How are high-voltage cables “harnessed”?

Comparison of installations for burning high-voltage cables made in Russia and Ukraine

We continue the series of articles devoted to the analysis of the market for testing and diagnostic equipment.

The Russian equipment market is constantly growing, and there are more and more offers of devices and installations similar in properties and purpose. On the one hand, competition between manufacturers is very beneficial to the consumer, as it contributes to the appearance on the market of modern high-tech equipment at an adequate price. On the other hand, such diversity greatly complicates the selection process: the more offers, the more difficult it is to make a decision in favor of one option or another. In order for you to be able to freely navigate the vast sea of offers coming from manufacturers, we invited Irina Kuzmenko, head of the marketing department specializing in complex supplies of equipment for energy needs, to be the expert and author of this column. In one of the previous issues of the magazine, we talked about locators designed to determine the location of damage to cable lines. The article in this issue is devoted to market analysis and comparison of burning installations, without which it is simply impossible to carry out a set of works to search and find locations of damage to high-voltage cable lines.

The most popular scheme for searching for faults on energy cables in Russia is the traditional scheme “burning - pulse reflectometry - induction search - acoustic confirmation”.

To effectively find faults using pulse reflectometry and induction search, high-quality burning is required, ensuring the conversion of high-resistance single-phase cable faults into low-resistance two- or three-phase cables with the appearance of a reliable metal bridge at the damage site. If during burning it is possible to achieve a short circuit between the core and the core, then, as a rule, no further problems arise in finding the exact location of the damage.

Cable line maintenance specialists often encounter such an unpleasant phenomenon as a short circuit of one core to the cable sheath, in which pulse reflectometry and induction search methods do not allow them to detect the exact location of the defect. In this case, it is necessary to first destroy the metal junction between the core and the sheath, which in practice is not always possible to do without damaging the condition of the entire cable.

Burning process technology

The first stage - preliminary high-voltage burning is carried out using high voltage and low currents until a breakdown occurs in the cable. A standard burning installation produces a maximum voltage of about 20-25 kV. The process of high-voltage burning occurs as follows: a minimum voltage is applied to the damaged cable and then it gradually rises to 20-25 kV or to the value at which breakdown can be achieved, after which the burning process begins.

It is believed that the maximum voltage during burning should not exceed 0.5-0.7 U isp., however, in practice, such voltage is not always enough to carry out preliminary burning. If a burning installation that produces a maximum voltage of 20–25 kV is not able to provide cable breakdown, an additional installation with a maximum voltage of 60–70 kV, but with less power, is used in combination with it. Equipment of this type is called installations for testing and burning high-voltage cables; they can be connected to a burning installation or used separately.

The second stage - burning, begins from the moment the cable breaks down and a short circuit occurs and is carried out by lowering the voltage and increasing the current until the single-phase circuit is converted into a two- or three-phase one (welding core to core). Initially, the high voltage source destroys the cable insulation with a minimum current, then, as the burn is carried out, the voltage values gradually decrease and the current values increase.

In the case of additional use of a testing and burning installation with a maximum voltage of 60–70 kV, it carries out the burning process with a voltage from 60–70 kV to 20–25 kV, after which the main burning installation, which has a higher power, is automatically switched on.

The third stage - afterburning, is the final stage of burning and is carried out at low voltages and high currents of the order of 20–60 A, depending on the model of the burning installation. This stage is carried out using a low-voltage source, which is automatically connected when the voltage drops to certain values.

In the event of a short circuit of one core to the shell, to destroy the conductive bridge between the core and the shell, special sufficiently powerful burning installations are used, capable of delivering high current values (300 A). It should be noted that the use of installations of this type can lead to a decrease in the life of the cable and its damage in other, “weak” places.

Table 1. Types of installations for burning cables

| Name of equipment | City | Testing and burning installations (60–70 kV) | Burning installations (voltage 20–25 kV, current from 20 A) | Afterburning installations for destroying the bridge between the core and the sheath (current 300 A) |

| AIP-70 | Penza | V | ||

| VPU-60 (replaces AID-60P Vulkan M) | Obninsk | V | ||

| APU 1-3M | Penza | V | ||

| VUPK-03-25 | Tula | V | ||

| MPU-3 Phoenix | Obninsk | V | ||

| SVP-05TS | Harkov city | V | ||

| UP-7-3M | Yaroslavl | V | ||

| UD-300 | Penza | V | ||

| VP-300 | Harkov city | V | ||

| IPK-1 (VPU-60+ MPU-3 Phoenix) | Obninsk | V | V |

Types of burning installations

Among the domestic and Ukrainian equipment offered on the Russian market, there are three types of burning installations (Table 1):

- Installations for testing and burning high-voltage cables with a maximum voltage of 60–70 kV, used as auxiliary equipment in the initial stages of burning.

- Burning installations with a maximum voltage of 20–25 kV, with several high-voltage and one low-voltage sources.

- Afterburning installations designed to destroy the metal bridge between the core and the sheath with high currents (300 A) in the event of a single-phase short circuit to the core.

Burning installation VUPK-03-25

The burning installation is designed to burn through defective insulation and create a metal connection between the cable cores at the site of insulation damage.

- discontinued

- Request analogue

Devices for testing electrical equipment, burning through defective insulation and creating a metal connection between cable cores at the site of insulation damage.

1992-2019 © TECHNO-AS LLC

Address:

140406, Kolomna, st.

October Revolution, 406 Multi-channel phones:

, 8 (496) 615-16-90

Email: Opening hours:

from 8:00 to 18:00

The information on the site is for reference only and is not a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. Product specifications and delivery packages are subject to change without prior notice. Check with our managers for information.

Important parameters of burning installations

The burning installation consists of several high-voltage sources and one low-voltage one. The maximum current and voltage values of each source are called stages, their number can vary from three to six from different manufacturers (Table 3).

Table 3. Main technical characteristics of burning installations from different manufacturers

| Name of equipment | Maximum output voltage, kV | Maximum output current, A | Number of steps | Characteristics of stages, kV |

| APU 1-3M | 24 | 30 | 4 | 25; 5; 1; 0,3 |

| VUPK-03-25 | 25 | 55 | 5 | 20; 5; 1,05; 0,4; 0,15 |

| MPU-3 Phoenix | 20 | 20 | 3 | 20; 5; 0,6 |

| SVP-05TS | 25 | 20 | 3 | 20; 5; 1 |

| UP-7-3M | 22 | 65 | 6 | 22; 11; 5,5; 1,4; 0,55; 0,16 |

| IPK-1 (VPU-60+ MPU-3 Phoenix) | 60 | 20 | 4 | 60; 20; 5; 0,6 |

| UD-300 | 0,25 | 300 | 1 | 0,25 |

| VP-300 | 0,25 | 300 | 1 | 0,25 |

During the burning process, as the breakdown voltage decreases, the transition to the next burning stage occurs. As soon as the installation parameters make it possible to switch on a more powerful stage for parallel operation (or separately), it is put into operation. A more powerful stage means a unit with lower internal resistance and higher current.

Installations for cable burning and diagnostics

Such installations weigh quite a lot, and damaged cables have to be looked for anywhere: in the tunnel, underground, and in the cable assembly. Therefore, electrical laboratories usually equip mobile units based on cars or buses. In addition to installation, the car is equipped with a gasoline or diesel generator.

Installations for burning the location of damage to power cables are usually not universal; they are designed for a specific range of voltages, adjustable in steps or do not have adjustment steps. Here are some examples:

- The APU 1-3M installation produces voltage up to 24 kV and current up to 30 A.

- Installation VUPK-03-25, voltage 25 kV, current – 55A.

- The IPK-1 installation, combined, consists of VPU-60 and MPU-3 Phoenix, burns voltages up to 60 kV, output currents up to 20A.

Low-voltage afterburning installation: UD-300 and VP-300, produces 250 Volts with a current of up to 300A. They have no adjustment steps.

The video below clearly shows how the UPI-10 cable burning installation works:

Useful on the topic:

Possibility of continuous burning

The previous generation of burning installations used manual switching of stages by the operator, which often led to interruption of the arc, increased the burning time and created the possibility of “swimming” breakdowns.

Modern burning devices are equipped with automatic systems for switching burning stages, eliminating arc rupture at the burning site, which significantly reduces the time spent on preparatory work to find damage sites. Often such burning is called “stepless”, which should not mislead specialists: this concept does not mean the absence of several power units (stages) - simply switching between them is carried out automatically, without operator participation.

To generate high voltage, the design of burning installations uses either oil transformers or “dry” transformers - power transistors (Table 4). The issue of automatic switching of stages without arc rupture has been resolved in both types of devices, however, there is an opinion that only dry transformers can provide continuous burning in any conditions. This phenomenon is associated with different energy consumption of two types of transformers in short circuit mode. Oil transformers have significantly higher power consumption in short circuit mode, so keeping them turned on simultaneously during the entire burning process is ineffective; therefore, when the voltage drops, the source with the oil transformer, which generates a higher voltage, is turned off.

Table 4. Weight and dimensions of equipment depending on the type of transformer

| Name of equipment | Transformer type | Equipment weight, kg |

| APU 1-3M | oil | 260 |

| VUPK-03-25 | dry | 45 |

| MPU-3 Phoenix | dry | 55 |

| SVP-05TS | oil | 215 |

| UP-7-3M | oil | 210 |

Very often, switching to a more powerful burning stage first leads to “swimming,” i.e. to increase the breakdown voltage, in this case you should return to the previous stage of a higher voltage, and then, after reducing the breakdown voltage, move on to the next stage.

In a situation where the breakdown “swims” and the voltage rises again, in types of devices with oil transformers, a higher voltage source may already be turned off, which leads to interruption of the arc. On the contrary, “dry transformers” (power transistors) in short-circuit mode have almost zero power consumption, which allows them to be kept on at the same time, so that the arc is not interrupted either when the voltage drops or when it rises (“floating” breakdown). It is believed that in the fight against floating breakdowns, burning installations made using dry-type transformers have the best performance.

Synchronization of work with high-voltage burning devices

At the beginning of the article, when considering the technology of the burning process, we talked about the possibility of connecting high-voltage burning devices that can start burning from 60–70 kV (Table 2). Today, all serious manufacturers of burning equipment use similar solutions, as this significantly expands the possibilities when performing work to detect damage to high-voltage cable lines. Burning installations are used not only permanently, but also as part of mobile electrical laboratories, where the possibility of high-voltage burning is always realized.

High-voltage burning device VPU-60

The high-voltage burning device VPU-60 is designed for burning damaged insulation of power cables with a rating of 380 V - 10 kV in the range from 60 kV to 0. VPU-60 differs from its predecessor in greater power and optimized current-voltage characteristics. These circumstances make it possible to significantly increase efficiency and reduce the time of high-voltage burning. In addition, the device is more reliable and more convenient to use.

- Price on request

- Buy

Burning unit power

The power of the burning installation is one of the important characteristics that affects the burning time and its efficiency. Also, more powerful installations have proven themselves well in conditions where the cables are very frozen and require “drying” (Table 5).

Table 5. Examples of output power values of burning installations

| Name of equipment | Output power, kVA |

| MPU-3 Phoenix | 6 |

| SVP-05TS | 8 |

Operating time without overheating

On complex and inconvenient damage, burning can last several hours. If the device overheats, the process must be interrupted, which can lead to re-sinking of the damaged area. The longer the continuous operating time of the installation, the better (Table 6).

Table 6. Continuous operation time of burning installations from different manufacturers

| Name of equipment | Continuous operation time declared by the manufacturer |

| APU 1-3M | 5 minutes in burning mode with a floating breakdown, restart after 30 minutes |

| VUPK-03-25 | Cyclic work: 1.5 minutes of work - 40 seconds break |

| MPU-3 Phoenix | About 3 hours at a temperature of +20°C, without burning time restrictions at temperatures below 0°C |

| SVP-05TS | The longest continuous operation time at load current: 100% of the maximum - 10 minutes, restart after 5 minutes 70% of the maximum - 30 minutes, restart after 15 minutes |

| UP-7-3M | No more than 20 minutes, restart after 20 minutes |

Comparison of the cost of installations for burning high-voltage cables

At the end of the article, let's talk about such an important factor as the cost of equipment.

There are not so many offers of burning installations on the market, among them three main price segments can be distinguished: low-budget (Kharkov, Penza, Tula), medium-budget (Obninsk, Yaroslavl), and high-budget (Germany, Austria and other imported installations). In the segment of medium- and high-budget installations, manufacturers conduct active marketing and advertising activities in order to convey to consumers information about the benefits of purchasing a particular model and justify its price: they participate in exhibitions and conduct technical seminars. Manufacturers of low-budget installations pay less attention to marketing and promotion, relying on the affordability of equipment.

The installations discussed in this article are difficult to compare only by price, since they are all designed according to different schemes, have different capabilities, each manufacturer focuses on certain individual advantages, so we advise specialists, based on the material in our article, to first All you have to do is understand the characteristics of the equipment, understand its capabilities, choose the best option for working in your conditions, and only then conduct your own analysis of “price - my advantages when working with this installation.” Current prices on our company website - www.electronpribor.ru

We hope that our article will help you make the right choice.

Analytics and Marketing Division of ELEKTRONPRIBOR LLC

source

What is cable burning and what is it used for?

If there is insulation damage on a high-voltage cable, then it is necessary to localize the damaged area, and then begin to eliminate the accident. An important condition for applying methods for searching for defective insulation is the level of transition resistance at the accident site; it should not be more than 3.0-5.0 kOhm. Otherwise, problems will arise with localizing the damage.

In some cases, even low contact resistance will not help. For example, an effective acoustic method may fail when the cable is laid at a large depth or if there are problems with determining its passage. In such cases, a cable sheath burning apparatus is used. Using a burning installation, it is possible to create interphase short circuits from single-phase cable cores and localize them using the induction method. You can learn more about various methods of searching for damage, including breaks in cable lines, on our website.

Burning is carried out by energy that is released at the short circuit point (that is, the operating principle is the same as that of a heating cable). As a result, the shell is charred and the contact resistance decreases where there is an insulation defect.

Note that using this technique you can determine damage to cable couplings and end switches. If the cable route is not closed, then it will not be difficult to detect the problem area tactilely or by the emitted burning.

Main indicators

All of the above indicates that the main characteristics of the device will be the operating current and output voltage. The number of steps is also equally important.

The desired result can be achieved under this condition - the indicators of transient and internal voltage in the damage zone should correspond to each other as closely as possible. In reality, if these parameters differ significantly, the operation of the device is simply impossible.

Only the use of a multi-stage technique will help solve such a problem. The essence of the process is to switch at a lower transient voltage to a source with lower voltage parameters. Stages 3-6 have modern models of burning devices.

Several models of similar equipment:

Types of cable burning installations

In Russia and neighboring countries, the installations in question are usually classified according to their intended purpose. In this regard, burning devices are divided into the following three types:

- Devices used both during testing and during high-voltage burning . The peak voltage of such devices is about 60.0-70.0 kilovolts.

- Devices with an operating range of up to 20.0-25.0 kilovolts. As a rule, several high-voltage sources and one low-voltage source are installed on them.

Burning apparatus APU 1-3 M - Afterburners destroy the contact (metal bridge) formed during a single-phase short circuit of one of the cores to the cable sheath. For this purpose, a current of up to 300.0 Amperes is passed through the damaged cable.

Installations for burning cables

In the CIS countries and the Russian Federation, burning equipment is classified taking into account its purpose. Let's consider three main types:

- devices for high-voltage burning and testing. At the highest point, the voltage of these devices reaches 60-70 kilovolts;

- within the range of 20-25 kW, equipment operates that is used with one source with a low rated voltage and several with a high one;

- The contact that appears during a single-phase short circuit on one of the conductors on the shell is destroyed by units of the afterburning category. The required result is achieved by passing a current of up to 300 Amps through the damaged area.

When choosing a burning device, it is important to carefully consider the performance characteristics specified in the instructions and possible incompatibility of equipment from different manufacturers.

Burning process technology

In practice, three methods are most often used:

- For burning through couplings.

- Reducing cable insulation resistance.

- Destruction of the solder joint of a single-phase short circuit.

Burning of couplings

Couplings placed on the ends of the cable may be damaged. The reason for this may be either improper installation or the destructive influence of the external environment. To detect such damage, cable networks are regularly tested for preventive purposes.

The test procedure is as follows:

- Using a high-voltage device, a breakdown voltage is applied to one of the wires. After a series of breakdowns, the voltage and dielectric strength should decrease. Otherwise, everything indicates that there are problems with the connecting or end couplings (the latter is unlikely; most often the malfunction occurs at the point where the cable is extended).

- Continuous burning continues for up to 10 minutes; if during this period the discharge voltage does not decrease, the tests are stopped and localization of the damage begins.

The selected method of searching for the location of the damage is selected depending on the established resistance value at the breakdown site.

Cable check

As in the previous method, problems with the cable sheath are most often discovered during preventative maintenance, which must be done regularly even for apparently serviceable cables. If during testing a series of discharges with a gradual decrease in voltage is observed, everything indicates damage to the insulation, for example, a puncture of the cable. As soon as the minimum discharge voltage is established, burning is performed at the maximum level, that is, with an increased voltage.

As a result, the insulation will char and dry out, high-voltage discharge pulses will be replaced by a steady flow of current at the fault point, and a drop in resistance will be observed at the emergency point. This will require lowering the source voltage, that is, lowering the stage. If during the burning process the junction resistance value begins to increase, the stage is changed to a higher one until the situation stabilizes.

Now let's look at the cable connection diagram, when it is necessary to transform a single-phase short circuit into an interphase one.

How to turn a single-phase short circuit into a two-phase one

The above scheme works according to the following algorithm:

- Using the burning device “2” we destroy the contact between the damaged core “c” and the metal sheath of the cable.

- In this case, the test device “1” is connected at one end to two intact conductors “a” and “b”, and at the other end to the arrester “3” (also connected to conductor “c”). The capacitance formed by the two conductors stores the charge until it matches the spark gap voltage (typically 5.0 to 10.0 kilovolts). During a pulsed discharge, the contact between the damaged core and the sheath is destroyed.

- Due to the presence of a charge on the conductors “a” and “b” during transient processes, a breakdown between the intact conductors and the damaged “c” is highly likely to occur. In this case, the voltage of the test unit “2” will not be enough to trigger the arrester.

Note that using this circuit it may not be possible to create an interphase short circuit. At the same time, attempts to increase the output voltage of the test device can cause a breakdown at a completely different point.

Work order

In principle, there are two types of damage - a break in the cable or one of its cores and a short circuit. However, the short circuit is not so clear; it can be low-resistance or high-resistance. In the first case, a regular test will show a short circuit, in the second - not. To reduce the resistance of the damaged area, it is necessary to burn through the insulation until a low-resistance circuit is formed or a single-phase circuit is converted to a 2-3-phase one.

The initial stage of cable burning occurs at high voltage, but with low current. Under the influence of high voltage, insulation breakdown occurs and current begins to flow. Gradually, the breakdown voltage of the insulation decreases along with the resistance of the damaged area. As the current increases and the resistance decreases, the firing voltage is reduced and the current is increased. This is how they achieve a reduction in resistance from tens of kOhms to several tens of Ohms. The voltage is reduced to limit the burning power. This process is carried out with both direct and alternating current; the operation algorithms of the installation depend on the specific model.

Burning the cable allows you to localize the damaged area, both visually and by the smell of burning and other consequences of the process.

Typical situations include a breakdown in the coupling. Then burning is characterized by a decrease in resistance during the work and a reverse increase after its completion. Another case is when the damaged area is under water and an almost constant current flows, and the resistance of the damaged area remains within 2-3 kOhm. After burning, a search for the damaged area is carried out using an acoustic or induction method.

When burning cables under high voltage, breakdowns occur, and after 5-10 minutes of repeating the procedure, the breakdown voltage decreases, then the installation is transferred to another burning stage.

If, during the process of burning the damaged area of the power cables, the breakdown voltage increases back, the installation is again transferred to a higher voltage and so on until stable low-impedance results are achieved and a reliable metal bridge is formed between the conductors.

To destroy a metal connection resulting from a breakdown, pulsed electrodynamic effects are used, for example, by discharging the capacitance of two serviceable wires onto a third and a screen. Or they use the capacity of a battery of capacitors charged to high voltage (about 5 kV) and a capacity of up to 200 μF. The discharge energy directly depends on the capacity.

During initial high-voltage burning, the currents amount to fractions and units of amperes, and with further decreases in voltage, the current increases to hundreds of amperes. This procedure is carried out by specialists from the electrical laboratory.

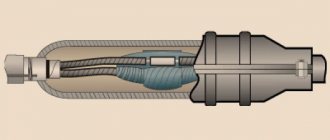

The picture shows one of the cable burning schemes, where the lower core is damaged: