How to treat logs from rotting

Logs are supporting elements that give the entire structure the required rigidity. Flooring is installed on top of them. In order to be able to use the floor for a long time, it is necessary to reliably protect the wooden elements from rotting and insect pests. And for this you need to know how to treat joists and subfloors.

Harm from humidity and microorganisms

Regardless of the construction in which lumber is used, it is still exposed to precipitation or moisture vapor inside rooms. Precipitation is understandable; it penetrates into the fibrous structure of the wood, reducing the strength of the material. Under favorable temperature conditions, fungi and mold begin to appear inside damp wood, for which the humid environment is their home.

Boards, beams, logs begin to darken and rot, which ultimately reduces their strength and leads to destruction.

As for humidity inside the house, it is good if wooden wall decoration is used in dry rooms. Here it will last longer, but you must also take into account the fact that wood is a material that burns well. Therefore, we need to think about the question of how to reduce the fire hazard of a building. Thus, it is best to choose a composition for impregnating wood that will protect not only from moisture and rot, but also from fire.

When to start treating floor and ceiling beams with fire-retardant compounds:

- You can protect floor and ceiling beams from darkening, protect interfloor ceilings from mold and mildew, and treat floor and ceiling beams, boards and beams while storing harvested logs or lumber prepared for cutting a log house or timber before its assembly.

- It is necessary to protect floor beams from mold and bark beetles, protect joists and floor joists at the time of assembling your house or bathhouse.

- You can treat floor beams against fungus with a fire-retardant antiseptic or treat ceiling beams immediately after assembling a house from logs or timber on the customer’s site after its final installation “under the roof” for the entire period of “shrinkage” and “standing” of the log house until the start of finishing the log house or covering a timber house with siding. It is very important to protect the floor and ceiling beams as soon as possible after assembly, because The wood of a log house or bathhouse may have high humidity and is most susceptible to darkening and the negative effects of fungal and mold spores. The beams carry the main load of the floors and everything that you will load on them. When a floor joist rots, the cost to repair or replace it can be very expensive.

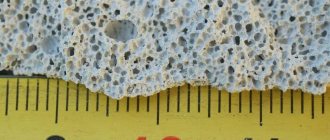

← Photo of how to properly treat floor and ceiling beams with a fire-resistant antiseptic

What kind of protection will floor beams, ceiling beams, hidden cavities and interfloor ceilings in the house treated with a fire-bioprotective composition receive:

- protection of floor and ceiling beams from fire, protection of ceiling beams from fire,

- protection of ceiling and floor joists and beams in a log house from darkening, mold, mildew,

- protection of floor beams and ceiling beams in a log house from bark beetles, protection of beams from woodworm larvae infestation,

- protection of interfloor ceilings, floor and ceiling beams from wetness and moisture,

- reducing cracking of floor and ceiling beams from cracking.

BUY an antiseptic to protect floor beams and ceiling beams in the house and bathhouse:

| FIRE-protective compounds for wood - protection of floor and ceiling beams from fire, fire, mold, bark beetle, fungus, wood borer. Comprehensive protection of floor and ceiling beams. | BIOprotective compounds for wood. protection of floor and ceiling beams, interfloor ceilings of the house and bathhouse from mold, bark beetle, fungus, wood borer, darkening, etc. |

| In the category, some antiseptics are selected and offered for fire protection of floor and ceiling beams, interfloor wooden structures according to the criterion of MAXIMUM EFFICIENCY and QUALITY of protective impregnations at MINIMUM COSTS to the customer for the entire life of the composition. | |

| BUY fire-bioprotective antiseptic from the ColorLak Trading House. Our RECOMMENDED formulations - a possible solution with free delivery | BUY a bioprotective antiseptic at the ColorLak Trading House. Our RECOMMENDED formulations - a possible solution with free delivery |

| More information about our recommended protective compounds |

| Calculator for calculating the required amount of antiseptic to protect floor and ceiling beams |

| Consultation with a TECHNOLOGIST on choosing the most optimal composition for your home |

| certificates for antiseptics for treating floor, ceiling and ceiling beams |

| Instructions for antiseptics for treating floor and ceiling beams, interfloor ceilings |

| PRICE list for all antiseptics for protecting floor and ceiling beams in the house and baths download |

| PHOTO of the treated surface of log cabins exposed to recommended antiseptics |

| DISCOUNT get |

| Pickup BUY from warehouse WITHOUT TRADE MARKUPS and INTERMEDIARIES |

| a review about the quality of the product and the service of TD ColorLak |

Protective means

Such compositions perform two useful functions:

- They preserve the wood and thereby prevent dangerous fungi from penetrating its structure, the impact of which leads to rotting of the wood.

- They maintain the integrity of the wood because they prevent it from cracking.

Depending on the components present and purpose, protective compounds are divided into the following groups:

- Wax based products.

Water-repellent mastic for floors

- Oil-based products.

Applying oil

- Painting compositions.

Impregnating varnish

Each of these groups has its own properties and characteristics, we will talk about them in more detail.

The most popular antiseptics

The modern remedy Senezh has proven itself well in practice. This antiseptic can be used to treat roofing, wooden sheathing, and floor beams. The composition is presented in the form of a ready-to-use water-based solution. Its advantages:

- bioprotection for a period of 30-35 years;

- type of composition – difficult to wash out;

- chemical bond with wood;

- penetrates deeply into the fiber structure without increasing hygroscopicity;

- allows the tree to breathe;

- has a decorative effect.

The recommended consumption is 250-300 g/m. cube when applied without immersion, 60-80 kg/m. cube when soaking. Senezh penetrates deeply into floor beams and other elements, forming a two-level protective barrier. Prevents the development of fungi and mold microorganisms, insects. The manufacturer produces various series of antiseptics - Ultra, Bio, Thor, Sauna for specific wooden structures.

Estonian-made Pinotex Impra is highly effective. Suitable for bioprotection of floor beams, sheathing, mauerlats, rafters. It is a water-based antiseptic with an alkyd binder. It is deeply absorbed into the surface of the wood, providing good protection against rot, blue stains, and mold.

The consumption of the substance ranges from 85 to 200 g per square meter, depending on the wood processing - sawn or planed. Pinotex Impra cannot be used for elements of the rafter system already affected by microorganisms, unlike the Senezh composition.

The product produced in Russia, Drevotex, is used to protect wood material from the formation of rot and mold. Main characteristics:

- effectively protects floor beams and boards from exposure to atmospheric moisture;

- the bio series is suitable for the prevention of healthy wood material, the anti-mold series is used for wood affected by focal microorganisms;

- type of impregnation – difficult to wash out, allows the wood to “breathe”;

- the bioprotection period of the rafter system with the complex agent Drevotex is about 30 years;

- product consumption is 250-350 g/sq.m. m when brushing and 200 kg/m. cube when immersed.

The product can be applied to new wood or as a treatment for existing roofing structures.

When choosing antiseptic compounds for floor beams, sheathing boards and mauerlats, it is necessary to pay attention to the moisture content of the wood, since not all antiseptics are suitable for wood with a moisture content of more than 20 percent.

Expert opinions

It is necessary to provide additional protection to the sheathing and rafter system. After all, wood, as you know, is susceptible to rotting. Microorganisms formed in the wood structure rapidly begin to destroy the fibers, which leads to a deterioration in the strength properties of the entire structure. Antiseptics will help prevent the formation of biological pests for decades. But it is advisable to use powerful formulations that are indelible. It is also recommended to treat the rafter system with deep-penetrating antiseptics; their compositions penetrate deep into the wood structure of the rafters and provide it with longer-term biological protection.

For the construction of the rafter system, mainly coniferous species are used, which, due to the presence of their resin structure, ignite instantly. Therefore, it is necessary to use fire retardants, especially if the building is located in a hot climate. These compounds, after being applied to a wooden material, provide it with a second or first degree of fire resistance, it all depends on the product itself. It is better to purchase a fire retardant impregnation with the highest level of resistance to fire. The task of fire retardants is to prevent fire from spreading to wood. This is accomplished by swelling of the film of the composition under the influence of high temperatures, and preventing the penetration of oxygen into the wooden material. Therefore, the fire cannot be maintained and gradually begins to die out.

Methods for treating wood against insects - combating wood-boring beetles (cattle beetles)

Question: Can you tell us more about the methods of treating wood against insects, such as wood-boring beetles (shasheli). How to deal with them, what means are used for this?

Building your own house or cottage is unthinkable without the use of wood building materials. Wood is used to make wooden houses, floors, windows, window sills, doors, rafters, floor beams, etc.

But sometimes, even when choosing very good quality wood, ignoring additional protective treatment against harmful insects leads to premature destruction of the wood. If a characteristic grinding sound appears in the house and small shavings (wood flour) fall from wooden products and structures, this means that wood-boring beetles and their larvae have settled in the wood. People call these insects shashel (black house beetle).

Wood-boring beetle (shashel) - how to get rid of it?

This beetle is an 8...20 mm brown or black insect, photo 1. The lifespan of an adult is 3...7 years. The wood-boring beetle mainly loves pine wood most of all, in a dry state, although they do not refuse other types of wood. The main part of the tree they attack is the sapwood.

Varieties of wood-boring beetles and their larvae

The wood-boring beetle is not as dangerous as its larvae, which hatch from eggs that it lays in the pores, blockages and cracks of wood. One wood-boring beetle is capable of laying up to 200...300 eggs at a time, and after 2...3 weeks, larvae hatch from them and immediately begin to sharpen the wood.

The lifespan of the larvae is 5...17 years, and during their life span they are able to make “tunnels” in wood with a total length of up to 40 km. The larva is capable of laying a mini-tunnel 15...30 mm long in wood in a day, and at the same time grows intensively - its weight can double in a day.

The danger of the larvae lies in the fact that from the moment they begin their lives, they remain inside the wood for a long time, without showing themselves outside, and only when the larvae transform into beetles do they rush out, as evidenced by small round holes, photo 2. Therefore, as a rule, when the presence of this beetle is detected, its larvae have already done a large amount of work to destroy the wood.

Examples of wood destruction by woodworm (shashel)

There are many methods to combat woodworm. Conventionally, they can be divided into:

- preventive methods of protecting “healthy” wood from possible penetration of pests;

- ways to combat insects that have already attacked wood.

Preventive protection consists of treating beams, bars, boards and other wood elements using special solutions and antiseptics, even before the start of construction, photo 3.

Treating wood with antiseptics and woodworm control agents

The modern construction market has a very large selection of preventive protective equipment from various manufacturers. Here are some of them:

Belinka is an organic solvent. If it is necessary to treat for the purpose of prevention and additional protection, use Belinka Belocid, and if the wood is already affected, then Belinka Fentin should be used, photo 4;

Antishashelin is a drug intended for the destruction of wood-boring beetles, shashelin and their larvae. It is effective when injected directly into holes made by insects using a syringe;

Lignofix antiseptic is absolutely safe for humans and does not emit toxic substances. The drug is only dangerous for chitin-containing insects, disrupting the physiological processes in their bodies that are responsible for the development and reproduction of insects. This drug does not decompose over time and retains its properties for 10 years.

Types of antiseptics for wood processing

Also popular antiseptics from such manufacturers as Pinotex, Olimp, BioColor, Aquatex, etc., photo 4.

Advice: You should pay attention to the purpose of the antiseptic you choose, because not all antiseptics are able to destroy or prevent the penetration of wood borers. To obtain a high effect from treating wood with antiseptics, it should be coated in 2...3 layers with an interval of 2...3 days. If the technology for applying the antiseptic is fully observed, the wood will be saturated by 2...3 mm. In practice, antiseptics are effective as a prophylactic agent, i.e. when new, uninfected wood is processed.

An additional way to protect wood from rot

In practice, another option is used for treating lag from the rotting process - it consists of using creosote. It is customary to treat railway sleepers with this composition. Unfortunately, when applying creosote there is also an unpleasant odor that is difficult to get rid of. It will also not be entirely pleasant to be in such a house.

On the domestic market, the choice of antiseptics for wooden elements is not limited to Senezh. You can treat logs using various high-quality products (read: How to clean a floor after repair).

When choosing an antiseptic composition, you must not forget that materials from different types of trees have distinctive properties and the drug should be purchased taking into account the characteristics of wooden structures for flooring.

Types of wood preservatives

Wood antiseptic is an impregnating composition that has special properties aimed at destroying mold, mildew and insects that destroy the integrity of lumber.

Almost all antiseptic impregnations contain organic and synthetic insecticide molecules that can attack the nervous system of insects (parasites), as well as chemicals that actively destroy mold.

Types of wood antiseptics depending on the purpose:

- Preventative - used in the initial stages, immediately after purchasing lumber.

- Medicinal - designed to eliminate existing problems when the wood has already rotted or been damaged by insects. Sometimes it is appropriate to use such compositions as a preventive treatment, when it is assumed that the structure will be operated in unfavorable conditions (high humidity).

Types of antiseptics depending on the composition:

- Water-soluble ones are used for preventive purposes to treat surfaces that will not have direct contact with water in the future.

- Oil paints are used in cases where it is necessary to protect wood from moisture. The disadvantage of such products is flammability, unpleasant odor and the ability to change the color of the material.

- Antiseptics based on organic solvents are used when treating wood to give it hydrophobic (water-repellent) and adhesive (improving adhesion) properties. Can be used for both external and internal work. After drying, they form a protective film.

- Combined - combine several properties (protect against insects, mold, mildew, and at the same time have fire-retardant properties).

- Winter antiseptics are used at temperatures as low as -15°C.

When choosing antiseptics for treating the rafter system, pay special attention to the instructions. Certain products can cause metal corrosion, react with adhesives and sealants, and be toxic.

Let's look at examples of antiseptics from various manufacturers:

| Antiseptic "Senezh Ecobio" is intended to protect wood from rot, mold, blue stain and insects (woodworms) indoors and outdoors (under a canopy) under conditions of hygroscopic and condensation moisture without contact with the ground, exposure to precipitation, soil moisture alone or in as a bioprotective primer for paints and varnishes. |

| "Pinotex Impra" (Pinotex Impra) is an antiseptic (impregnation) for treating wood with deep penetration, water-based with a high content of biocides. Protects hidden wooden structures from mold, blue stains and rot. Has a green indicator to ensure uniform application. It has excellent impregnating properties and prevents moisture from penetrating into wood. Easy to apply, without splashing or drips. Does not have a pungent odor. |

| "Drevotex" is a remedy against the possible occurrence of rot, mold and insects inside wood. Designed for processing wooden structures that are located indoors or under a canopy. Suitable for use in moderate weather conditions. It practically does not wash out when moisture gets on it and does not interfere with the passage of air to the wood. |

It is worth noting that there were particular examples of antiseptic compositions considered. If you study the entire range in more detail, you can highlight a huge variety of products. So, for example, in the Senezh line of antiseptics there are the following positions:

- “Senezh aquadecor” is a tinted antiseptic on an alkyd-acrylate base with a UV filter and wax for long-term protection and finishing of wood.

- "Senezh ecobio" is an economical colorless antiseptic for rooms and wooden structures under a canopy.

- "Senezh Ultra" is an economical, hard-to-clean antiseptic for wood for external and internal use.

- "Senezh" is a preservative, difficult-to-wash-out antiseptic for critical structures in harsh operating conditions.

- "Senezh Bio" is a preservative, difficult-to-wash-out antiseptic for residential buildings in harsh operating conditions.

- "Senezh impra" is a concentrated, non-washable antiseptic without chromium for deep impregnation of wood.

Treatment against rotting: nuances

This is perhaps the main type of processing of any wooden structures. Without it, any house will quickly fail. This also applies to floors. Today there are many products on the market that can combat this kind of problem.

The drug "Senezh" is used to protect wood in various conditions; in addition, it has antiseptic and fire-resistant properties.

According to numerous customer reviews, the most effective method of combating rot is the Senezh product. However, this is not a universal remedy. It is individually developed for each type of wood.

When choosing, you need to pay attention to this fact. Depending on the composition, the price also varies. The method of use is also not the same for all substances in this group. Today, Senezh Ognebio is considered the best option for lags. This protective material is easy to apply and is not too expensive.

"Senezh Ognebio" is used not only as a biological protector of logs, it is able to prevent a fire in a wooden house. With its help you can process almost all areas of wooden structures. There are no exceptions. It is used both for covering log structures and for agricultural purposes. Protects against fire for up to 3 years. If you use a professional version of antiseptic, this period is extended to 5 years.

As for biological protection, we can talk about a period of 20 years. This is quite a long period. When applying this composition to logs, it is unacceptable that they were pre-treated with other film and paint materials.

Senezh Ognebio is applied quite easily. The instructions on the package will tell you how to do this. After the composition is applied to the logs, they slightly change their shade. Elements treated with this material become reddish. This antiseptic is considered one of the most effective on the modern market, but there are other options for protecting wood from rot. Senezh antiseptics themselves have about 10 varieties.

Many experts advise treating underfloor joists with hot transformer oil.

Resin, which is applied hot with a brush, is excellent for fighting insects.

This product is also effective due to the fact that the substance penetrates the wood. Moreover, it penetrates quite deeply, in some cases several centimeters. Transformer oil embalms the wood, making its properties slightly different than they were originally.

Processing of floor beams

The roof truss system is a wood material that is easily destroyed upon contact with moisture and quickly ignites in the event of a fire.

How to treat rafters to extend their service life and prevent the formation of mold microflora.

Which of the formulations available on the market is most effective? This depends on the type of wood and the prevailing climatic conditions. If it’s humid, you need protection from water; if it’s hot, you need to protect the wood from fire.

Strengthening the attic floor - ways to strengthen wooden beams

The installation of an attic significantly increases the living space of the house. In practice, another usable floor appears in the house. But for its full use, it is necessary to strengthen the attic floor, since the loads on the structure increase significantly. First of all, this applies to wooden beams, most often used in the construction of private buildings.

Logs and external environment

Theoretically, lags should not be directly affected by aggressive environmental factors. First of all, we are talking about dampness. The fact is that if the logs are laid on the foundation of a building, they do not have direct contact with the environment, since the material is vapor-proofed and waterproofed. However, due to temperature differences between the upper and lower levels, condensation still accumulates in the underground.

It should be understood that builders do not always strictly follow the technological process when laying floors, and if this was the case, then the wooden structure will also begin to rot.

Scheme of a wooden floor on joists

Another enemy of wood is harmful microorganisms. Due to natural factors, any unprotected wooden structure is susceptible to pests. Therefore, processing of any wooden structures is an urgent need.

There is no single correct way to handle lags. In each specific case, many circumstances must be taken into account, for example, the type of wood. After all, each type of wood reacts to humidity differently. However, a number of general recommendations can be given that will give you an idea of the correct approach to treating floor joists.

The main way to protect wood from rotting and microorganisms is treatment with chemicals.

Processing of the rafter system

The rafter system, being an important component of the structure of the roof and the entire house, is often made from lumber. Wood, as you know, is susceptible to biological decomposition, mold, mildew, and insects. Therefore, in order to protect the construction material, it is necessary to treat the rafter system with special compounds. And how to treat rafters is described in detail in this review.

Basic properties of protective compounds

Protective agents (antiseptics) used to treat rafters, sheathing and other wooden roof elements have the following important properties:

- They penetrate deeply into the wood.

- They are applied easily to the surface and dry quickly.

- Do not interfere with normal ventilation of the processed material.

- Safe for humans and animals, non-volatile, do not irritate the skin.

- They do not lose their properties upon contact with water.

- They create a reliable protective barrier against biological destruction and fire of wood.

Most protective agents can also improve the decorative properties of wooden elements. This is achieved due to the alkyd resin contained in the composition, which changes the shade of the wood.

A unified characterization of properties requires a more detailed consideration in the context of a specific composition. Therefore, at the preparatory stage it is necessary to correctly prioritize and decide on the main processing task. For operation in humid climates, the following processing sequence will be optimal:

- The first layer is a deeply penetrating antiseptic.

- The next step is the application of fire retardants, which make the wood resistant to fire.

It is important to maintain consistency when processing rafters. The enhancement of specific properties - biological resistance or fire protection - depends on which composition is applied first.

Types of wood preservatives

Wood antiseptic is an impregnating composition that has special properties aimed at destroying mold, mildew and insects that destroy the integrity of lumber.

Almost all antiseptic impregnations contain organic and synthetic insecticide molecules that can attack the nervous system of insects (parasites), as well as chemicals that actively destroy mold.

Types of wood antiseptics depending on the purpose:

- Preventative - used in the initial stages, immediately after purchasing lumber.

- Medicinal - designed to eliminate existing problems when the wood has already rotted or been damaged by insects. Sometimes it is appropriate to use such compositions as a preventive treatment, when it is assumed that the structure will be operated in unfavorable conditions (high humidity).

Types of antiseptics depending on the composition:

- Water-soluble ones are used for preventive purposes to treat surfaces that will not have direct contact with water in the future.

- Oil paints are used in cases where it is necessary to protect wood from moisture. The disadvantage of such products is flammability, unpleasant odor and the ability to change the color of the material.

- Antiseptics based on organic solvents are used when treating wood to give it hydrophobic (water-repellent) and adhesive (improving adhesion) properties. Can be used for both external and internal work. After drying, they form a protective film.

- Combined - combine several properties (protect against insects, mold, mildew, and at the same time have fire-retardant properties).

- Winter antiseptics are used at temperatures as low as -15°C.

When choosing antiseptics for treating the rafter system, pay special attention to the instructions. Certain products can cause metal corrosion, react with adhesives and sealants, and be toxic.

Let's look at examples of antiseptics from various manufacturers:

Antiseptic "Senezh Ecobio" is intended to protect wood from rot, mold, blue stain and insects (woodworms) indoors and outdoors (under a canopy) under conditions of hygroscopic and condensation moisture without contact with the ground, exposure to precipitation, soil moisture alone or in as a bioprotective primer for paints and varnishes.

"Drevotex" is a remedy against the possible occurrence of rot, mold and insects inside wood. Designed for processing wooden structures that are located indoors or under a canopy. Suitable for use in moderate weather conditions. It practically does not wash out when moisture gets on it and does not interfere with the passage of air to the wood.

It is worth noting that there were particular examples of antiseptic compositions considered. If you study the entire range in more detail, you can highlight a huge variety of products. So, for example, in the Senezh line of antiseptics there are the following positions:

- “Senezh aquadecor” is a tinted antiseptic on an alkyd-acrylate base with a UV filter and wax for long-term protection and finishing of wood.

- "Senezh ecobio" is an economical colorless antiseptic for rooms and wooden structures under a canopy.

- "Senezh Ultra" is an economical, hard-to-clean antiseptic for wood for external and internal use.

- "Senezh" is a preservative, difficult-to-wash-out antiseptic for critical structures in harsh operating conditions.

- "Senezh Bio" is a preservative, difficult-to-wash-out antiseptic for residential buildings in harsh operating conditions.

- "Senezh impra" is a concentrated, non-washable antiseptic without chromium for deep impregnation of wood.

We recommend: Do-it-yourself sandblasting for high-pressure washing

Fire retardants for rafter systems

Fire retardants are special compounds that increase wood's resistance to fire and reduce flammability.

In most cases, fire retardants are applied as a second layer after antiseptics. However, if there is a high risk of fire in the rafter system, then they must be used as the main impregnation.

Depending on the specific purpose, fire retardants are divided into:

- Impregnations - salt solutions.

- Coating agents are in paste form.

- Varnishes are used as a decorative coating.

- Paints create a thin film on the surface of the wood, which provides protection from fire.

When using fire retardant as the main means of treating rafters, impregnation would be the best option. Coating compounds are suitable if they are applied over an antiseptic.

Let's look at examples of compositions based on fire retardants from various manufacturers:

| "Pinotex Impra" (Pinotex Impra) is an antiseptic (impregnation) for treating wood with deep penetration, water-based with a high content of biocides. Protects hidden wooden structures from mold, blue stains and rot. Has a green indicator to ensure uniform application. It has excellent impregnating properties and prevents moisture from penetrating into wood. Easy to apply, without splashing or drips. Does not have a pungent odor. |

The product "Senezh Ognebio" is intended for comprehensive protection of wood from fire, flame spread, rot, mold, blue stains and insects (woodworms) indoors and outdoors (under a canopy) under conditions of hygroscopic and condensation moisture without contact with the ground, exposure to precipitation , soil moisture.

"Pirilax-Classic" (Pirilax Classic) is a fire- and bioprotective impregnating composition for wood and wood-based materials. For external and internal works. The product protects wood from fire and stops the spread of flames. Destroys mold and wood-staining fungi, algae and prevents their reappearance. Protects against woodworm beetles. Increases the service life of wooden buildings. Reduces wood cracking and preserves the surface. Compatible with most paints and varnishes.

"Neomid 450-1" is a highly effective fire protection and antiseptic agent for wood for external and internal work under conditions that prevent the composition from being washed out from the treated surface. Converts wood into a low-flammability and low-combustibility material, providing Group I (first) fire-retardant efficiency, protects against rotting and mold. Designed for comprehensive protection against fire and biological damage to wooden structures and products (walls, beams, building systems, load-bearing beams, ceilings, joists, window and door blocks).

As you can see, most fire retardants for rafters and other structures, containing fire retardants, also perform antiseptic functions. In fact, these are universal products with a pronounced fire-resistant effect.

Methods for applying protective compounds to rafters and sheathing

The technology for treating rafters (sheathing boards) with both fire retardants and antiseptics is the same. Wood protection measures can be carried out in several ways:

- Immersion method. In this case, the rafters are treated by completely immersing them in an antiseptic. To work, you will need a large container (a bathtub or a regular pit covered with plastic film) filled with a protective compound.

- Surface application - spraying, spraying or painting. This technology is less effective. Therefore, for high-quality treatment, the compositions must be applied to the rafters and sheathing in several layers with an interval for drying.

In conclusion, it is worth noting that soft wood absorbs more antiseptic than hard wood, and coniferous wood, in addition, can release resin, which negatively affects the protective properties after treatment. Also, as noted above, it is important to decide how to process the rafters, and in what order to do it. Thus, the first applied product affects the protective characteristics more than the subsequent layer of another product.

Treatment against rotting: nuances

This is perhaps the main type of processing of any wooden structures. Without it, any house will quickly fail. This also applies to floors. Today there are many products on the market that can combat this kind of problem.

The drug “Senezh” is used to protect wood in various conditions; in addition, it has antiseptic and fire-resistant properties.

According to numerous customer reviews, the most effective method of combating rot is the Senezh product. However, this is not a universal remedy. It is individually developed for each type of wood.

When choosing, you need to pay attention to this fact. Depending on the composition, the price also varies. The method of use is also not the same for all substances in this group. Today, “Senezh Ognebio” is considered the best option for lags. This protective material is easy to apply and is not too expensive.

“Senezh Ognebio” is used not only as a biological protector of logs, it is able to prevent a fire in a wooden house. With its help you can process almost all areas of wooden structures. There are no exceptions. It is used both for covering log structures and for agricultural purposes. Protects against fire for up to 3 years. If you use a professional version of antiseptic, this period is extended to 5 years.

Application of fire retardants

Fire protection is designed to give wood material additional qualities - fire resistance, reduced flammability. If you decide that the likelihood of a fire is higher than the possibility of rotting of the rafter structure, first of all, all wooden fragments of the roof should be treated with fire retardants.

They are classified into the first and second efficiency groups. The products of the first group provide fire protection for 5-7 years, so they are more effective. Most fire retardants are based on ammonium phosphates and sulfates, borax, boric acid and combinations of these substances.

All fire retardants are divided into:

- Impregnations are solutions of salts that are applied manually or by immersion.

- Coating fire retardants have a paste-like consistency.

- Varnishes are used for decorative purposes. Their use on the roof is unnecessary.

- Paints form a thin protective film on the surface.

Most often, to protect floor beams and rafters, impregnation is used, when the fire retardant will serve as the main protection, and coating, if the fire retardant is applied to the antiseptic. The methods of coating with fire protection are identical to the application of antiseptics. The market offers a large selection of compounds of the first and second categories. Neomid is very popular.

Since the composition has received a lot of positive customer reviews, we can take a closer look at its properties.

Products: necessity or evil?

By the way, recently underground spaces are increasingly being built without ventilation. Thus, the masters call this “a Russian tradition - first driving humid air underground, and then actively expelling it from there.” Therefore, today, more and more often, the foundation and floor are simply well insulated - and that’s all. This way the floor will never rot. What does this design solve?

Let's take a closer look at this point. For example, in the spring the air outside is much warmer than underground, and besides, it is also humid (the snow is melting). And this warm and moisture-saturated air penetrates through the vents under your floor and immediately settles in the form of condensation on the cold boards. And they spend a lot of time in this dampness - until the summer. Is it any wonder that wooden floors completely rot within a few years? And through the same vents, rodents sneak into the house in hordes in the fall. That is why today other design solutions are actively used, and ventilation is carried out in a slightly different way - through the house itself.

Such an underground is called closed air-conditioned, i.e. mechanically ventilated. The fact of the matter is that if the temperature of the underground and the room does not differ much, then condensation on the floorboards will not occur. On the other hand, if your underground is and will be ventilated with vents, the movement of air from it through the floor must then be completely blocked.

These are the solutions to this problem - everything is actually very simple.