- Types and features of siphons

- Required materials and tools

- Siphon assembly

- Dismantling the old structure

- Installation of a new device

You can replace the siphon in the bathroom yourself. This will require a minimum set of tools and materials. It is important to choose the right device that removes wastewater and prevents the spread of unpleasant odors in the room.

Features of siphons.

Types and principle of operation of equipment

The overflow drain removes used liquid and prevents the bowl from overflowing due to uncontrolled water supply. The structure provides two holes - at the bottom and in the wall of the bathtub. They are supplied with interconnected hoses connected to the sewer drain.

Features of mechanical devices

There are three options for drain and overflow systems on sale. The difference between them lies in the method of removing the plug blocking the drain hole. If you are planning to buy a bathtub drain and overflow and are not sure which one is better to choose, you should pay attention to the model of your bathtub and its location in the room.

The simplest type of device is determined by the traditional design, found in almost every apartment. It has no moving components or levers. Water is drawn in when the plug is closed, and released when it is opened.

Mechanical products rarely break down and last a long time. The plug is attached to the drain grate on a chain, removed and placed in the opening manually

Products in this category differ in the type of connection to the sewer, sealing of connections, and the shape of the pipe. Devices include the following elements:

- Drain neck . Installed in a hole made in the bottom. It consists of a chrome funnel that “catches” large particles of debris, and an expanding pipe with a built-in nut. The parts are joined with a reinforced metal screw. A rubber ring seal is responsible for the impermeability.

- Overflow neck . Inserted into the wall of the bathtub. The design is similar to a drain, but is adjacent to the general contour of the network through a lateral, rather than direct, drainage system.

- Siphon . An arched removable pipe designed to act as a water seal. Blocks attempts of unpleasant sewer odors to enter the bathroom. Connects mechanisms with each other and with the sewer network. Available in a variety of configurations. Models with a deep shutter that holds at least 300 ml of liquid are considered optimal.

- Connecting corrugated tube . Diverts water entering the overflow to the siphon. Connects to other components with pipes.

- Auxiliary pipe - soft or hard. Provides drainage from the siphon into the sewer pipe.

The kit also includes connecting parts that increase the tightness of the system. These are flat and conical gaskets used together with a union nut. Conical products are mounted from the nut with a sharp edge so that the thin part goes inside the opposite element.

Devices not equipped with mechanisms are produced in universal sizes and are designed for bathtubs with an average distance from the center of the overflow to the drain not exceeding 57.5 centimeters

Advantages of manual strapping: budget price, simplest assembly/installation algorithm, rare breakdowns, reliability. Among the disadvantages, rapid wear of the seals should be noted.

Characteristics of semi-automatic devices

A later modification of the traditional design is a semi-automatic system. It contains the largest number of components. It is supplemented by a control unit that raises/lowers the plug, a shutter valve, and a cable that controls its position.

The control unit is implemented in the form of a handle, valve, rotary ring, button. You can operate it by turning the lever 90 degrees or pressing a button without bending over to the bottom of the bathtub. Thus, the shut-off rod rises and falls, opening or closing the valve

The system is activated by tightening and releasing an auxiliary cable located inside or outside the overflow pipe. The first option looks more aesthetically pleasing, but is much more difficult to repair.

Advantages of semi-automatic machines:

- Convenience of closing the drain (without having to bend over or wet your hands);

- comfortable management and operation;

- stylish design.

The disadvantages of the device include a complex structure with a mass of moving and connecting components and the risk of the cable jamming over time. In semi-automatic systems, the overflow holes are hidden behind the control unit. Visible details perform a decorative function in the interior thanks to a thoughtful design.

What are the benefits of automatic drains and overflows?

A distinctive feature of automatic systems is their complex structure with a click-clack valve button, equipped with a latch and a built-in spring.

In automatic systems, the button, as in mechanical ones, is operated manually (or by pressing the heel of the foot while in the shower). When pressed, the plug lowers, closing the drain opening. If you repeat the manipulation again, it rises, starting the drainage of water

The buttons are designed in elegant high-tech, modern, and retro design styles. They are made from brass and copper, coated with chrome or nickel plating.

Advantages of automated devices:

- ergonomics and presentable appearance;

- compactness;

- convenient drainage.

There are also many disadvantages: the high cost of the proposals, the vulnerability of the spring holding the valve, difficulties in replacing the button, painstaking installation, often requiring professional intervention.

The automatic drain can be equipped with the functionality of collecting water. It is considered if it is impossible to rationally place a faucet in the bathroom.

The diagram includes pipes for the liner, which are connected to the overflow hole. The bowl is filled through the top connector, which eliminates flooding, since the flow automatically stops when there is an excess of water.

In addition to the usual types of fittings, there are separate products adapted to the characteristics of specific bathtub models

Preventing a clogged drain in the bathroom.

As you can see, the procedure for cleaning the drain hole in the bathroom from hair is simple. But it takes time. Therefore, it is easier to avoid such situations.

- We install small mesh in the drain hole, which will trap not only hair or wool, but also small debris.

- Periodically pour chemicals into the drain hole to clean sewer pipes.

- Once a quarter we clean the siphon under the bathtub.

And then you won’t have to worry about how to clear the bathroom drain from clogged hair.

- October 19, 2017

- 729

- 0

(0)

This note is about one of the elements of the roofing system that the customer will most likely never see unless the builder himself or technical supervision shows him, namely the drain hole in the gutter. The one through which water from the gutter enters the outlet of the gutter (funnel) and then into the pipe.

Sometimes it is done like this:

So.

Strike the grinder four times and the hole is ready in the gutter. Of course, it can only have a rectangular shape, and the edge will be uneven - with splinters and burrs. It is difficult to make such a hole large, because the design features of the tool impose restrictions. Scale flies from the grinder to the sides, and after a short time “saffron caps” of rust may appear on the drain. Obviously, this method of constructing a drain hole in the gutter is a sacrifice of quality for the sake of speed and simplicity and a forced tribute to the low qualifications of the worker. If you don’t know how to use anything other than an angle grinder, where to go?

Sometimes they do this:

This hole appears to have been made by repeatedly drilling the gutter around the perimeter, after which a circle of metal was broken out or “bitten out” with the noses of scissors, and the resulting notches were slightly bent down with a hammer. One can guess why the drain is so small. Drilling hole after hole is painstaking work. If you increase the diameter, the number of holes will increase in proportion.

And sometimes they do it like this:

Here - let's try to figure out the technology - the metal was drilled once. And not at the edge (so as not to damage the straight line of the edge), but in a place that will later be completely removed. They drilled only to “bite” the scissors. Then, using small metal scissors, we went to the perimeter of the hole and cut along the perimeter. Then we used a small mallet to process the edge, making a reverse bend. There may be other variations on this theme, but in general, this is probably the case.

Question for builders - what is better? Or - to rephrase - how would you like the gutters to be done on your house?

With your permission, I don’t believe that the most common answer is “I don’t care, as long as there is a hole for water to drain.” Because in general, every builder (and not only builders) understands that the drain hole should be no smaller in diameter than the pipe (or slightly larger), round in shape, with smooth edges - so as not to collect debris on burrs and jagged edges. By the way, all builders also know that it is impossible to cut galvanized steel with a polymer coating with a grinder (not just metal tiles, but any kind).

This means that the correct option is in the last photo.

The technology for making a neat drain hole is not difficult to master. If you know how to hold a mallet and scissors in your hands, you can do it well the first time, I’ve tested it on myself. But then you can safely show the drain to the client and/or technical supervision, without raising questions or comments, but, on the contrary, receiving compliments, gratitude and recommendations through word of mouth.

And we are proud to realize that another step has been taken on the path to a high level of roofing craftsmanship.

What are drain systems made of?

In the production of devices, materials are used that are resistant to corrosion, alkaline and acidic substances, and hot water. In the last century, when the range of plumbing equipment was quite narrow, drainage systems were made mainly of ferrous metal.

Although this material quickly loses its original aesthetics, it serves well for a long time, bravely withstanding high pressure and temperature changes. Despite its advantages, now manufacturers still give preference to non-ferrous metals and plastic.

Plastic harnesses are attractive at an affordable price. They are appropriate in bathtubs equipped with a decorative screen. Their universal dimensions adapt to non-standard sewer outlets and drains.

Plastic products are light in weight, easy to assemble, and do not undergo deformation due to the interaction of moisture and impurities contained in it

Metal objects are significantly ahead of plastic in terms of strength, service life and design. The most common products are made of brass, bronze, and copper. Chromium or nickel is applied to the drain grids and certain parts in them using electroplating techniques.

Provided that the devices are cleaned in a timely manner and the washer joints are disassembled, unlike plastic, they are unlikely to fail even after decades.

You can understand what kind of metal the structure is made of by carefully examining the pipe connecting the drain and overflow holes. Copper is recognizable by its reddish tint, ductility and softness. Brass is a durable yellow alloy of zinc and copper. Bronze is a fairly hard, dark brown material containing copper and tin.

Bronze and brass trims look great in classic and retro interiors. They look very elegant and neat, which is especially valuable when the bathtub is in the center of the room

Main selection criteria

When choosing a device, buyers are guided by personal requirements and wishes. It is no less important to evaluate the product you like taking into account other serious criteria.

For example:

- Price category . For a low budget, plastic equipment with manual draining is optimal. A more expensive device with automatic/semi-automatic mechanisms is suitable for those who are looking for a solution with an original style and a convenient modern design.

- Material . The quality indicator of propylene is a dense shell, brass is a perfectly smooth surface, cast iron is the absence of the slightest cracks, since they cannot be repaired.

- Additional options . Siphons may have several inlets for connecting other consumers in addition to the bath. They may not be used by closing them with a nut. In the future, this thoughtful step will give you a chance to save money on branching drains under the sink, washing machine and dishwasher.

- The diameter corresponds to the siphon and sewer pipe. If the sections are incompatible, you need to select rubber or plastic adapters.

- Completeness . The kit of any system must include all elements for connection, O-rings, gaskets for pipes and overflows to prevent leaks.

Another criterion that is far from least important is the manufacturer of the plumbing fixtures. The service life and proper operation of the selected drain-overflow system depend on it.

Rating of the best manufacturers

In order not to get into trouble and not suffer with a problematic product of dubious quality, you should purchase products from well-known and trusted European companies. They produce equipment according to generally accepted international standards and norms.

Geberit . A high-quality Swiss brand with a wide range of products at mid-range prices. The product is easy to use and adapts well to non-standard sizes.

Most designs have an adjustment plug near the overflow hole that opens the drain plug

Alcaplast . One of the largest manufacturers of sanitary ware in Eastern and Central Europe. The Czech brand produces devices with a special design and simple construction, which stably and silently perform their functional tasks throughout their entire service life, regardless of the influence of aggressive environmental factors.

Kaiser . Manufacturer from Germany, producing trims for modern bathtubs. The company's products allow you to adjust the length of the siphon over a wide range, which makes it possible to easily install it, including in deep bowl models.

Viega . A German company that has established itself in the market as a manufacturer of safe plumbing products of the highest quality that can last about half a century. They successfully combine design and engineering ideas.

The assortment includes drain-overflow systems with different shapes, materials, and color variations. They are characterized by a relatively low price and simple installation.

Many Viega models have a water filling function. They are convenient for rooms where there is not enough space to install a faucet.

Hansgrohe . Another representative of good German quality. The company's harnesses are reliable, efficient, and feature a complex, high-tech structure. In interiors they are valued for their functionality and excellent decorative performance.

Materials

For the production of drains and overflows, plastic and metal are used. Brass, chrome and bronze can also be used. Which material is best to choose? It all depends on the style of the bathroom interior and its features. So, if all communications are hidden under the screen, then there is simply no point in buying expensive and beautiful parts.

In this case, it is better to purchase inexpensive plastic models, which, moreover, have many advantages:

- Long service life. Plastic is resistant to a variety of factors, and this type of overflow will serve you for a very long time;

- Persistence. Metal is also highly durable, but with constant contact with water, rust may appear on its surface, but with plastic there will be no such problems;

- Low prices. If there is a screen under the bathtub, plastic devices will be the best option, because they have excellent performance characteristics and are inexpensive;

- Simple and convenient installation (most of the drains and overflows consist of corrugated pipes, which allows them to be adjusted in length).

You should only look at metal options when you are not making decorative screens. Otherwise, it will be a waste of money. To avoid problems with repairing the drain, you need to make a special hatch for service. If you forget about this important point, problems will arise.

So, a leak may appear and you will have to completely disassemble the screen. By the way, it is worth noting that screens are not available for all types of bathtubs. Today there are bowls on the market in which the outer part is not made very carefully. There are also options for non-standard shapes and with unusual legs. All these points must be taken into account before purchasing a drain and overflow.

If you do not want to install a screen under the bathtub, then you should take a closer look at the drain-overflow options, which look more attractive. For this purpose, there are metal devices on the market; they are more expensive than plastic fittings, but they will improve the style of the plumbing and the entire room.

It is worth choosing the material of the drain and overflow taking into account the style of the interior. So, if the room is decorated in a modern style, then it is better to use nickel-plated models. Brass or bronze products look great in retro style.

Rules for installation work

Having experience installing a mechanical drain in a bathroom, you won’t need a circuit for a semi-automatic one - it is almost identical. Even without the skills, you can master it with your own hands, but first, it is advisable to read the instructions and documents that come with the kit.

The manufacturer's recommendations regarding the installation of the bathtub trim should be followed exactly. Otherwise, the device may not work or function incorrectly. It is not recommended to take on automatic systems: after installation without the participation of a specialist, the warranty on the device ceases to apply.

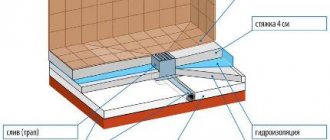

At the first stage, the old siphon, if any, is removed, and the insides of the pipe and the junction areas are thoroughly cleaned. Then the lower overflow is installed. A sealing collar is put on the outlet, after which it is placed against the drain opening.

Before installing the drain and overflow, it does not hurt to make sure that the bathtub is positioned correctly, stable and level and that the gap from the drain hole to the floor is at least 15 centimeters

Another gasket is placed on the inside of the hole, the lid with the grill is screwed on and secured with a screw. Cone-type cuffs are placed with the thick edge towards the nut, and the narrow edge towards the neck.

After checking that the connection is correct, tighten the screw with a screwdriver. The top overflow is installed using a similar method.

Tying under the bathtub is quite difficult. Most likely, you will have to take an awkward position to get to the right places. To fasten the inner and outer parts of the drain structure, it is advisable to work with a partner

The next stage is attaching the overflow to the drain. To do this, it is more convenient to use a flexible corrugated hose that stretches to a size that will easily fit into the pipe. Each joint is crimped with a nut and spacers.

Next, a glass is installed to form a water seal. Places for gaskets are first cleaned of defects with a file. The valve is also connected with a union nut with a flat or cone seal.

At the end, the siphon outlet is connected to the sewer with a drain pipe. This is done through the sealing collar or directly into the socket. To avoid leaks that occur due to cuff wear, they are treated with silicone lubricant.

When performing installation, do not use excessive physical force. Because of this, the strapping elements may burst, and you will have to buy new parts.

When the installation work is completed, you need to check the quality of the assembly by covering the drain with a stopper and opening the water. The floor under the bathroom is covered with paper, the drain and connections are inspected. When leaks are detected, the nuts are tightened.

Design Features

Despite the wide range, variety of designs, designs and capabilities. The operating principle of each product is the same and consists of several points:

- Neck. The element is installed at the bottom. During installation, attention must be paid to sealing, since durability and reliability depend on it. The kit should contain special seals; if they are not present, then it is better not to buy such equipment. The neck has a grille that prevents large debris from entering and accumulating inside the system. Therefore, the chance of clogging is minimal.

- Siphon. The product is designed to form a water seal that prevents the penetration and spread of unpleasant odors into the room. Often the product is compact in size, since the space under the bathtub is limited, which does not allow the installation of large models. Another useful feature is the connection of all pipes to the sewer main. When choosing, attention is paid to volume, since its effectiveness depends on quantity. It is recommended to buy products where this value is at least 300 ml, more is possible.

- To connect to the sewerage pipes are used. The diameter of this element is universal – 50 mm. However, there are models with different designs. There is a cylindrical section at the end.

- An overflow neck is installed on the top of the bathtub. The product is equipped with an elbow, which is directed downward during installation. When the user buys a ready-made version, this element is connected to all the main parts at once, which greatly simplifies installation and operation.

- For the interaction between the drain neck and the overflow, a pipe is used, which is made of various materials. It can be rigid (made of metal or durable plastic) or flexible (for example, corrugated, often made of PVC). Differences in curvature and length are permitted.

- Closing device. The element allows you to control the filling of the bath.

Tips for care and use

All drain and overflow systems require appropriate care. This is the only way to preserve their original condition and performance, ensure durability and high efficiency. Devices must be inspected regularly to ensure there are no mechanical damage or leaks.

Also, we must not forget about additional events:

- to prevent the accumulation of deposits and scale, the siphon is washed every three months with hot water with the addition of citric acid or suitable chemical oxidizing agents;

- approximately every six months, thin rubber gaskets that have lost their elastic properties are replaced;

- The water seal, which collects various contaminants and debris, is periodically cleaned.

If chips and cracks are detected during a visual inspection, the siphon must be replaced. Such malfunctions provoke flooding of premises and cannot be repaired.

The following article will introduce you to the intricacies of installing a conventional siphon on a bathtub, the contents of which we recommend that you familiarize yourself with.