What types of transformers are there?

Types of transformers

Transformers differ in technical characteristics and purpose, they are divided into several types, these are:

- Power – used to convert electrical energy in electrical networks of various voltages (0.4/10.0/35.0/110.0/220.0/500.0/1150.0 kV) with an industrial frequency of 50 Hz. They are installed at transformer substations and specially equipped foundations and sites. They differ in the design of the cooling system (oil and dry), the number of windings (2, 3 or more windings).

- Network - used to supply power to low-voltage appliances, household and other devices. They differ in the number of windings on the secondary side and the output voltage (from 1.5 to 127.0 V), the primary voltage being 220 V. These are low-frequency transformers.

- Autotransformers - a distinctive feature of these devices is that one winding is part of the second (primary secondary or secondary primary), making it possible to adjust the voltage on one of the windings.

- Current transformers are devices whose primary winding is connected to the power supply circuit of an electrical energy source, and devices designed for lower currents are connected to the secondary winding. Used in electrical energy metering and control systems. Available for all voltage classes. The main technical characteristic is the transformation ratio, defined as the ratio of the current in the primary winding to the current in the secondary winding. They differ in accuracy class, differ in the type of insulation (oil, cast, gas, dry), according to the principle of current conversion (electromagnetic, electro-optical, magneto-semiconductor), according to the design of the primary winding (coil, feed-through, busbar), according to placement conditions and the type of transformed quantities.

- Voltage and measuring transformers are similar in principle to power transformers. The difference is in purpose - they are used in systems for accounting and quality control of electrical energy.

Online electrical magazine

When operating power transformers, it is necessary to overload them at certain hours of the day so that, due to underload at other hours, the daily wear of the winding insulation from overheating is not higher than the wear that corresponds to the nominal operating mode of the transformer, since a change in the insulation temperature by 6 °C causes a change its service life is doubled.

The duration t times per day of the permissible periodic overload of the transformer, estimated by the excess load coefficient K2, depends on the initial load coefficient K1 of the transformer, its rated power Snom, the cooling system, the constant heating time and the equivalent temperature of the cooling air corresponding to a given period of the year.

Coefficients K1 and K2 are determined by the ratios of the equivalent initial and maximum currents to the rated current of the transformer, while equivalent values are understood as their root mean square values before the arrival of a larger load and during the period of its maximum.

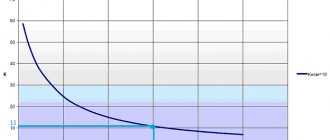

Graphs of the load capacity of transformers K2 (K1), corresponding to different durations t of periodic overload (Fig. 1), allow for a given initial state of the transformer, characterized by the coefficient K1 determined from the daily load schedule I(t) 10 hours before the arrival of its maximum, and this duration t of periodic overload, find the permissible overload coefficient K2 for the period of the highest load of the transformer.

Rice. 1. Graphs of the load capacity of three-phase transformers with a rated power of up to 1000 kVA with natural circulation of air and oil and a constant heating time of 2.5 hours at an equivalent cooling air temperature of 20 °C.

The equivalent temperature of the cooling air is its constant temperature, at which the same wear of the insulation of the windings of a transformer carrying a constant load occurs, as with the existing variable air temperature. With a virtually constant load and the absence of periodic daily and seasonal fluctuations, the equivalent cooling air temperature is assumed to be 20 °C.

If the maximum of the average load curve I(t) in the summer is less than the rated power of the transformer, then in the winter months an additional 1% overload of the transformer is allowed for each percentage of underload in the summer, but less than 15%, while the total load should be less than 150 % nominal.

In emergency cases, short-term overload of transformers above the rated value is allowed, which is accompanied by increased wear of the winding insulation and a decrease in the service life of the transformers (see table).

Permissible short-term overloads of transformers during emergency conditions

| Transformers | |||

| oil-filled | dry | ||

| excess current overload, % | duration of transformer overload, min. | excess current overload, % | duration of transformer overload, min. |

| 30 | 120 | 20 | 60 |

| 45 | 80 | 30 | 45 |

| 60 | 45 | 40 | 32 |

| 75 | 20 | 50 | 18 |

| 100 | 10 | 60 | 5 |

| 200 | 1,5 | ||

Such overloads are permissible for all cooling systems, regardless of the previous mode, the temperature of the cooling air and the location of the transformers, provided that the oil temperature in the upper layers is not higher than 115 ° C. In addition, for oil-filled transformers operating with an initial load coefficient K1 < 0.93, an overload of 40% above the rated current is allowed for less than 5 days during peak loads with a total duration of less than 6 hours per day, while taking all measures to enhance the cooling of the transformer.

When there is a variable load on a substation with several transformers, it is necessary to draw up a schedule for turning on and off parallel operating transformers in order to achieve economical modes of their operation.

In real conditions, it is necessary to deviate somewhat from the design mode so that the number of operational switchings of each transformer does not exceed 10 during the day, i.e., it would not be necessary to turn off the transformers for at least 2 - 3 hours.

When operating transformers in parallel, the total load on the transformer substation must provide sufficient load to each of them, as judged by the evidence of the corresponding ammeters, the installation of which is mandatory for transformers with a rated power of 1000 kVA and above.

Modern transformers operating at high magnetic induction should not be in operation with a significant increase in the primary voltage, because this is accompanied by an increase in the loss of electronic energy due to heating of the magnetic circuits. A long increase in the primary voltage when the transformer load is not higher than the rated one is allowed up to 5% of the voltage of this branch, and when it is loaded at 25% of the rated power - up to 10%, which can be allowed at a load not higher than the rated duration for up to 6 hours per day.

The degree of load unevenness across the transformer phases should not exceed 20%. It is defined like this:

Kn = (Imax - Iav / Iav) x 100,

where, Imax is the current of the overloaded phase at the moment of greater load on the transformer, Iav is the average current of the 3 phases of the transformer at the same moment.

Electrician school

Principle of operation

The operation of the transformer is based on the principle of electromagnetic induction, which is created in the magnetic core of the device.

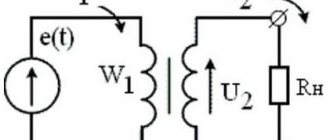

Electromagnetic induction occurs under the influence of an electric current passing in the primary winding of a device, and through it an electric current arises in the secondary winding.

Primary and secondary winding of the device

Main characteristics

Power – determines the amount of power consumers that can be connected to this device in normal operation;

Voltage – determines the characteristics of the electrical network for which the device is intended.

Transformer operating modes

- Operating mode – when the device operates in accordance with the specified technical parameters and in accordance with the requirements.

- Idling mode - in this operating mode, no-load current flows in the primary winding, the secondary network is open (no load);

- Short circuit mode is an emergency operating mode, characterized by a short circuit of the secondary winding.

Another mode that may arise during operation is an overload mode, which is not yet characterized by a short circuit mode, but, nevertheless, by parameters that do not correspond to the operating mode.

Read also

2.2. Maintenance of power transformers and autotransformers

2.2. Maintenance of power transformers and autotransformers 2.2.1. Terms and definitions Transformers and reactors are one of the most widespread types of products of electrical machine-building plants and the most common type of electrical equipment in the world.

2.2.2 Parameters and operating modes of transformers and autotransformers

2.2.2 Parameters and operating modes of transformers and autotransformers Oil transformers are the most widely used. The main advantage of oil transformers compared to dry ones is the protection of their windings from external influences, which

2.4. Parallel operation of transformers

2.4. Parallel operation of transformers Parallel operation of transformers (autotransformers) is permitted under the following conditions: the winding connection groups are the same. Parallel operation of transformers belonging to different winding connection groups,

2.10. Damage during operation of transformers

2.10. Damage during operation of transformers During operation, malfunctions may occur in the operation of transformers, with some of which the transformers may remain in operation for a long time, while others require immediate removal from operation. Causes of damage

5.3.3. Parallel operation of transformers

5.3.3. Parallel operation of transformers Parallel operation of two or more transformers is work in which at least two main windings of one of them are connected in parallel with the same number of main windings of another transformer (others).

5.3.4. Operating mode of autotransformers

5.3.4. Operating mode of autotransformers The following main operating modes are typical for AT: 1. The HV - MV and MV - HV modes are purely autotransformer modes. In these modes, the full rated power of the AT.2 can be transmitted. HV - LV and LV - HV modes are

Transformer overload, its types

The totality of permissible loads and overloads determines the load capacity of the transformer.

Permissible load - a load corresponding to the nominal operating mode, unlimited in time, at which the winding insulation does not wear out due to heating during operation.

Overload is an operating mode caused by connecting a load power greater than the rated one or an ambient temperature greater than the calculated one. When overloaded, accelerated wear of the winding insulation occurs.

There are overloads:

- Systematic – caused by the daily work schedule. Such operating modes must correspond to the permissible overload factors and their passage time for each specific device.

- Emergency – caused by emergency situations. Overloads of this type are:

- Short term;

- Long lasting.

Overloading oil transformers

An oil transformer is a power unit that uses oil as a coolant.

The operating mode of devices of this type is regulated by GOST 14209-97 (IEC354-91) “Guidelines for the loading of power oil transformers,” which came into force in 2001.

Temperature and current limits for overload mode:

| Load type | Transformers | ||

| Distribution | medium power | High power | |

| Systematic | |||

| Electric current values (relative units) | 1,5 | 1,5 | 1,3 |

| Temperature of the hottest area, °C | 140 | 140 | 120 |

| Temperature of the cooling agent (oil) in the upper layer, °C | 105 | 105 | 105 |

| Emergency, long-term | |||

| Electric current values (relative units) | 1,8 | 1,5 | 1,3 |

| Temperature of the hottest area, °C | 150 | 140 | 130 |

| Temperature of the cooling agent (oil) in the upper layer, °C | 115 | 115 | 115 |

| Emergency, short-term | |||

| Electric current values (relative units) | 2,0 | 1,8 | 1,5 |

| Temperature of the hottest area, °C | See notes | 160 | 160 |

| Temperature of the cooling agent (oil) in the upper layer, °C | See notes | 115 | 115 |

*Notes:

- For emergency overloads that are short-term in nature, the temperature limits of the coolant (oil) in the upper layer and the most heated area have not been established. The reason for this is that when operating this type of equipment, it is not possible to control the duration of emergency overload of this type of transformers.

- When operating distribution transformers, it is necessary not to forget that at temperatures exceeding 140-160 °C, gas bubbles may be released, which reduce the electrical strength of the insulation.

Current transformer overload

The design and operating mode of devices are regulated by GOST 7746-2001 “Current transformers. General technical conditions”, adopted by the Interstate Council for Standardization, Metrology and Certification (Protocol No. 20 of November 1, 2001) and put into effect on January 1, 2003.

Overload of this type of device occurs when connecting a load greater than the rated one; therefore, the amount of current in the primary network increases, which negatively affects the insulation of the device.

The safety factor (primary current overload) is determined by the device manufacturer, meets the requirements of GOST and IEC and is 5 and 10.[/wpmfc_cab_sw]

Loading Guide for Power Oil Transformers

When choosing transformers, in addition to their rating data, possible short-term and long-term overloads in operation must be taken into account. When checking the admissibility of loads and overloads of transformers, the following definitions are used [11].

Distribution transformer - a three-phase transformer with a rated power of no more than 2500 kVA×A or a single-phase rated power of no more than 833 kVA×A of voltage classes up to 35 kV inclusive, that is, a step-down transformer with ON cooling and without switching winding taps under load.

Medium power transformer - a three-phase transformer with a rated power of no more than 100 MV×A or a single-phase transformer with a rated power of no more than 33.3 MV×A

The load on transformers continuously changes throughout the day. In this case, part of the day the transformer load may be less than the rated one, the temperature of the hottest point of the winding will be less than the long-term permissible one and the transformer will be underused for heating. The optimal mode for a transformer should be such a mode in which the wear of its insulation would be close to the design one.

The design or natural wear life of a transformer operating in nominal mode is considered to be approximately 20 years. A longer period is considered inappropriate from the point of view of its obsolescence. This period is determined by the aging of the insulation. For normal daily wear of transformer insulation with cooling type M, the temperature of the hottest point of the winding (the hottest inner layer of the winding) in a long-term mode should not exceed 98°C. If the temperature is increased by 6°C, the service life of the insulation will be reduced by almost half (6 degree rule).

In order for the actual service life to be closer to the natural one, the transformer must be loaded in accordance with the so-called load capacity. The load capacity of a transformer is understood as such a set of loads and overloads under which the wear of the winding insulation during the cycle does not exceed the wear corresponding to the nominal operating mode.

Let's consider possible operating modes according to GOST 14209.

Cyclic load mode

Load mode with cyclic changes (usually the cycle is equal to a day), which is determined taking into account the average wear value over the duration of the cycle. The cyclic load mode can be a systematic load mode or a continuous emergency overload mode.

Systematic load mode is a mode during part of the cycle of which the temperature of the cooling medium may be higher and the load current exceeds the rated current, but from the point of view of thermal wear, such a load is equivalent to the rated load at the rated temperature of the cooling medium. This is achieved by lowering the coolant temperature or load current during the rest of the cycle. The load (overload) of the transformer, which is allowed by its load capacity and which, over the duration of the cycle of the load schedule, does not cause a reduction in the normal service life of the transformer (due to reduced wear during hours of reduced load) is called systematic. The mode, during part of the cycle of which the temperature of the cooling medium may be higher and the load current exceeds the rated one, but from the point of view of thermal wear, such a load during the cycle (day) is equivalent to the rated load, is called a systematic load mode.

When planning loads, this principle can be extended to long periods, during which cycles with a relative insulation wear rate of more than one are compensated by cycles with a wear rate of less than one.

Long-term emergency overload mode is a load mode that occurs as a result of prolonged failure of some network elements, which can be restored only after reaching a constant value of the transformer temperature rise. The permissible duration of such a load is greater than the thermal time constant of the transformer. This condition is expected to occur rarely, but can last for weeks or even months and cause significant thermal wear. However, such a load should not cause an accident due to thermal damage or reduced dielectric strength of the transformer.

Short-term emergency overload mode is a mode of extremely high load caused by unexpected impacts that lead to significant disruptions to the normal operation of the network. In this case, the temperature of the hottest point of the conductors reaches dangerous values and in some cases a temporary decrease in the electrical strength of the insulation occurs. The permissible duration of such a load is less than the thermal time constant of the transformer and depends on the temperature reached before the overload; Typically, the duration of the overload is less than half an hour. They must be reduced as quickly as possible or the transformer must be switched off for a short time to avoid damage.

The PUE [1] introduces definitions of two long-term consumer modes: normal and post-emergency. The normal mode of an electrical energy consumer is a mode in which the specified values of its operating parameters are ensured. Post-emergency mode is the mode in which the consumer of electrical energy is located as a result of a disruption in its power supply system until the establishment of a normal mode after the elimination of the failure. If the post-emergency mode of the consumer is caused by the failure of one of the transformers, then its duration will be determined by the time of repair or replacement of the damaged transformer.

Let's draw a parallel between the consumer modes and the transformer load modes.

The regime of systematic loads of the transformer occurs in the normal mode of the consumer's power supply circuit, provided that at some time intervals of the day the load current of the transformer exceeds the rated one.

The mode of prolonged emergency transformer overloads occurs in the post-emergency mode of the consumer's power supply system, when one of the transformers is under repair and the second has taken over its load, provided that the temperature of the most heated part of the winding and the oil temperature have exceeded the normally permissible values, but remain less than the maximum acceptable values. In this case, there is no danger of thermal damage or a decrease in the electrical strength of the transformer insulation, but there is increased thermal wear of the transformer. Therefore, the magnitude and duration of long-term emergency transformer overloads in the post-emergency consumer mode should be limited, for example, by unloading the transformer by turning off part of the electrical receivers for the entire repair period or only during the hours of the transformer’s daily maximum load. Thus, in the general case, the mode of prolonged emergency transformer overloads occurs in the post-emergency mode of the consumer's power supply system after unloading the transformer by turning off part of the electrical receivers.

The mode of short-term emergency overloads occurs due to an increase in the load power of the transformer due to the operation of an ATS during an emergency shutdown of one of the transformers in the time interval from the operation of the ATS to the unloading of the transformer, provided that the temperature of the most heated part of the winding or the oil temperature exceeded the maximum permissible values. In real time, the mode of short-term emergency overloads is an intermediate mode between the normal and post-emergency modes of the consumer.

The choice of the number of transformers is discussed in subsection 7.2 of this manual, the choice of the type and design of transformers is discussed in subsection 7.3, the choice of transformer power and checking for permissible overloads is discussed in subsection 7.4.

The load capacity of a transformer is the property of a transformer to carry a load in excess of the rated load under certain operating conditions (preceding the load of the transformer, the temperature of the cooling medium) is called load capacity [12].

Mode of permissible systematic loads. Systematic overload mode is acceptable for an unlimited time if:

— insulation wear during the cycle does not exceed the nominal value (NRACH < 24 hours);

— temperature of the upper layers of oil QM <950С;

— temperature of the upper most heated point of the winding QННТ <1400С;

— the highest load current is not more than 1.5 INOM (SC.M<1.5).

Mode of permissible long-term emergency overloads. If the wear of the insulation per day is > 24 hours. then the overload mode is classified as emergency. The emergency overload mode is acceptable. If

– if its duration during the cycle does not exceed the calculated permissible (TPER<TDOP);

— temperature of the upper layers of oil QM <1150С;

— temperature of the upper hottest point of the winding QННТ <1600С;

— the highest load current is not more than 2.0 (INOM (SC.M<2.0).

The mode of permissible short-term emergency overloads is standardized by PTEEP.

| 2.1.21. In emergency modes, short-term overload of transformers above the rated current is allowed for all cooling systems, regardless of the duration and value of the previous load and the temperature of the cooling medium within the following limits: |

| Oil transformers: |

overcurrent, % 30 45 60 75 100 overload duration, min. 10

| Dry transformers: |

overcurrent, % 20 30 40 50 60 overload duration, min. 60 45 32 18 5.

Current and temperature limits for loads exceeding the rated load according to GOST

When the load exceeds the rated load, GOST 14209 [11] recommends not to exceed the current and temperature limits given in the table.

Temperature and current limits for load conditions exceeding rated load

| Load type | Transformers | |

| distribution | medium power | |

| Systematic load mode | ||

| Current, rel. units | 1,5 | 1,5 |

| Temperature of the hottest point of the winding, °C | ||

| Oil temperature in the upper layers, °C | ||

| Long-term emergency overload mode | ||

| Current, rel. units | 1,8 | 1,5 |

| Temperature of the hottest point of the winding, °C | ||

| Oil temperature in the upper layers, °C | ||

| Short-term emergency overload mode | ||

| Current, rel. units | 2,0 | 1,8 |

| Temperature of the hottest point of the winding, °C | — | |

| Oil temperature in the upper layers, °C | — |

The maximum values of load current, temperature of the hottest point of the windings and oil temperature in the upper layers given in Table 6.3 should not be exceeded. For distribution transformers with a power of no more than 2500 kVA for short-term emergency overload modes, the maximum values of the oil temperature in the upper layers and the hottest point are not established, since in practice it is impossible to control the duration of emergency overload of distribution transformers. It should be borne in mind that at a temperature of the hottest point exceeding 140-160 °C, gas bubbles may be released, reducing the electrical strength of the transformer insulation.

13. Sequence and preliminary determination of the power of power transformers.

The selection of the optimal power of transformers should be made in accordance with the size and nature of the electrical loads. In this case, both economic requirements (in normal mode) and possible short-term and long-term overloads in operation must be taken into account.

There is a distinction between the choice of power of distribution transformers and GPP transformers.

The choice of power of distribution transformers should be made on the basis of technical and economic calculations. Preliminary power selection is made either by specific load density or by recommended load factors.

The power of transformers is determined by the specific load density for workshops with a known load density in kVA/(square meter). When the load density is less than 0.2 kVA/m2, it is advisable to use transformers with a power of 1000 kVA or less. For a load density of 0.2 kVA/m2 or more, it is more appropriate to use transformers with a capacity of 1600-2500 kVA.

The power of transformers is determined by load factor in the absence of data on the specific load density. Including, both for workshops and for field facilities. In this case, for transformers of distribution substations, the following load factors should, as a rule, be accepted:

- for objects with a predominant load of category I with two-transformer substations - 0.65-0.7;

- for workshops with a predominant load of category II with single-transformer substations with mutual redundancy of transformers - 0.7-0.8;

- for workshops with a predominant load of category II, with the possibility of using a centralized reserve of transformers, and for workshops with loads of category III - 0.9-0.95.

The preliminary selection of the power of GPP and PGV transformers should be made in accordance with the technological design standards for step-down substations with a higher voltage of 35-750 kV. In this case, when one transformer goes out of operation, the remaining transformer must ensure the operation of the enterprise while the retired transformer is being replaced, taking into account possible load limitations without compromising the main activity of the enterprise and using the permissible overload of the transformer.

The most advantageous transformer power corresponds to the minimum given costs, which take into account the capital costs of construction and installation of transformer substations (including the cost of transformers) and current costs associated with operation, including the cost of electricity losses in transformers.

On the other hand, it is known that minimal power losses in a transformer occur at a load factor

,

where RO

and

РК

- certified values of power losses in steel (no-load losses) and in windings (load losses).

For step-down power transformers used in electrical networks of industrial enterprises, bE

are in the range of 0.36 - 0.59.

However, with such a low load on transformers, the installed capacity of the transformer increases, and therefore the share of capital costs for transformers increases. Therefore, the optimal transformer load factor b

, which takes into account not only power losses in the transformer, but also power losses in the supply network, capital costs for the construction and installation of transformer substations, is usually higher than

bE

.

At the design stage, it is recommended for GPP transformers b

= 0.65-7 [13].

In this case, the rated power of distribution substations transformers and GPP transformers is determined by the expression

, (6.1)

where ST

— the total calculated load power transmitted through

N

transformers in the fifth year of operation.

For GPP as ST

It is recommended to take

the calculated (maximum) power SP

(

SM

) of the half-hour maximum, and for all other transformers, including distribution substations, the average power

SСМ

for the busiest shift.

When the temperature of the cooling medium differs from the standard one (20°C), when choosing the rated power of the transformer, the temperature of the cooling medium must be taken into account. The temperature of the cooling medium affects the thermal conditions of the transformer, and, consequently, the permissible load factor. If the temperature of the cooling medium differs from the standard one, and the transformer load does not change significantly for some time, then when calculating the permissible load of the transformer in GOST 14209 [11], it is recommended to recalculate the permissible current (power) of the load. In this case, the value of the acceptable load factor b

in formula (6.1) can be multiplied by the temperature factor. The values of this coefficient for continuous operation are given in Table 6.1 for different temperatures of the cooling medium [11].

Table 6.1

Permissible load factors for continuous operation at different coolant temperatures

(cooling type M. D. ONAN, ON, OF

and

O.D.

)

| Coolant temperature C | Transformers | ||

| distribution | medium and high power | ||

| ONAN (M) | ONAN (M) | ONAF (D) | |

| -25 | 1,37 | 1,33 | 1,33 |

| -20 | 1,33 | 1,30 | 1,30 |

| -10 | 1,25 | 1,22 | 1,22 |

| 1,17 | 1,15 | 1,15 | |

| 1,09 | 1,08 | 1,08 | |

| 1,00 | 1,00 | 1,00 | |

| 0,91 | 0,92 | 0,92 | |

| 0,81 | 0,82 | 0,82 |

During operation, the transformer load may change and at certain times may exceed the rated load. To take into account possible short-term and long-term overloads in operation, it is advisable to select the rated power of transformers in the following sequence. First, the appropriate power of the transformer is preliminarily calculated according to (6.1) based on the recommended load factors in normal mode and two options with rated powers (from the standard range) closest to the calculated value. In general, it is advisable to take the nearest higher and the nearest lower rated power. However, if the calculated rated power value turns out to be close to one of the standard values, then it may be advisable to accept the standard rated power values in both options, either up or down.

Selected transformers are checked:

- on the permissible systematic load in the normal mode of the power supply circuit;

- for permissible short-term emergency overload (when the automatic transfer switch is triggered) without taking into account the unloading of the transformer;

- for permissible long-term emergency overload in post-emergency mode of the power supply circuit, taking into account the unloading of the transformer by operating personnel by disconnecting some of the non-critical electrical receivers (consumers), if such a disconnection is possible and acceptable for a given consumer.

Permissible systematic and emergency overloads for oil transformers with a power of up to 100 MVA inclusive are established in GOST 14209-97 [11], and for dry transformers and transformers with non-flammable liquid dielectric - in standards or technical conditions for specific groups or types of transformers.

Mode of permissible systematic loads. Systematic overload mode is acceptable for an unlimited time if:

— insulation wear during the cycle does not exceed the nominal value (NRACH < 24 hours);

— temperature of the upper layers of oil QM <950С;

— temperature of the upper most heated point of the winding QННТ <1400С;

— the highest load current is not more than 1.5 INOM (SC.M<1.5).

Mode of permissible long-term emergency overloads. If the wear of the insulation per day is > 24 hours. then the overload mode is classified as emergency. The emergency overload mode is acceptable. If

– if its duration during the cycle does not exceed the calculated permissible (TPER<TDOP);

— temperature of the upper layers of oil QM <1150С;

— temperature of the upper hottest point of the winding QННТ <1600С;

— the highest load current is not more than 2.0 (INOM (SC.M<2.0).

The mode of permissible short-term emergency overloads is standardized by PTEEP.

| 2.1.21. In emergency modes, short-term overload of transformers above the rated current is allowed for all cooling systems, regardless of the duration and value of the previous load and the temperature of the cooling medium within the following limits: |

| Oil transformers: |

overcurrent, % 30 45 60 75 100 overload duration, min. 10

| Dry transformers: |

overcurrent, % 20 30 40 50 60 overload duration, min. 60 45 32 18 5.

If the transformers in both options pass all tests, then technical and economic calculations are carried out and the final decision is made based on a comparison of the options at the given costs.

14. Conversion of real daily load graphs into equivalent two-stage rectangular graphs

To determine the admissibility of a particular operating mode of a transformer, it is necessary to construct heating curves and evaluate its thermal regime during the cycle. In engineering practice and design, thermal heating curves are not plotted. The thermal conditions and wear of the transformer insulation are determined indirectly by the coefficients of the equivalent load curve.

At the same time, to check transformers for overload, it is necessary to convert the real daily load schedule into an equivalent two-stage one. The form of a two-stage load graph is shown in Figure 6.1. The real daily load schedule and the two-stage one should be equivalent in terms of power losses in the transformer. In this case, they will be equivalent in terms of the heating temperature of the transformer, and therefore in terms of the wear rate of the insulation. In Figure 6.1 K

1 and

K

2 are two load stages, with

K

1 being the initial or preliminary load

, K

2

being

the maximum load.

The maximum load duration is t

(or h) hours.

Figure 6.1 - Equivalent two-stage load diagram

Both exact and approximate transformation methods are used.

Refined method. The transformation of the original daily transformer load graph into a loss-equivalent two-stage rectangular graph representing the load as a fraction of the rated current (or rated power) is performed in the following sequence.

First, the load graph is presented in relative units: in fractions of the rated current (or rated power)

On the resulting graph of the transformer load, draw a line of rated current l

n, (or rated power).

When plotted in relative units, this line corresponds to K

= 1 (Figure 6.2).

At points A

and

B

intersection of the nominal line with the curve of the original load graph, an overload section of duration h

'

.

The remainder of the original schedule with a smaller load is divided into t

intervals of duration D

t

(usually D

t

= 30 min.) and determine the initial load

K1

of the equivalent schedule

(7.2)

where S1, S2, Sm —

average load values at the corresponding intervals Dt.

Overload section h'

on the original load graph, divide it into

p

intervals Dh and determine the preliminary excess overload of the equivalent load graph

(7.3)

Where , , —

average load values at the corresponding intervals Dh.

Compare the value with the maximum load factor Kmax

original graph: if , you should take

K

2 = ;

if, however, one should take K

2

=

0.9

Kmax

, and the duration

h

of the overload of the equivalent load schedule should be calculated using the formula

(7.4)

If the initial daily transformer load curve contains two similar maximums of different durations, the values of h

and

K

2 are determined by the maximum of the longer duration, and the value of

K

1

is

determined as the root mean square value of the remaining load.

If the original daily transformer load schedule contains several successive close maxima, the values of K

2 and

h

are determined from the coverage of all maxima, and the value of K1 is determined as the rms value of the remaining load.

1 —

original load schedule,

2 —

equivalent rectangular load diagram

Figure 7.2 - Conversion of the original transformer load curve into an equivalent two-stage rectangular

Simplified methods for converting a real load schedule into an equivalent two-stage one

In Simplified methods for converting a real load curve into an equivalent two-stage coefficient K2 of the maximum load is taken equal to the maximum load factor of the real schedule, and the duration of the overload and the initial load are determined by a graphical-analytical method.

Load diagram with one maximum. In this case, the value of t

should be determined as shown in Figure 6.2. A horizontal straight line K2 is drawn, corresponding to the maximum load. The straight line K1 is drawn (selected) and the time interval t is selected so that between the real schedule and the equivalent two-stage one, the conditions for equality of areas are met: 1=2+3+4 and a+b=c+d.

Fulfillment of the first of these conditions means that the value of K1

is defined as the average load value for the section of the load graph without a maximum. The fulfillment of the second of these conditions means that the area of the rectangle with sides K1, t is equal to the area under the maximum of the real load graph.

Figure 6.2 - Load graph with one maximum

Overload protection

To create safe and reliable operating conditions for all elements of electrical networks and devices, various protection systems are provided against non-standard situations, which include overload modes.

Overload protection is based on the use of:

- Fuses and circuit breakers;

- Relay protection (overcurrent protection; cut-off current protection; zero-sequence current protection; differential current protection.)

- Gas protection;

- Fire protection;

- A system for using special programs and automating processes.

Requirements for the protection conditions of various types of transformers are regulated by the Electrical Installation Rules (PUE) chapter 3.1 “Protection of electrical networks up to 1 kV” and chapter 3.2 “Relay protection”.