What is a junction box

Electrical, or distribution, box is a product for cable installation or wire outlet. Used for distributing electricity indoors. Currently made from different materials. Comes in various types and colors.

What does an electrical box look like?

It should not be confused with a socket box. It is used to install the mechanisms of sockets, switches and other electrical installation products on the wall.

Detailed description of the device

For your information! A distribution junction box is a container for electrical connections and terminals that allows you to hide the wire branch from view.

Made from steel, aluminum, plastic, fiberglass. It comes in round, square, rectangular shapes.

Requirements for installation of distribution boxes

Let's look at the requirements for the installation of distribution boxes, as well as the location of their installation.

- The installation height of the device is 10-30 cm from the base surface of the ceiling. The exact size is determined by the height of the ceilings themselves.

- If hidden wiring is used inside the building, then a niche is made for each box to suit its size and shape. In this case, the installation depth should be such that the device cover is ultimately flush with the finished wall surface.

- If an overhead model is used, then it is installed directly on the already prepared decorated wall.

- A very important point, which is indicated in the PUE, is a free approach to the installation site of the distribution box for maintenance and repair.

- An equally important point, or rather, the most important, is knowledge of where the distribution box of a hidden installation is located.

- Don't forget about the aesthetic side of things. Therefore, the lid of the box is sealed to match the overall design of the room or a device with a decorative lid is selected.

- If the installation location of the plastic distribution device is under a suspended or suspended ceiling structure, it is necessary to leave a hatch in the latter for free access to the device cover.

Specifications

Distribution boxes for external and internal wiring are used together with corrugated, smooth, reinforced conductors. Depending on the type and assortment of the market, they are made of plastic, polystyrene, and metal.

Average technical characteristics

They have different external and internal dimensions, most of them with a diameter of 70-80 and a depth of 50-60 mm. Their degree of protection is IP55.

Types of distribution boxes

The electrical distribution box is available in end and feed-through versions. A multi-post section is obtained by connecting the necessary boxes of the two types indicated. Often, a product is classified by type of installation. There is an external and internal model, for open and hidden wiring.

For your information! In addition to classification by type of installation, there is a gradation of distribution boxes according to purpose and safety. This classification is valid in premises where it is necessary to protect a large amount of industrial electrical equipment from an aggressive external environment.

In terms of safety, there are classic, dust-proof, splash-proof and fire-resistant products that have increased strength. The first ones are used in ordinary industrial premises outside. Designed for a standard voltage of 220 V. They have a cover without a rubber gasket and standard rubber sealing edges. The second ones are intended for objects where there is a high dust content and it is necessary to protect the wires from it so that the power supply system works properly.

You may be interested in this Determination of short circuit current

Splash-proof distribution boxes with terminals are used for hidden wiring in rooms with high air humidity. They are covered with special rubber gaskets and seals. Fire-resistant, used where fire-hazardous work is carried out.

Placement option and mounting method

The external model is fixed on top of the wall. This option is used when equipping office, industrial and commercial premises. In a private house, utility rooms and technical rooms are equipped with such distribution boxes.

External model

The internal model is designed to secure wires in the wall opening or partition voids so that the wiring that was laid in the channels does not come out. The cover on such a product after installation or wire connection is hidden using plaster or putty.

Internal model

The most popular mounting method is wall-mounted, but there is also a floor-mounted method. As a rule, the second one is most often used in industry.

Note! According to the closing method, there is a model with a simple lid and a lid that is closed with a screw or screw.

Hinged mounting method

Shape and dimensions of the product

The shape of the distribution box can be round, square, rectangular, with smooth, perforated, conical walls. According to the protection of the case, it can be unprotected, protected and sealed. Sizes small, medium and large. Depending on the method of cable entry, there is a product for pipes, corrugations, and cables.

Number and sizes of holes in the housing

According to the nomenclature, there is a soldered model. It is used for distributing electricity in a home or industrial workshop. It contains from two to four holes. There is a distribution model with six housing openings for nodal cable connections.

Standard number of holes

For your information! An installation model is also available. This is a socket box. It has 2-6 holes.

Material

The distribution terminal box is mainly made of plastic and metal. Plastic has excellent dielectric properties and is cheap. Products made from it are available in different shapes and sizes. They are equipped with rubber seals, mounting strips and fixing screws. The models are durable because the plastic does not break down naturally.

Metal junction box is used in warehouse, hangar, workshop and industrial sector. It is used where it is necessary not only to attach electrical wires, but also to protect them from the adverse factors of industrial premises. Metal products are created by stamping, followed by priming and painting. Fixation of the cover is achieved by a screw connection. The tightness of the structure is increased by rubber seals and covers.

You may be interested in this: Designation of various electrical equipment on diagrams

Plastic is no worse than metal

Note! Plastic boxes have a decent degree of shell protection. Cast fluoroplastic or propylene is resistant to chemicals. Non-metallic products can be exposed to high humidity for a long time. They are not subject to corrosion compared to metal. Plastic is inferior in strength to metal.

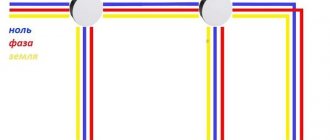

Methods for connecting wires in junction boxes

Putting the wires inside the box is half the battle. Now you need to choose a connection that is reliable and easy to maintain.

All cable line connections are divided into two main categories:

- Detachable, that is, the wiring can be disconnected and reconnected many times, without critical damage to the wire or connecting device. For example, a screw connection on terminal blocks.

- One-piece, that is, when the conductors are separated. the connection is destroyed. There is no big problem with this, it’s just that the cable gets shorter each time, and the connecting devices have to be purchased again.

The type of splicing when disconnecting boxes is selected based on the design of the overall network. If you plan to periodically disconnect one or two branches from a common box, it is better to choose a screw connection or reusable quick-release terminals.

For permanent connections that will not be dismantled for many years, the same terminals are used, only for one-time use. Despite the obvious drawback: the impossibility of reuse, such terminals provide more reliable contact compared to reusable ones.

If you use only copper conductor both in the backbone network and in subscriber branches, there are cheaper ways to permanently connect the wires:

- Twisting with welding. Creates reliable contact, without the danger of sparking and heating the wiring under heavy load. The connection is simple, but requires special equipment. As a last resort. You can melt the copper tips with a portable gas torch.

- Twisting with soldering. It is not as reliable as with tip reflow, but when using refractory solders, the connection practically does not lose strength, even when heated. The advantage is accessibility. A powerful soldering iron is easier to find than welding equipment. The basic rule: strength is ensured by twisting; we simply fill the voids with solder, improving contact.

- Twisting with mechanical fixation (crimping). A questionable method, since there is a possibility of damage to current-carrying wires.

- There is nothing to say about ordinary twisting: although it is not prohibited, this technique is practically not used.

Direct connection (disconnection)

Is it possible to organize electrical wiring without junction boxes? When branching no more than 2 lines, it’s easy. Several conditions must be met:

- If the connection is made by twisting, soldering with refractory solder is required. Crimping can be used.

- "T" shaped connections are undesirable; it is better to make a "Y" shaped branch.

- After connecting and checking the quality of contact, the splice area must be carefully insulated and protected from moisture. Especially if the connection is made in hidden wiring (plaster wall) or on the street.

Shell protection degree

There are seven types of junction boxes according to the degree of protection:

- IP 20 for electrical appliances that can only be used in a dry room. Such products are not protected from water, snow and other liquids;

- IP 30 for devices located in dry rooms, since such equipment is not equipped with moisture protection;

- IP 44 for devices with limited use outdoors, in damp places, under a canopy and canopy, in rooms with high humidity;

- IP 55 for electrical equipment exposed to weather conditions, protected from dust formation and temporary ingress of moisture. Common electrical installation models of distribution boxes. Often, many manufacturers of electrical and technical products indicate exactly the presented IP degree;

- IP 65 for electrical devices highly exposed to precipitation. Such distribution boxes are considered completely protected from dust particles and water and can be used outdoors;

- IP 67 for electrical equipment exposed to strong weather conditions. Boxes that can be placed on the ground or directly in the ground;

- IP 68 for devices that can be submerged in water.

As for choosing a product according to the degree of protection, it is necessary to purchase a junction box depending on the operating conditions. To install a socket box in an apartment, it is enough to use IP55. In 99% of cases they perform their function perfectly.

First degree of protection

Important! In order to maintain the degree of protection during installation, it is necessary to protect the inputs of such products with glands according to the diameter of the cable, PVC pipes and corrugations.

Classification

It should be noted that lines branch off in the distribution elements, which is why there is another name for this device - branch box. Also, due to the fact that electrical connections inside the boxes were made by soldering, they are also called desoldering. However, in practice, these names refer to distribution boxes, which are divided into several classes, depending on the criterion under consideration in accordance with section 7 of GOST 31195.2.5-2012.

Types of distribution boxes

So, depending on the material, all distribution boxes can be divided into:

- Insulating – made of dielectric, plastic or other durable polymer;

- Metal – most often stainless or tin-plated steel; in specialized areas, models made of non-ferrous metals are used;

- Composite - obtained by combining several non-combustible structures.

Depending on the installation method, all distribution boxes are divided into three categories:

Open and hidden distribution boxes

- Open - located on the outer part of the wall or supporting structure, the wires being connected also have an external routing;

- Semi-hidden - partially located in the wall, the wires have a hidden routing, but access to the cover is always provided;

- Hidden - both the box and the wires connected in it are located inside the wall.

Depending on the type of wire entry, there are:

- Without inputs - holes are developed during installation work as necessary;

- For flexible cable or wire;

- Protected brands of cable and wire products;

- Smooth or corrugated products;

- For conductors with special couplings.

Box with special connecting entries

According to the type of surface into which the connecting fittings will be installed:

- Boxes for solid walls or ceilings - mounted on a mortar in a designed hole;

- For hollow walls - relevant for plasterboard structures, fastening is carried out by pressing screws to a sheet of plasterboard;

- In a structure made of combustible or non-combustible materials;

- In floor coverings subject to mechanical stress;

- Boxes for floors subjected to wet cleaning.

Also, all devices are divided according to the range of permissible installation and operating temperatures, the presence or absence of suspension means. According to their shape, distribution boxes can be divided into round, rectangular or square devices.

Where is it used?

Distribution boxes are designed for wiring and installing sockets and switches in solid parts of brick and concrete walls. They are installed in hollow walls or partitions, in various electrical installation products, in particular, dimmers. Those types that are intended for outdoor installation are used in environments with high humidity, dust, chemical and corrosive aggressiveness.

Wiring around the house

They are needed to create durable, safe, controlled wiring, telephone connection, socket, switch, dimmer and communication device. Distribution and mounting boxes protect cable connections of cores from external influences. They create an aesthetic appearance of the interior and facade.

You may be interested in this. What is the unit of measurement for current?

Box structure

Any junction box has a structure that protects the cables inside it from dust, moisture and other aggressive environmental factors. It consists of a rectangular, round, triangular plastic, metal shell and special perforated holes. The latter are needed so that they can be inserted into the cable.

Design features

Note! Often the box includes a lid, a seal, fasteners for fixing, grooves for fastening and other accessories.

How to use it correctly

The conductors inside the box are not laid in a chaotic manner, but according to clear rules that are prescribed in the PUE. The conductors run along the top of the wall, but no closer than 15 cm from the ceiling covering. Upon reaching the branching site, they descend vertically. At the branch they are put into a box. The remaining cables are connected to the first within the existing electrical circuit.

A niche is created in the wall for the internal distribution box. There is only a cover on the surface, installed at the same level where the finishing material is. It is allowed to cover the lid with decorative materials. It is important to make sure that you can remove the cover from the mounting socket at any time without destroying the wall and decorative covering.

You need to choose the junction box carefully, since the safety of the electrical connections will depend on it. A correctly selected and installed model will serve its purpose properly throughout the entire period and fulfill its main purpose. Will ensure the safety and efficiency of the system.

Proper Use

Distribution, electrical box - a product for cable installation, removal of conductors for the purpose of their insulation, increasing fire safety. It has optimal technical characteristics to make high-quality wiring around your home or industrial facility. There are different types that have their own characteristics. When choosing, it is important to consider the conditions of use and safety rules.

DIY installation instructions

When purchasing products for installation, you should keep in mind: each branded product is usually packaged and accompanied by a product label.

Each branded product must be accompanied by a label with the technical parameters and other information indicated on it. This way you can distinguish the original product from a fake. The product label indicates: technical information, product barcode, certification mark.

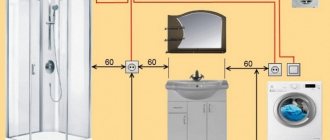

Dimensions and installation location

A standard box for household needs is 10 centimeters in diameter.

Design features and dimensions depend on the number of inputs and the number of consumers. The greater the electrical demand, the larger the distributor.

Overhead devices are usually mounted 15–30 cm below the ceiling. This is a special maneuver by electricians to minimize access and eliminate an accident. If the apartment has a suspended ceiling, the box is skillfully disguised as a rubberized sheet. This is an erroneous action during installation, since access to the point should always be unobstructed.

In order to hide the wiring, distribution. the box is installed in a specially drilled hole in the wall of the specified diameter. The height of the point is determined similarly to overhead boxes.

Installation of various types of fittings

Outdoor installation:

- On the body of the junction box, cut off the plugs of the sealed inputs with a sharp thin knife. The cuts are made along the marking lines on the plug in accordance with the diameter of the cable channel or the cable itself.

- Tubular channels - corrugated or straight plastic tubes - are inserted into the holes formed after the cuts.

- The ends of the wires are led into the junction box body through the channels.

If necessary, install a terminal block in special guides and connect the conductors according to the diagram. To finish, close the junction box with a lid, pressing it with some force until it is completely secured with locks.

Instructions in pictures for installing an external electrical junction box. The standard option, which is used in most cases of installation of household electrical wiring

Instructions for installing an external universal box for cable duct:

- Make cuts using a knife according to the standard marks on the box body to the size of the rectangular cable channel. Standard tags are designed for joining with cable channels with a cross-section of at least 10*7 mm, maximum 40*25 mm.

- Carefully break off the notched part of the plastic housing, thus obtaining an opening for the cable channel.

- Attach terminal blocks to the base of the universal box for mechanical connection of electrical conductors.

Having laid the electrical wiring through the cable channel, connect the ends of the conductors according to the diagram on the terminals. When the work is completed, install the box cover and secure it with a fastening screw.

Instructions in pictures for installing a junction box in combination with a rectangular plastic cable duct. This is also an outdoor mounting option

Installation procedure for the installation (hidden) box:

- Prepare the product by first preparing the required number of input holes in the housing. Holes are created by breaking the edges of the finished stencil. Up to 11 stencils for inlet holes can be placed on the body of the installation box.

- Make a mounting hole in a hollow wall, for example, in plasterboard, using a cutting bit to match the diameter of the product. Or use a ready-made mounting hole in a solid wall.

All that remains is to connect the cable channels with the wire, combine them with the box, bring the ends of the wiring under the connections and fix the box body by spreading the fastening legs with screws (for drywall) or fill it with solution.

Installation is carried out approximately in this way according to the instructions for installing distribution (installation) boxes of hidden wiring. This option is often used for installing electrical wiring in urban apartments.

Having connected the conductors of the hidden main in accordance with the wiring diagram, close the box(es) with a lid. Externally, this design fits well into the existing interior.

- We insert the cables into the junction box and cut them so that the length of each remnant is 3-5 cm greater than the diameter of the box body

- We remove the general insulation from each of the cables placed in the box. You need to remove approximately 8-11 cm

- We remove 11 mm of insulation from the wires being prepared for connection. We check whether the current-carrying conductor was damaged when removing the insulation

- We separate the wires stripped before connection in different directions. Lightly clean the current-carrying wires with sandpaper and straighten them with pliers

- We first place the terminals on the wires of the input cable. Then we make connections sequentially in accordance with the insulation color

- We fix the wires held by each terminal with plastic clamps so that they can be conveniently placed in the box.

- We place the created nodes in the box body, trying to evenly distribute all the wires in it without overlaps or intersections

- After checking whether one of the wires has come loose during installation, close the box with the front panel by snapping it onto the body

- Step 1: Entering cables into the junction box

- Step 2: Stripping Cables with a Stripper

- Step 3: Stripping the insulation of the connected wires

- Step 4: Route the wires in different directions

- Step 5: Installing terminals on the input wires

- Step 6: Fixing the connected wires with clamps

- Step 7: Laying Assemblies in the Junction Box

- Step 8: Attaching the Bezel

Installation of a metal junction box

The design of metal junction boxes provides only for external installation of such products.

Therefore, the instructions in this case are simple:

- Bring tubular channels with wire to the entry points.

- Mechanically thread the pipes to the walls of the housing and lead the cable ends into its internal area.

The box body is secured to the wall with screws through the holes intended for fastening. Then connect the cables according to the diagram, cover the box and secure the cover with screws.

This is what the installation of electrical wiring looks like with the inclusion of a metal junction box. The set of tools for installing different types of boxes is the same. This is roughly how the installation of distribution modules with different designs is carried out.