Halogen lamps

These are improved incandescent lamps. The advantage of halogen lamps is their consistently bright light, excellent color reproduction and the ability to create a variety of light shades. Thanks to the addition of fluorine, bromine, chlorine, and iodine gases to the flask, which reduce the amount of tungsten evaporation, the lamp service life increased to 2000-5000 hours. The use of special filters applied to quartz glass “stops” ultraviolet radiation, which protects illuminated items from fading. Dichroic reflectors divert thermal radiation beyond the illuminated area. The brightness of the lighting is adjustable using a wide range of reflector diameters.

Linear halogen lamps with a spiral-shaped filament and a transparent quartz tube. These double-ended lamps are used to illuminate wide surfaces. Thanks to the use of reinforced holders, the filaments are highly resistant to mechanical stress. For lamps with a power of up to 500 W, the glow position is arbitrary, with a power of over 500 W - only horizontal, with a permissible deviation of 4°. The lamps combine high luminous efficiency, “living” white shine, excellent color rendering coefficient, constant luminous flux throughout their entire service life, instant re-ignition, and brightness adjustment capabilities.

Halogen lamps with glass reflector and colored protective glass. Colored glass adds a certain tint to the light beam. Designed for decorative lighting.

Halogen lamps with a parabolic glass reflector coated with a metallic aluminum layer. Designed to create light accents. The slightly corrugated surface of the front glass well emphasizes the effect of “sparkling” light and protects the burner from dirt and dust, as well as from contact with human hands. It is used in accent lighting, lighting of public and residential premises, street lighting (when used outdoors, the lamp must be protected from moisture).

Halogen lamps with a double bulb operate on mains voltage and have a threaded base. The lamps are characterized by stable light output and excellent color rendering (Ra=100). The lamps can be dimmed. Used for lighting residential and public spaces.

Incandescent lamps lose brightness over time. Modern halogen lamps do not have this disadvantage due to the addition of halogen elements to the filler gas. Halogen lamps have bright, rich and even light, the spectral composition of which is significantly different from the spectral composition of light from a conventional incandescent lamp and is close to the spectrum of sunlight. Thanks to this, the colors of furniture and interiors in warm and neutral tones, as well as the complexion of a person, are perfectly conveyed. *Research conducted by the author.

Advantages of halogen lamps:

- high light output;

- Consistently bright light throughout its service life;

- long service life;

- miniature design;

- possibility of adjusting the light flux;

- high level of safety, especially in conditions of high humidity (low-voltage lamps).

Disadvantages of halogen lamps:

- It is better not to touch the glass surface of the lamp with bare hands, as greasy stains remain on it, which can lead to melting of the glass of the bulb in this place. The lamp must be taken using a piece of clean cloth, and if the bulb is dirty with something, then you need to wipe it with medical alcohol;

- halogen lamps are very sensitive to power surges, so they should be turned on through a voltage stabilizer, and low-voltage lamps - through a transformer;

- the temperature of the bulb can reach 500 °C, therefore, when installing lamps, fire safety standards must be observed (for example, ensure a sufficient distance between the ceiling surface and the suspended ceiling).

Fluorescent Lamp

This is a low pressure gas discharge light source. Its luminous flux is determined by the glow of the phosphor under the influence of ultraviolet radiation, which occurs as a result of an electrical discharge. According to experts, in terms of price and quality ratio, fluorescent lamps are the most effective and in demand in the field of commercial real estate.

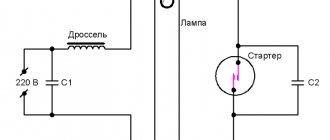

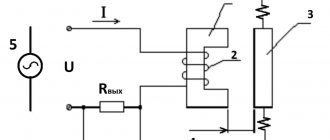

The inside of the flask wall is coated with a mixture of luminescent powders called phosphor. Lamps with three-strip phosphor are more economical, since their luminous efficiency is up to 104 Lm/W, but have worse color rendering (Ra=80), and lamps with five-strip phosphor have excellent color rendering (Ra=90-98) with lower luminous efficiency ( up to 88 Lm/W). There are two ways to ignite fluorescent lamps - electromagnetic and electronic ballast. The type of ballast affects the ignition of the lamps, as well as the flicker in operation and the service life of the ignition electrodes. When igniting fluorescent lamps with electromagnetic ballast, up to 30% of electricity losses occur. The main difference between a fluorescent luminaire with electronic ballast and the same luminaire with electromagnetic ballast, in addition to energy savings, weight and volume, is the flicker frequency: Lamps with electronic ballast operate with a high flicker frequency of about 42,000 Hz per second, while lamps with electromagnetic ballast operate with frequency of 100 Hz per second, which causes eye fatigue with prolonged use.

LED bulbs

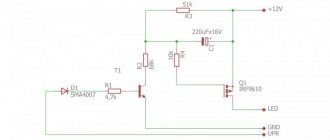

LED light sources are semiconductor devices consisting of two semiconductors connected to each other. When a current passes, one of the materials receives an excess of electrons, and the other receives a deficiency. Electrons begin to move to vacant places, thereby generating light and heat. Today, LEDs are leaders in automotive, aviation and lighting equipment. In addition, they are characterized by a high potential service life and customizability. However, LED light sources also have their drawbacks: efficiency and service life depend on the connection temperature.

Fluorescent lamps in the form of a ring

Due to their shape, they are used in a wide range of lighting devices. Due to the small dimensions of the tube, this lamp can be used in extremely flat luminaires. It is used for lighting public and residential premises.

Advantages of fluorescent lamps:

- compared to incandescent lamps, it provides the same luminous flux, but consumes 4-5 times less energy;

- have a low flask temperature;

- increased service life;

Disadvantages of fluorescent lamps:

- reduces luminous flux at elevated temperatures;

- mercury content (albeit in very small quantities, 40-60 mg). This dose is harmless, but continued exposure may be harmful to health;

- fluorescent lamps are not suitable for operation at air temperatures below 15-20 °C.

Types of artificial lighting. Classification

The main types of artificial lighting, distinguished by the location and purpose of the light sources:

1) General. In any type of premises (residential, office, industrial) this type of lighting requires the presence of lamps in the upper zone or on the ceiling. When organizing the overall appearance, the light should be evenly distributed throughout the entire area of the room. For a small living room, this could be a chandelier or ceiling lamp. An office or industrial space typically uses a lighting system.

2) Local. This type of lighting is designed to highlight certain areas by placing light sources directly on a designated area of the room. For local lighting of housing, the following types of lamps are used: floor, wall, pendant, tabletop, built-in. In production or office premises, special lamps are used that direct light directly to the workplace.

3) Combined. Involves the simultaneous use of general and local types of artificial lighting. Effective for all types of premises: residential, office, public and industrial.

Compact (energy saving) fluorescent lamps

They produce light on the same principle as conventional fluorescent lamps, only over a much smaller area, and are a compact alternative to fluorescent tube lamps.

Advantages of compact lamps compared to incandescent lamps:

- up to 80% less current consumption with the same amount of light;

- for fluorescent lamps: the service life is 6-15 times longer compared to conventional incandescent lamps and is, accordingly, 6000-15,000 hours, depending on the type;

- fluorescent lamps: lower maintenance losses due to long service life; fluorescent lamps: ability to choose the color of the glow.

High pressure discharge lamps

The peculiarities of gas-discharge lamps, according to experts, are their high luminous efficiency and long service life in a wide range of ambient temperatures. In our climate zone, it is preferable to use gas-discharge lamps for architectural (outdoor) lighting, since they work well at sub-zero temperatures. The use of gas-discharge lamps is recommended only with protective glass, high-quality components and qualified circuit assembly, otherwise they are unsafe for home use. For example, a lamp explosion or a short circuit in the circuit can lead to a fire. It should also be noted that gas-discharge lamps do not shine at full power immediately, but after 2 to 7 minutes.

The group of gas-discharge lamps includes metal halide, sodium and mercury lamps.

Metal halide lamps

These are high-pressure mercury lamps that use additives from metal iodides, including rare earth ones, as well as complex compounds of cesium and tin halide. All these additives significantly improve the luminous efficiency and color rendering characteristics of lamps under mercury discharge. All metal halide lamps produce white light with different color temperatures. Their feature is a good level of color rendering. Any objects and plants underneath them look absolutely natural. According to experts, metal halide lamps are widely used in lighting commercial real estate, as well as exhibitions, office premises, hotels and restaurants, for illuminating billboards and shop windows, lighting sports facilities and stadiums, for architectural lighting of buildings and structures. *Research conducted by the author.

Advantages of metal halide lamps:

- high luminous efficiency (60 - 110 lm/W);

- long service life (up to 10,000 hours);

- compact dimensions;

Disadvantages of metal halide lamps:

- not suitable for smooth adjustment;

- long ignition and re-ignition.

Sodium lamps

They are among the most efficient sources of visible radiation: they have the highest luminous efficiency among gas discharge lamps, are economical and have a long service life. Usually the lamps emit a characteristic yellow color, but if the igniter contains xenon, they produce a bright white light. Sodium lamps come in high pressure (they emit a warm yellow light, suitable for illuminating large parks, roads and squares) and low pressure (ideal for street lighting).

Advantages of sodium lamps:

- high level of light output (up to 130 lm/W);

- long service life (up to 12,000 hours);

- energy efficiency;

Disadvantages of sodium lamps:

- poor color rendering (Ra = 20);

- long ignition and re-ignition (up to 10 minutes).

Gas-discharge sodium lamps are used to illuminate streets, as well as industrial premises, where the main conditions are economy and brightness, and the requirements for light transmission are insignificant.

Incandescent lamps

The tungsten coil in the flask is heated by electric current. To reduce the rate of tungsten sputtering and, accordingly, increase the service life of the lamp, the bulb is filled with an inert gas. According to the principle of operation, an incandescent lamp is classified as a thermal light source, i.e., a significant proportion of the energy consumed is spent on thermal and infrared radiation.

Typical luminous efficacy for incandescent lamps is 10–15 lm/W, and the service life rarely exceeds 2000 hours. The advantages of these lamps: low price and quality of light (Tcv=2700, Ra=100). A continuous spectrum qualitatively reproduces the colors of surrounding objects. Incandescent lamps are gradually being replaced by discharge light sources and LED lamps.

Mercury lamp

Its work is based on the use of radiation from an electrical discharge in mercury vapor. Lamps of this type are characterized by high luminous efficiency with relatively small dimensions, they have a long service life. 40% of radiation occurs in the ultraviolet region of the spectrum. To increase light output, ultraviolet radiation is converted into visible light using a phosphor that coats the lamp bulb. These lamps significantly reduce installation, operating and maintenance costs in the following applications: road lighting, landscape lighting.

A high-pressure mercury lamp contains mercury vapor, the partial pressure of which during operation reaches 105 Pa. Such lamps are highly reliable, have good color rendering, and reduce installation and maintenance costs. They are used for indoor and outdoor lighting of commercial and industrial facilities, for decorative and security lighting. A mercury-tungsten lamp is a lamp, inside of which, in the same bulb, there are a discharge tube of a high-pressure mercury lamp and a spiral of an incandescent lamp, connected in series. The flask can be coated with a phosphor. The tungsten filament serves as an additional light source in the red light region and at the same time acts as a ballast pressure for the mercury burner. Thanks to this device, color reproduction is improved and there is no need to use an additional choke.

Advantages of mercury gas discharge lamps:

- wide power range;

- sufficient level of luminous efficiency (30-60 lm/W);

- long service life (up to 12,000 hours);

- mercury-tungsten lamps do not require a ballast;

- compact dimensions;

Disadvantages of mercury gas discharge lamps:

- poor color rendering;

- long ignition and re-ignition (up to 5-10 minutes).

According to most experts, the future of lighting lies in lamps and LED luminaires . At the moment, they are not yet as in demand on the market as fluorescent lamps or incandescent lamps, and are mainly used in architectural, landscape and decorative lighting. I would like to pay special attention to LEDs that produce a large luminous flux, as a rule, these LEDs with a power of 1 W up to 15 W. These light sources have a fairly high luminous efficiency, already approaching the luminous efficiency of gas-discharge lamps, a long service life, compact dimensions and sufficiently high brightness. All these properties open up new possibilities for the use of LEDs, both for general and floodlighting. Due to the absence of a filament body, LEDs are characterized by high efficiency and a long service life (80,000 - 100,000 hours).

Advantages of LEDs:

- low energy consumption - no more than 10% of consumption when using incandescent lamps; — long service life — up to 100,000 hours;

- high durability - shock and vibration resistance;

- purity and variety of colors, radiation direction;

- adjustable intensity;

- low operating voltage;

- environmental and fire safety. They do not contain mercury and hardly heat up.

Now we can see a clear picture of the future of LEDs and their clear advantages over other light sources. The production of LEDs in recent years has exceeded all the most optimistic forecasts by 20-30%. Most experts agree that in 7 to 10 years, LEDs will take over all major positions in the lighting market.

Author Romanovsky A.N. from the company FOCUS.

Characteristics of the main light sources

| Item: | Physics |

| Kind of work: | Essay |

| Language: | Russian |

| Date added: | 23.07.2019 |

- This type of work is not a scientific work, it is not a finished final qualifying work!

- This type of work is a finished result of processing, structuring and formatting collected information intended for use as a source of material for independent preparation of educational work.

If you have a hard time understanding this topic, write to me on WhatsApp, we’ll look into your topic, agree on a deadline, and I’ll help you!

At this link you can find many ready-made abstracts on physics:

| Lots of ready-made physics essays |

Check out these similar threads, they might be useful to you:

| Relationship between physics and other sciences |

| All about the human biofield |

| The essence of the external photoelectric effect |

| Features of light interference |

Introduction:

We live in a world of light and the images it creates. Sunlight was the beginning of life and the cradle of man on Earth. Human consciousness began to be determined by its imaginative thinking. Natural light, born of the sun, created for us a huge world of sensations and gave us the opportunity to determine our relationship to the world around us, and artificial light became the beginning of human civilization. Today, electric light determines the quality of our lives and human comfort. Bad light, like bad glasses, can cause fatigue, irritability, bad mood and other unpleasant consequences. The art of lighting is trying to comprehend millions of people, equip their homes and workplaces. Taking into account the improvement of lighting comfort and coziness in your own home or apartment, it is useful to have at least the most basic information about lighting technologies and the rules of efficient lighting.

Improving light comfort at home and at work not only creates a person’s mood, but also allows them to maintain working capacity for a long time; and the right lighting design and the right environmental colors determine the internal state and help maintain health. We, of course, should not forget that we associate a healthy lifestyle with a bright and pleasant-looking environment, which creates a margin of safety for us in all our endeavors in life.

Lamp technology development

Electric light is international in its birthplace. Outstanding scientists and inventors from many countries of the world took part in its discovery and creation. The first stage in the development of electric light sources, thanks to the discoveries and inventions of Devi, Volta, Petrov, Molien, Gabel, Adamas, Sprengel, Ladygin, Yablochkov, Dedrickson and others, was completed in 1879. Edison created the incandescent lamp in a design form that is familiar to us. The first public installations of electric lighting appeared at the end of the 19th century in Western Europe, America and Russia. The electric “Yablochkov candle” created a sensation in Paris and was called “Russian Light”.

Competition with incandescent lamps arose with the development of a generation of gas-discharge lamps in the 30s of our century: fluorescent and mercury lamps, which have two outstanding advantages: several times greater energy efficiency and service life. Despite their high cost, the need to use special control mechanisms (PRA) to turn them on and operate, and many other disadvantages, these lamps began to quickly replace incandescent lamps, and this primarily affected the areas of industrial and street lighting.

Since the 50s, fluorescent lamps have gained a strong position in the lighting of public buildings (auditoriums and classrooms, offices, hospitals, etc.). In the late 1960s, a new class of metal halide lamps was added to discharge lamps, which, while retaining the advantages of high-pressure mercury lamps (DRL), are characterized by higher energy efficiency and color rendering.

These lamps were most widely used primarily in the lighting of sports facilities (to meet the requirements of television broadcasts). High-pressure sodium lamps with yellow-golden light should be considered the pinnacle in the development of energy-saving lamps. One such 400 W lamp replaces a 1000 W DRL lamp and 10 incandescent lamps of 300 W each. Due to their lack of color rendering, these lamps are mainly used in street lighting. Expand area

Application of gas-discharge lamps in residential and public buildings. In the 70s, compact fluorescent lamps (CFLs) were developed, including those with the same base as incandescent lamps. By screwing such a lamp into a regular lamp, you can reduce its power by 5-6 times (for example, a 13 W CFL will replace a 75 W incandescent lamp). In those same years, halogen lamps illuminated displays at exhibitions and museums, differing from conventional lamps in their exceptional compactness, 1.5-2 times greater efficiency and service life. The most efficient and safe lamps are designed for a voltage of 12 V, although when powered from the mains they require the installation of step-down transformers. Today, mirrored halogen incandescent lamps have become an effective and prestigious light source for lighting offices, banks, restaurants, shops and other premises.

The modern history of light sources is striking in terms of the duration of operation of “eternal” lamps with a new operating principle (Fig. 1.2). These are so-called compact electrodeless high-frequency fluorescent lamps in QL type with a power of 85 W and a service life of 60 thousand hours, which are not inferior in other characteristics to the best discharge lamps. Introduced by Philips in the early 90s, these lamps are increasingly used, especially in Northern Europe. Most recently they have been used to retrofit large class lighting in Finland. The authors of the project claim that the next replacement of lamps will be carried out in 2025.

Different types of light sources

Incandescent lamps

According to the features of the device and the principle of operation, incandescent lamps used for lighting can be divided into 2 large groups: ordinary lamps (ordinary lamps in a traditional design) and halogen incandescent lamps, which are discussed in the next section.

The arrangement of the lamps remained in principle the same as that proposed by Edison. To increase the temperature of the filament body and reduce its atomization rate (these are the main ways to increase the luminous efficiency and life of incandescent lamps), instead of a carbon filament, modern lamps use a helix or bi-coil (coil). tungsten wire and in the vast majority of types of lamps with inert gas: argon or krypton. A class of lamps with a mirror lamp reflector also appeared. Lamps are very sensitive to voltage fluctuations in the network: overvoltage sharply reduces service life, and insufficient voltage leads to a disproportionate loss of luminous flux (although service life increases). Normal operation of luminaires is ensured with voltage fluctuations of no more than 5%. For networks with constant overvoltage, lamps labeled 230-240 V are produced in Russia. Incandescent lamps work equally well on both alternating and direct current.

For almost all types of lamps, the average lifespan is 1000 hours. In real conditions, it may be shorter depending on the operating conditions and the design of the luminaire. When used on average 8 hours a day, the lamp usually lasts 3-5 months.

The lamps have a low luminous efficiency of 7 to 17 lm/W. This indicator increases with increasing lamp power and decreasing the voltage for which it is intended. For example, a 40 W lamp at 220 V has a luminous efficacy of about 10 lm/W, and a 100 W lamp up to 14 lm/W. Lamps of the same power for 127 and 220 V differ in luminous flux by 1012%. The best energy-saving lamp can be distinguished by its white radiation.

Incandescent lamps are a traditional light source in residential and public buildings. They create a unique atmosphere of comfort and comfort and are used in all cases where it is necessary for the project conditions. Functionally, they are very effective when illuminating paintings and other exhibits that are not resistant to light. Their low service life and luminous efficiency are not so important in rooms with short-term occupancy and at low standard illuminance values.

Halogen lamps

In principle, these lamps are designed in the same way as other incandescent lamps. The main difference is that the internal volume of the lamp is filled with iodine or bromine vapor, that is, halogen elements, which is reflected in the name of the lamps. The chemical power of these elements was used to continually "collect" the vaporized tungsten particles deposited on the flask (oxidation reaction) and return them "home" to the tungsten coil (reduction reaction). This "halogen-tungsten cycle" increases the temperature and life of the filament housing and ultimately increases luminous efficiency and lamp life by 1.5 to 2 times. Another important difference is that the flask is not made of ordinary glass, but of quartz glass, which is more resistant to high temperatures and chemical interactions. Due to this, the size of halogen lamps can be reduced several times compared to conventional lamps of the same power.

The design of mirror halogen lamps differs in that the mirror reflector, together with the base, is glued to the lamp bulb. Mirror coating is performed by spraying chemically pure aluminum (opaque coating) or a special translucent coating onto a glass reflector. Lamps with a translucent (interference) coating practically do not heat the illuminated surface, since the IR radiation is transmitted “back” by the reflector. Some types of lamps also have filters that block ultraviolet rays.

Along with lamps designed for direct connection to a network with a voltage of 220, 127 or 110 V, low voltage lamps, usually 12 V, are very widely used. Like all incandescent lamps, halogen lamps react sharply to changes in voltage in the network. An increase in voltage by 5-6% can lead to an almost twofold reduction in service life. Energy efficiency is 1.5-2 times higher than other incandescent lamps.

The service life of most lamps is 2000 hours, that is, 2 times longer than conventional incandescent lamps. Some types of mirror lamps are available with 3000 and 4000 hour life.

Energy efficiency is 1.5-2 times higher than other incandescent lamps. The luminous power of tubular lamps varies from 14 lm/W (at 60 W) to 25 lm/W (at 2000 W). For other lamps, luminous efficiency varies from 14 to 17 lm/W at mains voltage and up to almost 20 lm/W for low-power low-voltage lamps.

Mains voltage lamps with cylindrical or candle lamps successfully replace conventional lamps in all areas of their application, and especially where small dimensions are required for placement in limited spaces or in hidden places. Mirror luminaires, especially for low voltage, are almost indispensable in the technique of accent lighting for exhibitions, museums, shop windows, restaurants, residential premises, etc.

Fluorescent lamps

It is more convenient for consumers to carry it out according to the shape of the lamps: straight tubular, curly and compact fluorescent lamps (CFLs). The principle of operation is to use electroluminescence (the glow of metal and gas vapors when an electric current passes through them) and photoluminescence (the glow of a phosphor substance when it is irradiated with another, for example, invisible ultraviolet light). In a fluorescent lamp, electrical discharge occurs at low pressure of mercury and some inert gases; Electroluminescence is characterized by very weak visible and strong ultraviolet radiation. The luminous flux of the lamp is created mainly by photoluminescence converting UV radiation into visible light through a layer of phosphor covering the inside walls of the tubular glass bulb.

Thus, the lamp is a kind of converter of invisible light into visible light. Energy efficiency is the main advantage of fluorescent lamps. Their luminous efficiency, depending on color, color rendering quality, power and type of ballast, varies from 50 to 90 lm/W. Lamps with low power and high color rendering quality are the least economical.

Since the lamp is not intended for direct connection to the network, when marking it, the voltage value on the lamp is not indicated. The lamps included in the ballast are usually designed to be powered by AC power. DC power requires special ballasts.

The lamps have a long service life of up to 15,000 hours. Some manufacturers cite economical lifespans that can be half as long to optimize lighting costs. The service life specified in the technical documentation is significantly less than the lamp service life before complete failure. Frequent switching on will shorten the lamp life.

Fluorescent lamps are the most popular light source for creating general lighting in public buildings: offices, schools, educational and design institutes, hospitals, shops, banks, textile and electronic industries, etc. It is highly recommended to use them in residential areas: for illumination of workers surfaces in the kitchen, general or local (next to the mirror) lighting in the hallway and bathroom. It is not recommended to use lamps in high rooms, at air temperatures below 5 ° C and in difficult operating conditions.

Compact fluorescent lamps

The main feature of compact fluorescent lamps (CFLs) is the formation of a gas-discharge tube in various ways, which would ensure a sharp reduction in the length of the lamp. In addition, most low-power lamps designed to replace incandescent lamps are designed so that they can be screwed into a threaded holder directly or through an adapter. Lamps are also produced: with an external light-diffusing shell or reflector. Sensitivity to voltage fluctuations is the same as that of other fluorescent lamps. Short-term voltage fluctuations in the network are allowed within ± 5-7%, although the efficiency of the lamps is maintained even with large voltage fluctuations.

Most lamps have a lifespan of 10,000 hours, which is 10 times longer than incandescent lamps. With an average operating time of 8 hours a day, lamp replacement is required once every 3-4 years.

Lamps with built-in ballasts do not require any additional devices for their operation. Other lamps can be operated with a remote control mechanism or a control mechanism built into the adapter for a standard threaded holder.

Energy efficiency is one of the main advantages of CFLs over incandescent lamps. The luminous efficiency of lamps ranges from 40 to 80 lm/W, increasing with increasing power and deteriorating color quality. CFLs with a power of 5, 7, 11, 15 and 20 W are replaced without reducing illumination by incandescent lamps with a power of 25, 40, 60, 75 and 100 W.

CFLs combine the best properties of incandescent lamps and conventional fluorescent lamps and are gradually replacing these sources from traditional applications in residential and public buildings. Their use has been successful in illuminating surrounding areas and for emergency evacuation purposes. In some countries, energy saving programs are implemented at the state level and are based on replacing incandescent lamps with CFLs.

High pressure discharge lamps

High-pressure discharge lamps used for lighting can be divided into three groups: mercury arc fluorescent (DRL), metal halide (MGL), and high-pressure sodium (NLVD) lamps.

The basic elements of all lamps are the same. In a burner made of durable, refractory, chemically resistant transparent material, in the presence of gases and metal vapors, a glow discharge of electroluminescence appears. The burner of DRL and MGL lamps is made of quartz, and the NLVD is made of special polycor ceramics. The burners contain flammable argon or xenon gas and metal vapors under high pressure: mercury (for DRL), mercury and a mixture of halides of some metals (for MGL, hence the name of these lamps), mercury and sodium vapor (for NLVD). The discharge occurs under the influence of voltage , applied to the burner electrodes. Some lamps have an auxiliary electrode for easier ignition. The burner is located inside an outer bulb, usually transparent for MGL and NLVD, or coated on the inside with a layer of phosphor (to improve color rendering) for DRL. Small lamps MGL and NLVD are also produced without an external lamp (mainly for installation in floodlights).

Lamps can have very high power, reaching 1000 and 2000 W. For indoor lighting of relatively small rooms, MGL and NLVD with a power of 35 and 70 W and DRL with a power of 50,80 and 125 W are of interest.

DRL lamps are the least sensitive to voltage fluctuations. When the mains voltage changes by 10-15% up or down, the work lamp reacts with a corresponding increase or loss of luminous flux by 25-30%. If the voltage is less than 80%, the power lamp may not light up and may go out when turned on.

Most lamps have a lifespan of 10,000-15,000 hours. Some manufacturers claim a lifespan of 20,000 hours for some types of NLVD.

DRL lamps have the lowest luminous efficiency among the gas-discharge lamps considered: 40-60 lm/W, the highest LVD up to 120 lm/W. MGL lamps occupy an intermediate position: their luminous efficiency ranges from 60 to 100 lm/W. The luminous flux of lamps increases with increasing power.

Traditional use of DRL lamps: lighting of open areas, industrial, agricultural and warehouse premises. Wherever this is due to the need for significant energy savings, these lamps are gradually being replaced by NLVD (lighting of cities, large construction sites, high-performance workshops, etc.). The main areas of application of MGL are: outdoor and indoor sports facilities, some rooms such as halls in public buildings, high production premises with high requirements for color rendering. Lamps of all types, low power, can be successfully used for lighting areas, garages, and also for emergency lighting. MGL and NLVD with improved color rendering power of up to 70-100 W are beginning to displace incandescent and fluorescent lamps from their applications in public and residential buildings. All types of lamps are successfully used for outdoor lighting and lighting design of cities (building facades, fountains, monuments, green spaces, etc.)

Optical fiber

Fiber optic lighting technologies have been around for decades but are still considered exotic. Meanwhile, the use of optical fiber can easily and elegantly solve hundreds of technical problems that arise in the development of lighting projects, and in many cases it is the only possible solution.

And this is not at all surprising when you consider the amazing nature of fiber optic lighting technology, which allows you to manipulate light like a genie in a bottle: direct it into a flexible light guide, send it through walls, through land and water, around corners and avoiding obstacles, and if necessary, extract in the required quantities and use for its intended purpose. The physical phenomenon of multiple total internal reflection helps to “command” light. The structural basis of flexible optical fibers is glass optical fibers, which are manufactured with special additives that ensure their resistance to fungi, mold and algae, as well as additives against the harmful effects of ultraviolet radiation. The fiber consists of a soft core and a hard shell.

Different materials refract light differently, which forces the physics of total internal reflection to work: the core must have a higher refractive index than the cladding. Fiberglass has long been used in telecommunications for high-speed data transmission. Much hope is now placed on polymer fibers (POF plastic optical fiber), which are about half the price of glass. Plastic is not suitable for creating high-speed data lines, but it is quite suitable for distances of the order of several tens of meters. Therefore, it is expected that polymer fiber will become the basis for the next revolution in home networks, creating a new generation of smart homes.

A POF-based network will connect all home management and maintenance systems with multimedia storage of audiovisual and any other information. If such a project is successful, the price of polymer fiber will naturally fall, which, among other things, will lead to wear and tear of fiber optic lighting systems, the main disadvantage of which is still the relatively high cost. However, this is the future and the present must recognize the fact that today plastic fiber is widely used in lighting, leaving glass far behind in terms of sales.

Fibers come in different diameters, and the thinner the fiber, the easier it is to bend, so using an optical fiber (fiber optic cable) that combines multiple fibers is more practical than using a single larger diameter fiber. To mechanically protect the fibers, the fiber uses a plastic sheath, similar to the insulation of a conventional cable (PVC, Megolon, etc.).

In case of significant mechanical loads, a double shell is used. There are two types of light guides: end and side illumination. Fiber optic cables with end glow operate according to the classical scheme of transmitting light with minimal losses at a given point in space. The principle of operation of side-glow cables, on the contrary, is based on the “side effect” of glow of the optical fiber, which arises due to losses due to internal reflection when part of the light passes through (this occurs when the fiber is bent, when the angle of incidence of the rays is less than the limiting one and, in fact, , internal reflection does not become.Side glow light guides use the same fibers as edge light cables, only they are specially twisted or woven using a transparent flexible sheath, and the light becomes clearly visible, creating a side glow along the light guide.

How does fiber optic lighting work? Light enters from the projector at one end of the optical fiber, is delivered to the desired point in space by propagating within the fiber due to the phenomenon of total internal reflection, and is freely emitted by the other end of the optical fiber.

Is fiber optic lighting efficient? The efficiency of a fiber-optic lighting system does not exceed 15-20%.

At first glance, conventional lighting is much more efficient: the typical luminous efficiency of conventional lamps is 50-70%.

However, it should be borne in mind that traditional lighting installations are characterized by high light losses, where part of the emitted light is lost in space or even leads to unwanted (stray) lighting. At the same time, the overall efficiency of the installation, taking into account the so-called utilization of luminous flux, can be significantly lower, and the 15% provided by a fiber optic system becomes a completely competitive result.

Is it economical to use fiber? The answer to this question depends heavily on your system configuration. When a single projector is used to power a large number of relatively short optical fibers, the use of optical fibers can provide significant savings.

Is it easy to work with fiber optics? Today, working with fiber optic systems may be even easier than working with conventional electric lighting.

Is fiber optic safe? Optical fibers do not conduct electricity, and the amount of heat they generate is negligible.

Fiber optics can be in direct contact with water and any building materials. Optical fibers do not conduct ultraviolet and infrared radiation.

How durable are fiber optic systems? Manufacturers of both polymer and fiberglass claim an average service life of more than 20 years.

Fiber optic lighting system. The three main parts of the system are the projector, light guide and optical attachments. A projector is not just a box with a lamp, but a rather complex device, which, in addition to a light source with a built-in reflector, may contain a power source, ballasts, a screen, an optical port, a cooling system with a fan, as well as devices for creating special effects: an electric motor with a disk or drum for installation of color filters or perforated screens, synchronizers, DMX control devices, etc.

Depending on the light sources used, the projector can be halogen, gas discharge or LED.

Halogen projectors are equipped with dichroic halogen lamps, typically 50.75 and 100 Watts. Halogen projectors can be animated, with controlled color changes (including the DMX512 protocol used in professional stage lighting), and also adapted to create special effects (for example, “starry skies”). HID projectors are equipped with metal halide lamps, usually 70 or 150 W, rarely 250 and 400 W. Additional options are the same as their halogen counterparts.

LED illuminators use semiconductor devices (LEDs) as a light source.

The projector is an active element of a fiber-optic lighting system that requires special handling during installation and maintenance. First, it is typically the only device that requires light voltage to power it, so the projector must be connected by a qualified electrician with the appropriate approval. Secondly, proper placement of the projector is very important. If possible, it should be placed near the ends of the optical fibers; this will significantly reduce the cost of the system. Provide access to the projector for cleaning and lamp replacement. Finally, ventilation is a very important aspect. For polymer fiber systems, ensure that the temperature around the optical port does not exceed 30°C, so there must be enough air in the room where the projector is to be installed. If the projector is installed in a sealed box (such as in the ground), provide forced ventilation.

A fiber optic bundle is a unique part of a system consisting of a group of fibers and optical fibers of various sizes and lengths. The light guide beam, or rather the end connected to the projector, is processed in a special way and inserted into the optical port connecting device.

The bare light guide beam is used for decorative purposes: signs, plaques, starry skies and other installations with a large number of light points. A bundle of light guides made of clad fibers and end light guides is used both for decorative purposes and for illuminating objects. Side light guides are used for decorative purposes as a replacement for neon tubes with the unique ability to change color. Glass light guides are used in industrial projects at high ambient temperatures and in applications where clear color reproduction is required.

The optical attachments used to redistribute the light output from a fiber optic light guide in space are very diverse and are similar to different types of miniature lamps. The attachment is fixed, rotatable, angled (“slant light”) with a light beam adjustable in width and is purely decorative. Often there is a need to develop custom applications to solve a specific problem.

Conclusion

Light is the most important visual means of controlling the shape of objects: it can enhance its expressiveness and destroy it. To better define the shape, you need to choose the preferred direction of the light; with uniform illumination of a volumetric element from all sides, it may look flat. The desired modeling effect can be achieved with the right combination of general diffused or indirect lighting with direct directional light; When lighting objects with deep, pronounced relief, soft diffused or reflected light should most often play a predominant role (this case also applies to lighting a person’s face).

When using directional lamps, it is necessary to carefully check the possibility of the formation of unwanted falling shadows, which can disrupt the shape of both the illuminated and nearby objects, as well as the interior as a whole. Thanks to the targeted use of falling shadows, it is possible to create light images and different light rhythms on the planes of the room, enriching the shape and plasticity of the interior.

Black and blue visually reduce the size of the object, while white and red increase it.

Ensuring the comfort of light colors with balanced lighting is a major challenge in interior design for work or leisure. The main components of lighting comfort include: a sufficient level of illumination to perform a given visual work; reducing the level of direct and reflected glare; balance of brightness and color of the floor, ceiling, walls, as well as the visual work area; tied to the color finish, the color tone of artificial lighting; increased color rendering, properties of light sources and low pulsation of lighting in the workplace.

When decorating the interior, the following features and recommendations regarding measures to reduce the harmful effects of light on materials and products should be taken into account:

- the least resistant to light are photographs, manuscripts and documents; painting (watercolor, tempera or pastel) and graphics; tapestries, lace and clothing; collections of stamps or insects;

- for such products, lighting levels in accordance with museum lighting standards should not exceed 50 lux;

- incandescent lamps have the least destructive properties, natural light, especially direct sunlight, has the greatest;

- ultraviolet radiation has the greatest effect on fading, and infrared radiation has the greatest effect on drying and deformation;

- The most valuable and light-resistant products are preferably placed at the back of the room or in areas without natural light.