Polystyrene concrete is a modern building material produced on the basis of cement binder and expanded polystyrene filler (foamed granular polystyrene or PVG), which is classified as cellular concrete. This material has high performance characteristics, such as heat and sound insulation, which makes it possible to use this material in the construction of energy-efficient buildings and structures. Polystyrene concrete blocks are relatively light in weight, which makes it possible to avoid the use of lifting equipment in private housing construction. Larger sizes compared to bricks speed up and simplify laying.

Material characteristics

One of the main characteristics of polystyrene concrete, which distinguishes it favorably from other building materials, is the heat transfer resistance coefficient. This value is the inverse of the thermal conductivity coefficient. It characterizes the thermal conductivity of the material and is equal to the amount of thermal energy passed through a unit of surface in a certain time when the temperature changes by 1 degree. The SI unit of measurement is Watt/(meter*degree Kelvin), or W/(m C). In this case, degrees Kelvin are equal to degrees Celsius.

Table 1. Thermal conductivity coefficient of polystyrene concrete

| Brand of polystyrene concrete | Thermal conductivity coefficient of polystyrene concrete, W/(m 0C) | Strength class, B | Frost resistance coefficient, F |

| D150 | 0,055 | Not standardized | Not standardized |

| D200 | 0,065 | B0.5 | F25-F35 |

| D250 | 0,075 | B0.5 | F25-F35 |

| D300 | 0,085 | B0.75 | F35 - F50 |

| D350 | 0,095 | B1.0 | F35 - F50 |

| D400 | 0,10 | B1.5 | F35 - F50 |

| D450 | 0,115 | B2.0 | F35-F75 |

| D500 | 0,125 | B2.0 | F35-F75 |

| D550 | 0,135 | B2.5 | F50-F100 |

| D600 | 0,145 | B2.5 | F50-F100 |

Compressive strength class is measured in megapascals, for example, strength class B2.0 shows that the material can withstand a load of 2 mPa. The frost resistance coefficient shows the number of freeze-thaw cycles that the material can withstand without losing more than 5% of its strength.

Due to the fact that PVG granules are located in the body of the concrete structure and do not have contact with air, polystyrene concrete is classified as a low-combustible and non-flammable material. Flammability group G1, can be used in structures without additional fire protection.

As can be seen from the table, the thermal conductivity of polystyrene concrete depends on the density of the material; the higher the density, the higher the thermal conductivity. To reduce the density and, therefore, improve the insulating characteristics of the material, foamed polystyrene granules are introduced into the solution. However, as the thermal insulation properties increase, the strength characteristics decrease. Compositions with a density of up to 250 kg/m3 are called thermal insulation and have low strength and are used exclusively for sound and heat insulation; a material with a density of 250-450 kg/m3 is thermal insulating and structural - for non-load-bearing and self-supporting walls, over 450 - for load-bearing walls - structural thermal insulation.

It is important to use material of calculated density when performing work.

Comparison of the thermal conductivity of polystyrene concrete with other materials

Thanks to the inclusion of PVG in the structure of polystyrene concrete, it is significantly superior to many structural building materials, which can significantly reduce heating costs in the cold season, or make walls thinner without loss of thermal resistance. For example, a 400 mm thick wall made of D600 polystyrene concrete, the most common type in private construction, has approximately the same heat-saving characteristics as a 1.5 meter thick brick wall or 3 meter thick concrete. It should be taken into account that these indicators are applicable only when laying polystyrene concrete blocks with a special glue that allows the formation of thin joints 1-2 mm thick. When installing blocks on ordinary masonry mortar, the seams are much thicker and cold bridges are formed.

Table 2. Comparison of the thermal conductivity of polystyrene concrete with other building materials.

The diagram shows how polystyrene concrete is more effective at saving heat than more traditional materials. The ratio of wall thickness required for high-quality heat conservation will be the same.

Comparison with mineral wool

The thermal conductivity of polystyrene concrete blocks and mineral wool does not differ much from each other when we are talking about low-density material. Thermal insulation composition with a density of 200-300 kg/m3 is not much inferior in thermal conductivity to mineral wool and can be used instead of it when insulating walls. For insulation, the material can be used in the form of blocks, slabs, or monolithic, poured into removable or permanent formwork. In the first case, the blocks are attached to walls made of brick, concrete or cinder block or laid between two layers of brick, one of which performs a load-bearing function, and the second, external one, serves as a facing one. When using monolithic thermal insulating polystyrene concrete, several options are possible. In one of them, the formwork is also 2 layers of brick, only foam concrete is not laid, but poured between them. In the second option, a frame is erected from a galvanized metal profile, sheathed with various moisture-resistant sheet materials, for example, on the outside with DSP, on the inside with SML, and also filled with polystyrene concrete.

Also, polystyrene concrete of various densities can be used in the construction of slab foundations as insulation, for the production of wet or semi-dry screeds.

Is it possible to use polystyrene concrete in “warm floor” structures? It can be used as a heat-insulating underlying layer.

The low weight of polystyrene concrete allows it to be used in the production of screeds with high sound insulation characteristics, even on light floors in frame and wooden buildings. The porous structure provides good insulation from airborne noise and additional thermal protection.

What is polystyrene concrete

First, it’s worth figuring out what kind of material polystyrene concrete is? Let's take a closer look at the main characteristics of the material and its composition.

Composition and technical requirements

Polystyrene concrete is a composite containing a mixture of cement mortar and polystyrene. It belongs to particularly lightweight concrete.

Polystyrene crumbs

Cement gives the material strength, and polystyrene gives it lightness and provides a low thermal conductivity coefficient. The more cement, the stronger the product.

Proportions for the manufacture of polystyrene concrete

In addition to cement and polystyrene, the composition includes special modified additives that can improve the quality of future products.

Composition of polystyrene concrete

GOST for polystyrene concrete defines the following set of physical and mechanical characteristics that are subject to control:

- Frost resistance;

- Thermal conductivity;

- Medium density;

- Vapor permeability;

- Compressive and bending strength;

- Medium density;

- Drying shrinkage.

Now let's look in more detail: what indicators should polystyrene concrete have.

GOST R 51263 99 polystyrene concrete: brief analysis of numerical indicators of material properties:

| Indicator name | Meaning according to standard, comments |

| Average density (kg/m3) | Polystyrene concrete can have an average density value ranging from 150 to 600. The grades correspond to products that are in a dry state. The numerical values of the average density determine the future scope of the material, which can be very diverse. But we'll talk about this a little later. |

| Thermal conductivity (W*mS) | The minimum value of the thermal conductivity coefficient is 0.05, and the maximum is 0.145. The operating humidity of the products will undoubtedly affect this indicator, but the ability to maintain temperature will remain high.

|

| Strength | Strength directly depends on the density of the material, the value starts from M0.35. The maximum indicator, in accordance with GOST, can reach M5. The corresponding technical specifications are shown in the photo below. |

| Frost resistance | Polystyrene concrete products that are used in the construction of structures subject to freezing and thawing must meet certain frost resistance grades, which should not be less than 25.

|

| Moisture absorption | The hygroscopicity of polystyrene concrete is not great. The value should not exceed 8%. |

| Shrinkage | Polystyrene concrete is subject to shrinkage. In quantitative terms, the value can reach 1 mm/m2. Much depends on the manufacturer, the quality of raw materials and the brand of strength of the products. |

| Vapor permeability | Polystyrene concrete is vapor permeable. The material is able to establish a favorable climate in the room by absorbing excess moisture when it is present and saturating it with it when the air is excessively dry. |

Characteristics of polystyrene concrete

- In addition to the technical characteristics, it is worth mentioning others. This concerns, first of all, the flammability, environmental friendliness and performance properties of the material.

- Despite the fact that one of the main components of the material, polystyrene foam, is flammable, in combination with cement mortar, this negative quality is successfully leveled out. GOST for polystyrene concrete blocks confidently states: the products do not burn.

- Polystyrene concrete does not contain harmful and dangerous substances, and therefore is environmentally friendly.

- The durability of buildings built from this material is high. According to manufacturers, it can reach 200-300 years.

Polystyrene concrete has excellent sound insulation characteristics. It is often used for soundproofing structures.

Types and scope

In accordance with the standard, polystyrene concrete can be divided into several types depending on certain factors. Let's take a closer look.

In accordance with the density of the material, it can be: heat-insulating, heat-insulating-structural and structural-thermal-insulating:

- The first type has a minimum grade of average density, but at the same time is characterized by a low thermal conductivity coefficient, which makes it possible to use the material for insulating structures.

- The second type, in addition to material for thermal insulation, can be used in the construction of structures that are not subject to significant loads.

- The third type can reach a density of up to D600. Used in the construction of walls and partitions. To put it simply - in low-rise construction.

It can be:

- 3D wall panels. They are used in the installation of floors, stairs, partitions, and ceilings. They are lightweight. The metal frame gives the products additional strength. Subsequently, the panels are covered with concrete mixture.

Polystyrene wall panels

- Ordinary ordinary blocks used for the construction of walls and partitions. Products can be large or small format, depending on the size.

Small polystyrene concrete blocks

- Also in the range of products made using a combination of polystyrene and concrete, there are so-called heat blocks. They are available in block and panel form. The products consist of three layers, one of which is polystyrene. They have increased heat-saving characteristics.

Heat block

- Products made of polystyrene concrete are also presented in the form of elements used as permanent formwork.

Fixed formwork made of polystyrene concrete

- Ventilation units are distinguished by the presence of ready-made holes, which are used for wiring communications.

Ventilation unit

- Window and door openings can be blocked using polystyrene concrete lintels.

Polystyrene concrete lintel

- Thanks to the availability of products with a facing side, developers can save themselves from the need for exterior finishing of the building.

Polystyrene concrete block with cladding

As mentioned above, monolithic polystyrene concrete is also actively used in the construction industry. With its help, for example, you can build walls using formwork or other monolithic structures.

Application of monolithic polystyrene concrete

The video in this article: “GOST expanded polystyrene concrete: main areas of application of the material” contains all the information necessary for the developer regarding the use of various polystyrene concrete products.

Positive and negative qualities of the material

Since we have already reviewed the general characteristics and some types of products, let's now analyze the set of positive and negative aspects of the material and figure out whether it is worth giving preference to polystyrene concrete in construction?

Advantages of polystyrene concrete:

| The low weight of the products helps reduce the load on the base of the building. |

| The ability of polystyrene concrete to maintain temperature is extremely high. This will help save on insulation and heating of the finished structure. |

| The brand has a high frost resistance rating. |

| Environmental friendliness of the material |

| Fire resistance |

| Wide scope of application. As already mentioned, polystyrene concrete is produced in a large number of products, which ensures their various applications. |

| Low price. |

| Ease of production and the ability to make products yourself. |

| Good strength and density indicators |

| Good soundproofing ability. |

| Vapor permeability and reduced hygroscopicity. |

| Availability of blocks with cladding in the product range. |

| Relatively large sizes of finished products and ease of handling. Polystyrene concrete is easy to cut and saw. |

| Biological resistance |

The negative aspects include:

- Tendency to shrink;

- The presence of small handicraft industries on the market, where the necessary requirements for production are not always met;

- A requirement related to the need to design ventilation systems;

- Experts advise not to begin finishing work earlier than 28 days from the end of laying the blocks;

- Requirements for surface plastering;

- Low resistance to prolonged exposure to high temperatures;

- Poor fixation of hardware to the polystyrene concrete wall. You need to purchase specialized fasteners.

- Additional costs for increasing the level of adhesion of polystyrene concrete walls with finishing materials.

- The density and strength of polystyrene concrete is somewhat less than that of its competitors - varieties of lightweight concrete.

Thermal capacity of polystyrene concrete blocks

Heat capacity shows how much thermal energy is required to increase the temperature of a material by 1 degree. Specific heat capacity is measured in kJ/kg*degree. For polystyrene concrete this figure is 1.06, which is comparable to brickwork. However, it should be taken into account that this value depends on the density of the material, which means that heating a brick wall by 1 degree will require 2.5 times more heat than heating a polystyrene concrete wall.

How to calculate wall thickness

To calculate the required wall thickness you need to know:

- thermal characteristics of the material from which the structure will be built. If there are several materials - all materials.

- Degree-days of the heating period (GSOP) This parameter can be taken from a reference book or calculated using the formula GSOP = (tв - tо)zоt,

where tо, zоt is the average outdoor air temperature, °С, and the duration, days/year, of the heating period, tв is the estimated temperature of the building’s internal air, °С, according to GOST 30494. For Moscow and St. Petersburg, GSOP is equal to 6000

- Wall resistance to heat transfer. This is a reference value that depends on the GSOP; you can find out its value in SNiP 2-3-79. For residential buildings in Moscow this is 3.5 (m2? ° C)/W.

The calculation is carried out according to the formula R = s / ? (m2•°C/W), where R is the heat transfer resistance, s is the wall thickness (m), and ? — thermal conductivity. Based on this formula, we get S= R * ?. An example of calculating the wall thickness of a residential building made of D600 polystyrene concrete blocks in Moscow: S = 3.5*0.14=0.49 m, i.e. In order for the building to comply with SNiP 02/23/2003 “Thermal protection of buildings”, a polystyrene concrete wall almost half a meter thick is required. Red brick wall thickness should be S=3.5*0.56=1.96 m. These are calculations for dry material; with increasing humidity, the thermal conductivity coefficient also increases.

Due to its low hygroscopicity, it is allowed to operate structures made of polystyrene concrete without covering the facade.

Thinner walls not only allow you to save useful space inside the building, but also reduce the overall weight of the structure, thereby reducing the load on the foundation. Low-rise houses made of polystyrene concrete can be erected on shallow strip foundations and even on pile-screw foundations.

Relatively low weight with high thermal protection indicators allows the use of polystyrene concrete when adding additional floors or attics to already constructed buildings.

Information for organizing the production of polystyrene concrete

Polystyrene concrete, economics, composition, recipe, production features.

Polystyrene concrete. General description.

Polystyrene concrete is concrete whose lightweight filler is foamed polystyrene. In terms of its properties, polystyrene concrete belongs to lightweight concrete (cellular concrete), but has a number of significant differences. Its advantages include the possibility of varying its density over a wide range, as a result of which polystyrene concrete can be both a structural and thermal insulation material. The exceptionally low bulk density of foamed plastic particles allows the production of lightweight concrete with a bulk density range that can be selected to suit the requirements of a particular application, and the concrete has a correspondingly wide range of properties. Also, unlike foam concrete and aerated concrete, it is not difficult to obtain polystyrene concrete with a density of less than 200 kg/m3, which has increased thermal insulation properties.

Polystyrene concrete (GOST R 51263-99) is a composite material that includes Portland cement and its varieties, silica filler (quartz sand or fly ash from thermal power plants, used in the production of high-density polystyrene concrete), porous filler, which is granules foamed polystyrene (PVG), as well as modifying additives (setting accelerators, plasticizers, etc.) The density of produced polystyrene concrete, as a rule, varies from D600 (for structural blocks) to D150 (when used as a thermal insulation material).

The main advantages of polystyrene concrete

Lightweight concrete with expanded polystyrene core ( polystyrene concrete ) has been known for a long time. While polystyrene concrete has been known for at least 25 years in our market, and in the Western market for more than 40 years, to date, expectations regarding the volume of use of the material have only been met in some areas of application. However, there has been a growing interest in polystyrene concrete in the building materials industry, indicating some changes in this regard, mainly due to the following reasons:

— polystyrene concrete has become a serious alternative to cellular concrete, due to its wider range of applications, ease of manufacture and excellent thermal performance of the material,

- requirements for thermal insulation of buildings are becoming much more stringent, as a result of which it has become necessary to functionally separate building materials into thermal insulation and load-bearing ones, and these materials must be properly combined in building elements. In this regard, interesting solutions are offered by the use of lightweight concrete with expanded polystyrene (polystyrene concrete) filler.

Significant reduction in material consumption

Saving up to 70% solution.

Lower cost of polystyrene concrete compared to other materials.

Reduced heating costs due to the lower thermal conductivity of polystyrene concrete compared to other materials.

Large-sized blocks make laying walls easier.

High technology of construction, blocks are easy to saw, nail (give any geometric shape, create channels for hidden wiring).

The blocks have a variety of shapes and are easy to install, increasing the speed of construction of walls and partitions by 10 times.

The masonry is carried out on an adhesive base for foam concrete, which makes it possible to obtain an interblock seam of no more than 3-4 mm and avoid the formation of cold bridges.

Reduced labor costs by 3 times.

The use of heavy lifting equipment is not required when building a house.

One block replaces 17 bricks and weighs no more than 22 kg.

Low-flammability, when plastered or faced with bricks, can be used in the construction of buildings of fire resistance category I and fire resistance class CO, i.e. up to 25 floors inclusive (joint Conclusion dated December 25, 2000 of the State Construction Committee of the Russian Federation No. 9-18/604 and the Ministry of Internal Affairs of the Russian Federation No. 20/22/4578).

Durability over 100 years.

High frost resistance.

Polystyrene concrete is not a breeding ground for microorganisms and fungi and is not susceptible to rotting.

Environmentally friendly.

Excellent sound insulation.

Excellent waterproofing while maintaining vapor permeability.

Main technical characteristics of polystyrene concrete

| Brand of blocks by average density (kg/m3) | Compressive strength class | Average compressive strength R, MPa | Tensile strength in bending, MPa | Thermal conductivity coefficient, W/m °С | Frost resistance grade | ||

| dry | at operating humidity | ||||||

| A | B | ||||||

| D150 | M 2.5 | — | 0,10 | 0,055 | 0,057 | 0,060 | F25 |

| D200 | M 3.5 | — | 0,15 | 0,065 | 0,070 | 0,075 | F25-F35 |

| D250 | B 0.35 | — | 0,25 | 0,075 | 0,085 | 0,090 | F35-F50 |

| D300 | V 0.5 | 0,73 | 0,35 | 0,085 | 0,095 | 0,105 | F35-F50 |

| D350 | B 0.75 | 1,09 | 0,50 | 0,095 | 0,110 | 0,120 | F50-F75 |

| D400 | B 1.0 | 1,45 | 0,60 | 0,105 | 0,120 | 0,130 | F50-F75 |

| D450 | B 1.5 | 2,16 | 0,65 | 0,115 | 0,130 | 0,140 | F75-F100 |

| D500 | B 2.5 | 2,90 | 0,70 | 0,125 | 0,140 | 0,155 | F75-F100 |

| D550 | B 3.0 | 3,60 | 0,73 | 0,135 | 0,155 | 0,175 | F100-F150 |

flammability group G1; (self-extinguishing)

vapor permeability D400 - 0.085 mg/m-h-Pa, D500 - 0.075 mg/m-h-Pa with high water resistance;

application temperature from - 60°C to + 70°C;

specific heat capacity 1.06 kJ/(kg • °C);

low operational humidity in the range of 4 - 8% by weight and low shrinkage value, not exceeding 1 mm/m, has low sorption humidity, which allows the material to maintain low thermal conductivity values even in conditions of high humidity.

Comparative characteristics of various materials and polystyrene concrete

| Material | Density, kg/m3 | Coefficient thermal conductivity, W/(m*C) | heat loss, W/m2 | Wall thickness at Ropr=3.15, m. | Weight of 1m2 wall, kg |

| solid clay brick | 1700 | 0,81 | 54 | 2,55 | 4337,55 |

| clay brick (hollowness 20%) | 1400 | 0,43 | 28,67 | 1,35 | 1896,3 |

| sand-lime brick | 1800 | 0,87 | 58 | 2,74 | 4932,9 |

| cellular concrete (autoclaved) | 500 | 0,18 | 17,5 | 0,55 | 303,19 |

| expanded clay concrete | 850 | 0,38 | 26,67 | 1,18 | 1004,06 |

| tree | 500 | 0,15 | 33,33 | 0,47 | 236,25 |

| POLYSTYRENE CONCRETE | 500 | 0,13 | 13,33 | 0,30 | 135 |

Areas of application of polystyrene concrete

This material is used on roofs and floors as thermal and sound insulation. It is also used for void filling in masonry, underground walls, insulation in hollow blocks, ideal for bulk and any other filling where high insulating properties are required. It is used for the production of prefabricated blocks and partition panels, covering slabs of suspended ceilings, thermal and sound insulation in multi-level residential and commercial buildings. Polystyrene concrete is used in concrete blocks and panels for external walls and partitions, concrete slabs for roof coverings and floor slabs. Polystyrene concrete is used in precast panels of any size for commercial and industrial use, monolithic walls, garden decorations and other applications. Ideal for building superstructures where the weight of the structure plays a decisive role.

Waste polystyrene foam as lightweight filler.

In Germany, about 40,000 tons of raw materials are currently used annually for the production of packaging materials for the production of expanded polystyrene, from which expanded polystyrene is produced in a volume of up to 2 million m3. These packaging materials contain 98% air, contain no CFCs, and can be recycled to serve any reasonable purpose again.

Our country also has a sufficient amount of waste, and with the development of industry and the growth of product production, the issue of packaging recycling becomes acute.

In this regard, systems have been developed for the recycling of polystyrene foam, allowing for complete recycling of used packaging materials received from industrial, commercial enterprises and private consumers.

In this article we consider only the use of waste polystyrene in lightweight concrete. Fine-grained (crushed material), made from waste from the production of polystyrene foam packaging, is suitable for use in the production of building materials: as a pore-forming substance in the production of blocks, panels, and as a lightweight aggregate for the production of lightweight concrete (polystyrene concrete).

The use of crushed polystyrene foam as a lightweight aggregate requires certain requirements to be met to prevent deterioration in the quality of the concrete.

In terms of grain size and shape, the differences between (crushed material) and freshly baked polystyrene foam particles should be as small as possible:

— most of the grains should have a round shape;

— most of the grains should have sizes ranging from 0.5 mm to 4.0 mm;

— the crushed material should not contain very small particles.

These quality requirements can be satisfied if the following conditions are met:

- using appropriate crushers to separate the polystyrene foam particles in wheelbarrows in which they are fused together, so that the original spherical shape of the grains is retained to a very large extent,

- The particle size of polystyrene foam granules used for the production of packaging materials is usually the size required for lightweight polystyrene foam core made from (fresh material), this is achievable by using suitable screens in the crusher. Currently, such prepared (crushed material) is offered by some Western manufacturers of packaging materials at a price of 12 to 25 euros, which is much lower than the price level for freshly foamed lightweight polystyrene foam filler.

There is also one on the Russian market, which unfortunately rarely satisfies the above requirements. The compressive and flexural strength values obtained from the 28-day tests are, in each case, the average of three specimens. Compressive strength tests were carried out on cubes with an edge length of 20 cm, and bending strength tests were carried out on bars 70*15*15 cm.

The compressive strength of polystyrene concrete samples made using expanded polystyrene from (crushed material) - primarily at the lower end of the polystyrene concrete bulk range - is approximately 40% lower than that of polystyrene concrete made using fresh polystyrene foam particles.

The tensile strength in bending of both variants of polystyrene concrete within the specified range of volumetric masses is approximately at the same level.

The use of polystyrene foam, compared to expanded polystyrene foam, does not affect thermal conductivity, since it primarily depends on the volumetric mass of polystyrene concrete. The use of polystyrene foam does not have a negative impact on quality requirements such as water absorption, frost resistance, fire resistance, etc.

Detailed description of the manufacturing process

polystyrene concrete wall blocks.

Foaming of EPS granulate, dosage of components, mixing, feeding, molding.

EPS granules are polystyrene containing a low-boiling component (pentane). EPS granules are bead granules that can be supplied to the consumer either after separation or without separation into fractions. When using seeded granules, foamed polystyrene granules have the same dimensions; in the case of using non-seeded granulate, foamed polystyrene granules will have significant differences in size (0.5-12 mm).

The process of foaming EPS granules can be divided into two stages:

1. Pre-foaming;

2. Drying (maturing) foam granules for their further use.

Foaming.

Activation of the pentane contained in EPS granules occurs under the influence of water vapor. EPS granules soften under the influence of steam and begin to foam, increasing in volume. A fiftyfold increase in the initial volume of granules is possible. The bulk weight of the granules changes accordingly: For example, from 680 g/l to 14 g/l.

To speed up the foaming process, EPS granules are moved into the foaming agent containers using a mechanical activator-turner. Constant circulation of granules when exposed to water vapor allows you to foam large volumes of material as quickly and efficiently as possible. The size of the foam material directly depends on the temperature and time of exposure to water vapor, as well as the rotation speed and design of the agitator activator.

Description of the process of foaming ESV granules on a PP-4 unit equipped with a built-in steam generator.

The feedstock (PSV granules) from the supply hopper is supplied to the lower part of the foamer via a screw feeder. By changing the amount of supplied material (consumable hopper regulator), the volume of foam granules is regulated.

Under the influence of water vapor, the low-boiling agent (pentane) contained in the EPS granules is activated. The granules increase in volume, are displaced by non-foamed granules supplied by the screw feeder to the lower part of the installation, and the filling level of the foamer increases. The foamed granules reach the discharge window at the top of the foamer tank and enter the drying unit. By changing the height of the curtain of the unloading window, you can change the volume of foam granules. The higher the curtain of the unloading window and the lower the supply of raw materials by the screw feeder, the longer the time the water vapor acts on the EPS granules and the correspondingly greater the volume and lower density of the foamed granules. And, conversely, with an increase in the supply of raw materials to the installation and the lower location of the discharge window curtain, the bulk density of the finished material increases.

Foaming of EPS granules in the installation occurs with constant mixing of the material by an activator-agitator. The activator blades mix the foam granules, preventing sticking and promoting uniform movement of the material to the discharge window of the installation, under constant exposure to water vapor.

Diagram of the PSV granulate foaming line

Drying the material.

Foamed polystyrene contains up to 10-15% moisture, and a vacuum is created inside the granules due to condensation of pentane residues and water vapor. This can lead to deformation (compression) of the foam granules; compression of the granules sharply reduces the volume of the material and leads to a significant increase in bulk density. Therefore, foamed PSV granules must be dried to stabilize the internal pressure and strengthen the outer walls of the granules. The diffusion penetration of air into the cells of foamed polystyrene gives the material high compression resistance. The rate of air absorption by foam granules is higher for material with a lower bulk density.

Conveyor dryer.

The use of pneumodynamic drying-conveyors of foamed polystyrene allows you to quickly and effectively reduce the residual moisture content of the material to 6-3%, while simultaneously moving the material into storage bunkers. Gentle transportation of foam granules in an air flow heated to a temperature of 35-40°C gives the drying process the necessary dynamics and allows for a continuous supply of material to the curing area. As the foamed granules pass through the drying unit, along with the loss of residual moisture, the fluidity of the material increases significantly, which has a positive effect on the filling capacity of the storage bins.

Aging of foamed PSV granules.

To finally stabilize the internal vacuum and achieve the residual moisture content of EPS granules at the level of 0.5-1%, it is necessary to keep the material in storage bins. The aging bunkers are a lightweight welded structure with an attached bag made of breathable fabric. Bunkers can be manufactured in various volumes; PP METEM offers bunkers with a volume of 20 m3. Bunkers of this volume are easy to operate and maintain, allowing you to place a storage area in almost any room suitable for these purposes. The maturing bunkers are connected by pneumatic lines, which combine the maturing unit and make it possible to create a bunker module of the required volume.

Foamed PSV granules are kept in the storage bunker for about 4-12 hours, depending on the size of the granules, bulk density and residual moisture. To reduce the holding time of the material in the bunker, it is recommended to place the maturing area in a room with low relative humidity. A significant reduction in holding time can be achieved by using the method of pumping granules with a heated air flow from hopper to hopper. In this case, the exposure time of EPS granules is reduced to 2-3 hours.

Features of storage of PSV granulate.

PSV granulate (TU 38.602-22-57-96) is supplied to the consumer mainly packaged in container bags weighing 30-50 kg. When purchasing material, it should be taken into account that the shelf life of EPS granules in bags should not exceed six months from the date of manufacture and packaging. The temperature in the room where raw materials are stored should not rise above +20°C. These restrictions are due to a decrease in the content of the low-boiling agent, pentane, in the granules. However, foaming of EPS granulate for the production of polystyrene concrete is usually carried out according to a one-stage scheme (in the production of sheet foam, a two-stage or even three-stage scheme) therefore the pentane content remains sufficient for one-stage foaming even after 12 months from the date of production of EPS granulate. Storage warehouses must provide protection for packaged EPS granulates from adverse weather conditions.

Storage of foamed PSV granules.

Foamed granules of PSV, after equalizing the internal pressure, have fairly stable characteristics, both water absorption and strength, and can be stored for quite a long time. However, when aging pellets in bunkers, it is necessary to protect them from exposure to low temperatures. At low temperatures, the drying process of the material sharply slows down, the granules freeze, which negatively affects the quality of the resulting EPS granules. The temperature in the production room should not fall below +8°C.

Mandatory ventilation of production and warehouse premises.

When the pentane contained in the EPS granulate is combined with air, an explosive air-pentane mixture is formed. The air-pentane mixture is heavier than air, so it is necessary to provide ventilation for the foaming and curing area at floor level. Fresh air is supplied from the top. Ventilation hatches must be installed on the roof of the industrial building to ensure sufficient fresh air flow. It is recommended to install an exhaust fan at floor level.

It is necessary to install exhaust hoods above the discharge window of the foamer and the drying inlet to prevent the accumulation of pentane (pentane-air mixture).

The considered scheme for the production of PSV foam granules based on the PP-4 foaming unit allows us to obtain up to 60 m3 of finished material in an eight-hour shift.

Dosing, transportation of foamed granules of EPS, cement and water.

PSV

The finished foamed granules of PSV from the aging bunker are supplied by air flow through an air duct to the receiving bunker of the volumetric dispenser. Excess air pressure is released through the dispenser outlet filter. When the dispenser is filled, the inlet valve closes and the outlet valve opens. PSV granules enter the polystyrene concrete mixer. The dispensers have a mechanism for adjusting the volume over a wide range and can be equipped with automated pneumatic damper drives.

Cement

Cement is supplied from the storage bin by a screw feeder to the component dispenser after precise dosing into the polystyrene concrete mixer.

The use of an automatic component dispenser ensures maximum accuracy of cement supply with minimal time consumption.

Water

For the most accurate water supply, in the production of polystyrene concrete, PP "METEM" produces water dispensers: Automatic dispenser for water and chemical additives DZ-V-01.

Preparation of polystyrene concrete.

The components of polystyrene concrete (PSV foam granules, cement binders, water, additives) are fed into the mixer in dosed parts. The sequence of supply of components is determined by the technological regulations of the manufacturer. Typically, the sequence of loading the components of the mixture is as follows:

1. Supply of a dosed volume of foamed granules of PSV into the mixer.

2. Initial (starting) supply of water with additives to the mixer. About 25% of the required volume of water.

3. Stirring to wet the surface of the EPS granules.

4.Supply the required amount of cement into the mixer.

5. Mixing EPS granules treated with water with cement binders.

6. Supply the main volume of water to the mixer to completely saturate the solution with water.

7.Final mixing.

8. Unloading the mixer.

Supply of polystyrene concrete to the molding area

(in the manufacture of wall blocks or wall stones).

Movable polystyrene concrete solutions can be supplied to the molding section (pouring into molds) using gerototor pumps and low or high pressure pneumatic conveyors.

Methods for forming polystyrene concrete solutions (mixtures).

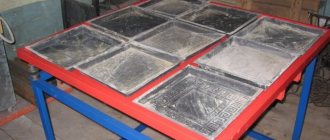

Casting movable, plastic polystyrene concrete solutions into molds is by far the most common method of molding. The presence of a large number of metal (plastic, metal-plastic) forms is an integral part of this technology.

A foam generator can be included in the production process of producing polystyrene concrete blocks based on injection molding technology for the production of low and medium density foam concrete (from 800 kg/m3). The use of a foam generator allows you to supply stable (stable) water-foam solutions to a forced-action concrete mixer (polystyrene concrete mixer). The resulting foam concrete (foamed concrete) of medium density, when mixed with PSV granules, forms a unique material - expanded polystyrene concrete. The use of medium-density foam concrete in the production of polystyrene concrete blocks can significantly reduce the thermal conductivity coefficient of the material.

Improved Thermal Performance

Such characteristics of polystyrene concrete as thermal conductivity and thermal resistance coefficient can be improved at the mortar production stage by increasing the amount or fraction of foamed polystyrene granules and accordingly changing the composition of the mixture. When making polystyrene concrete yourself on a construction site, for example for monolithic work, it is important to strictly follow the dosage. Even a slight change in composition can seriously change the strength and insulating properties of the material.

You cannot change the ratio of the mixture components or use materials with characteristics different from those calculated, for example, PC 400 cement instead of 500.

With increasing humidity and wetting of the material, the thermal insulation characteristics deteriorate significantly. Walls made of high-density polystyrene concrete can be additionally insulated using low-density polystyrene concrete or mineral wool.