What are concrete gratings?

Geogrid of any model are paving elements, the configuration of which allows you to create large holes in the coating during its installation. The recesses do not prevent the penetration of air and water to the roots of trees and allow grass to grow.

Each block is a stamped product made using simple casting technology or vibration pressing. In the second case, the material can withstand loads of up to 20 tons, and these elements are recommended for installation in parking lots and driveways. Cast slabs are best used for walking paths or recreation areas.

The standard dimensions of the products are 60x40 cm. The thickness of the tiles is 10 cm. This is enough to protect the lawn and provide mechanical strength.

The main functions that the geogrid performs are as follows:

- protection of the root system of herbaceous plants;

- ensuring a clean and dry surface of the parking space, path, area;

- strengthening the soil on slopes;

- leveling the area and maintaining an attractive appearance of the lawn.

Correct installation will make the structure durable and strong, providing reliable protection for vegetation and the surface of the site paved with geogrid.

Lawn gratings made of plastic

Plastic grating has many advantages over concrete grating:

- weighs much less and is less noticeable, which creates a wider range of applications;

- more durable and wear-resistant;

- resistant to frost and ultraviolet rays;

- prevents soil leaching and weathering;

- 90% of grass stand from the laying area;

- non-toxic.

There are several types of plastic cellular modules. The differences are in cell shape, color and load capacity.

Plastic lawn modules sag under excessive load. They are placed on slopes and embankments of roads. The canvas, joined from many pieces, perfectly replicates the small radii and unevenness of the slopes. Functional service life is more than 25 years. Modern materials make it possible to use plastic cellular modules in parking lots and places with increased soil loads. It is also worth noting that plastic can be easily sawed with a jigsaw, making it possible to create more complex landscape compositions.

Disadvantages of plastic lawn modules:

- the edges cut off grass crushed by the car;

- it is necessary to periodically move the car, as the grass withers under the wheels;

- technical fluids draining from the car will fall into the soil;

- For parking, site preparation is required.

Advantages and disadvantages

Compared to monolithic and continuous coatings made of concrete, asphalt, paving slabs, etc., lawn tiles (concrete grating) have a number of advantages:

- Permeates 100% water and air. In green areas under continuous covering, the roots of trees and shrubs suffer, as they receive only a small part of the moisture from precipitation. The large cells of geogrids allow water and oxygen to penetrate the soil, as in areas without coverage. At the same time, moisture does not remain on the surface of the paved area at all, thanks to the rounded profile of the ribs of the cells.

- Promotes plant growth. The dimensions of the recesses formed by the paving parts allow the sown lawn grass to grow freely. When walking or passing vehicles, concrete prevents injury to grass roots. Thanks to this, it always retains its splendor and is not trampled. In winter, cells filled with snow well protect plants from the effects of frost.

- Variety of choice. Concrete products are produced in different patterns and colors. You can purchase elements that, when laid, form a simple lattice with square or diamond-shaped cells, but manufacturers also produce decorative options that imitate loose masonry, slabs with round or hexagonal holes, etc. When making colored products, color is added directly to the solution. The entire monolith becomes painted. This makes the lattice paving slabs resistant to fading in the sun or when walked on.

- Long service life. Manufacturers claim an approximate service life of tiles of 25 years.

- Easy to repair. If a coating element is accidentally destroyed, it can be replaced in any weather without complex equipment. The tile must be removed from its seat and a new one of the same model must be laid.

The disadvantage of concrete slabs is the massiveness and rather large thickness of the partitions. The characteristics of the material do not allow making thin and durable slabs. Installation of the coating is no different from paving with other types of paving slabs and requires time and physical labor.

The disadvantages include the high cost of concrete geogrids compared to plastic ones (about 2-3 times).

What is a geogrid for parking

A lawn grate, the cost of which depends on the type and material of manufacture, is a building product with a honeycomb structure. It is made of geosynthetic polymer or concrete. The cell size is in a wide range, which is selected depending on the area of use of the grid. The length, width and height of the honeycomb are also different - the optimal values are selected based on the total load on the structure.

The lawn grate should be selected based on the expected load on the surface where it will be used

This polymer building material is used as a covering for sidewalks, parking lots, parking lots and lawns. It has also proven itself well as a reinforcing frame for unstable soil. The material is increasingly being used instead of paving slabs. A lawn trellis is a more economical and environmentally friendly solution.

When stretched, this product creates a stable and durable reinforcing frame, the cells of which can be filled with sand, crushed stone, soil or other material that is fixed and limited in movement. Using concrete mortar as a filler, you can create a monolithic platform. If you pour marble chips into the honeycomb, the result will be a decorative path.

The main advantages of geogrid are the following indicators:

- increased strength of the frame due to reliable fastening of polymer tapes in a checkerboard pattern;

- obstacle to soil shifts;

- resistance to temperature changes, moisture and corrosion;

- providing comfortable conditions for plant growth;

- resistance to mechanical loads;

- the ability to pass moisture absorbed into the soil, which eliminates the formation of puddles;

Concrete lawn grating is highly durable and durable

- repetition of the distinctive features of the soil relief;

- immunity to chemical influences, mold and rodents;

- environmental friendliness of the material;

- preventing siltation of the territory;

- ease and simplicity of installation and dismantling;

- plastic products can be recycled;

- affordable price.

Thanks to the cellular structure and resistance to mechanical stress, the load is evenly distributed over the entire area of the roadway. Geogrid can significantly increase the strength of a parking lot surface.

Helpful advice! Since each type of grating has a different strength factor, when choosing, it is recommended to take into account the operating characteristics of the parking lot.

Using lawn grates to create parking spaces is an increasingly popular trend.

Characteristics

The performance characteristics of the grating tiles are determined by the properties of the material:

- concrete is not subject to rotting or corrosion;

- subject to production technology, the monolith tolerates low and high temperatures, as well as their sharp fluctuations;

- the material does not contain components harmful to the environment or humans, is environmentally friendly and durable;

- The variety of colors and color fastness allows you to choose slabs for any design solution.

Geogrid is used for:

- paving paths and areas for any purpose;

- creating a decorative border;

- strengthening the shore of an artificial reservoir;

- design of a site with a complex profile.

Kinds

Concrete gratings are distinguished by their ability to bear load:

- up to 20 tons per 1 sq. m - used to create coatings in private areas, in areas of intense pedestrian or bicycle traffic;

- up to 400 tons per 1 sq. m - for areas with heavy traffic (public eco-parking lots, access roads, etc.).

The variety of types is complemented by the type of cell pattern:

- square (simple) of different sizes;

- diamond-shaped (oblique);

- cellular (hexagonal);

- slabs with round holes in the canvas and semicircular recesses on the edges (when connecting 2 elements, the pattern of circles is not disturbed).

Laying technology

Installing a geogrid coating is not too different from laying simple paving slabs. The main attention should be paid to preparing the base: not only lawn types of grass, but also perennial weeds can grow in the holes of the modules. To prevent this, it is necessary to lay geofabric under the base.

Paving work is carried out in the following order:

- Mark the area or path, taking into account the installation of curbs and other additional elements.

- Remove the turf from the area and deepen the pit to 30-35 cm. Level the bottom, and in horizontal areas check for slopes using a building level.

- Spread the geofabric with an overlap on the edges of the excavation in the ground (this will protect against the penetration of rhizomes of weeds from below and from the sides).

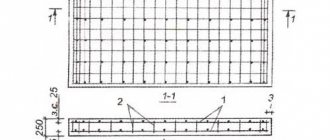

- The pillow is formed from 2 layers. The first is 10 cm of fine crushed stone (fraction no more than 3 cm). Lay the second layer of sand or ASG (10-15 cm). Each layer must be leveled and compacted. To achieve the most uniform compaction, the sand layer is watered, material is poured into the formed recesses and compacted again. If during use a poorly compacted cushion develops depressions, the tile may break.

- Laying tiles begins with installing curb stones (if they are needed for the project). After this, paving elements are laid, starting from any corner. The slabs must be deepened flush with the general ground level on an unsurfaced lawn. A wooden or rubber mallet will help to install the elements evenly and close to each other. The tool is used to tap on the side and top planes of the product, adjusting it to those already laid. During work, you need to constantly check the overall horizontal surface of the coating. The protruding parts are tapped with a mallet, deepening to the desired level.

After the installation of concrete slabs is completed, fertile soil is scattered over the surface of the paved area. The soil is driven into the holes of the grate using a wooden scraper or the flat side of a garden rake. The area is sown with grass and watered until the seeds germinate 1-2 times a day, using a watering can or sprinkler nozzles. On rainy days, watering is not carried out.

Areas of application

Lawn parking grates serve not only to create a spectacular lawn in parking areas. It is convenient to use for keeping parking lots or paths dry at any time of the year. Melt and rainwater do not linger on the cellular surface, quickly absorbing into the drainage layers of the cushion.

Grates can also be used to cover drainage ditches to divert flows flowing from the roof. In this case, the laying technology will be different: the slabs cover the empty space, and grass will not grow in them.

In megacities (Moscow, St. Petersburg), installing geogrids in green areas helps solve the problem of walking and relaxing on lawns. Eco-parking not only does not spoil the appearance of the streets, but also allows you to preserve greenery in courtyards and parking lots.

In regions with high groundwater levels, eco-parking areas do not have the risk of waterlogging due to soil compaction, and parking lots do not need to be paved or filled with concrete over large areas where flora can grow.

Sequence of laying a lawn grate: do-it-yourself eco-parking

The first stage is to mark the territory based on the number of vehicles that will be located on it and their dimensions. Here you should provide space for maneuvering, check-in and check-out. Also at this stage the size of the lawn grate is taken into account. This is especially true for bulk products.

Next, they begin to remove the soil. The depth of the pit depends on the thickness of the underlying foundation and the height of the structure. The bottom of the pit should be thoroughly compacted. Then a sand layer is made, which is also compacted. Geotextiles are laid on top of the pillow. The next stage is the formation of a gravel layer, which is also covered with polymer geotextiles. Then a leveling layer is formed. Sand is used for this. The result should be a flat, compacted area.

The lawn grate must be installed on a previously cleaned, prepared surface.

Features of installing a lawn grate depend on its type. Sections of concrete lawn grating for parking are laid in a checkerboard pattern, which increases the strength of the structure, and are tapped with a mallet to create a flat surface. In the same way, modular polymer structures are installed, which are attached to each other using locking connections.

Volumetric gratings with their longitudinal side are fixed in the ground using anchors in increments of 1 m. Then the grating should be stretched to the required size and secured with anchors. Each subsequent strip is mounted in the same way. The elements are connected to each other using snap locks.

Note! The lawn grid should completely cover the entire area of the future green parking lot.

Modular polymer structures are good for their plasticity and ease of installation.