Where are cable lugs used for crimping?

We can talk endlessly about the areas of application of crimp wire lugs. In order not to overload the reader with unnecessary information, we will consider only the main ones:

- in production. Not a single connection of power lines to each other or to electrical equipment is complete without crimping the cable lugs. This ensures tight contact and, as a result, reliable operation of electrical appliances and equipment. The shape and size of such elements are selected according to the cross-section of the cores and the material of manufacture;

The main advantage of such connections is reliability.

- household sphere. A home craftsman rarely thinks about the benefits of tips, but in vain. If we disassemble any household appliance, we will see that not a single connection is complete without them. In everyday life, elements that differ from industrial ones are used. But they perform the same function: tight contact, no heating and no need for periodic tightening of the terminals.

Cable lugs for crimping: main characteristics

Wire lugs (terminals) are universal parts used for contact connection of cables. The use of such products has a positive effect on the functioning of the electrical circuit as a whole. There is a huge range of different types of lugs on the market, so it is not difficult for consumers to choose the appropriate option for performing certain electrical installation work.

Manufacturers offer a wide range of different types of tips

Ferrules for stranded wire allow you to create a reliable connection with various components of the electrical circuit:

- screw clamp;

- terminal block;

- household electrical appliance;

- another cable.

The lugs perform well in circuits where strong vibrations often occur. They can also be used in cases where standard joining methods are not suitable. For example, if the wires are not long enough, soldering or welding cannot be used. To crimp wires in such a situation, a tip or sleeve is simply installed on the bare end, after which this area is crimped.

Advantages of using tips:

- The bundle of veins remains intact, it does not flatten or fall apart.

- The connection area does not burn or heat up.

- The integrity of the wires is maintained.

- Metal conductors are reliably protected from moisture and air.

- All wires of the bundle take part in the transmission of current.

- The tips have a large contact area.

Thanks to the lugs, the bundle of wires remains intact and does not fall apart

Connecting cables using the crimping method is used in production (connecting power lines) and in domestic conditions. The popularity of this method, in contrast to the use of conventional clamps, is due to its high reliability. In addition, connecting wires using a ferrule is much easier than using soldering or welding.

Note! The size of lugs for wires for crimping, as well as sleeves, must be selected taking into account the main characteristics of the wire. These parameters include the diameter of the cable and the type of metal from which it is made.

Marking and decoding

The industry produces a large number of all kinds of tips, which differ in design and materials.

Color coding option

There is a special marking system that allows you to distinguish the material and use it for its intended purpose. Here is a breakdown of some of the symbols:

- A – the sleeve is made of aluminum;

- L – brass is used;

- M – the base of the product is copper;

- T – the element is made of tubular metal;

- U – the connector is made in the shape of an angle.

There is also a designation in the form of the letter O, which indicates the presence of an inspection window through which you can make sure that the cables are correctly located in the sleeve inside.

If the marking is TML (O), then it means tinned tubular copper with an inspection window. NSHVI - means a pin sleeve tip, and NKI - a ring one. In this case, the numbers indicate the cross-sectional area or diameters of the rod. To make it easier to find suitable connectors, for example, NShVI or KVT, you can use a special catalog or tables.

After the letter designations in the markings there are usually numbers that contain information about:

- nominal section;

- diameter of the contact rod;

- internal diameter of the shank.

For example, the product is marked TML (O). This means that this wire termination is made of copper tubing and is tinned. Its distinctive feature is the presence of a small hole - an inspection window, with which you can verify whether the wire is inserted correctly for crimping.

Such contacts are used mainly in production, so not all electricians are aware of their existence.

Marking of tips and sleeves

To mark tips for crimping, symbols are used, including letters and numbers. For example, let’s take the marking TML 25 - 10 - 8:

- T - “pipe”, initial blank;

- M - “copper”, the material from which it is made;

- L - “tinned”, protective coating;

- 25 - cross-section, in mm²;

- 10 — hole size for the mounting bolt;

- 8 - internal diameter of the shank in mm.

Sometimes the designation may contain not three, but two digits. They indicate, respectively, the cross-section and diameter of the bolt hole.

For aluminum products, the “TA” marking is used. For example: TA 35 - 10 - 8. The letter “A” indicates the tube material - aluminum, the remaining letters and numbers indicate the same as in the marking above.

There are two types of copper sleeves: GM and GML. GM - “copper sleeve”, is a piece of copper tube without a protective coating. GML - “tinned copper sleeve” - the same design, but with a protective coating.

Designation example: GML-16 tinned copper sleeve with a cross-section of 16 mm². The cross-section of the sleeves always corresponds to the cross-section of the standard wire.

What does the tip marking mean: full explanation

Each type and type of product has its own alphanumeric marking, without knowing which it is impossible for a home craftsman to explain in the store what he needs. Let's look at popular markings:

- TML is a tin-plated tip, to work with which you need a special tool - a crimper. Looks like NSP. The only difference is that NShP is copper;

- TA – the same tip, but made of aluminum;

- SIP is a self-supporting tip that has its own insulation along the tube and an annular mounting plate;

- NSHVI - common in household use, sleeve pin;

- NKB - used in industry as geophysical cable;

- RFI-M is already a flag tip;

- IEK – copper fork;

- TMD – double blind connectors;

- NKI - isolated ring.

Aluminum products are regulated by GOST-9581-80, copper - GOST-7368-80.

Products for crimping are made of copper, aluminum or bimetal

Types of tips

For equipment to operate efficiently, simply connecting to an electrical outlet is not enough. Another important condition is to ensure a reliable contract between the equipment and the wire. A bad connection can cause:

- overloads;

- power surges.

These situations in most cases lead to devices breaking down and requiring expensive repairs or replacement. The use of special connectors will help to avoid such problems.

The material used for their production may vary. The most common:

- Aluminum. Suitable for wires with aluminum conductors with a cross section of 16−240 mm2. For their manufacture, an AD1M aluminum pipe is used.

- Aluminum-copper. Used to connect aluminum cables to copper terminals of electrical devices. The cylindrical part of such products is made from AD1M aluminum rod, the contact part, on which the mounting hole is located, is made from M1 copper rod. Both parts are connected by frictional diffusion.

- Copper. Used for wires with copper conductors with a diameter of 2.5−240 mm2. The starting material for them is solid drawn copper pipes of grade M2 and sheets of copper grades M1 and M2.

Types of tips by design

Depending on the design of the terminal and the connected electrical appliance, the shape of the tip is selected. It comes in several types.

| Photo | Name |

| Ring | |

| Fork | |

| Power | |

| Tubular or sleeve | |

| With pin | |

| Socket for quick connection of wires |

The lugs can be used to connect one or two wires; for the second case, special parts are produced. Fixation is carried out by crimping or a bolt built into the shank. The first option is most applicable in everyday life and in production; it is intended for flexible wires made of multiple cores. The second is suitable for rigid cables.

How to choose the right tip for crimping

The correct choice of this electrical installation element depends on the material of manufacture, flexibility, cable cross-section, as well as the method of connection to the device or equipment:

- Cable cross-section is an important aspect. If it is larger, the cable simply will not fit into the sleeve, and if it is smaller, the crimp will not be tight, and there is no point in such a tip.

NShVI are usually sold in such sets, but can also be purchased individually - Flexibility of the wire – this can also lead to a loose connection. For example, we use a product with a bolted connection and a flexible electrical cable. When screwed in, the bolts push the wires apart, pressing only a few “hairs” in the middle. There is no talk of any contact anymore.

- The method of connecting to the equipment may also differ. If switching is not possible with a direct connection, it is necessary to use.

Tip material

Another relevant point in choosing a tip is the material of manufacture. When purchasing, make sure that they are selling you copper or tinned tips. To do this, it is enough to first purchase one tip and file it with something foreign.

With copper material, especially if high-quality copper is used, the cut will be reddish in color. If ordinary copper alloys are used, which is most often the case, then the cut will be a pale yellowish color.

When exposed to air, copper may darken and lose contact quality. Copper tinning is a long-known method that makes the contact durable and reliable.

Advantages of crimping wires with lugs

- the crimped end of the wire is considered airtight

- the ferrule sleeve prevents individual wires from being damaged or excluded from contact

- tinned tip surface – reliable protection from environmental influences

Main types of lugs for crimping

Depending on the material from which the tips are made, there are several types of these elements:

- copper – used for cables made of copper conductors;

- tinned copper – tinning treatment provides protection against corrosion;

- aluminum – suitable for aluminum wires;

- aluminum-copper - allow you to connect aluminum and copper wires.

Elements can have different cable connector diameters and bolt mounting holes, different blade sizes and shapes. Some of them are equipped with an inspection window that allows you to adjust the position of the cores inside the part.

Types of tips by material

Copper cable lugs: general information

Copper cable lugs for crimp testing are made from copper pipes of a certain diameter. The pipes are cut and flattened on one side. A hole of a certain diameter for a bolt is made in the flattened part. Produced at special enterprises.

There are two types of copper cable contacts:

- uncoated cable lugs;

- with tinned coating.

Tinned contacts are considered more practical to use. Tinned coating protects the part from corrosion and extends its service life. In addition, tinned contacts are resistant to solutions of nitric, sulfuric and hydrochloric acid.

They are not afraid of exposure to air, moisture and other aggressive environmental factors. Due to the coating, the electrical conductivity of the terminals is reduced. However, it consistently maintains excellent performance.

But uncoated copper contacts will oxidize very quickly. Because of this, the conductivity indicator decreases, the resistance increases, which leads to heating of the connection.

The lugs are used for terminating cables with copper cores. For their installation, special press pliers are usually used, which are used to crimp the end onto the cable.

Copper cable lugs for crimping are used for:

- establishing communication between the power grid and the device;

- establishing contact between devices or a group of devices;

- splicing several electrical wires to increase the length.

Homemade copper

Today there are many cable copper crimp terminations, which, in particular, are very easy to decipher. But there are cases where it is impossible to select a cable lug of the required volume. Then it is possible to use a non-standard option - to create one yourself.

The creation process is simple. To do this, you need to take a copper tube with a certain size. Next, flatten the end and make a hole with the desired diameter.

Homemade copper

NShVI pin lug

NSHVI - insulated pin sleeve end. The sizes of NShVI tips are from 0.25 to 150 mm. Made from tinned electrolytic copper. Designed for household use, suitable for any multi-core wires.

Main types

There are different types of lugs for use with wires of different modifications and cross-sections. Let's look at the most popular of them:

Used to work with copper wires. They are made from seamless tubes. On one side there is a clamping part, and on the other side there is a tubular hole for the wire. This type of product is used for installing electrical appliances, connecting input distribution devices and for grounding.

For aluminum cores, connecting parts made of the same material are used. At one end there is a contact blade with a hole, and at the other there is a tubular hole. The cores are connected to the tip by crimping with a special tool. The product is first lubricated with quartz vaseline lubricant, which protects against oxidation.

Switchgears can use copper busbars, for which aluminum-copper terminations are suitable. In them, the landing tube is made of aluminum, and the contact blade is made of copper. Products are made using the friction diffusion method or gas-dynamic spraying method. In this case, copper plating covers the product on top, which allows for stable contact.

Fastened with a clamping bolt. In this case, crimping is not necessary, since the bolt is part of the contact connection. Tightening is done with a wrench.

Sleeves for wires for crimping

Sometimes there is no need to use a ferrule, but crimping the wires with sleeves is required. They can be of two types - GML (tinned copper sleeve) or GAO (copper-plated aluminum sleeve). The choice depends on the cable material.

Good to know! When connecting aluminum wires, it is advisable to use quartz vaseline paste. It prevents the oxidation process from occurring.

Twisted pair cables are crimped in a similar way. The only difference is in the matrices

Copper and aluminum tips

The choice of ferrule or sleeve depends on the core or wire material and the environment. For copper, copper cable lugs are used, for aluminum - aluminum cable lugs for crimping. In aggressive environments, tinned copper is used.

To make a reliable electrical connection of the wires, use the appropriate type of sleeve. Special grades of electrical copper and aluminum are used as materials for the manufacture of tips and sleeves.

Copper - used for terminating copper cables and wires and are used for cables with copper cores, cross-section 2.5-240 mm² and voltage up to 35 kV. The best material for cable products is copper, grade M2 and higher (GOST 617−72). Copper ensures reliable contact. It is less susceptible to aggressive environments. A copper cable lug is manufactured for crimping from a solid-drawn copper tube using the flattening method. A hole is drilled in the flattened part for a bolt of the required diameter.

There are two types of copper:

- Without coating - standard.

- Tinned by electrolytic method.

Preference should be given to tinned products. The coating contains tin and bismuth. The thickness of the coating ranges from 6 to 12 microns. This coating protects the tips from moisture and aggressive environments, which increases their durability. Products without coating quickly corrode, which impairs their electrical conductivity and causes heating at the joint.

Aluminum lugs are used for crimping cable cores and aluminum wires with a cross-section from 16 to 240 mm. The material used is aluminum tube AD1M (GOST 1847582).

Why crimping?

Soldering a stranded wire is not the easiest operation, because you need to expose all the wires, make sure that they are clean in terms of contact, and only then start soldering. Any core in a stranded wire has insulation, and this often creates difficulties in establishing reliable contact.

Just crimping the cable lugs solves all these problems, because with the help of mechanical force (compression) not only the insulation of individual cores is destroyed, but also a strong connection of the entire cable is created for better contact.

This is where the moment arises of how to choose the correct sleeves for crimping wires, because they are made from different materials and have very precisely specified current characteristics.

The problem is that the size of these cartridges is small, and the markings are unclear to those who are not specialists. But before that, let's define the difference between a sleeve and a cable crimp lug.

Another point that is not even in the markings is the moment of tightening the sleeve or tip during crimping. And they are completely different for different types of tips, such as:

- ring (NKI).

- fork (NVI).

- pin round (NSHKI).

- flat (plug) connectors (RPI-P, RPI-M, RSHI-P, RSHI-M, etc.).

- piercing type couplers (OV).

Here it is necessary to return to the tool that is used to crimp the wires, because on each tool the dimensions are indicated for the standard shape of the jaws, and the force itself is accurately measured by diameters. So, unless you made a mistake with the diameter, you cannot apply excessive force.

And, despite the fact that the lugs for wires for crimping are different, with the same diameter both the force and the standard of the tool will be the same. It's a pity that this parameter is not reflected on the labeling. Apparently because such work is usually done by professionals, not home electricians.

But it is precisely the standards that allow home electricians to stock up on universal crimping pliers and crimp cable lugs for their own purposes without any problems. This procedure is quite simple to master, and technologically it is the same for crimping an RG-45 connector and a tip for a three-phase machine.

When crimping a multi-core cable, you cannot do without special lubricants. Therefore, use sleeves and tips that already have this lubricant inside. In any case, this is a one-time operation. It is not possible to remove a part to move it to another location.

As a result, having mastered the installation of sleeves and tips, you will be able to quickly restore the desired connection, carry out repairs without problems, as well as a connection that, in fact, will not need repair for many years.

What are wire lugs for crimping used for and areas of application?

The use of cable lugs significantly increases the quality of the electrician’s work and also facilitates the procedure for connecting cables. Cables are terminated with the help of lugs and sleeves for their strong fixation. Using aluminum, copper and combined lugs, it is possible to combine power sources and different installations.

Tip and stripped wire

Tips are a universal tool. On the modern market there is a huge assortment of them, from which you can choose the necessary option for a certain type of installation work.

Different types of tips

In order to be able to select a tip for a specific cross-section, it is marked at production. If the dimensions are chosen correctly, the crimping of the cable lugs will be as reliable as possible.

Preparation for crimping

To crimp using a cable lug, you need to prepare the wire. See the table below for how to do this.

| Photo | Action |

| Measure the depth of the shank, add 5 mm and make a mark on the cable | |

| Clean the conductors from the insulating layer, check that the edge is smooth | |

| Degrease the wire and put a tip on it, the wires should fit tightly inside the shank |

Procedure for crimping cable lugs and sleeves

For crimping thick-walled tips and sleeves, it is best to use a hydraulic press. The press set initially includes universal dies for any tips and wires.

Under no circumstances use a tool not intended for crimping (hammer, chisel, etc.). A contact pressed in this way will not last long, especially if it constantly experiences heavy loads.

The next question that arises for an ignorant user is: how many times should I press the tip with a press? Once, twice or three times?

This depends on 2 parameters - the length of the tip and the width of the matrix.

In the operating instructions for the press that comes with the tool, there is a sign indicating the required number of crimps. Please note that this table is intended for tips and sleeves made in accordance with GOST.

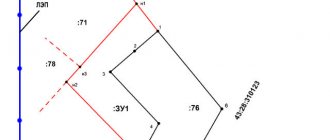

Insert the tip into the press so that the matrix cross-section markings (35-50-70, etc.) are imprinted on the front side of the tip, and not on the side or bottom.

- do the first crimp test closer to the blade (where the bolt is inserted);

- Perform the following crimps in order, moving from the blade to the tail of the tip.

The same rules apply for connecting sleeves.

This must be done in this sequence, because with each press the tip tends to lengthen (sometimes up to ten percent!).

And if you start pressing from the end (not from the blade), during the last crimp, there is a high probability that you will have a void at the end of the sleeve. And you will not achieve the contact that was necessary. First of all, this applies to all aluminum products. For copper this is not yet so critical.

Crimping tools

A special tool is used for crimping. Human effort is not enough for high-quality crimping of a cable core. The choice of tool depends on the cross-section of the cable or wire and the product used. Enterprises produce several types of such tools. Here are some of them:

- Press jaws PK-2. Hand tool. It is used if the core cross-section does not exceed 10 mm².

- Press jaws PK-1. Reinforced hand tools due to elongated handles. Used for core cross-sections up to 50 mm².

- Manual mechanical press RMP-7 - used for cross-sections up to 240 mm².

- Hydraulic press MI-2 - core cross-section up to 240 mm².

Before starting work on crimping the ends of the core and wire, you need to prepare:

- The cut of the cores must be strictly perpendicular.

- It is necessary to remove the insulation from the core. The length of the core without insulation should be 5 mm greater than the size of the tip shank.

- You need to remove the oxide film from the surface of the copper core and degrease it, then lubricate it with technical petroleum jelly.

- If the core has a sector shape, it must be rounded.

- The surface of the aluminum core must be cleaned to a metallic shine, then lubricated with quartz-vaseline grease. The lubricant protects the core from the formation of an oxide film.

Ferrule crimping

To find out which tool is best to use for crimping various types of tips, watch this video:

As you can see, you don’t need any special intelligence or experience to use the tips; everything is done easily and quickly. The only thing you will need are special devices - a stripper and press pliers, but they are affordable and can be purchased. When connecting multi-core conductors, be sure to use lugs and make the power supply as reliable and safe as possible.

How to crimp a wire: instructions for single and double NShVI

The wire with the tip must be installed in press jaws in a matrix of a suitable size. During the crimping process, you need to ensure that the wire does not move inside the sleeve. The first crimp is done with an indentation of 1–2 mm from the edge, if necessary, the second at the same distance from the first.

The handle of the press pliers is compressed until it is in full contact with the surface of the part and the matrix is connected, then the sleeve is moved and a second crimping is done. If the shank is long, work continues until the colored skirt.

The crimping scheme for a double tip is practically the same. You only need to insert two wires into one hole in the shank at the same time.

Stages of wire crimping

Visual instructions for crimping a wire with an NShVI lug are presented in the video:

Crimping power cable lugs

When crimping power cables, tinned copper lugs are used, which are well protected from corrosion. If, when cutting the cable, its cores “fluff” significantly and become larger in diameter than the rest, then perform the work on a sharpener. When unrolling the cable, make sure that the circle removes excess knots along the cores and does not bend them.

Soldering is absolutely not suitable for crimping a power cable, since single tin contacts cannot be used on such wires.

Installation tool

Cable lugs are held on the wire by elastic force. Bare conductors are inserted into the tube and crimped. Wire lugs are crimped using press pliers, also called crimpers. You can often hear the name “crimper”. Press jaws can be mechanical or pneumatic.

Press jaws KVT PKVk-16u (74594). Designed for sleeve tips NShV and NShVI from 0.25 mm² to 16 mm² and NShVI2 from 0.5 mm² to 6 mm²

In everyday life, mechanical ones are definitely used, since pneumatics are too expensive. Note that choosing even a mechanical crimper is not easy. Prices range from several hundred rubles to fifteen to twenty thousand. It’s clear that you don’t need too expensive models for your home. At the same time, it is necessary that they can crimp the most common conductor diameters. Therefore, first of all, we look at what wire sections the tool works with. Typically the gradation goes like this: from 0.25 mm² to 6 mm², then from 6 mm² to 16 mm². But you can also find models with a wider “grip” - from 0.5 mm² to 10 mm². This tool is a godsend for the home electrician. More than 10 squares of wire are very rarely used in home wiring.

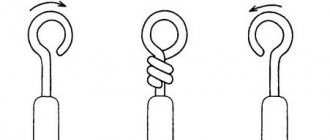

The two most common types of crimping pliers

Mechanical pliers for crimping sleeve (sleeve) tips are popular in two types: with a spring or with replaceable dies. Spring ones, in turn, can be crimped in the form of a quadrangle or hexagon. Models with removable dies can generally have a great variety of them - for different types of tips. Hexagonal ones are good with imported tips; domestic ones crimp well in the form of a quadrangle.

The shape of the die is selected according to the type of tip being installed

You need to choose crimping pliers for ferrules based on the size of the wires you will be working with. Usually this parameter is indicated directly in the name, since it is what determines many things.

Why can't you twist the wires?

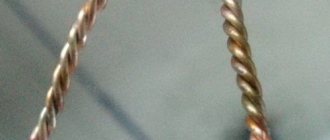

The wires inside the bushing are crimped under very high pressure, so that they can even change their original circular shape if they lie parallel to each other. From a circle they turn into a hexagon, and this increases the area of their contact surface with each other.

And when you twist them, during crimping, in those places where the veins intersect, they can be pressed against each other.

Required Tools

Crimping is carried out with a special tool that allows you to create the necessary force. The following tools are popular:

- Press pliers for crimping PK2 and PK2M lugs are used for terminating cores with a cross-section of up to 10 sq. mm;

- PK1 and PK1M brand tools are a more powerful version of hand pliers;

- hydraulic pliers allow you to crimp wires up to 10 sq. mm;

- In industrial production, a hand press is used. It is suitable for wires up to 240 sq. mm;

- hydraulic press with electric drive is used for cables up to 300 sq. mm.

Types of instruments

Press pliers with hinges increase the pressure of the tool, which makes the manual crimping process easier. Devices with a ratcheting mechanism are especially convenient. They prevent the instrument from unclenching until the procedure is completed.

You can watch how to crimp a wire without tools in this video:

Types of press jaws

The manual crimper is used for crimping non-insulated cable lugs, contact connectors, terminals and contact sleeves of various sizes. If a manual crimper has special blades (usually they are located where the handles are attached), then this tool can also be used for cutting cables and wires.

Electric pliers are a multifunctional tool for professional use. They can do almost any work with wires. Electric pliers are mainly used for cutting and stripping wires, but they can also be used to crimp uninsulated and insulated cable ends.

A crimper is a tool for crimping wire lugs, twisted pair cables, and connectors. It has two long handles (one or both can be movable) and a massive working part in the form of metal jaws, which have holes for cables.

When the handles are brought together, the jaws close and the cable connector is crimped using forceful pressing. Some models have a blade on the working part, which simplifies the work - no additional tools are required to cut the cable.

How to choose press jaws

The choice of crimping tool is determined by the cross-section of the wire. The larger it is, the more powerful the device should be. Human effort is not enough to create a tight and uniform pressure, even when using household tips.

Crimping of cable lugs is performed using one of the following tools:

- Press pliers of brands PK2 or PK2M - for manual use, suitable for wires with a cross-section of up to 10 sq. mm.

- Hydraulic pliers – designed for terminating cables up to 10 sq. mm.

- Press pliers for crimping terminals, brands PK1 or PK1M - similar to the first tool, but reinforced with long handles, due to this they are capable of crimping a wire up to 50 sq. mm.

More powerful devices, such as manual and hydraulic presses, are used in production. With their help, you can crimp wires with a cross-section of up to 30 sq. mm.

Hand press pliers for home use

Popular crimping tool

To install KVT tips, use the following tool:

- WS-04A is the optimal pliers for beginners. With their help, it is possible to solve the main set of problems in the process of installing various electrical circuits and assembling panels. Its functions include the ability to bite off and strip wires (cables) with a cross-section of up to 10-16 square meters. mm. In addition, it provides recesses for NShVI tips up to 6 sq. mm. (if desired, a cable up to 10 “square” is included) or up to 10 sq. mm. (includes up to 16 “square”). On sale you can find WS-04A pliers, which are equipped with dies for crimping NShVI. Their disadvantage is that the matrices can only cope with products of standard sizes up to 6 square. If you use wires with a reduced cross-section (fake), the quality of the connection will be poor.

- PKVk-10 is a universal tool that is used for crimping conductors of 0.5-10 sq. mm. But this is in theory, because in practice the situation is different. For example, to crimp a cable from 6 "square" and above, a lot of force will be required, and if you reduce the crimping force, the quality of contact when crimping connectors with a small cross-section deteriorates. The advantage of PKVk-10 is its compactness and the ability to get into even hard-to-reach places for installation (if necessary). The tool is best used for crimping conductors up to 4 square.

- STK-03 - powerful pliers that are suitable for large sections (from 10 to 25 “square”).

- PC-16. These pliers are useful for crimping TML from 6 to 10 sq. mm. The manufacturer sets the upper limit at 16 sq. mm., but in practice, crimping such a cable requires a strong hand and a lot of effort. Overall, the tool is not very good, but it has an affordable price. The PK-16u version is available for sale - a reinforced version that is more durable. The tool is suitable for cases where crimping is rarely carried out.

- PGRs-70 is a hydraulic press that is used for TML and sleeves. Many consider the tool as an alternative to PC-16. A special feature of the press is the availability of interchangeable dies with different cross-sections in the range of 4-70 sq. mm. With the help of such equipment it is convenient to crimp classic cables - six, ten or sixteen square millimeters. It does not require a lot of load or excessive effort.

- PKVsh-6 - used for crimping NShVI and NShV from 0.25 to 6 sq. mm., as well as a double tip NSHVI-2 with a cross-section from 0.5 to 4.0 sq. mm.

As for Wiedmuller or Knipex pliers, their disadvantage is the large divergence of the handles. As a result, it is difficult to crimp the NShVI with one hand (the fingers are not long enough).

To avoid discomfort when performing work, you should select a tool based on ease of use, and not focus on the brand.

How to crimp wire lugs without tools

What to do if you don’t have special tools for crimping on hand or you just don’t want to buy them if you only need to crimp one or two tips?

Many, faced with this problem, resort to incorrect methods, which in the future only worsen the contact, without ensuring a reliable connection. They begin to flatten the tip with hammers, simply squeeze it in a bench vice, crush it with pliers, and press it in with a chisel. All these methods are incorrect and do not bring the desired result. After such amateur activity, poor contact is obtained with its further heating during operation.

Where to buy cable lugs for crimping

Before you go to the store, you should familiarize yourself with the options offered on the market in advance. The table shows prices for some cable lugs for crimping.

Photo Products Characteristics Average price, rub.

| Tinned copper tip GPH (w = 29 mm) 120 mm.sq.*M 16 | The flange shape is ring. Material copper. | 320 | |

| Tinned copper tip GPH (w = 29 mm) | |||

| Sealed insulated tips NIM 25 (CPTAU 25) IEK | Combined material - copper and aluminum. Cross section 25 sq. mm. Longitudinal sealing available | 268 | |

| Sealed insulated tips NIM 25 (CPTAU 25) IEK | |||

| Tinned copper tip TML 2.5mm.sq. x M5 (W=10mm) | Material copper. Cross section 2.5 sq. mm. Ring flange shape. | 433 | |

| Tinned copper tip TML 2.5mm.sq. x M5 (W=10mm) | |||

| Navigator NShvi 10-12 NET-E10-12 isolated 4670004710920 155767 | Material tinned copper. Polyamide insulation. | 536 | |

| Navigator NShvi 10-12 NET-E10-12 isolated 4670004710920 155767 | |||

| Pin sleeve insulated tip NSHVI2 2.5-10, 50 pcs Peredovik 26685 | PVC insulation. Material tinned brass. Wire cross-section 2.5 sq. mm. | 87 | |

| Pin sleeve insulated tip NSHVI2 2.5-10, 50 pcs Peredovik 26685 | |||

Pin sleeve insulated tip NSHVI2 2.5-10, 50 pcs Peredovik 26685

To choose a quality product, remember that each tip must have a specific wire. The discrepancy between these two elements most often leads to errors when performing crimping. You cannot use homemade tips or cut the sleeve into two parts to save money. We hope that our advice will be useful to you and help you make the right choice.

What are wire lugs used for?

When using flexible stranded or stranded wires or cables, connections are not easy to make. For example, you need to insert a stranded wire into a screw terminal. No matter how hard you try, some of the wiring comes out from under the screw. Good luck, if you have a pressure plate - it's easier with it. But even if you manage to thread all the wiring, under the pressure of the screw, some may break off over time. Not even that. They will definitely break off. This will reduce the contact area. This will not lead to anything good.

One example of why flexible wire lugs are needed

Old school electricians use tinning to solve the problem. The wires are treated with rosin and filled with solder. Seems like a good way. All wires “keep” in a bunch and have good contact. But solder has a low melting point; when heated, it spreads and this can cause damage. And the connection can get very hot. So tinning is also not the best option.

To solve the problem, use wire lugs. They are made from highly conductive metals - copper and aluminum, less often - from brass. The cable lugs are held in place by elastic force. They are made a little larger in size than the cable/wire, and then crimped. The process is called "terminating" or "crimping". Any flexible wire with a ferrule on the end is much easier to connect. You just need to choose the type of tip. It is selected according to the type of fastener.