Power aluminum cable

Power cables and wires with aluminum conductors are used in high voltage power lines.

At high voltage values, the throughput does not depend on the resistance of the current-carrying conductors. At low voltages, this factor reduces the throughput. Aluminum power cable is widely used due to its low cost and small overall weight. Accordingly, these mentioned advantages determine its superiority over similar conductors made of copper conductors. When there are operating restrictions in terms of weight and the need for large diameter cable lines, aluminum conductors are used. Despite the presence of a number of limitations and disadvantages, this does not reduce the share of its use in various fields of human activity and production. First of all, during operation, you need to focus on the effective use of the positive qualities of the product.

In low voltage power lines, aluminum power cable has also found its application; the high resistance is compensated by increasing the cross-sectional area of the conductors.

In residential premises, it is preferable not to lay cables with current-carrying conductors made of aluminum, because aluminum connections are short-lived, unlike similar copper conductors. It is strictly prohibited to connect copper and aluminum conductors to each other. The ion exchange that occurs as a result of the connection worsens the properties of aluminum, which can lead to an emergency. When connecting, special lugs or intermediate conductors made of tin are used.

The cost of power cables with aluminum conductors varies depending on the LME/LME (London Metal Exchange) price data.

Insulation

In academic terms, insulation is a material that prevents the spread of electrical current. Dry and not entirely clear. The following sounds a little differently: insulation is a dielectric substance, a protective “jacket” that covers the conductors that transmit electric current. Glass, ceramics and various polymers, such as polyvinyl chloride or celluloid, are used as dielectrics. Recently, insulating polymers have been used, which not only protect a person from electric shock and conductors from contact with each other, which can lead to dire consequences, but also have a number of other properties. For example, they protect the conductors from mechanical stress, temperature and humidity - in general, from the destructive influence of the external environment.

PBPP wire

A wire is one or more conductive cores, twisted together, or each in its own sheath, connecting the source of electric current and the consumer. Wires can be either bare or insulated, with different types of cores. On top of the core insulation, the wires are additionally covered with another sheath, which serves to protect them from humidity, mechanical damage, light, aggressive environments, etc. In this case, the wire is called protected. For example, APRN and PRVD. Such a wire can easily be confused with a cable, and, in essence, they are not very different. In any case, it will not be a serious mistake for a home craftsman if he calls a cable a wire or vice versa.

Bare uninsulated wire is practically never found at home, since it is mounted in devices and connections inaccessible to the common man. For example, in overhead lines. In everyday life it is used only as a clamp.

Insulated wires are widely used for the distribution and transmission of electricity, not only in home networks, but also in cars. Brands PV, PV-3, APPV and PPV are the most common. They are isolated and unprotected. A separate article discusses in detail the marking of wires and describes what it means.

Design features

The aluminum power cable consists of a current-carrying core. The core is an aluminum wire. In the multi-wire version, the insulation and the supporting neutral core are distinguished by color markings. The core insulation is made of polyvinyl chloride (PVC). The outer insulating shell is made of PVC plastic. Various modifications of the cable have an armored sheath in the form of metal strips. Armor increases the resistance of conductors to mechanical damage, as well as aggressive environmental influences. When using armor, flexibility decreases.

Electrical cords

A cord differs from a cable in that it is made of 2 or 3 elastic cores that have their own insulation. Such conductors are enclosed in a common sheath of soft PVC plastic or rubber. The softness of the design allows them to be widely used in the household to power a variety of household appliances. Two current-carrying conductors are used in cases in which grounding is not required. For example, in lighting systems.

You may be interested in this Features of the branch clamp

The ShPV-1 cord is very popular among users; it is quite resistant to any external deformation, and is produced for use in electrical networks up to 380 V. Structurally, it is made of 2 parallel conductors 0.3/0.7 mm2, insulated with flexible PVC. Mainly used when connecting radio and television equipment. Another popular modification is the ShPV-2 cord for 220 V, in similar PVC insulation, and with the same cross-section as that of ShPV-1.

PVA is used to connect equipment that needs increased flexibility, for example, vacuum cleaners, portables, electric fireplaces. The voltage range is 380-660V, consists of 3/4 twisted wires, one of them is used for grounding. The cross-section of the conductors is 0.7/2.5 mm2, the product is insulated with a PVC sheath, with high elasticity.

Installation wires

Cable Specifications

Power cables with aluminum conductors are used in energy systems with the following characteristics:

Source voltage: from 0.66 to 1 kV. Manufacturing plants also produce products for voltage of 35 kV. Nominal frequency 50 Hz.

The outer shell consists of PVC insulation, which makes it possible to install it in industrial facilities, residential premises, in the ground, along bridges. They have increased moisture resistance and are not subject to corrosion. When laying in open areas, it is necessary to provide protection from ultraviolet exposure.

Cable laying conditions and environmental indicators:

— Permissible operating temperature varies from -50 °C to +50 °C;

— Humidity level up to 98% (at maximum temperature no more than +35°C);

— It is recommended to install conductors at an ambient temperature of at least -5°C, with a minimum bending radius of at least 4 cable diameters.

When laying, it is not recommended to stretch the conductor. The fire safety condition for conventional cables is met when installed separately. If a bundle of cables is being laid, it is recommended to use a cable with a lower smoke emission value. If all requirements and instructions from manufacturers are met, the service life is at least 30 years.

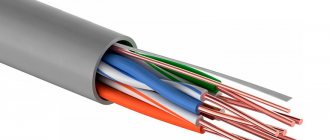

Network cables

For local networks, a cable is installed, which will be called a network cable. It consists of copper, intertwined in pairs, insulated conductors. A classic network product contains 8 wires or 4 pairs, although there are also two-pair designs. The colors of the internal insulation are strictly standardized, and the gap between two points connected by a twisted pair cannot be more than 100 m.

Based on the protection system - an electrically grounded braid of copper or aluminum foil around twisted pairs, there are variations of the network wire:

- UTP - unprotected, without additional protection. Apart from conductors with their own plastic protection, no additional braids or grounding wires are used;

- F/UTP - protected foil.

You might be interested in Description of SIP wire 2x16

There are now several groups of network cables, labeled CAT1 to CAT7. The higher the rank, the higher the quality of the product and the better characteristics it contains. Local digital Internet networks of the Ethernet standard use CAT5 with a bandwidth of 100 MHz. When building modern networks, the upgraded CAT5e 125 MHz is used.

Advantages of aluminum power cables

When compared with copper cables, power cables with aluminum conductors have both advantages and disadvantages. The disadvantage is low throughput. The main advantage is the low cost of production.

Network parameters such as reliability and long service life are ensured through the use of high-quality cable and wire products, which have high technical and operational properties. In addition, the main line made of AVBbShv 4x16 power cable must fully comply with regulatory documents and be laid in accordance with the requirements... Read more →

Cable AAShv 3x120 is used to create power lines. It is equipped with aluminum cores, specially impregnated paper insulation, an aluminum sheath and a polyvinyl chloride coating. Low cost is one of the advantages of the product. At the same time, it is characterized by resistance to corrosive activity... Read more →

The AABl-10 3x240 cable is used for the installation of power transmission lines. It is equipped with 3 conductive aluminum elements with a cross-section of 240 mm2, covered with impregnated paper insulation, an aluminum layer and protection with metal strips. When installing a conductor in a permanent network... Read more →

The cable APvBBShP 4x95 consists of four conductive parts made of aluminum wire. Their area is 95 mm2, they have an insulating coating, a shell made of cross-linked polyethylene (PEX), and armor made of a pair of galvanized tapes. Since 2012, a slightly different product labeling has been used - ... Read more →

The AVVG 4x25 cable is a wire for laying power lines, the cross-section of its conductive part is 25 square meters. mm. The product contains four cores made of aluminum. It is necessary for the installation of fixed power lines in everyday life and industry at maximum ... Read more →

The ASBL-10 3x185 cable transmits and distributes electrical energy in networks with load parameters of 50 Hz and 10 kV. When using the wire in a DC network, voltage up to 25,000 V is allowed. It can be installed in areas with tropical, temperate and cold... Read more →

The APvBbShp 4x120 cable is used when laying power lines. An armoring layer of a pair of tapes (steel coated with a thin layer of zinc) allows the conductor to be used under conditions of possible mechanical stress. In the cross-section of the wire there are four cores with an area of 120 mm2, an insulating layer is placed on top of them, ... Read more →

The AVVG 4x16 cable belongs to the power group of conductors and is characterized by the maximum area of aluminum current-carrying conductors in its class - 16 mm2. There are four wires in the wire cross-section. Most often, the cable is used in electrical networks and power lines for permanent connection of equipment. Suitable… Read more →

The AVBBShv 4x185 cable is presented in the form of a current-carrying aluminum part coated with polyvinyl chloride. This is a product with armor, it consists of four cores, the area of which is 185 mm2. Depending on the marking, the design of the conductor differs. If the name contains the index “ozh” (“ok”), the wire... Read more →

The AVVG 4x120 cable is a conductor that consists of four current-carrying cores with a total area of 120 mm2, an insulating layer and a coating made of PVC composite material. The insulating coating is yellow-green in color, with individual stripes of colors arranged diametrically. This wire is intended for… Read more →

Source: kabeltehsnab.ru

Optical

Fiber optic cable, also called fiber optic, is a completely new type of conductor product compared to other types of electrical cables. It transmits information that is transported over communication lines, not using an electrical signal, but using light. Its most important component is colorless fiberglass. The design is capable of transmitting light over significant distances up to 10,000 m with minimal light loss.

You might be interested in: Features of electrical wires and cables

Optical cables

The fiber optic cable is made of the thinnest elastic light guides 5/60 microns, which serve as a medium for signal propagation. This is a particularly high-quality type of conductor product - it guarantees information transmission at very high speeds of over 10.0 Gbit/s. The advantage of such transmission is that the design of the cable allows it to protect information from external interference better than other types. Due to the specific nature of light distribution, such signals are simply screened.

Additional Information. The light guide is made of a central core in the form of glass fiber and a glass shell, which has a lower refractive index than the core. Therefore, moving along the core, such rays cannot go beyond its boundaries, but are reflected from the protective layer of the shell.

Marking of cables and wires

At first glance, the decoding (marking) of cable and wire designations resembles a secret code that cannot be deciphered.

In fact, each symbol carries information, knowing which you can easily understand what type of cable is in front of you and what its main characteristics are. The letters indicate the insulation and core material, the area of application of the wire, and design features. They go strictly one after another.

The numbers indicate the number of cores and their cross-section. The letter code consists of four basic symbols that you need to know. Sometimes there are more than four letters, but these are usually quite specific types of products that you are unlikely to encounter. The first letter indicates the material from which the core is made. A - aluminum; if it is copper, then there is no letter. For example, VVG and AVVG. The first cable is copper, the second is aluminum. The second letter is the area of application of the wire: K - control, M - installation, P (U) or Ш - installation, MG - flexible installation cable. If there is no letter, then it is a power wire. The third letter is the type of insulation TPG. There are many designations here: B or BP - polyvinyl chloride, D - double winding, K - nylon, P - polyethylene, P - rubber, HP or N - non-flammable rubber, C - fiberglass, W - polyamide silk, E - shielded. The fourth letter indicates the design features of the cable: B - armored with tapes, G - flexible, T - for installation in pipes, K - armored with round wire, O - braided. In addition to these designations, there are additional ones that are not written in capital letters, but in capital letters and are placed after all the others. For example, VVGng is non-flammable VVG, VVGz is filled with VVG. With numbers, everything is much simpler: the first indicates the number of cores, the second the cross-section of the core. For example, PVA 3×6 means that the wire has three cores, the cross-sectional area of each of which is 6 mm2. However, sometimes there are cables with more complex digital markings, for example, power cable KG 3×6+1×4. This means that in addition to three main conductors with a cross-section of 6 mm2, it has another smaller cross-section - 4 mm2, which serves for grounding. Foreign-made cables have a completely different type of marking, unlike GOST standards.

Explanation (marking) of abbreviations used to designate power cables with PVC (vinyl) and rubber insulation (according to GOST 16442-80, TU16.71-277-98, TU 16.K71-335-2004)

HOW TO UNDERSTAND THE MARKING OF WIRES

Wire marking

There are a large number of different brands of wire - PVA 2x0.75; PUGV 1x2.5; ShVVP 2x0.5; APPV 2x2.5; PUGVV 2x1.5, etc., but what do these letters and numbers mean in their markings?

In the wire marking, after the letter designation, the number of current-carrying cores and their cross-sectional area are written in numbers, i.e. the inscription 3x1.5 means that the wire contains three cores with a cross-sectional area of one and a half millimeters each.

The following classification is adopted for wire marking:

- “A” – aluminum. Indicates that the material of the conductive wires is aluminum; if the letter A is absent, then the wire is based on copper conductors;

- “P” means “wire”;

- “PP” – “flat wire”;

- “G” – flexible conductors. (for example, PRGI).

After the letter “P” there is a letter that characterizes the insulation material:

In addition, the insulation is often protected by various shells:

- “B” – the wire has an additional sheath of PVC plastic;

- “N” – non-flammable shell;

- “L” is a braid made of cotton yarn coated with varnish. The letter L is placed in last place in the designation of the wire brand;

- “TO” – braid impregnated with an anti-rot compound, for installation in steel pipes (for example, PRTO).

Wires for overhead power lines are deciphered as follows:

- SIP is a self-supporting insulated wire. Insulation made of light-stabilized cross-linked polyethylene;

- SIP-1 – with uninsulated neutral;

- SIP-2 – with insulated neutral;

- SIP-4 – with insulated conductors of equal cross-section;

- A – bare wire twisted from aluminum wires;

- AC is a bare wire consisting of a steel core and aluminum wires.

Wires for electrical installations of the PV brand have digital indices 1; 2; 3 and 4. These numbers indicate the degree of flexibility of the wires. The higher the value, the more flexible the wire.

Let's look at all of the above using an example: PVS wire 2x0.75

- This cable has 2 copper cores, 0.75 sq. mm. each;

- P – wire;

- B – vinyl shell made of polyvinyl chloride (PVC) plastic;

- C – connecting.

Cable marking Cable marking is done in the same way:

VVG cable

- A – current-carrying conductor – aluminum. If the letter A is missing, then the conductor is made of copper;

- B – vinyl. Shell made of polyvinyl chloride (PVC) plastic;

- B – vinyl. Insulation made of polyvinyl chloride (PVC) plastic;

- G – flexible or unarmored.

Depending on the group of use, the following designations are found in cable markings:

VVG-P:

- “P” – layered, insulated cores are laid parallel in one plane.

VVGz:

- “z” – with filling, filling made of rubber mixture.

VVGng:

- “ng” - non-flammable, PVC plastic compound of reduced flammability.

VVGng -LS:

- “LS” – “low tuxedo” (low smoke emission), PVC of reduced fire hazard.

- “FR” - from the English fire resistant, which means “fire resistant”

AVBbShv:

- B – armor made of steel tapes;

- Ш - protective hose made of PVC plastic;

- c – vinyl. Insulation made of polyvinyl chloride (PVC) plastic.

ASB2lG, ASKl, TsSB:

- C – lead sheath;

- 2l – two lavsan ribbons;

- G – naked. Protective cover made of two galvanized steel strips;

- K – protective cover made of round galvanized steel wires;

- C – paper insulation impregnated with a non-drip compound.

AKVVGE:

- K – control;

- E – common screen made of aluminum foil over twisted cores;

APvBbShp:

- “P” – insulation made of silanol cross-linked polyethylene;

- “p” – outer shell made of polyethylene.

APvPu2g:

- “u” – reinforced polyethylene shell;

- “2g” – “double sealing”, cross-linked polyethylene insulation with aluminum tape over a sealed screen.

KG:

ASRG, AVRG, VRG:

APsVG, APVGi, etc.:

VVGng(ozh):

- “(ozh)” – single-core. If there is no “ozh” in the brand, this means, by default, that the design is stranded (mp) or multi-core (mn).

Let's look at all of the above using an example: cable VVGng (ozh) -0.66 kV 3x1.5

- This cable has 3 copper cores, 1.5 sq. mm. each;

- B – vinyl shell made of polyvinyl chloride (PVC) plastic;

- B – vinyl insulation made of polyvinyl chloride (PVC) plastic;

- (ng) – non-flammable material.

- 0.66 kV – voltage. For this cable it is 660 V. In general, cables are low voltage (0.38 -1 kV), medium (6-35 kV) and high voltage (110-500 kV).

- (ozh) – execution – single-core.

Source: kabelsnabservis.satom.ru

Online home handyman assistant

A power cable refers to a large group of cables with different structural and electrical characteristics. Power cables are necessary to transmit electricity (3-phase current) from the source to the end consumer. The choice of the type of power cable depends on the object to be connected and the conditions for installing the power cable...For convenience, power cables can be classified according to a number of criteria.

A power cable refers to a large group of cables with different structural and electrical characteristics. Power cables are necessary to transmit electricity (3-phase current) from the source to the end consumer. The choice of the type of power cable depends on the object to be connected and the conditions for installing the power cable. The choice of power cable must be approached very carefully. Usually, during the construction of certain objects, an electrical network project is drawn up, which indicates the required cable characteristics based on the number of connected objects, power, line length and many other parameters in accordance with which cable brands are selected. In this article we will try to figure out what kind of power cables there are, characterize each group of power cables, in particular their application, design features and the most popular brands.

Brief contents of the article:

Power cables. Classification

For convenience, power cables can be classified according to a number of characteristics:

By voltage: - low voltage power cables: 0.66 kV, 1 kV, 3 kV, 6 kV, 10 kV, 20 kV, 35 kV; – power cables for high voltage: 110 kV, 220 kV, 330 kV, 380 kV, 500 kV, 750 kV and above; By insulation material: – plastic; -polyethylene; – rubber; -paper; According to the material and shape of current-carrying conductors: – aluminum; - copper; - round, sector or segmental shape of cores.

Read here! Fire-resistant anti-corrosion chemical-resistant coatings

The following groups of power cables can be distinguished:

Power cables with PVC insulation

– a common type of cable both in industry and in everyday life. PVC or polyvinyl chloride is a solid polymer with low electrical insulating properties, but with good resistance to acids, alkalis, salts, and moisture. The long-term operating temperature of power cables with PVC insulation can be +80-90 C. At higher temperatures, PVC begins to melt, releasing dangerous hydrogen chloride. PVC also deteriorates its properties in sunlight.

Paper insulated power cables

- a popular cheap type of cable with its own disadvantages and advantages. Paper insulation is a non-uniform dielectric made of several layers of cable paper impregnated with an oil composition of varying viscosity - flowing or non-draining. The advantage of this type of cable is its relative cheapness and the ability to manufacture cables for high voltages.

Power cables with rubber insulation

– a type that is used where increased cable resistance to repeated bending is required. Rubber insulation consists of natural or synthetic rubber combined with fillers, softeners and other additives. Rubber practically does not absorb water, but it can withstand lower operating temperatures (up to + 65 C), as a result of which the permissible current load on the cable is low.

Power cables with XLPE insulation

– have become one of the leading trends in the cable industry. Cross-linked polyethylene is polyethylene that has been processed at the molecular level, thereby improving the electrical properties of the material. The advantages of cables with XLPE insulation are a larger overall construction length and lower weight of the cable, high throughput, resistance to moisture, and others.

Aluminum cable

, operating in the domestic market since 2000, today firmly occupies a leading position in the field of production of cable and wire products. The company offers its customers a wide range and constant high quality of all cables and wires produced. One of the plant’s activities is the production of various types of aluminum cables that meet all GOST requirements.

Aluminum power cables are in great demand today due to their cost-effectiveness.

A cable with aluminum conductors has a lower specific gravity than a cable with copper conductors. A power cable with aluminum conductors can have different designs depending on operating conditions. For example, if the shell of an aluminum cable can often be subject to mechanical shock, friction and vibration, its structure must include special armor (such a cable is often placed in areas where seismic activity is higher or the soil itself is very mobile). In conditions of constant/variable low temperatures, when an aluminum cable must withstand changes of up to -60 degrees Celsius, a cable with a polyvinyl chloride sheath is used, which guarantees resistance to extreme cold (type -HL).

Aluminum cable is used in various circuits for current distribution in classic stationary installations, if the current frequency is no more than 100 Hz and the voltage is no more than 1000 W.

Brands of aluminum wires and cables and their areas of application

Advantages and disadvantages of aluminum conductors. What brands of aluminum wires and cables are there, and what is the scope of each.

Aluminum wires and cables are prohibited for use as wiring in apartments and residential buildings. But their use is permitted only for connecting electrical installations with a cable cross-section exceeding 16 square meters. mm or for connecting engineering equipment (pumps, climate control devices, etc.) with a wire of 2.5 sq. mm. This is stated in the PUE of the publication after 2002. However, the demand for cables with aluminum cores of various sections remains high - this is caused by two banal reasons: banal savings and situations when you need to replace part of the old wiring, but there is no finance for laying new copper cores, as well as in the situations described above. In this article we will look at the pros and cons, as well as what brands of aluminum wires and cables there are. Content:

- Advantages and disadvantages of aluminum

- Brands of aluminum wires

- Aluminum cable grades

Cables ABBГ, ABBGE

Cables of the AVVG, AVVGE brands are intended for laying cable lines in cable structures and premises.

Cables of the AVVGE brand, in the design of which an electrically conductive screen made of wires or tapes is placed under the sheath, are recommended for installation in rooms with a high required level of electrical protection, incl. for use in hazardous areas.

The operating temperature of the cable should be no more than 70 degrees Celsius. The power cable can be heated up to +160 degrees if it is protected with polyvinyl chloride insulation, and up to +130 degrees if the cable is protected with polyethylene insulation.

Cables AVVGng(A)-LS, AVVGng(A)-LS, AVVGEng(A)-LS, AVBShvng(A)-LS

Power cables with aluminum cores, version -ng-LS-, are used for group installation, do not propagate fire under category A. The cables are intended for use in cable structures and premises. Smoke formation in the test chamber is no more than 50%. Such cables are ideal for ensuring high-quality transmission of electricity.

The voltage in the installation itself can be either alternating or constant. The cable with aluminum conductors is ideal for use in general industrial use, as well as at nuclear power plants of classes 3 and 4 according to the OPB-88 classification (PNAE G - 01-011-97).

What do the letters AC mean?

The abbreviation AC refers to a bare aluminum wire with reinforcement in the form of a steel cable. The letters in the markings have the following meaning:

- A - the current-carrying core is made of aluminum;

- C - the wire is reinforced with a steel core.

The numbers following the letters in the marking indicate the cross-sections of the cores used. For example, in the AC-16/2.7 conductor, for the aluminum part it is 16 mm2, and for the steel part it is 2.7 mm2.

Product marking

Each product has a specific marking consisting of letters, numbers and color symbols. It indicates not only belonging to a certain group, but also the material, diameter, number of cores, scope of application, etc.

The first letter indicates the material of manufacture (with the exception of the letter “A” - it indicates that the core is made of aluminum):

- B – PVC;

- P – polyethylene;

- PV – vulcanizing polyethylene;

- PS – self-extinguishing polyethylene, etc.

The second letter denotes the insulating material : B – PVC, R – rubber, etc. Each subsequent letter has a meaning. For example, the marking AVVGng 3x2.5 is deciphered as follows:

- “A” – aluminum (core material);

- “B” – PVC core insulation;

- “B” – the general shell is also made of PVC;

- “G” – no armor;

- “ng” – does not burn;

- “3x2.5” - the product contains three cores, their cross-section is 2.5 mm2.

Since each core is enclosed in an individual sheath, this is a cable decoding. If the marking contained the letter “E”, this would mean that the cable is equipped with a screen. “P” indicates the presence of rubber protection, “B” indicates armor from aggressive chemicals and combustion. The content of the letter “Ш” in the marking indicates that the protective layer of the cable has the form of a hose.

Wire markings have different meanings for some symbols. Thus, a product of the PuGV brand is an installation wire coated with PVC and having good flexibility. Since there are so many different combinations of letters in the markings, it can be difficult to decipher. Then it is better to turn to special reference books or search for information on the Internet.

Cable structure

The structure of the speaker wire resembles an ordinary rag rope, but curled from two materials. There is a steel cable in the middle. It is made of one or more thin wires. The purpose of a steel cable is to give the conductor strength, flexibility and resistance to stretching. It performs a mechanical, load-bearing function.

From the outside, many aluminum wires are wound around the steel cable. The majority of the load current flows through them. If the AC cable is designed for a large cross-section, then the winding is done layer by layer, alternating directions. This avoids spontaneous unwinding of the structure.

The resulting conductor combines the advantages of the materials used:

- steel strength;

- good electrical conductivity of aluminum;

- light weight of the resulting product.

The final mass of the cable is also affected by the absence of an outer insulation layer.

VVG cable

With the help of this conductor, residential buildings are electrified. Its markings show: flexibility of cores, insulation on the outside - polyvinyl chloride, insulation of rods - similarly. The wiring is not particularly flexible.

The cable insulation is resistant to environmental aggression, and the cable itself does not burn. The cores consist of one or many wires, taking into account cable modifications.

This cable must deliver and distribute electrical impulses at a factor of 1000 volts when the AC power frequency is 50 Hz. For equipping home networks, a VVG liner with a cut of 6 square millimeters is suitable; for supplying light to households, this norm increases to 16 sq. mm. A break along the shortest radius is possible with a cord 10 times wide. The cable is supplied in coils of 1 hundred meters.

The VVG cable has a gradation: AVVG - aluminum core, VVGng - fire-resistant sheath, VVGp - flat cut, VVGz - the presence of PVC or rubber insulation between the cores.

VVG – copper cable – for indoor installation. It is laid openly, laid in grooves. Serves for 30 years. The number of cores meets the requirements of the network phases: from 2 to 5. The predominant tone of the surface insulating material of these leads is black, sometimes white. Modifications of the VVG cable with “NG” and “LS” show, respectively, non-propagation of combustion and low smoke emission during fire. A modification of the VVG is known that can withstand open fire for several minutes.

The foreign analogue of the VVG cable is produced according to the DIN standard. We are talking about the NYM product. Its special internal filler extinguishes itself.

Operating conditions and characteristics of the speakers

The characteristics of speaker conductors vary greatly depending on their cross-section. But there are also common properties that are inherent in all products in this category:

- operating temperature from –60 to +40°C (ideal for the CIS);

- solid service life of 45 years;

- maximum permissible temperature +90°C;

- temporary tensile strength - from 160 MPa;

- guaranteed period of work 4 years;

Characteristics of steel-aluminum wires grade AC

The remaining properties are determined based on the cross-section and length of the wire. The electrical parameters of some AC cables are shown in the table.

| Wire type | Continuous permissible current, A | Maximum resistance of 1 km of wire, Ohm |

| AS-16/2.7 | 111 | 1,78 |

| AS-50/8.0 | 210 | 0,59 |

| AS-70/11.0 | 265 | 0,42 |

| AS-120/19.0 | 390 | 0,24 |

| AS-150/19.0 | 450 | 0,20 |

And below are the mechanical properties of wires of the same brands.

| Wire type | Diameter of aluminum/steel wire, mm | Weight of 1 km cable, kg |

| AS-16/2.7 | 1,85/1,85 | 64,9 |

| AS-50/8.0 | 3,20/3,20 | 195 |

| AS-70/11.0 | 3,80/3,80 | 276 |

| AS-120/19.0 | 2,40/1,85 | 471 |

| AS-150/19.0 | 2,80/1,85 | 554 |

Purpose of AC wires

The design of the conductor determines its purpose. Cables of the AC family do not have an external insulating layer, so they are only suitable for installation of overhead power lines. The suspension is created using glass or ceramic insulators.

The following conditions must be met in the cable operating area:

- Climatic conditions - according to GOST, any except the tropics and subtropics.

- The concentration of sulfur dioxide gases should not exceed 150 mg/m3.

- The surface of the wire should not be heated above 90°C.

Application in power lines

The main task of AC cables is to transmit electricity over long distances. Including for connecting substations in one area with wires. Steel-aluminum conductors are used to power consumers with voltages above 1 kV. There must be an air gap between the wires. It depends on the magnitude of the transmitted voltage and plays the role of insulation.

Corona discharge occurs on lines above 110 kV. To combat this phenomenon, it is customary to increase the effective cross-section of the speaker cable. And when constructing main power lines, the active and inductive resistance of the line should be taken into account.

AC wire is used for main power lines

Storage conditions

Aluminum wires should be stored in coils. Storage in dry, unheated rooms is acceptable. The coil on which the conductor is wound is a wooden drum. To protect the cable, it is covered with boards and thin sheet iron. The type of wire, its original and current length and shelf life must be indicated on the drum.

Important! In air, aluminum becomes covered with a layer of thin oxide film in a few seconds. It acts as a protective barrier and prevents further oxidation of the metal. The film can withstand the aggressive environment of humid air and even most acids.

The coils should be placed in a vertical position, so that individual cables do not creep on top of each other and do not bunch up. This will prevent them from deforming under their own weight.

Storing speaker wires on wooden drums

During transportation, the coil is securely fixed with steel tapes, cables or synthetic belts. This is necessary to prevent it from rolling from place to place.