- 1 Purpose

- 2 Types

- 3 Sodium and calcium chloride in concrete

- 4 Advantages and disadvantages of use

- 5 How to add it to the solution correctly?

- 6 Conclusion

To make concrete durable in winter, an anti-frost additive is used. Often these are salts of calcium chloride, sodium chloride, sodium nitrate, which enable concrete to slowly harden at sub-zero temperatures. Salts reduce the freezing point of the liquid in the solution, which shortens the setting period, and, therefore, reduces the amount of cement consumed and financial costs. But a large volume of salt introduced into concrete leads to deterioration of the structure and shortens its service life. If you operate a concrete structure at high humidity, there is a risk of damage to the reinforcement from exposure to chloride salts. Therefore, antifreeze additives should not be used in critical reinforced concrete structures.

Purpose

Applying antifreeze additives involves a simple technological process that can be easily done with your own hands. An anti-frost additive is intended to maintain the required mobility of the solution, accelerate the hardening of the mixture and accelerate the hydration of the concrete composition. The use of antifreeze admixtures saves the cost of additional heating equipment and payment for central heat supply to the room in the winter season. Thanks to antifreeze additives for concrete, the ability to operate buildings and structures is accelerated, as well as the consumption of impurities in the solution is reduced and energy is saved.

Return to contents

Areas of application of technical salt

Halite contains a large amount of table salt, which is used in the food, chemical, mining, energy and electrical engineering industries, and public utilities.

- Chemical industry. Sodium chloride is necessary as a raw material and basis for the production of alkalis, oxides, inorganic acids, mineral fertilizers, polymers, dyes, rubber, and other materials. Technical salt halite is used to produce sodium silicofluoride and hydrogen chloride, caustic and soda ash, chlorine gas, ammonia, sodium hydroxide and hydrochloric acid.

- Medicine and biology. Without this mineral concentrate, it will not be possible to prepare a saline solution used to maintain the vital functions of various tissues of the body. In addition, salt is needed for the production of Glauber's salt, mercuric chloride, copper monochloride, pyramidon and antipyrine, as well as the preparation of many drugs for various purposes. Visiting salt caves is becoming popular, the effect of which heals many body systems. Salt solutions are also used to treat clothing, fur and leather, and are used in the production of glazes for earthenware and porcelain.

- The food and medical industries widely use this mineral. Salt is an excellent natural preservative and antiseptic. Various isotonic solutions and medicines based on them are very common for the treatment of many diseases. Heating with salt for various diseases is also known. In the food industry, the use of halite makes it possible to provide suitable temperature conditions for storing and freezing food products; it is used in the production of “artificial cold”

- Oil industry. Sodium chloride is used in oil production: a salt solution is pumped into a well to soften cold soil. The use of saline solution when developing wells makes the work much easier. In addition, halite is used to make a special drilling fluid, which serves to strengthen the walls of the well. In this case, the mineral is mixed with clay.

- Metalworking. Sodium chloride is widely in demand in this area. It is necessary for heat treatment of various metals. Halite is involved in the cooling and hardening process of steel blanks.

- Ferrous metallurgy. Mineral halite concentrate is used for pickling wire, pipes and metal cords in sulfuric acid solutions. It is also needed when galvanizing metal products, which helps protect important parts from oxidation by oxygen.

- Non-ferrous metallurgy. Technical salt is involved in the production of metals: nickel, copper, cobalt and many others.

- Production of porcelain and earthenware. Here, using technology, halite is used to prepare a glaze that gives plumbing fixtures, dishes and other products an attractive appearance and other important consumer properties, such as strength and hygiene.

- Paint and varnish industry. Self-precipitating salt is used to create various intermediate compounds.

- Timber chemical industry. Sodium chlorine is a component of rosin and is also used to clarify turpentine. Salt is sprinkled on the bottom of cars when transporting goods. This allows you to prevent freezing of cargo. Halite is most often used in the transportation of coke and wet manganese ore.

- Construction. In construction, salt has found its use in the manufacture of magnesium screeds and floors, products made from decorative magnesite concrete, and sand-lime brick. It is used as an active additive to increase the resistance of bricks to sudden temperature changes, for use in difficult climates. To speed up the hydration, setting and shrinkage of cement, the addition of salt became necessary and made it possible to reduce construction time by half!

- Utilities. A large amount of self-setting salt is used to protect steam boilers from scale, to soften hard water in boiler rooms, and so on. Water is passed through a mixture of silicon, aluminum oxides and sodium. The chemical reaction takes away calcium, which makes the water hard, and sodium goes into the liquid and softens it. As a result, all the sodium is consumed. Therefore, the composition of elements in filters is periodically restored. For water treatment, industrial salt must meet several criteria: highest or first grade, absence of impurities (for example, anti-caking additives), third or fourth grinding type C or D. Mineral halite concentrate is used for water treatment and water purification in boiler rooms (preparation of water for technical needs) , swimming pools and other systems with ionic filters. The use of technical salt in water treatment is environmentally friendly and safe. To purify water, use salt with a sodium chlorine content of at least 95%.

- Road maintenance. In most cases, this mineral is used as a deicing agent due to its effectiveness and environmental friendliness. It is worth noting the cost-effectiveness of application: per 1 square meter. 30 to 150 grams of halite is sufficient, sufficient to melt ice crust and snow down to -30 degrees below zero. When mixed with sand or granite chips, the effectiveness of industrial salt increases. To clean roads, halite of the first and highest grade is used.

More than 14,000 different uses for salt today! Nature generously endowed this essential element, having hidden deposits deep in its depths, which will last for several million years.

You can purchase industrial salt (mineral halite concentrate) on our website in the “products” section.

Kinds

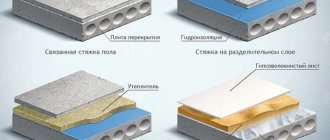

Impurities that allow concrete to maintain its strength characteristics and improve the indoor microclimate during the cold season are divided into the following types:

- Impurities that, by lowering the freezing temperatures of the working mixture, act as a barrier to the crystallization process of water present in the concrete composition. Such additives are called cement mixture hardening retarders or weak hardening accelerators. The process of reducing temperatures is carried out by electrolytes, which are strong and weak.

- Antifreeze additives in the concrete composition accelerate the hardening of the solution and have considerable antifreeze properties.

Return to contents

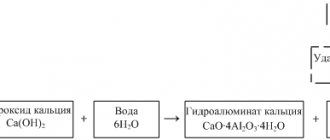

Sodium and calcium chloride in concrete

Antifreeze additive in concrete sodium chloride.

Sodium chloride or ordinary construction salt has many advantages, due to which the popularity of this composition increases. Used in construction as an anti-frost component during sub-zero temperatures. Allows you to reduce the crystallization temperature of water.

Calcium chloride is used as an accelerator for the hardening of concrete mortar, as well as to increase its strength and resistance to variable weather conditions. By accelerating the setting process of concrete, the time for installation of cement-based structures is reduced. The use of an anti-frost additive in concrete allows construction to continue during the cold season.

Return to contents

Sodium chloride in the fight against frost

In the photo - additive in bags

NaCl – sodium chloride (CN) or ordinary commercial salt. Concrete with technical salt is an excellent substance for construction work in winter in conditions of negative temperatures.

Main characteristics of CN

Technical salt is added to the concrete solution in order to provide it with anti-frost characteristics.

This additive has the following properties and characteristics:

- Salt, introduced into the solution with your own hands, allows you to lower the freezing point of water, which will avoid destruction of the structure of the product and the formation of cavities in a monolithic structure filled in in winter;

- The price of this supplement is low;

Note! This component for concrete is the cheapest antifreeze additive.

- NaCl does not affect the rate of hardening of the solution, so concrete can be mixed with salt in winter long before it is poured. Thus, mixing the building mass with this additive can be done, for example, at the factory long before its transportation to the construction site without loss of basic properties;

- Such an additive increases the mobility of solution particles, which facilitates the process of forming products of the required shape from a given mass;

- It does not change the structure of the cement mass.

Advice. It is recommended to use calcium chloride together with sodium chloride.

The availability of this kind of antifreeze additive and its low price is often the reason that most builders resort to using completely different, more expensive means.

In addition to the many advantages of such an additive, it also has one significant drawback, which often becomes the reason for the impossibility of using it for concrete. The fact is that salt has a high level of corrosive activity.

This means that the use of metal reinforcement simultaneously with a cement mixture with the addition of sodium chloride will lead to the process of rusting and peeling of this structure from the concrete.

Thus, the reinforced concrete structure loses its integrity, which qualitatively reduces the level of strength of the entire product.

The process of adding salt to a solution

The instructions stipulating the proportions of salt in the concrete solution are based on the average daily temperature and expected strength:

- The average daily air temperature from 0 to -5 degrees suggests the addition of CN in the amount of 2% of the total mass of the mixture. The expected strength of the structure when dried in frost for 7 days will be 30%, 28 days - 80% and 90 days - 100%;

- The average daily air temperature from -6 to -15 degrees suggests the addition of CN in the amount of 4% of the total mass of the mixture. The expected strength of the structure when dried in frost for 7 days will be 15%, 28 days – 35% and 90 days – 50%.

Advice. The proportions of salt in concrete also suggest the addition of calcium chloride in the first case in the amount of 0.5% by weight of the solution, and in the second 2%.

Advantages and disadvantages of use

Antifreeze additives based on sodium chloride have the following advantages:

- due to the salt introduced into the cement mixture, the crystallization temperature of the liquid is reduced, which prevents the destruction of structures and the formation of recesses in monolithic buildings, which lead to pouring in the winter season;

- low cost of the additive;

- technical salt in the solution does not affect the rate of crystallization of the solution, thereby allowing the mixture to be prepared long before its use;

- availability of antifreeze additive;

- the ability to prepare and apply it yourself;

- technical salt in concrete increases the movement of mixture particles, which simplifies the placement and formation of the mass.

Salt in concrete mortar causes reinforcement to rust.

Disadvantages include:

- The possibility of corrosion formation on metal reinforcement, which is laid in concrete mortar to add strength to the structure. Thus, the strength of reinforced concrete structures decreases and their integrity is lost. Salt in the solution of reinforced concrete structures leads to peeling and rusting of products.

- The availability of the composition is considered both an advantage and a disadvantage, because the low price of additives often repels consumers who trust more expensive antifreeze compositions.

The pros and cons of calcium chloride are similar to the pros and cons of sodium chloride. These admixtures are also used in the production of ready-mixed concrete and other complex materials used in construction. Calcium chloride is also used in the installation of paving slabs and curbs. It lowers the crystallization temperature of water and acts as an anti-icing reagent.

Disadvantages include the ability to cause corrosion of reinforcement and the low cost of the material, which is why consumers do not choose such antifreeze additives.

Return to contents

Advantages and disadvantages

In order to resolve this dispute, it is necessary to consider all the advantages and disadvantages of this method and draw a conclusion based on them. At the same time, the question of how much salt to add to concrete should be answered only if the research result is positive.

The consequences of using salt as an additive during winter installation affect not only the appearance, but also the strength

The need to use salt

It is generally accepted that if you add salt to concrete, it receives additional characteristics that allow it not to be covered with water in the cold, which means that work can be done in winter at sub-zero temperatures.

Also, some craftsmen claim that thanks to such delivery, the rate of hardening increases, since this substance draws out moisture.

It is worth remembering that concrete is also susceptible to corrosion, and a salty environment only accelerates this process.

- It is worth noting that no specialist can give an exact answer to the question of how much salt to add to concrete . The fact is that some builders believe that this depends on the total volume of the solution, while other craftsmen claim that the percentage is commensurate with the temperature outside.

- It is also necessary to say that the question of how much salt to add to concrete in winter is asked by people who have delayed repairs or have incorrectly allocated time for a particular process . If professionals plan to build in cold weather, they do not use additives, but additional heating systems and temperature-appropriate mixtures.

Appearance of concrete corrosion

- It is very important to say that adding salt to concrete to give it special qualities is a kind of myth . The fact is that there is practically no benefit from this, since according to those who use it, the temperature should not be less than 7 degrees.

Advice! It is much easier to purchase ready-made concrete from a company that makes hot mixtures with a high pour point. However, you need to work with such a composition very quickly so that it does not set.

There are many other, more effective ways to heat the solution

Flaws

First of all, it should be noted that material with added salt can be sawed with regular wheels. You will no longer need to cut reinforced concrete with diamond wheels, since the hardened product will be less durable, which will also affect its service life.

It is worth noting that a salty environment has a negative effect on fittings. Therefore, if we add salt to concrete with metal inclusions, we must remember that it will almost immediately begin to cause corrosion and weaken the entire structure over time.

For some types of concrete structures, such a solution can be fatal.

Also, such a technical solution will begin to produce visual effects over time. The salt will come to the surface in the form of a white sediment, which looks very unsightly.

Considering the seriousness of these shortcomings, professionals do not recommend using this method. At the same time, the question of how much salt should be added to concrete naturally remains unanswered.

Advice! Using warm formwork or artificial heating of concrete is much more practical, although it leads to additional costs.

Some antifreeze additives also significantly improve the strength of the finished product.

How to add it to the solution correctly?

Salts are added to the solution subject to the following characteristics of the surrounding space:

- the air temperature should be in the range from zero to minus five degrees Celsius, then sodium chloride is added to the composition in a volume of two percent of the total mass of the components (plus half a percent of calcium chloride);

- at an air temperature of minus six to minus fifteen degrees Celsius, construction salt is added in a volume of four percent of the total mass of the components used (and two percent of calcium chloride).

Return to contents

Why add salt to cement mortar?

Builders sometimes use the addition of salt when preparing cement mortar. It is the cheapest antifreeze additive. This is done in order to be able to continue construction work at negative air temperatures and to give the solution additional characteristics. It takes approximately two days for the cement mortar to set. In cold weather, the water in it can simply freeze and disrupt all construction work. The expansion of water does not allow the cement to fully combine with the filler; it becomes loose.

Manufacturers of building mixtures sometimes add salt to white cement to obtain a winter product. It is most commonly used in the production of tile adhesive, all-purpose mortar and masonry mortar. More responsible manufacturers use special polymer additives instead of salt. This makes the mixture more expensive, but dramatically improves its quality.

Expert opinions vary greatly regarding the advisability of adding salt to the solution. Let's look at the pros and cons of using salt when preparing cement mortar.

Disadvantages of a solution with salt: - the fittings in it rust much faster; — increases corrosion of concrete;

Advantages of using salt in cement mortar: - allows the use of cement mortar at subzero air temperatures; - low price, compared to other anti-frost compounds.

Methods of using salt when working with cement mortar

1. When expecting a temperature from 0 to - 5 degrees during construction work, add 2% salt from the total weight of the mixture.

2. When the air temperature can drop from - 6 to - 15, the amount of salt in the solution is 4% of the total mass of the mixture. Accordingly, we can conclude that the use of salt when working with cement mortar in the cold is permissible in the case when the structure does not have a reinforcing belt made of steel elements. When pouring unreinforced structures, it may well be an alternative to more expensive anti-frost additives.

According to expert builders, it is not worth pouring the solution at negative air temperatures at all. It is better to plan the time of work initially so that there is no need to fill the solution in the cold. The service life of objects built in winter will be shorter. True, no one gives exact figures for the difference in this period.

Conclusion

The construction of buildings and structures made of concrete in the winter season is impossible to imagine without the use of antifreeze additives. They simplify installation work and improve the quality of the concrete solution. However, it is important to remember that such construction impurities reduce the strength of concrete during periods of negative temperatures; the final achievement of the strength of the material is possible only during the thawing process.

Thus, structures erected using concrete mortar in the winter should not bear heavy loads.