Thermal effect of electric current

Back in the nineteenth century, experiments on conductivity showed that current passing through a load heats it. Research has shown that not only the load heats up, but also the conductors.

Rice. 1. Thermal effect of electric current.

This fact can be easily explained if we remember that electric current is the movement of charges in a load substance. When moving, the charges interact with the ions of the crystal lattice and give them part of the energy, which turns into heat.

Joule-Lenz law

Since the potential difference (voltage) across the load is equal to the work done by a unit charge moving across the load, to calculate the work of the current, it is necessary to multiply the voltage by the charge passing through the load. The charge is equal to the product of the current passing through the load and the passage time. Thus:

A detailed study of the thermal effect of electric current in the mid-19th century was carried out independently by D. Joule (Great Britain) and E. Lenz (Russia).

Rice. 2. Joule and Lenz.

It was found that if the load is stationary, then all the work of the electric current in this load will turn into heat:

As a rule, the voltage across the elements of an electrical circuit is different, but the current in it is common. Therefore, to determine the thermal effect, it is more convenient to express the voltage in terms of current, taking into account the resistance:

That is, the amount of heat generated in the load is equal to the product of the squared current, resistance and time. This conclusion is called the Joule-Lenz Law.

Sometimes the load current is unknown, but its resistance and input voltage are known. In this case, it is more convenient to express the current in terms of known quantities:

and, substituting into the formula above, we get:

From this formula you can see an interesting fact - if part of the spiral burns out in the heating plate, and we simply exclude the burnt places, then the resistance of the spiral will decrease, and since the network voltage remains the same, the heat generated by the stove will increase. The power of the tile will increase.

Practical significance

It is clear that the amount of heat generated depends on the current density and conductivity of a particular substance. The corresponding influences can be clearly recorded by successively passing a current of 2 and 50 A through a control copper conductor with a cross-section of 2 mm2. In the second experiment, the heating will be much stronger. It can be reduced by increasing the diameter of the conductor.

Reduced energy loss

This example demonstrates an undesirable phenomenon for power lines. Using part of the energy to heat the surrounding space increases the losses of overhead lines. Exceeding the threshold value provokes the destruction of veins and protective shells. Excessive temperature increases are the cause of fires.

Similar phenomena occur if excessive current is selected or the cross-section of the conductor is insufficient. The amount of heat generated in the line is inversely proportional to the square of the voltage (U) at the connected consuming device. By increasing U, losses can be reduced. However, such an action increases the likelihood of a short circuit and worsens the overall safety parameters.

Choosing wires for circuits

The thermal destruction problems noted above largely depend on the resistivity (Ry). For clarity, you can use materials with significantly different characteristics.

Calculations of the amount of heat ( Q , J) for samples 1 m long with a cross section of 1 mm square. with a current of 5A for 30 seconds:

- copper – 12.75;

- steel – 75;

- nickel – 315.

Particular attention should be paid to the parameters of power cables, which must maintain integrity during actual operation. As a rule, household lines are installed deep in building structures. This method implies good protection from adverse external influences. At the same time, the costs of correcting errors and eliminating the consequences of accidents are increasing.

To use cable products correctly, you should be guided by thematic standards that are set out in the PUE. To simplify the choice, specialized tables are offered that show the calculation results taking into account the following important factors:

- type of insulation;

- duration and magnitude of overloads;

- gasket features.

Correction factors that take into account the increase in resistance with increasing temperature are separately considered in the PUE. This phenomenon is explained by an increase in the vibration frequency of atoms, which creates additional obstacles to electric current.

Example:

- the conductor is heated with a rated current of 7 A to +50°C at an ambient temperature of +25°C;

- select suitable products taking into account real conditions;

- if the cable will be used outdoors, where the temperature rises to +45°C, use a coefficient of 0.45 (the permissible current is reduced I=7*0.45=3.15 A);

- in cold weather (-5°C) choose a different correction factor:

You can speed up your selection using pivot tables. They show the permissible currents for copper (aluminum) conductors with a standardized cross-section.

Electric heating devices

Taking into account the same amount of current in any part of a single circuit, it is possible to create a design for deliberate heating of a certain zone. Here a conductor with high resistivity is installed or the cross-sectional area is reduced. An accurate calculation will help eliminate temperature increases to a critical level that destroys the product.

Power supply conductors are selected based on the principles outlined in the previous section. They must not overheat excessively under the operating conditions specified in the plan.

Fuses

Thermal circuit break is used to protect equipment and consumers if the current exceeds the rated value. Specialized devices (fuses) are made of lead, steel, and other metals and alloys. Under normal operating conditions, heat is dissipated and does not cause damage. Once the threshold values are reached, the resistance and temperature increase significantly. At a certain level, the element is destroyed and the power source is simultaneously turned off.

Fuses are evaluated by a complex parameter (K) using the formula:

Where:

- I – threshold current value;

- t is the maximum destruction time.

Disposable, inexpensive products in this category are designed for relatively low currents (0.25-2 A). The typical design is a thin wire in a quartz glass tube with contacts for mounting on a circuit board. Such fuses are installed in radio equipment to protect individual circuits. A visual check can quickly determine the integrity of the fuses.

Inserts designed for high currents are placed in sand or other special medium. This solution prevents the formation of plasma and ensures rapid chain breaking. In some modifications, the fuse housing is made of special materials that generate gas when heated strongly. It speeds up arc extinction. Mechanisms are also used that increase the distance between the contact terminals in the event of emergency situations.

For your information. For high-current circuits, fuses with replaceable inserts are produced.

Application of the thermal effect of electric current

The thermal effect of electric current is used in heating elements:

- heating devices;

- boilers;

- irons;

- washing machines and dishwashers;

- kettles, coffee makers.

Using a special cable, they prevent freezing of pipes and the formation of ice on thresholds. Heat guns quickly raise the temperature in large rooms and speed up plastering work.

It should be noted that the use of electric convectors is promising in comparison with classic heating radiators:

- simplicity;

- compactness;

- light weight;

- durability;

- good compatibility with the latest control and monitoring systems of the “smart home” category.

Separately, the high level of security should be noted. Protection of high-current circuits can be provided by cheap fuses. This is much cheaper and more reliable compared to a set of measures to prevent the formation of a gas mixture.

The thermal effect does not always perform useful functions. Outdated incandescent lamps, for example, waste a significant part of their energy on uselessly heating the surrounding space. Economical gas-discharge and LED devices work much more efficiently.

Using the thermal effect of electricity

The thermal effect of electric current is widely used, primarily in heating devices.

Another important use of thermal action is in fuses. If it is necessary to disconnect the electrical circuit when the permissible current is exceeded, then a fuse can be included in the circuit.

Rice. 3. Fuse device.

This is a small flask made of non-flammable material, inside of which there is a fusible wire or tape, the resistance of which is calculated so that when the maximum current is exceeded, it will melt, thereby breaking the electrical circuit.

Use of the thermal effect of electric current in the construction of greenhouses and incubators

Electric current

Use of the thermal effect of electric current in the construction of greenhouses and incubators.

2. Thermal effect of electric current. Joule-Lenz law.

3. Use of the thermal effect of electric current in the construction of greenhouses.

4. Use of the thermal effect of electric current in the design of incubators.

It is already unthinkable to imagine the modern world without electricity. Electric current is used by humans everywhere. Household electrical appliances have firmly taken their place in human homes; in industry, transport and various institutions, it is also impossible to do without the use of electricity.

However, rural residents, especially the elderly, continue to be cautious about the use of electric current.

Purpose of the report: Show how electric current can be used for agricultural needs.

Select literature on the topic of the report

Analysis and synthesis of literature sources

Giving a report to an audience.

Thermal effect of electric current. Joule-Lenz law.

When an electric current passes through a conductor, as a result of collisions of free electrons with its atoms and ions, the conductor heats up. The amount of heat generated in a conductor during the passage of electric current is determined by the Joule-Lenz law. It is formulated as follows. The amount of heat released Q is equal to the product of the square of the current I2, the resistance of the conductor R and the time t for the current to pass through the conductor:

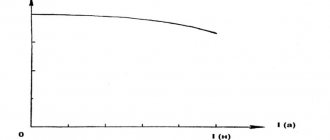

The amount of heat released in the wire is proportional to the volume of the wire and the temperature increment, and the rate of heat transfer to the surrounding space is proportional to the temperature difference between the wire and the environment.

For the first time after turning on the circuit, the temperature difference between the wire and the environment is small. Only a small part of the heat generated by the current is dissipated into the environment, and most of the heat remains in the wire and is used to heat it. This explains the rapid increase in wire temperature in the initial heating stage.

As the temperature of the wire increases, the temperature difference between the wire and the environment increases, and the amount of heat given off by the wire increases. In this regard, the increase in temperature of the wire slows down more and more. Finally, at a certain temperature, thermal equilibrium is established: in the same time, the amount of heat released in the wire becomes equal to the amount of heat released into the external environment.

Thermal effect of current, current density and their effect on heating of conductors

The thermal effect of electric current is understood as the release of thermal energy during the passage of current through a conductor. When current passes through a conductor, the free electrons that produce the current collide with ions and atoms in the conductor, heating it.

The amount of heat released in this case can be determined using the Joule-Lenz law , which is formulated as follows: the amount of heat released when an electric current passes through a conductor is equal to the product of the square of the current, the resistance of a given conductor and the time the current passes through the conductor.

Taking the current in amperes, the resistance in ohms, and the time in seconds, we obtain the amount of heat in joules. And considering that the product of current and resistance is voltage, and the product of voltage and current is power, the result is that the amount of heat released in this case is equal to the amount of electrical energy transferred to a given conductor during the passage of current through it. That is, electrical energy is converted into thermal energy.

The production of thermal energy from electrical energy has been widely used since ancient times in various technologies. Electric heating devices, such as heaters, water heaters, electric stoves, soldering irons, electric ovens, etc., as well as electric welding, incandescent lamps and much more, use this principle to produce heat.

But in a large number of electrical devices, heating caused by current is harmful: electric motors, transformers, wires, electromagnets, etc. - in these devices, not designed to generate heat, heating reduces their efficiency, interferes with efficient operation, and can even lead to emergency situations.

For any conductor, depending on the environmental parameters, there is a certain permissible current value at which the conductor does not noticeably heat up.

So, for example, to find the permissible current load on the wires, use the parameter “current density” , which characterizes the current per 1 sq. mm of the cross-sectional area of a given conductor.

The permissible current density for each conductive material under certain conditions is different; it depends on many factors: the type of insulation, cooling intensity, ambient temperature, cross-sectional area, etc.

For example, for electrical machines, where the windings are usually made of copper, the maximum permissible current density should not exceed 3-6 amperes per sq. mm. For an incandescent lamp, or more precisely for its tungsten filament, no more than 15 amperes per sq. mm.

For lighting and power network wires, the maximum permissible current density is taken based on the type of their insulation and cross-sectional area.

If the conductor material is copper and the insulation is rubber, then with a cross-sectional area of, for example, 4 sq. mm, a current density of no more than 10.2 amperes per sq. mm is allowed, and if the cross-section is 50 sq. mm, then the permissible current density will be only 4.3 amperes per sq.mm. If the conductors of the specified area do not have insulation, then the permissible current densities will be 12.5 and 5.6 amperes per sq. mm, respectively.

What is the reason for the decrease in permissible current density for conductors of larger cross-section? The fact is that conductors with a significant cross-sectional area, unlike conductors with a small cross-section, have a larger volume of conductive material located inside, and it turns out that the inner layers of the conductor are themselves surrounded by heating layers that interfere with heat removal from the inside.

The larger the surface area of the conductor in relation to its volume, the greater the current density the conductor can withstand without overheating. Uninsulated conductors allow heating to a higher temperature, since heat is removed from them directly into the environment; insulation does not interfere with this, and cooling occurs faster, so a higher current density is allowed for them than for insulated conductors.

Examples of the action of electric current

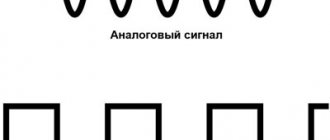

As you know, we cannot see moving charges (electrons, ions), since they are very small. But how then can electric current be detected?

EFFECTS OF ELECTRIC CURRENT

When electric current flows, various phenomena can occur, which are called the effects of electric current.

THERMAL EFFECT OF CURRENT

Electric current flowing through the wires causes them to heat up.

Let's connect iron or nickel wire to the poles of the current source. By closing the key, you can observe how the wire sag, that is, it heats up and lengthens. Thus, it can even be red-hot.

It is on the thermal effect of current that the operation of various household heating devices, such as an electric kettle, electric stoves, irons, etc. is based. The light bulb filament becomes hot and begins to glow.

CHEMICAL EFFECT OF CURRENT

Experience shows that a pure substance is released on electrodes immersed in an electrolyte solution. This process is called electrolysis. For example, by passing a current through a solution of copper sulfate, pure copper can be isolated.

Electric current in metals does not cause any chemical changes. The chemical effect of current occurs only in solutions and melts of electrolytes.

MAGNETIC EFFECT OF CURRENT

We wind a thin insulated wire around a large iron nail. We connect the ends of the wire through a key to a current source.

If you close the key, the nail will be magnetized and will attract nails, iron filings, and sawdust. When the current in the conductor stops, the magnetic properties of the nail will disappear.

The phenomenon of interaction between a current-carrying coil and a magnet underlies the operation of a device called a galvanometer . Using a galvanometer, you can judge the presence of current and its direction. The arrow of the device is connected to a moving coil. When electric current appears in the coil, the needle deflects.

MECHANICAL EFFECT OF CURRENT

Let's connect the metal frame to a current source. When an electric current is passed through the frame, it remains hanging motionless. But if this frame is placed between the poles of a horseshoe magnet, it will begin to rotate.

In this experiment, we observed the mechanical effect of electric current , which consists in the fact that electric current, when flowing through a frame placed between the poles of a magnet, causes it to rotate.

Chemical effect of current

An electric current passing through solutions of certain acids, alkalis or salts causes the release of a substance from them. This substance is deposited on electrodes - plates dipped into the solution and connected to a current source.

This effect of current is used in electroplating - metal coating of certain surfaces. Nickel plating, copper plating, chrome plating, as well as silver and gilding of surfaces are used.

Using a solution of copper sulfate, you can demonstrate the release of a substance under the influence of current. An aqueous solution of this salt has a bluish tint. By passing an electric current (link) through the solution, you can detect copper precipitation on one of the electrodes (Fig. 3).

At which electrode will copper be deposited?

Copper in the vitriol solution is present in the form of positive ions. Bodies with opposite charges attract each other. Therefore, copper ions will be attracted to the plate, which has a charge with a minus sign. That is, a plate connected to the negative terminal of the current source. This plate is called a negative electrode, or cathode.

The second plate connected to the positive terminal of the battery is called the anode.

Note: Copper sulfate can be found at a hardware store. Its chemical formula is \(\large CuSO_\). It is used in agriculture for spraying the foliage of fruit trees, shrubs and vegetable crops - for example, tomatoes, potatoes. Included in various solutions used in the fight against plant diseases and insect pests.

Application of the chemical action of current in medicine

The chemical effect of current is used not only in electroplating.