The high level of comfort of a modern person involves the use of a large number of electrical appliances. Therefore, installing sockets in the bathroom is not a whim, but an important necessity.

The selection and installation of power supply points occurs in accordance with the requirements of regulatory documents and the rules of the intra-apartment or intra-house electrical network arrangement. These provisions have been studied by us and outlined in detail in the article.

We will indicate areas acceptable for installing sockets, list the rules for laying electrical cables and give advice on choosing electrical appliances. The proposed step-by-step installation instructions will help you complete all electrical work yourself, without turning to specialists for help.

Need for sockets

In old houses, bathrooms are not equipped with sockets. And sometimes it is inconvenient to use various household appliances. Modern bathrooms are large in size and equipped with various devices: showers, boilers, hydromassage, hairdryer, electric razor. They make life comfortable. Since using extension cords is inconvenient and unsafe, there was a need to install sockets.

It must be taken into account that in bathrooms there is often a need to connect a curling iron or install a washing machine. The latter is not recommended to be connected via an extension cord. Additional moisture-proof outlets may be needed for a dryer, underfloor heating system or illuminated mirrors.

Wiring

The first thing you need to pay attention to is the electrical wiring. In the bathroom it should be hidden.

This means that it should be laid inside walls or slabs. Such wiring will ensure that there is no risk of fire or short circuit.

Determining the type of bathroom devices

According to the rules, placing sockets in the bathroom is not prohibited, although due to the possibility of condensation and water droplets, there is a danger of electric shock. This also applies to toilets. Therefore, the issue of placement and installation of sockets must be approached competently and seriously. Regular sockets for wet or water-exposed areas are suitable, but only when located 2.5 meters from the water. Waterproof outlets are best.

Their choice is slightly varied; it is based on a classification based on two criteria - the number of connected devices and power. The last indicator is important; it determines which sockets and for which devices should be purchased.

For example, you need a socket for a washing machine with a power of at least 16 A, and for an electric razor 8 A is enough. They will definitely require grounding, and you need to choose devices that have an additional contact.

Regarding the design of sockets, everything is individual. Manufacturers produce a sufficient variety of moisture-proof devices that can fit into any interior. But the most important rule in choosing such devices is to pay attention to the labeling. It will allow you to decide which socket is suitable for a particular place in the bathroom. Housing protection is one of the main characteristics developed in accordance with international standards.

There is a standardized four-character code called IPXX. The first two symbols directly indicate the concept of protection itself, and the next two symbols indicate protection against the penetration of dust with particles and humidity with water.

For example, the IP 44 marking means that the socket is protected from foreign particles larger than 1 mm, as well as all-round splashes. And the IP 68 marking indicates that the socket can withstand complete immersion in water. The final choice depends on the areas in which the outlets need to be located.

Installation of a socket box

Sampler. If the recess turns out to be small, you need to clear it with a chisel or screwdriver, then remove debris and dust from the hole. Applying putty.

Strengthening the socket box into a prepared niche. Remove excess solution and wait a day until completely dry.

Dividing the bathroom into zones

The process of installing socket devices in bathrooms is regulated by relevant standards and regulations. According to them, sockets must meet the following requirements:

- have a hidden type of installation (inside a wall, protective housing);

- be equipped with a grounding contact;

- correspond to a degree of moisture protection of at least 4 (IP);

- have a connection to the power grid through an isolation transformer, RCD, differential circuit breaker.

According to regulations, devices should be distributed according to bathroom zones. There are four such zones in total:

- 0 - located in close proximity to water sources (baths, sinks, showers); in this area it is allowed to place equipment whose operating voltage does not exceed 12 V;

- 1 - located above the previous zone; installation of socket devices is possible if there are shower rooms with a cover that acts as a partition between zones 0 and 1;

- 2 - is a strip 0.6 m wide, originating from the boundaries of the two previous zones (outer edges); here it is allowed to install devices with moisture protection class 4 and higher for electric shavers, hair dryers and similar devices;

- 3 - starts from the outer boundaries of zone 2, ending after 2.4 m; here it is allowed to install sockets marked IP1.

Before installing sockets, it is imperative to distribute the room into zones, and then proceed to the actual installation.

Choosing locations

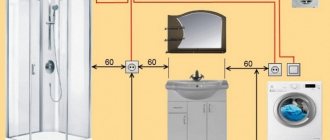

The guideline in choosing the location of sockets should be the division into zones and a number of additional parameters (PUE). It should be taken into account that the correct location of devices in bathrooms is 60 cm from the source of moisture. The optimal level corresponds to the average between the suitable zone and ease of use.

Therefore, the socket for the washing machine is installed at a height of 40 or 50 cm from the floor. It must be taken into account that dampness and temperature create conditions for the formation of condensation on the walls. This also applies to walls adjacent to staircase landings. Therefore, socket outlets should be installed at a height of at least 1.3 m from the floor surface.

And the height of the socket for the shower stall should not exceed its cover (2 m). The possibility of flooding should also be considered, so do not place sockets low to the floor. When installing sockets in old houses, preference should be given to semi-hermetic devices marked IP 44, installing them far from the water source.

Rules for laying electrical cables

When renovating new houses, the wiring is not dismantled; sockets are installed in the places provided for this. In older buildings, electrical cables need to be replaced. Aluminum wiring cannot withstand the load, so copper wires with a cross-section of more than 1.5 mm² are used. For household appliances, powerful power lines are created, equipped with an RCD. Special boxes are used to distribute wires. They are placed under the ceiling taking into account safety requirements.

Electrical cable with rubber protective tube.

When connecting directly, the wiring is hidden under floor tiles and suspended ceiling structures. The cables are covered with rubber protective sleeves. Internal wiring laid in grooves is considered safe for the bathroom. The external type is rarely used; in this case, the cables are covered with plastic channels.

Electrical safety rules

Having considered the rules for zoning the bathroom and choosing the optimal locations, you should move on to the installation rules regarding electrical safety.

- Performing grounding. It is a factor that is responsible for safety and is provided even in old-style houses. Grounding cannot be routed into the bathroom, metal pipelines, or building fittings. It needs to be brought to the entrance panel, where the circuit breakers for instant de-energization of the apartment are located, or to the distribution box.

- Automatic machines. Such switches should be installed when the power of the equipment connected to the sockets is sufficiently large. This situation occurs when a washing machine is installed indoors. If one electric razor operates, it can be connected to a general power supply.

- RCD. Such protection should not be abandoned. It is useful to install a device with a protective shutdown in the bathroom on all wiring. In this case, the RCD will react to the slightest leakage currents and turn off the power supply completely.

It should also be noted that in bathrooms no terminal strips with twists or other wire connectors are needed (even under tiles). An exception is terminals for lamps. Communication of the premises must be carried out outside the premises. When installing distribution wiring, do it on the other side of the wall.

Grounding

A properly wired bathtub outlet requires a reliable ground connection so that the possibility of electric shock is unlikely. The most important requirement is the use of an RCD that provides a “protective shutdown” of electricity if there are threats to human life, such as:

- touching live parts;

- leaks on the housing itself;

- short circuit.

The main parameter for choosing a machine is the leakage current indicators indicated on the body. The recommended RCD response value is 10-30 mA.

The leakage current is always indicated on the device body

Connection diagram of an RCD in a single-phase network with grounding

The device is connected to the network outside the bathroom, usually located in the main electrical panel of the apartment. For the system to work properly, a special cable with a grounding conductor is used. With its help, potentials are equalized to a safe level. Grounding to any construction fittings or iron pipelines is prohibited.

All electrical equipment must be grounded. However, if you decide to ground your bathroom, it is advisable to consider connecting other hazardous surfaces and devices

Selecting wires

Connect moisture-resistant electrical outlets using a three-conductor, double-insulated cable. Each conductor of such a cable has its own marking in the form of a different color shade, which facilitates the installation process. According to the rules, the phase wire is painted brown, the ground wire is yellow-green, and the neutral wire is blue or blue.

It is worth connecting sockets indoors using copper cables that:

- less susceptible to oxidation;

- are flexible, allowing you to easily connect the cable to the corresponding contacts;

- have the ability to withstand significant loads;

- have a small contact resistance when connected to sockets and automatic machines.

Copper cable strands can consist of a whole bunch of twisted cables or one thick wire. There are no big differences between them, but the thick wire is less flexible, so it will be somewhat difficult to connect the outlet close to the floor. And twisted wires when connected to an electrical outlet will require coating with solder. You should also pay attention to the diameter of the wire, which will directly depend on the number of devices connected to the outlet.

Carrying out wiring installation

The installation of electrical wiring is carried out at the rough finishing stage and can be done in two ways:

Grooving

Used for installing hidden wiring, allowing you to hide it in the wall. First you need to determine and mark the route on the walls of the bathroom where the cables are supposed to be laid. They should be placed vertically along a plumb line or under the ceiling, horizontally. Additionally, you should note the installation locations of sockets.

Then you need to move on to the direct gating procedure. It can be carried out using a strober or a hammer drill with a special nozzle. For large volumes, a disk cutting tool (grinder with a segmented diamond blade) is suitable. Then attach the cables using an aluminum mounting strip or perforated strip. In their absence, alabaster is also perfect. You can also use a dowel clamp. Next, all that remains is to seal the channel with the laid cables.

Installation in plasterboard

Partitions made of plasterboard have not lost popularity to this day, because they are of high quality, convenient and fast. And it’s also convenient to lay wiring under it. The main thing is to avoid “meetings” with self-tapping screws or screws that secure drywall. Usually, wiring laid 20 cm from the floor helps with this.

But for reliability, the cables should be installed in a corrugated pipe that has the appropriate fire safety certificate. This must be done before sheathing the second side of the partition. It should be pulled through the holes located in the vertical posts of the frame. If the corrugated pipe runs close to the screw, you should move it or bite off the screw. Next, you should fill the voids of the partition with sound insulation and sheathe the other side so that the cables are tightly clamped between the partitions.

If the above methods are not suitable, there is another option - installing electrical wiring in a box. Modern boxes are made of durable plastic, which is characterized by its inability to catch fire. The box consists of two parts: one needs to be attached to the wall using simple nails or screws. The second part easily snaps onto the finished base, only before doing this you need to stretch the wire through it. This installation option allows for additional safety from damage and fire.

Installing wires through a box is a very simple task. It is enough to make markings in accordance with the project, cut the necessary sections of the box and install it along with the wiring. Another advantage of using the box is the ability to open it at any time and replace the wires if necessary. The aesthetic side of the issue also plays an important role. Experienced manufacturers produce boxes of various colors and imitations for cornices or baseboards, so they do not spoil the interior at all.

Selection of necessary tools and materials

The materials you will need are putty, primer, and other wall finishing materials for the finishing coat. Goggles or a mask are needed at the stage of chipping a wall or floor; you will also need insulated gloves.

Bathroom rod - tips on the correct selection, installation and adjustment of modern rods (100 photos)

Glass for the bathroom: advantages of use, main disadvantages and recommendations for choosing glass elements for the bathroom (125 photos)

Wiring in the bathroom - 115 design photos, selection of the best schemes and optimal placement ideas

List of tools:

- Hammer and reliable drills.

- Drill and bit bit.

- Screwdriver, pliers, chisel, wire cutters, electrical tape.

- Indicator screwdriver

- Level

Installing sockets

Before installing sockets in the bathroom, you should decide how many there will be. It is necessary to provide each consumer with a power source. It is possible to install double or triple sockets. This is more convenient than installing several single ones. Next you need to move on to installation, which can be done in several ways.

- Overhead installation type. Involves the installation of external-type moisture-proof sockets with a protruding plastic casing. Often used when laying cables in plastic boxes. It is performed using self-tapping screws that fix the device to a partition or concrete (brick) wall.

- Hidden installation type. It is used when laying cables in drywall or fines. If you intend to mount it in drywall, you should make a hole in it the same size as the box for the socket. Then you need to press it to the drywall using special screws, and then connect the wires. Next you need to attach the socket to the box. When installing the device in the wall, you first need to make a ring groove corresponding in size to the socket box. After this, a hole is cut out with a hammer drill or chisel and the box is secured in it. Further installation does not differ from the previous option.

- Mounting inside a protective casing. According to safety requirements, sockets with a moisture protection class of at least IP4 should be installed in the bathroom. But if necessary, this requirement can be circumvented. The location of the device inside the electrical panel housing with water protection class IP4 will help with this. This design should be used in two cases:

- it is not possible to purchase waterproof sockets;

- there is a need to install a built-in lighting switch or a heated floor control unit inside the panel.

- First you need to fasten the shield to the wall using dowels and nails, then insert the end of the cable inside and connect it to the terminal block using the appropriate terminals. Mounting brackets will help secure the socket in the panel body.

Waterproof sockets are devices that are difficult to live without in modern life. They allow you to easily use a washing machine, heat water using a boiler, or dry your hair with a hairdryer. Such sockets are very diverse and require certain placement conditions. If you follow the necessary safety measures, using moisture-proof sockets will be a pleasure.

Hidden installation

In this option, the main difficulty lies in preparing the landing nest. It is necessary to drill or gouge out a recess into which the socket block will be installed. A brick wall can easily be drilled with a diamond-coated crown. Reinforced concrete panels are very difficult; in addition, you have to use a hammer drill.

The socket box is installed in the resulting blind hole. For reliability, fixation is carried out using alabaster solution or dowel nails. The further installation process is quite simple and does not present any difficulties:

- The decorative upper part of the housing is removed from the built-in socket;

- The mounting end of the cable is connected to the contacts;

- The socket is installed in its place;

- By rotating the mounting screw, the contact block is fixed by wedging the fastening tabs;

- The top cover of the housing is installed and secured with screws.

Installing a hidden socket