In early spring and late autumn, all homeowners are faced with the problem of freezing roof slopes and freezing melt water inside gutters. If it is not resolved in a timely manner, the safety of people, as well as the safety of their property, will be threatened by large icicles and frozen lumps of snow falling from the roof.

A good solution is to heat the gutters, which will prevent the formation of ice. In this material we will talk about why you need to equip your drainage system with heating. We will also talk about what materials are required for this and describe in detail the essence of the process.

Features of the heating system arrangement

Methods for heating different types of roofs may vary. We are talking about the so-called “cold” and “warm” roofs. Let's look at the features of each option.

Heating a cold roof

This is the name given to a roof without thermal insulation along slopes with good ventilation. Most often, such roofs are located above non-residential attic spaces. They do not allow heat to pass out, so the snow cover on them does not melt throughout the winter.

For such structures, installing heated gutters will be sufficient. The linear power of the laid cable should gradually increase. They start with 20-30 W per p/m and end with 60-70 W per meter of drainage.

How to heat a warm roof?

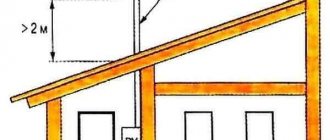

A roof with thermal insulation is considered warm. They allow heat to pass out, so that even at sub-zero temperatures the snow cover on the surface of a warm roof can melt. The resulting water flows onto cold parts of the roof and freezes, forming ice dams. For this reason, it is necessary to arrange heating for the edge of the roof.

The so-called warm roof allows heat to pass out. Therefore, the snow over the “warm” areas melts, the melt water falls on the “cold” fragments and freezes

It is implemented in the form of heating sections laid along the edge of the roof. They are laid in the form of loops 0.3-0.5 m wide. In this case, the specific power of the resulting heating system should be from 200 to 250 W per square meter. The arrangement of heating gutters is implemented in a similar way to that used for cold roofing.

Heating cable placement locations

The heating system must provide rapid melting of ice and removal of water from the roof. When installing anti-icing, it is important to choose the “cold zones” correctly. Heating cables are laid:

- Inside the drainpipes. When melt water drains and freezes inside the drainpipes, the risers can become deformed and even rupture. In addition, ice plugs prevent the removal of moisture from the roof and increase the accumulation of ice on the roof. The heating cable inside the risers is laid in one or 2 lines. If the drainage system is connected to a storm sewer, the heating cable is inserted to the approximate depth of its freezing.

- In trays. Dams of frozen water often form in gutters. A heating cable must be laid at the bottom of the trays.

- On the eaves. On slopes with a slope of 300 or less, the cable is laid in coils across the entire width of the cornice. On flat roofs with slopes greater than 110, several additional turns are laid near the drainage funnels. With a slope of 450 or more, heating elements are placed only in gutters.

- Between the edge of the roof and the snow guard. To protect against the melting of snow masses and blocks of ice, snow guards are installed on roofs with steep slopes. Heating cables are placed between the edge of the roof and the snow guard. This ensures the gradual melting of solid precipitation and prevents the fall of large pieces of compacted snow.

- On internal corners formed by adjacent slopes (in valleys). The height of the heating cable along these structures must be at least 2/3 of their length.

- In the drainage basins of internal drainage systems, as well as in the funnels of drainage systems for flat roofs. The loops of the heating cable should cover an area with a radius of 50 cm from the center of the funnel.

- Parapets and places adjacent to them. Along these roof elements, 1 line of warm cable is placed.

- In drippers, water jets and other places where ice is likely to form.

- Along the perimeter of the skylights.

The power of heating elements should be 180-300 W per m2 for roofs above an unheated attic. In houses with residential attics, this value increases to 300-400 W/m2. The power of heating elements running along pipes and trays is 40-70 W per meter. For polymer gutters and gutters, cables of 20-25 W/m are used.

If there are no gutters, the cable is installed along the edge of the roof. The lower edges of the turns should hang down by 4-5 cm. In this case, melt water flows from the heating cable. The pitch between the loops is selected based on the power density of the cable and the manufacturer’s recommendations. The minimum bending radius of heating cables is up to 50 mm.

The heating cable lines are fixed using mounting clips, tapes and clamps. To avoid damage to the insulating shell, use only fasteners recommended by the manufacturer.

We invite you to familiarize yourself with Lathing for lining in a bathhouse in a steam room

When fixing, it is important not to break the tightness of the roof. When using roofing nails or self-tapping screws, the fastening points must be treated with bitumen mastic or sealant. The cable should not hang freely in the air. The recommended distance between fasteners on horizontal areas is 25-30 cm, on inclined surfaces - 20-15 cm.

The main element of the anti-icing system is available in several variations.

Although the definition of “resistive” for this type of cable is firmly established, it is not entirely correct. It would be more correct to call this cable option “unregulated”, since all heating cables are resistive in nature.

An unregulated cable has the simplest design. This is an elongated heating element made of a metal alloy with high electrical resistance (usually nichrome is used), enclosed in a shielding shell and insulation. Its advantages are the following:

- has low cost;

- during switching on it does not cause a significant jump in current (the so-called inrush current).

Resistive cable is easy to connect and inexpensive, but it uses electrical energy inefficiently

Flaws:

- Has constant heat output. Because of this, those areas of the roof that currently need less heat are subject to overheating, and even at the expense of the user (overconsumption of electricity). In addition, if there is insufficient heat dissipation, an unregulated cable may overheat and burn out. Particularly susceptible to overheating are the areas where two cable lines overlap.

- It is impossible to shorten the length of the cable in an already installed system, since this will reduce its electrical resistance and, accordingly, increase the current strength in the circuit.

- The linear power also depends on the length.

- If the heating core breaks, the entire cable becomes inoperable.

In fact, a two-core cable also uses one core, only it is folded in half. This allowed us to win the following:

- There is no longer any need to close the circuit by pulling the other end to the connection point. Thus, the two-core cable is laid in one thread, and not in two, like a single-core cable, therefore, the danger of overlap when large masses of snow converges is eliminated. It should also be noted that a system with such a cable is simpler to design and install.

- The currents flowing in the cable cores, and essentially in the two halves of one core, have opposite directions, so the magnetic fields they generate cancel each other out. A single-core cable in close proximity to a person (for example, if the attic is residential) can cause harm to health with its electromagnetic field.

The heating core is also made of nichrome, but the cable is designed slightly differently: it consists of two insulated current-carrying wires (phase and zero), and the heating wire is wound on them in the form of a spiral. In this case, the nichrome conductor is divided into segments, which at their ends are connected to the current-carrying conductors. Thus, a zone cable consists of many heating fragments connected to the electrical network in parallel. This provides the following benefits:

- The length of the cable can be reduced, since the current at the input decreases, and the linear power remains constant at any length.

- If the heating core breaks in any place, other areas remain operational.

When the length of a resistive cable decreases, its linear power remains unchanged

A zonal resistive cable, as you might guess, costs more than a regular cable.

This cable, like the zonal one, has two conductive cores, but the heating wire is made of a completely different material: it is a special polymer with semiconductor properties, called a “matrix”. It is laid not around the current-carrying conductors, but between them. The peculiarity of the matrix is that its electrical resistance depends on temperature: the stronger the heating, the fewer current-carrying paths are active.

In the end, when heated to a certain temperature, the polymer generally turns into a dielectric, that is, it turns off, while areas with an acceptable temperature continue to function. The advantages of a self-regulating cable are obvious:

- Burnout in areas of overlap or due to insufficient heat removal is physically impossible.

- If the roof overheats in any place, the corresponding section of the cable automatically reduces the heat generation power, so that electricity is consumed very rationally. As practice has shown, on average, a system based on a self-regulating cable consumes 2 times less electricity than one equipped with an unregulated analogue.

- All current-carrying paths are connected in parallel, so the cable length can be reduced. A matrix break does not lead to cable failure.

- The service life is about 30 years. This is several times (!) more than that of an unregulated cable.

A self-regulating cable is more expensive than a regular cable, but it is much more reliable and economical to operate.

But there are also negative aspects:

- the cost of a self-regulating cable is 3 - 5 times higher than the cost of a non-regulated one (240 - 660 rubles / linear meter versus 90 - 150 rubles / linear meter);

- in a cold state, the matrix has a very low electrical resistance, so when turned on, a high inrush current occurs (more expensive protection devices have to be used).

Heating sections of the SNV brand are made on the basis of a resistive two-core heating cable with a constant specific heat release power of 28 W/m. External dimensions of the heating cable: 5.45x7.55 mm.

The heating cable for heating the roof is connected to a power wire reinforced with a plug and to an external wire, at the other end of which there is a coupling with a built-in thermostat with a temperature response range from –15°C to 6°C.

We invite you to familiarize yourself with Passage elements - the official Grand Line online store - materials and components for roofing

Design of a drain heating system

To heat the roof and gutters, a system with a heating cable is most often used. Let's consider its main elements.

Distribution block and sensors

The distribution block is designed for switching power (cold) and heating cables.

The node includes the following elements:

- signal cable that connects the sensors to the control unit;

- power cable;

- special couplings used to ensure the tightness of the system;

- installation box.

The unit can be installed directly on the roof, so it must be well protected from moisture.

The system can use three types of detectors: water, precipitation and temperature. They are located on the roof, in gutters and drains. Their main task is to collect information for automatic heating control.

The collected data enters the controller, which analyzes it, makes a decision to turn off/on the equipment and selects the optimal operating mode.

Controller and control panel

The controller is the brain of the entire system, responsible for its operation. In the most simplified version, this could be some kind of thermoregulatory device. In this case, the minimum operating range of the device must be in the range from +3 to -8 degrees C. In this case, control and switching of the system cannot be fully automated; human intervention will be required.

To fully automate the operation of the heating system, you will need a controller. This device collects and analyzes information coming from sensors and, based on it, adjusts the operation of the system

A more convenient option for operation is to use a complex electronic control device with programming capabilities. Such equipment is capable of independently controlling the process of melting precipitation, its quantity, and monitoring the temperature.

The controller quickly responds to changes and makes optimal decisions, choosing the best mode of operation of heating equipment under existing conditions.

The control panel is designed to control the entire system and ensure safety during its operation.

The following elements are usually used to arrange a node:

- three-phase input circuit breaker;

- RCD (also known as residual current device);

- four-pole contactor;

- signal lamp.

In addition, it will be necessary to install single-pole circuit breakers for each phase, as well as protection for the thermostat circuit.

In addition, during the installation process you will need parts for fastening: roofing nails, screws, rivets. You will need heat shrink tubing and special mounting tape.

How to choose a heating cable?

Perhaps the most important element of the system is the heating cable. In practice, one chooses between two types of devices: self-regulating and resistive cable. Let's consider all the pros and cons of using both options.

Features of resistive type cable

It is distinguished by the simplicity of its operating principle. Inside such a cable there is a metal conductor with high resistance. When electricity is supplied, it begins to quickly heat up and gives off heat to the heated object. The resistive cable system is very easy to operate and does not require large expenditures.

The design of a resistive heating cable is very simple. The main “working” element is the heating core. When current passes through it, it heats up very quickly

The main advantages of using a cable of this type are the absence of starting currents during startup, the low cost of a resistive wire and the presence of constant power.

The last statement can be considered controversial. Because in some cases, constant power will rather be a disadvantage. This will happen if parts of the system need different amounts of heat. Some of them may overheat, while the rest, on the contrary, will not receive enough heat.

To regulate the degree of heating of a system with a resistive cable, thermostats or other devices are necessarily used.

The efficiency and cost-effectiveness of such a system depends on the correctness of their settings, so reality is often far from what is desired. In this respect, a resistive cable is significantly inferior to a self-regulating cable.

Experts recommend laying zonal resistive cable whenever possible. This variety is distinguished by the presence of a nichrome heating filament. Its linear power does not depend on size; if necessary, the cable can be cut.

Also, the advantages of the heating cable include ease of installation and long-term operation.

Self-regulating cable and the nuances of its operation

It has a more complex device. Inside such a cable there are two heating cores, around which there is a special matrix. It “adjusts” the cable resistance depending on the ambient temperature. The higher it is, the less the cable heats up, and vice versa, the colder it is around, the better it heats up.

Inside the self-regulating cable there is a special matrix that can change the resistance of the heating core depending on the ambient temperature

A self-regulating cable has many advantages. First of all, for its normal operation it does not require the installation of a set of control devices: detectors and thermostats. The system will adjust itself, and overheating or insufficient heating, as can happen with a resistive cable, will not occur.

The self-regulating wire can be cut. The minimum length of the segment is 20 cm, its performance characteristics will not change depending on the length. During the installation process, if necessary, the cables can be crossed and even twisted, they will work as usual. Installation and operation of the self-regulating cable is very simple. It can be mounted outside or inside the heated object.

The system also has disadvantages. First of all, it's cost. A self-regulating cable costs about 2-3 times more than a resistive cable. It should be taken into account that it will cost less to operate. Another disadvantage is the gradual aging of the self-regulating matrix, as a result of which the self-regulating cable fails over time.

Read more about the features of choosing a self-regulating cable below.

How to choose the right heating system

Such systems differ primarily in the type of heating element. Options using cable or film heaters are possible. The second method has much in common with the “warm floor” system. The important difference is that the film should be located inside the roofing pie, because it is not designed for heavy loads and is poorly adapted to mechanical damage. But the cable, on the contrary, may be on the surface of the roofing material. But the wire can also be laid inside. This is usually used when installing a heating system for flat roofs, and also during the construction of high-rise buildings. Only cable is used to heat gutters and pipes.

The cable is used for external roof heating Source domsireni.ru

Characteristics of different types of heating elements:

- Self-regulating wire

This is a matrix with polymer insulation and two wire cores inside. This also includes a metal braid and an additional layer of insulating material. If it gets warmer outside, then the number of conductive paths inside the matrix decreases and, as a result, the temperature of the heater decreases. This type of heater has many advantages. Firstly, cable installation is quick and does not require much experience. Secondly, the matrix itself is resistant to overlaps and spot heating, thanks to the temperature self-regulation system. Thirdly, such a cable can be used in combination with absolutely any roofing materials. An important advantage is that the system selects the optimal temperature and thereby prevents the consumption of excess electricity. It is possible to install such heaters without the use of weather sensors, and you can also heat gutters using a self-regulating cable.

Self-regulating wire is most easily mounted on the roof Source raychemfutokabel.hu

- Resistive wire

Heating occurs due to the resistance of the conductor. Such a cable can be two-core or single-core. The insulation is made of a polymer layer, and on higher quality models a nichrome core is used. When installing such a cable, you need to pay attention to the fact that both the beginning and the end of each wire must necessarily converge at one point. There is one rather serious disadvantage of such a heating system: in the event of a single point damage, the entire anti-icing complex fails. Installation is inconvenient because the resistive cable cannot be cut. This method is suitable for heating large roof areas.

The resistive system is more complex, it is better to entrust it to an experienced technician Source teploobogrev.ru

Heating system calculation

Experts advise choosing cables with a power of at least 25-30 W per meter for heating the roof and gutters. You need to know that both types of heating cables are used for other purposes. For arranging heated floors, for example, but their power is much lower.

Before you begin calculating power, you need to decide how all elements of the system will be heated. The figure shows examples of possible organization of heating gutters and drains

Power consumption is estimated in active mode. This is the period when the system operates at maximum load. It lasts in total from 11 to 33% of the entire cold period, which conventionally lasts from mid-November to mid-March. These are average values, they are different for each area. The power of the system needs to be calculated.

To determine it, you need to know the parameters of the drainage system.

Let us give an example of calculations for a standard design with a cross-section of a vertical drain of 80-100 mm, a gutter pipe diameter of 120-150 mm.

- It is necessary to accurately measure the lengths of all gutters for water drainage and add up the resulting values.

- The result must be multiplied by two. This is the length of the cable that will be laid along the horizontal section of the heating system.

- The length of all vertical drains is measured. The resulting values are added together.

- The length of the vertical section of the system is equal to the total length of the gutters, since in this case one cable line will be sufficient.

- The calculated lengths of both sections of the heating system are added up.

- The result obtained is multiplied by 25. The result is the electric heating power in active mode.

Such calculations are considered approximate. Everything can be calculated more accurately if you use a special calculator on one of the Internet sites. If independent calculations are difficult, it is worth inviting a specialist.

Task

The task of the anti-icing system is to ensure unhindered removal of the resulting melt water from the roof surface through the drainage system until the water is completely removed from the roof and gutters. The roof heating system eliminates the need for mechanical cleaning of snow and ice, which often leads to damage to the roof and drainage system and leaks.

How effective the roof heating will ultimately be depends on the professionalism of the designers and installers. When calculating and installing, it is necessary to take into account the design features of the roof, its slope, covering material, the presence of architectural elements that contribute to the accumulation and retention of masses of snow on the roof.

Unqualified personnel and lack of experience in carrying out such work can lead to the fact that the cable heating system for gutters will not work effectively. Moreover, incorrect calculation of melt water flows or temperature loads from heating equipment through the roof (an example would be large heat release from production lines and machines in workshops or the installation of heating equipment in attics and attics) may not reduce the number of icicles, but rather increase it!

The main component of the system is heating cables. When placed in a drainage system, they provide a channel for melt water to drain and prevent clogging.

For roof heating systems, two types of heating cable are used - resistive or constant power cables and self-regulating.

We invite you to read: Make doors from clapboard

A constant power heating cable has a constant, constant resistance along its entire length. The length of sections of these cables is fixed, therefore, when selecting the required section with a certain length, it is necessary to strictly follow the technical parameters.

Self-regulating heating cable provides the optimal solution for heating roofs and gutters in most cases. The peculiarity of this type of cable is that self-regulating cables themselves change their heat output depending on environmental conditions and temperature.

This prevents the cable from overheating and failing, which ensures high safety and reliability of the system. Cables can be easily cut into sections of arbitrary length (up to several tens of meters) directly on site, which makes them convenient to use. The flat cross-section ensures good contact with the heated surface, reducing heat dissipation into the environment.

Choosing a place to lay the cable

Actually, the heating system for gutters is not that complicated, but in order for it to work as efficiently as possible, the cable should be laid in all areas where ice forms and in places where melted snow melts.

In roof valleys, the cable is installed down and up, extending over two-thirds of the valley. Minimum - 1 m from the beginning of the overhang. For every square meter of valley there should be 250-300 W of power.

On flat areas of the roof, heating is installed for the roof fragment located directly in front of the catchment area. This way, melt water will freely flow into the pipe.

Along the edge of the cornice, the wire is laid in the form of a snake. The snake pitch for soft roofs is 35-40 cm; on hard roofs it is made a multiple of the pattern. The length of the loops is chosen in such a way that there are no cold zones on the heated surface, otherwise ice will form here. The cable is laid on the water separation line along the drip line. This can be 1-3 threads, the choice is made based on the design of the system.

The heating cable is installed inside the gutters. Usually two threads are laid here, the power is selected depending on the diameter of the gutter. One heating core is laid inside the gutters. Particular attention should be paid to pipe outlets and funnels. This usually requires additional heating.

Installation of a roof heating system

When arranging a roof with electric heating , you need to take into account all its design features. If the roof does not have gutters, you can use several installation options.

The cable is laid on special guides. Often they are already included with the cable. If they are not available, then the corresponding set can be purchased at construction and repair supply stores.

If there is no drainage on the roof and it has a relatively slight slope, then you can install a system with a special recess in the center. With a steep roof slope, the system is laid towards the edges from the center. Near each corner you need to make small holes that will be used to remove melt water and wire loops.

Installation of cable in the drain

Self-regulating wires are often used for gutters. The cable must be installed at the bottom of the pipe at least two-thirds of its entire length. The system is fixed using special elements. The cable is laid in several rows.

If the installation involves installing a resistive wire, then it must be taken into account that it is forbidden to bend it too much, otherwise the core inside can easily be damaged. The distance between individual turns should be 4-6 cm.

Control unit selection

Connecting the system using an automatic temperature and humidity controller is considered the most justified option. Thanks to the built-in sensors, the system does not require human intervention.

The automatic control unit and self-regulating wires allow additional savings on electricity and increase the efficiency of the entire system. Connecting a manual control unit will cost much less, but such a system will need constant monitoring and attention depending on the weather outside .

Heating system technology

We suggest you study the detailed instructions for installing a heating system for the roof and gutters with your own hands. The process of installing a heating system for gutters includes a number of standard steps:

Image gallery

Photo from

Step 1: Installation of heating cable according to the project

Step 2: Laying vertically oriented heating lines

Step 3: Install the Icing Sensors

Step 4: Installation of distribution boxes and automation in the panel

First, we outline the places where the cable will be laid. It is important to take into account all the turns and their complexity. If the angle of rotation is too steep, it is recommended to cut the cable into pieces of the required length and then connect them using couplings.

When marking, carefully inspect the base. There should be no sharp protrusions or corners, otherwise the integrity of the cable will be at risk.

Inside the gutters, the cable is fixed with a special mounting tape. It is fixed across the wire. It is advisable to choose a tape that is as strong as possible.

The resistive cable is secured with tape every 0.25 m, the self-regulating cable - every 0.5 m. Each strip of tape is additionally secured with rivets. Their installation sites are treated with sealant.

To install the cable, use a special mounting tape. No other fasteners are recommended. Rivets, sealant or polyurethane foam are used to secure the tape.

Inside the gutters, the same installation tape or heat shrink tubing is used to secure the cable. For parts whose length exceeds 6 m, a metal cable is additionally used. A cable is attached to it to remove the load-bearing load from the latter.

Inside the funnels, the heating cable is attached to tape and rivets. On the roof - on mounting tape glued to sealant, or on mounting foam.

Important note from experts. It may seem that the roofing material's adhesion to the sealant or foam is not sufficient to make a reliable connection. However, it is strictly forbidden to make holes for rivets on the roofing material. Over time, this will inevitably lead to leaks and the roof will become unusable.

We choose a place for distribution boxes and install them. Then we call and accurately measure the insulation resistance of all the resulting sections. We put the thermostat sensors in place, put the power and signal wires. Each sensor is a small device with a wire, the length of the latter can be adjusted. Detectors are placed in strictly defined places.

Some areas of the system require increased heating. More cable is installed here. Such areas include the drain funnel, where ice can accumulate

For example, a place is selected for a snow sensor on the roof of a house, a water detector is selected at the lowest point of the gutter. We carry out all work according to the manufacturer's instructions. We connect the detectors to the controller. If the building is large, the sensors can be combined into groups, which are subsequently connected one by one to a common controller.

Next, we prepare the place where the automatic control system will be installed. Most often this is a distribution panel located inside the building. The controller and protective group are installed here.

Depending on the type of controller, the nuances of its installation may vary slightly. However, in any case, it will have terminals for connecting detectors, heating cables and for power supply.

The picture shows that the cable is fixed in a “suspended” state. Over time, a violation of the installation will inevitably lead to its breakage and breakdown of the heating system

We install the protective group, and then measure the resistance of the previously installed cables. Now you need to test the automatic safety shutdown to find out how well it copes with its functions.

If everything is in order, we program the thermostat and put the system into operation.

Water de-icing systems

The operating principle of water roof heating systems is the same as that of cable systems, only the coolant differs: the roof is heated by pipes through which hot water circulates.

Advantages of water roof heating systems:

- relatively low cost,

- high efficiency,

- ease of maintenance,

- Possibility of use over large areas.

Flaws:

- complexity of installation,

- risk of turning off hot water.

Typical mistakes when installing a system

Experienced installers identify typical mistakes that are often made by those who install heating of gutters on their own for the first time:

- Design errors. The most common is ignoring the features of a particular roof. When designing, no attention is paid to cold edges, warm areas, spillway areas, etc. As a result, ice continues to form on some areas of the roof.

- Errors in fastening the heating cable: a moving wire “hanging” on a mounting tape, holes in the roof for fasteners, the use of a tape that is intended for installing a heated floor on the roof.

- Installation of plastic clamps intended for interior use as fasteners. When exposed to ultraviolet radiation, they will become brittle and collapse in less than a year.

- Hanging a heating cable into a drain without additional fastening to a cable. Leads to wire breakage due to thermal expansion and the severity of ice.

- Installation of power cables that are not intended for installation on the roof. As a result, an insulation breakdown occurs, which threatens electric shock.

Errors include connecting a heating cable in areas where its use is not required. His work will be useless, and the owner will have to pay for it.