Wind turbines are a promising alternative to traditional energy. Wind energy, converted into electricity, promises to be cheap, easy to produce and low-cost. And if we take into account the bills that come in now for electricity, then in order to save money, it’s worth trying to build your own wind generator, don’t you agree?

There are real examples of creating installations that generate a decent amount of energy. Nevertheless, the capabilities of wind turbines are still significantly ahead of competitors that can withstand the traditional method of generating electricity.

We have presented a guide, following which you can assemble a wind generator from a car generator with your own hands. The article offered for your attention discusses in detail the common mistakes that are made when designing wind turbines. For clarity, the article is accompanied by thematic photo and video materials.

Wind generator design

There is a huge variety of types of wind generators and drawings for their manufacture. But any design includes the following mandatory elements:

- generator;

- blades;

- storage battery;

- mast;

- the electronic unit.

Having some skills, you can make a wind generator with your own hands.

In addition, you need to think through the control and distribution system of electricity in advance and draw an installation diagram.

How to make a rotor

When manufacturing a wind generator, it is necessary to take into account that the rotor of a car generator is equipped with an electromagnetic excitation winding. If you do everything yourself, its design can be simplified. You can remove the collector and rewind the stator windings, which will transform the unit into a low-speed one. It is recommended to remake the iron rotor.

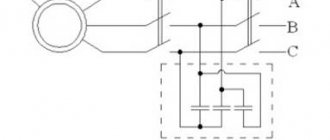

Diagram of a rotor with winding for a homemade windmill

A non-magnetic aluminum attachment must be machined onto the rotor shaft. A special bandage made of steel pipe is installed on it. This must be done with a little tension. Markings are made on the surface of the bandage and rectangles of neodymium magnets are installed using superglue, adhering to the alternating poles. Epoxy resin is poured between these elements, which allows you to level the surface.

Such a wind generator will generate sufficient energy only at a rotation speed of 6000 rpm. To make it productive at 600 rpm, it is necessary to increase the stator winding five times. At the same time, it is necessary to reduce the cross-section of the drive itself.

In order for the windmill to work more efficiently, it is necessary to use a homemade windmill generator using neodymium magnets. They are glued to the unit with a slight distortion, which prevents sticking. The blades of this windmill must be large. To reduce the magnetic field, it is recommended to sort out the stator plates, align them, and then put them back together.

Wind wheel

The blades are perhaps the most important part of a wind generator. The operation of the remaining components of the device will depend on the design. They are made from different materials. Even from a plastic sewer pipe. Pipe blades are easy to manufacture, inexpensive and not susceptible to moisture. The procedure for manufacturing a wind wheel is as follows:

- It is necessary to calculate the length of the blade. The diameter of the pipe should be equal to 1/5 of the total footage. For example, if the blade is one meter long, then a pipe with a diameter of 20 cm will do.

- Using a jigsaw, cut the pipe lengthwise into 4 parts.

- From one part we make a wing, which will serve as a template for cutting out subsequent blades.

- We smooth out burrs on the edges with abrasive.

- The blades are fixed to an aluminum disk with welded strips for fastening.

- Next, the generator is screwed to this disk.

Blades for the wind wheel

After assembly, the wind wheel needs balancing. It is mounted horizontally on a tripod. The operation is carried out in a room closed from the wind. If the balancing is carried out correctly, the wheel should not move. If the blades rotate on their own, then they need to be sharpened until the entire structure is balanced.

Only after successful completion of this procedure should you proceed to checking the accuracy of rotation of the blades; they should rotate in the same plane without distortion. Please allow 2mm error.

Generator assembly diagram

How to get a wind wheel

To make a wind generator from a car generator with your own hands, you need to make blades. For this purpose, pipes made of plastic or duralumin are used. Their diameter should be 5 times less than their length.

The pipe is cut into four parts and a wing is made from each. The edges of the resulting blades must be rounded and all irregularities removed.

Rotor blade mounting diagram

Mast

To make a mast, an old water pipe with a diameter of at least 15 cm and a length of about 7 m is suitable. If there are buildings within 30 m of the intended installation site, then the height of the structure is adjusted upward. For efficient operation of the wind turbine, the blade is raised above the obstacle by at least 1 m.

The base of the mast and the pegs for securing the guy wires are concreted. Clamps with bolts are welded to the stakes. For guy wires, galvanized 6 mm cable is used.

Advice. The assembled mast has considerable weight; if installed manually, you will need a counterweight made of a pipe with a load.

Wind generator assembly and installation

The wind generator should be installed away from residential buildings and other structures. The distance should be at least 20 meters, and, in general, the more, the better. It is best to install a wind farm in open space or on hills, where the wind is much stronger. When installing, take into account the density of the soil. This will determine the length of the wedges, which will be the attachment points for the guy wires of the mast itself.

If the soil in the installation area is soft, then wedges of larger diameter and length will be required. There should be at least three such wedges for attaching guy wires, and even better, 4.

Methods for arranging guy wires are chosen depending on the height of the mast. The wind generator mast itself is placed in the ground to a depth of half a meter or less. The base of the mast and the wedges to which the guy wires are attached are concreted. If this is not done, the soil may become loose after rain, which will lead to weakening of the stretch marks.

Generator conversion

To make a windmill generator, a generator from any car is suitable. Their designs are similar to each other, and the modification boils down to rewinding the stator wire and making a rotor with neodymium magnets. Holes are drilled in the rotor poles to fix the magnets. Install them alternating poles. The rotor is wrapped in paper, and the voids between the magnets are filled with epoxy resin.

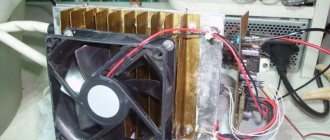

Car generator

In the same way, you can remake the engine from an old washing machine. Only the magnets in this case are glued at an angle to avoid sticking.

The new winding is rewound along the reel onto the stator tooth. You can make a random winding, depending on who you are comfortable with. The greater the number of turns, the more efficient the generator will be. The coils are wound in one direction according to a three-phase circuit.

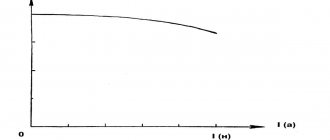

The finished generator is worth testing and measuring data. If at 300 rpm the generator produces about 30 volts, this is a good result.

Generator for a windmill from a car generator

Generator for a windmill from a self-generator

The generator is the same basic element of a windmill as the impeller. While the impeller blades convert wind energy into rotational motion, the generator converts rotation into electricity. Its design and capabilities determine the performance and power of the installation, and the ability to work in low wind flows.

When manufacturing wind turbines, the question of using a homemade or ready-made generator almost always arises. Most often, the solution is approached in a combined way - they use a ready-made car generator, sometimes without design changes, but most often with some modifications that increase sensitivity or output power.

Car generators are ready-made devices designed to generate electric current at a given voltage. It is constantly at the output, which provides a voltage stabilizer (regulator) that keeps the values within a narrow range. The only feature that requires intervention is the operating mode - car generators are driven by the engine and operate at high speeds.

Moreover, the rotation speed of the car engine is not constant, it varies throughout the entire operating time within significant limits - from 800 rpm to 6000 rpm, and sometimes more. In addition, a car generator has a current limit that the device cannot exceed under any circumstances.

The efficiency of self-generators does not exceed 60%, which is explained by the presence of losses in structural units and energy consumption on Foucault currents. The higher the total power of the device, the higher its efficiency. Alternating current is produced, which is converted to direct current using a diode rectifier.

Final assembly

The generator frame is welded from a profile pipe. The tail is made of galvanized sheet. The rotary axis is a tube with two bearings. The generator is attached to the mast in such a way that the distance from the blade to the mast is at least 25 cm. For safety reasons, it is worth choosing a calm day for the final assembly and installation of the mast. When exposed to strong winds, the blades can bend and break against the mast.

To use batteries to power equipment that operates on a 220 V network, you will need to install a voltage conversion inverter. The battery capacity is selected individually for the wind generator. This indicator depends on the wind speed in the area, the power of the connected equipment and the frequency of its use.

Wind generator device

To prevent the battery from being damaged by overcharging, you will need a voltage controller. You can make it yourself if you have sufficient knowledge in electronics, or buy a ready-made one. There are many controllers available for sale for alternative energy production mechanisms.

Advice. To prevent the blade from breaking in strong winds, install a simple device - a protective weather vane.

Installation of homemade windmills for home

Wind generator device

Recently, people have become very interested in wind energy at the level of using it in the domestic sphere. In principle, this can be explained if you take and look at the bill that comes for consumed electricity. The numbers speak for themselves. So people who can build things are starting to step up and look for different ways to use all the opportunities they have to get electricity inexpensively.

One of these real-life possibilities, which is interconnected with a windmill during its design, is the use of a car generator. In fact, a car generator is a ready-made device. The only thing left is to attach the blades to it. This must be done so that during operation it is possible to freely remove the obtained value of electricity from the generator. A distinctive feature of such a windmill is that it will only work effectively in windy weather.

In principle, we can say that using any car generator in everyday life to create a windmill is quite possible. Basically, craftsmen are in search of a more powerful model of such a generator, so that during operation it can deliver as much energy as possible. Therefore, various generator designs from trucks, buses, tractors and other large-sized automotive equipment have recently become very popular.

Additional components

In addition to the generator itself, which is the basis for creating a windmill, you also need to have several parts for the complete set:

- car battery;

- a propeller, which can be two- or three-bladed;

- electrical cable;

- support elements;

- fasteners;

- mast.

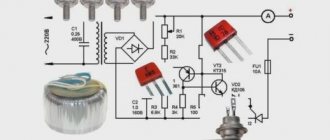

Wind generator for a private house diagram.

It is worth paying attention to the fact that a propeller that has three or two blades is rightfully considered the best option for a homemade design of a conventional classic wind generator. Naturally, the household design of a wind generator is not at all similar to the engineering model. In this regard, ready-made screws are mainly selected for home wind generator designs.

Screw for wind generator.

Thus, you can take as a basis an ordinary impeller from an external air conditioner unit or from a car fan. But, if a person sets a goal and has a desire to create an engineering model and follow all the basic features of designing generators, then he will have to build the entire wind generator propeller himself.

Wind turbine blades

Before you make a decision and personally assemble and then install a wind generator from a car generator, you must first assess the existing climatic conditions of the area where this installation will be installed and calculate the payback of this project.

Let's look at the main points that need to be taken into account when assembling a wind generator yourself.

Wind generator maintenance

A wind generator, like any other device, requires technical monitoring and maintenance. To ensure uninterrupted operation of the windmill, the following work is periodically carried out.

Wind generator operation diagram

- The current collector requires the most attention. Generator brushes need to be cleaned, lubricated and preventatively adjusted every two months.

- At the first sign of a malfunction of the blade (shaking and imbalance of the wheel), the wind generator is lowered to the ground and repaired.

- Every three years, metal parts are coated with anti-corrosion paint.

- Regularly check the fastenings and tension of the cables.

Now that the installation is complete, you can connect devices and use electricity. At least while it's windy.

How to make a wind generator with your own hands

The basis for creating a wind generator is a well-made project and a prepared drawing

This is very important, because without a clear idea of what the device should look like, it will be difficult to build it correctly without violating the order of installation of all elements

Drawings and diagrams

You need to start by drawing up a general sketch of the wind turbine, marking the key elements: the tower, the generator, the wooden base, the blades and the hub that connects them together. A self-composed diagram may not be very detailed: this is not necessary. It should be used to give a general idea of how the various parts of the wind turbine will be laid out and how the design will look in its final stages.

Wind electric generator assembly diagram

After preparing the diagram, you need to set the correct dimensions of the wind generator. These should include the height, length and width of the wooden base that connects the generator and the tail fin to the tower. Also determine the dimensions for blades made of metal pipes or PVC pipes, depending on what material will be used. Separate measurements are needed for the tail fin: height, width and length, and diameter for the blades, which determine the size of the wind turbine.

Once the drawing and rough sketch of the device with the set dimensions are ready, you can proceed to preparing materials and tools for work.