will not have any problems during the installation process. Another positive thing about using plywood is that the cost of the material is very low.

Plywood also has an advantage over regular plank flooring.

Despite the evenness of the wooden covering, it has a number of disadvantages:

- boards are subject to deformation over time;

- when walking, defective parts of the coating make themselves known by making a characteristic sound and sagging under the weight of the occupant;

- cracks form in the ceiling;

- If the boards are covered with a layer of paint, then over time it will begin to peel off.

Regardless of how well the work on laying linoleum is done, all of the above disadvantages will affect the coating during operation. It is unacceptable for any physical defects or traces of chemical processes occurring in wood to appear on the surface of the linoleum. In the photo, such a covering will look ugly, and you certainly won’t show off such a floor to your guests.

Pros of using plywood as a subfloor

The structure of household linoleum

Linoleum is a soft covering; over time it takes on the shape of the base, so if you do not use a continuous solid flooring underneath it, the finished floor may become uneven with significant differences.

Laying plywood on a wooden floor in this case has the following advantages over other leveling methods:

- creation of a continuous flooring that will not acquire relief over time; no need to dismantle the old covering; reduction in the cost and labor intensity of work (follows from the previous one); availability of material; the possibility of using moisture-resistant types of plywood, which allows you to additionally protect the wooden floor in rooms such as the bathroom, bathroom and kitchen; minimum number of seams between elements, which are the weak point of any design.

Advantages of plywood

Based on the above, the use of plywood is very important. The initial task of this material is to redistribute the load when walking over the entire surface. This happens due to the fact that the plywood sheet is solid and the person’s weight falls on the entire area, and not on 1-2 boards.

The positive aspects of using plywood do not end there:

- Using this material, you can level a concrete or wooden floor, regardless of its quality and service life. Moreover, the cost of purchasing a sheet of plywood is significantly less than in the case of pouring a screed.

- In this way, the entire flooring system can be significantly strengthened.

- Uniform distribution of load from people walking or static arrangement of heavy furniture, household appliances, etc. allows you to ensure the absence of any movement of the linoleum and keep it intact during operation.

- There will be no noise, squeaks, crackles, etc. during use.

- A single sheet of plywood reliably covers any cracks and cavities, which prevents rodents, insects, debris, etc. from entering the coating structure.

- Additionally, plywood creates a barrier to sound and cold.

- You can easily lay flooring on sheet material. Any owner, if desired and patient, can carry out the work independently.

Advantages and disadvantages

At the stage of choosing plywood for linoleum, it is necessary to take into account that, like all building materials, it has its pros and cons. Let's update on decent qualities:

- the cost of wood material is significantly lower than that of a concrete screed;

- You can lay it on any type of rough surface, the main thing is to place it strictly according to the level;

- uniform distribution of the load is provided, and therefore the service life is extended;

- has a strengthening effect on the flooring system;

- Laying decorative coverings is quite easy on top of plywood;

- installation does not require special skills and dexterity;

- plywood well insulates sounds and cold that can penetrate from the concrete screed (for example, if there is a basement below).

Installation of linoleum can be done on boards if it is not possible to make logs Source remontnik.ru

Disadvantages of plywood

However, there are also disadvantages to such a process as laying plywood on a wooden floor under linoleum. All of them are mainly related to the physical and chemical properties of the material.

When working with plywood, it is worth remembering the following key points:

- the material is essentially compressed wood, and therefore exposure to moisture and chemicals leads to deformation;

- Wood is characterized by an active reaction to any fluctuations in humidity in the room. The point is that a sheet of plywood can shrink, diverge and swell with changes in microclimate. On linoleum this will appear in the form of swelling, surface irregularities, etc.;

- natural wood does not tolerate biological processes in its structure: the formation of mold and fungi, the proliferation of bacteria and insects, rotting, etc.;

- this material does not resist fire well, like any wood;

- Certain types of plywood are created with the addition of an adhesive composition, which emits toxic fumes during operation.

Technology for laying plywood sheets on the floor

After completing the preparatory work and completing the marking of the room and material, you can begin installation. Installation must begin from the far corner of the room towards the exit. Laying plywood can be done in several ways.

Option for rough coating with plywood sheets directly on glue

Installation steps:

Rough coating from plywood sheets

- Each next row of the layout must be shifted relative to the previous one by no less than 15 cm.

- When installing plywood directly, the surface of the area must be dust-free, degreased and primed.

- A layer of glue up to 2 cm thick is evenly applied to the prepared area of the coating and the first plywood sheet is laid.

- To install each subsequent sheet of plywood, you need to perform the steps described in paragraphs 2 and 3.

- Let the glue dry.

- The plywood flooring must be additionally reinforced with screws at a distance from the edge of the element surface equal to 2 cm in increments of 15 to 20 cm.

- The joints between the coating elements should be puttied with a special compound for wood.

- Let the putty dry.

- The surface at the joints should be smoothed with an electric grinder or sandpaper.

- Next, linoleum is laid, baseboards are installed, and the floor is ready for use.

Attention! Before laying linoleum, it is necessary to clean the surface from dust, shavings and other construction debris, make sure that all sheets of plywood are securely fastened, the surface is smooth and does not have subsidence. An important nuance is also to check that all required clearances are present.

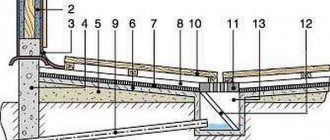

Option for laying plywood sheets under linoleum along joists

Installation steps:

- Before installing the logs, it is necessary to carry out waterproofing measures.

- The logs must be installed level directly on the old floor covering.

- The pitch between the slats should be approximately 0.4 m.

- After installing the logs, the connecting slats should be installed at a pitch of 0.5 m.

- You need to lay glassine on the laid logs.

- Next, you need to mount the plywood sheets.

- Laying linoleum.

One of the options for laying plywood on a wooden floor

Plywood processing

If you carefully study all the characteristics of plywood described above, you can understand what kind of plywood is needed for a linoleum floor, but it is best to make your choice not on your own, but on the recommendation of a specialist. As for the problems that arise during operation, it is enough just to properly treat such a base in order to protect it from deformation (for more details: “How to treat plywood on the floor - is it necessary to impregnate it”).

Depending on what problem the owner plans to deal with, we can conclude how to treat plywood under linoleum and how effective it will be:

- You can increase the fire resistance of the material with the help of fire retardants, but it is more advisable not to look for a remedy, but to purchase already treated plywood;

- antiseptics will do an excellent job against insects, rodents and fungal growths;

- The following will help fight moisture: drying oil, varnish coatings, various stains, and you can also buy already treated material in advance.

Experts believe that it is better not to search for the means described above, but to immediately buy plywood prepared for use in certain conditions. It is worth remembering that you will also have to figure out how exactly the above substances should be used.

Selection and preparation of plywood

Plywood for linoleum must be chosen responsibly so as not to get negative surprises in the future. The thickness of the plywood must be at least 20 mm. It is desirable that the plywood be moisture resistant and treated with antifungal antiseptics. If you purchased untreated material, be sure to saturate the sheets yourself with drying oil or moisture-resistant stain.

Related article: How to cut blinds to size

Scheme of fastening a sheet of plywood.

For ease of installation, plywood sheets are cut into squares based on the size of your room. This can be done using a special jigsaw or buying ready-made squares. Then the squares must be placed on the floor without fastening in order to adjust them to size and number them. Before this, we get rid of old baseboards and debris on the floor. The plywood is placed in a shear position, using the principle of laying a brick wall, to increase the strength of the covering. It is imperative to leave technical gaps under the walls up to 2 cm and between squares up to 0.5 cm, so that during expansion there is no friction between the sheets of plywood.

Choosing plywood for linoleum

The process of laying plywood itself will not be a problem for a person with even minimal construction skills, but it is very important to choose the right material so that its operation is as efficient as possible. If plywood is laid on the floor under linoleum, thickness is a fundamental parameter. Many experts still do not agree on what the thickness of plywood should be.

Practice shows that on the building materials market, plywood is represented by types with a thickness of 0.8 to 2 centimeters, and those that are located in the range of 1.4-1.8 centimeters are ideal for laying under linoleum. Moreover, the thickness of plywood for linoleum on a wooden floor is no different from the option with a concrete base. It is also important that a value of even 2 centimeters will not significantly reduce the overall height of the room.

It would be more practical to use alternative materials with much better characteristics. We are talking about OSB and MDF. Chipboard is also an interesting option, but its effectiveness is achieved only with a thickness of 16-20 centimeters and careful processing (read: “Laying chipboard under linoleum - instructions”).

What kind of plywood to lay under linoleum?

Before laying sheets on a wooden or concrete base, you need to familiarize yourself with the existing types of plywood, their properties and technical characteristics. The property owner must clearly understand what product is in front of him. Several decades ago, plywood was presented on the construction market in the following varieties:

- The packaging option is a product with thin walls, which was used as containers for various products. Now such products are not used due to the use of cheaper analogues.

- Structural plywood sheets are used for sheathing the surfaces of building envelopes and for other purposes, such as the construction of the frame of residential buildings.

- Furniture plywood has found wide application in the field of furniture manufacturing. The products have different thicknesses and are used for rear walls, shelves and other purposes. Laminated material is used for the manufacture of furniture facades and side walls. The surface of the products can imitate the texture of wood and has a special protective coating.

- Construction plywood sheets are considered one of the most common options. This material is used in a wide variety of areas of construction and can be used as a base for subsequent laying of linoleum.

By the way, we have a useful article about what glue to use when laying linoleum on a wooden surface.

Does plywood need to be treated? It is recommended to impregnate ordinary sheets, with the exception of moisture-resistant products, with antiseptics and fire retardants, which will prevent the appearance of fungus and mold and protect the products from fire as a result of exposure to high temperatures. The lamination procedure improves the attractiveness of the material and increases its moisture resistance.

One more question: do I need to putty the plywood ? Yes, it is necessary, but you cannot use ordinary putty for this purpose. The seams between the sheets are treated with a special solution that prevents the occurrence of fungus and damage to the material by parasites. The primer is applied with a brush. After complete drying, the cracks are puttied with a special composition of epoxy resin and wood dust in equal proportions. The mixture is heated to a temperature of 40 degrees and all cracks are filled. A day after puttying, they begin sanding the surface.

This is how old wooden floors are leveled: a frame is assembled, insulation is laid, then sheets of plywood are laid.

Interesting article on the topic: Leveling the floor

Sheets of plywood for preliminary leveling of the base under linoleum are marked as follows:

- FC is a material with good moisture resistance. The veneer sheets here are glued together using a special carbide composition. The material in question has a minimal amount of harmful substances, so it can be used for interior decoration of residential buildings.

- FSF is a sheet with increased moisture resistance. The veneer in such products is glued together using formaldehyde glue. This substance is harmful to human health, especially in high concentrations.

- FBA is plywood that is glued using albumin casein glue, which is absolutely safe for humans. Such materials are recommended to be used for leveling the base in dry rooms due to low moisture resistance.

- FB is considered the most durable and reliable product; it differs from other options in its good moisture resistance and resistance to various external influences. The veneer sheets are glued together using bakelite glue. Such products are designed for use in rooms with the most unfavorable conditions.

- FSF-TV is treated with special impregnations and fire retardants, which increases the product’s resistance to fire.

Many users wonder whether it is possible to paint the surface of plywood sheets. Paint is often used instead of an antiseptic. This composition covers the sheets on the outside and inside. Paint improves the moisture resistance of the material, prevents it from rotting and mold. One more question: do you need to dry the plywood? Drying oil is often used as a primer for pre-impregnation of the material.

In addition to the brand and purpose, plywood sheets are divided by grade. To pre-level the base under linoleum, the following materials can be used:

- The first grade has improved quality. There are no chips, cracks, potholes or other defects on the surface of such material. The sheets are impregnated with various compounds and are often used as an independent floor covering.

- The second grade of material has a limited number of surface defects, their number is indicated in special documents. This is also an attractive option and is used as an independent finishing material.

- The third grade of plywood has a larger number of knots and other defects than the two previous options. Such sheets can be used to install a base under linoleum or used to install hidden parts of building structures.

- Plywood of the fourth grade has the maximum number of defects, knots and flaws on its surface. Such products are notable for their low price, but have worse quality indicators.

Note! A sheet of plywood can have a different grade of veneer on each side. The main thing here is the front layer; the inner surface may have flaws, but they should not affect the strength of the material.

Grade 3 or 4 plywood can be used as a base for the flooring. This surface will be hidden, which means you need to pay attention to strength and reliability indicators, and not the appearance of the product. It is also necessary to take into account that with an increase in the number of grades, the cost of building material decreases. It is unwise to spend extra money on purchasing a substrate.

Important! When purchasing plywood, ask sellers for quality certificates for the supplied products. Inquire about the moisture content of the material, recommended parameters are within 12-15%

Laying plywood

Leveling the floor with plywood under linoleum is very simple:

- Initially, the material should be cut into rectangular or square pieces. The standard form has dimensions of 50x50 or 100x100 centimeters, but under certain room conditions you can select non-standard values.

- Next, you should make markings by simply laying the blanks without gluing them. This will allow you to understand whether the measurements were accurate and whether there is enough material to create a high-quality foundation. During installation, it is necessary to leave gaps between sheets, as it is important to remember the tendency of plywood to expand with changes in temperature and humidity.

- Each sheet must be glued to a special floor glue or regular PVA, and also secured with self-tapping screws at intervals of 15-25 centimeters. Holes are prepared for the self-tapping screws using countersinking methods so that the fastener heads are below the level of the plywood surface. If this condition is not met, the linoleum may be damaged during installation or during operation.

- After the sheets are fixed, the glue should dry within 2 days. Then the gaps between adjacent sections must be sealed with putty or the same glue, but with the addition of shavings or gypsum. The holes for the screws also need to be puttied.

- The dried surface can be treated with hot drying oil or proceed directly to laying linoleum. Walking on the surface is prohibited until the laying of plywood on the concrete floor under the linoleum is completed in accordance with the algorithm of actions described above. Otherwise, any shifts of the sheets will lead to distortions on the surface of the linoleum, which will indicate in the photo and during visual inspection the poor quality of the floor leveling work performed.

Bottom line

The article describes in detail the process of selecting and laying plywood as a base for covering a linoleum floor. An attentive reader can understand that this procedure is very simple and anyone who is persistent and patient can cope with it. As for what kind of plywood to lay on the floor under linoleum, if you are unsure about this issue, you can always turn to specialists (about

How to lay plywood on a wooden floor?

Laying plywood on the surface of a wooden floor under linoleum is very similar to the process of laying it on concrete. But at the same time, there are some subtleties that must be observed so that the coating does not deteriorate in the future and will serve you for a long time. Before work, be sure to de-energize the room.

First you need to replace those wooden boards that have become unusable. After this, the surface is checked with a level and knocked down with a hammer in places where it bulges. Using a vacuum cleaner, the floor is freed from dust and then thoroughly washed.

Scheme of laying plywood on a concrete screed.

It is very important to wait until the floor is completely dry. Therefore, it is advisable to check the humidity level by applying film for a day. If there is no condensation after removal, you can proceed to the next stage of work, in which the surface is coated with a primer with the addition of an antiseptic.

If there is condensation, you need to dry the floor some more. For this purpose, you can use a regular hairdryer or place a heater in the room. Just don’t leave the device on while you’re away from home! After all, dry wood ignites very well.

Approximately two days after the primer has completely absorbed and the surface has completely dried, you can begin attaching the plywood. To do this, the sheets are again cut into squares, as when laying them on a concrete screed, after which they are laid in rough form. Be careful to ensure that the gaps are maintained.

Fastening is done using bustilate or self-tapping screws. It is better to combine these two methods.

The caps of the screws must be well recessed. After finishing the work, the plywood is cleaned of dust and covered with a thin layer of wood varnish. Now you can safely lay linoleum on plywood!

So, now you are familiar with the basic properties of plywood and the intricacies of its installation under linoleum, both on a concrete screed and on a wooden floor base.

If you follow these basic rules, then after laying linoleum the floor will not cause you any problems. And the room will have a noticeable feeling of warmth and comfort.

Laying linoleum as a floor covering is one of the most economical ways to create beautiful floors. It also has good external characteristics.

Its only drawback is its thickness, which does not allow it to independently cover even minimal unevenness of the rough surface. Therefore, before laying the material, it is necessary to level the floor. Very often, builders level the floor with plywood under linoleum.

Properties and options for laying plywood

The layers in plywood are laid perpendicular to each other.

Plywood is a product made of glued wood layers of peeled veneer, laid mutually perpendicular to each other relative to the location of the fibers. The material is made from deciduous and coniferous wood.

The design and special glue give the slab geometric accuracy, strength and water resistance. For construction work, an important indicator of water resistance divides plywood into three types:

- FC – refers to a product with an average level of water absorption. It is used for interior work, in the manufacture of furniture and souvenirs.

- FSF – refers to a product with increased moisture resistance. It is used in external construction work, when constructing rough floors, bases for soft tile roofing, and outdoor advertising structures.

- FBS – moisture resistance of the product prevents swelling of the material in a humid environment.

Made from softwood veneer, wood and birch, the board is the most durable of these.

To increase the biological resistance of the slab, the sheets of the product are coated with synthetic resin. Thanks to these properties, a subfloor made of plywood grades 2 and 3 FSF, unsanded and sanded on one side of the product, is used as a base for a linoleum covering.

Very often this material is chosen as a subfloor.

Using plywood for a subfloor

One of the installation options is on a concrete floor, when the old wooden covering is removed along with the joists.

The cleaned surface of the concrete floor is checked with a laser level for horizontalness. If the deviations are less than 5 mm, a self-leveling self-leveling floor is used. In case of greater deviation, a concrete screed is applied to the base.

After the leveling coating has dried, work on installing the sheets of the product is carried out. The concrete surface is primed to prevent dust from getting between the sheets of the product and the base.

To prevent warping of the coating, the sheets of the product are cut into squares with a side of 50-60 cm. After sawing, the edges of the slabs are sanded and the slab is covered with a protective layer of antiseptic.

If plywood is placed directly on concrete, then glue is sufficient.

Laying plywood under linoleum on a concrete base is done using glue. We lay out the sheets according to a previously prepared diagram, which takes into account the dimensions of the floor of the room and the size of the slab.

To prevent the panels from pressing through at the joints, the sheets are laid out in a checkerboard pattern. A compensation gap of 3–4 mm is left between the sheets, taking into account temperature fluctuations and the changing load on the floor covering.

The gap between the walls and the flooring is 10 - 15 mm. The sheets laid on the glue are additionally fixed to the base with dowels so that the sheet does not move until the glue dries. After fixing the sheets, the subfloor is sanded and primed, and a linoleum coating is laid on the flooring with a dried primer layer.

When installing a linoleum floor covering, the durability of the product depends on the condition of the base. A foundation made in violation of the instructions will lead to a defective subfloor.