Often, during the operation and maintenance of a cable route, it is necessary to lift the wires from the sewer. This can only be done using a special tool. Most often, a cable stocking is used for this. This device is intended for pulling wires through sewer pipes.

On one side of this structure there is an eye (loop) to which the cable to be pulled is attached, on the other there are cables in the shape of a proboscis. The last element is attached to the end of the wire and then fixed.

What it is

Cable stockings are often called sleeves, although, in fact, the sleeve is one of the parts of the structure. Products consist of polymer materials in the form of threads or wires. An end loop (eyelet) is used to independently clamp all pulled cables into one route; a cable is also necessary for attaching the device to a particular surface.

The principle of laying a cable using a stocking is simple. When the loop is tightened, the device contracts, which leads to a decrease in diameter. This causes compression of all conductors, which are converted into a single circuit. The stocking for pulling the cable is almost impossible to remove. The tighter the loop is, the more the wires will shrink. Despite the fact that the loop breaks under strong tension, the structure remains intact. Usually the “eye” is made either from an elastic cable or from a special flexible wire.

Note. To increase the service life and structural strength, the wire from which the cable stocking is made is additionally coated with a layer of zinc.

There are special cable elements with a high degree of protection from dust and moisture. These products are made from polymer materials with increased dielectric properties and good resistance to corrosion. Such devices should be used when laying cable lines in places of direct contact with water or at facilities with maximum requirements for electrical and fire safety.

The factory loop has a special plug on which the working cross-section of the cable is indicated. Instead of a cork, a colored sleeve can be used (its color indicates a specific device model).

Using this equipment, conductors can be fixed anywhere along the cable route. In this case, detachable stockings are used, installed on the sides of the wires. To ensure fastening, they are supplemented with a polymer cord.

The advantages of using products when pulling lines include:

- absolute protection of the laid cable from mechanical damage that could occur during the installation process;

- the ability to construct long-distance communication lines without damaging current-carrying conductors;

- when fixed to the wall, the cable practically does not sag;

- high fastening strength;

- ease of installation (provided that a suitable stocking for the cable has been selected);

- simplicity of design.

Main types of stockings

There are different types of such instruments. Which cable stocking will be used depends on the installation conditions and cable routing.

The following device types exist:

- Standard or classic with a single loop. Used when pulling cables to grip them from the end side. Their high strength is explained by the double twisting of the cable (steel).

- Standard with one pair of loops. Their purpose is the same as in classical devices; they are used in the ordinary stretching workflow. This cable stocking is elastic, making it easy to install.

- Pass-throughs with one loop. Such devices are used when it is necessary to stretch the electrical wire in any accessible area while pulling the electrical wire.

- Pass-through (detachable) with a pair of loops. They are used when it is impossible to secure the device to the end (for example, during sharp turns).

- Triple. Used to stretch three cords at once. The design of the mechanism is as follows: three elongated wires are connected by one loop.

- Side. Used to temporarily grab an electrical wire from the side (end side).

- Transit or portable devices. With their help, individual conductors are connected.

- Cable stocking for light weight cables. Used when the size of the electrical wire is small. This could be television wires, indoor wiring in a room, or fiber optic cables.

Design features

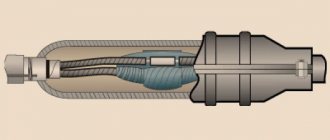

Despite the simplicity of the design, the principles of the cable stocking structure are necessarily regulated by the corresponding clause of GOST. The main elements are the sleeve and the loop. The product also includes a flexible braid from which a sleeve of the required density is made. To increase the strength of fixation of the stocking to the cable, the sleeve is made long (up to 2 m). The larger the diameters of the laid conductors, the longer the braid should be.

For the production of braiding, in most cases, steel wire or double-braided cable is used. The diameter is selected based on the required dimensions of the final structure. In order to increase the service life, all surfaces are galvanized.

If the diameter and linear weight of the wire being laid are minimal, then cable stockings made from polymer dielectrics are used. They are preferable in cases of contact with water or when high electrical safety requirements are required.

The end loop is made from cable or wire. On its neck there is a crimp sleeve with markings indicating the working diameters of the wires. A colored plastic sleeve can be used to identify the product.

The cable loop is considered more flexible, making it much easier to navigate sharp turns on the line. To simplify the fastening process, some products have a nut. In this case, the broach tip is screwed on either directly or through a special adapter.

Important. In order to increase the flexibility of the product, the cable stocking can consist of two loops. This type is best suited for laying cable routes with a large number of bends and turns.

Much less often, fastening loops are fixed through eye bolts and rotation compensators. In this case, the design becomes significantly more complicated. On the other hand, this option is preferable due to the compensation of twisting actions on the cable.

Design features of the stocking

The design of the cable stocking in any form is extremely simple, and its general principles are defined by GOST 50889-96. A cable stocking in most cases consists of a sleeve and a loop, which are its main components.

The base of the stocking is a flexible braid, which is made in the form of a sleeve of varying density. To increase the strength of attachment to the cable, the sleeve is made quite long (ranging from several tens of centimeters to two meters). As the diameter of the cable being pulled increases, the length of the braid increases.

The braiding material is predominantly steel wire or double braided cable of various diameters. To increase the service life of the product, the upper surface of the wire is galvanized.

Cable stockings for laying cable lines

The second main element is the broaching ring, which is usually made in the form of an end loop made of wire or cable. The neck of the loop is equipped with a crimp sleeve, on which the article number for the working diameters of the cable is usually stamped. For identification purposes, an additional colored plastic sleeve is used.

The cable version of the loop has increased flexibility and makes cornering easier. On the loop of some types of broaches, in order to increase the convenience of fastening, a nut is provided for screwing onto the threaded part of the broach tip directly or through an adapter.

Tip #1. The introduction of a second loop into the design of the stocking, all other things being equal, increases its flexibility, which makes such stockings preferable when working on tracks with a large number of turns.

Much less common is the fastening of a broaching ring through an eye bolt or a rotation compensator in another form. Despite its great complexity, this design is preferable because it completely compensates for the twisting effects on the cable, guaranteeing compliance with the laying technology.

Standard cable stocking

Operating principle

Before installing the cable stocking, it must be compressed in the axial direction, which will significantly increase the internal diameter. Then the wire to be laid is threaded through it and, due to the pulling force at the second end, a tight fit of the product to the cable sheath is ensured. The edge of the broach or an ultrasonic rod, which was previously installed in the channel cavity, is attached to the ring. After this, you can begin to carry out work - pulling the cable through the pipes.

Due to the resulting elasticity or friction (due to forced stretching of the stocking), an initial force is created. With the advent of drawing force, friction increases, which is affected by the angular position of the braiding threads relative to the conductor. Thus, as the pulling force increases, the compression density of the braid and fixation will increase, which will ensure maximum fastening strength.

One of the main properties of the cable stocking is associated with the uniform distribution of force over a large coverage area, which guarantees reliable protection of the conductor core from any damage and eliminates slipping during operation. To remove the stocking, slide the open part in the direction of the loop or wire cut. The pressure exerted on the shell will decrease, which will lead to a decrease in the friction force and easy dismantling of the product.

Main varieties

Cable stockings are divided into several main types, and the choice in favor of one or another is determined by the conditions of installation and cable laying:

- Classic stocking with a single loop. Used for laying cable lines when gripping the end part. Increased strength is ensured by the fact that the steel cable is made of double turns.

- Classic with a pair of loops. The purpose is identical to the first type, but the product itself is considered more flexible and elastic.

- Pass-through stocking with one loop. This option is relevant in cases where the electrical wire must be stretched on a particular section of the cable route directly during the installation process.

- A pass-through stocking with a pair of loops. Often called detachable. The product can be used during installation when it is not possible to fix it by the end of the cable (for example, on sharp turns).

- A triple stocking is used in the case of laying three wires at once. They are all connected using one loop.

- The side stocking is used to temporarily capture the wiring at the end part.

- The transit sleeve allows you to connect individual cables.

Additionally, cable stockings designed for light weight should be highlighted. The need for them arises less often than others, since these products are usually not used for laying electrical wiring of small diameters.

Cable stocking - varieties

Currently, various types of this device are produced:

- Classic devices with a single loop. This tool is used to pull the cable and grab it from the end. The device is made on the basis of a double cable made of steel.

- Standard fixtures with a pair of hinges. This device is more elastic, therefore it is convenient to use and is used in almost every stretching procedure.

- Pass-through devices with loop. This mechanism is used when stretching the cable in various accessible places while pulling the electrical wire.

- Detachable stockings with a pair of loops. Used in case it is not possible to fix the device at the end of the cable.

- Portable devices. Using this type, individual conductors are connected.

Some other types of devices are made: triple mechanisms, side tools, as well as devices for cables that are small in size.

What to do if a person is electrocuted? Everyone should know this!

Side and triple cable stockings

The side mechanism is used to pull the electrical wire. The cable, which needs to be grabbed during production, can be pushed in entirely, and the loop will be located on its side. In this case, the traction load shifts from the end of the cable. Its sleeve is made of galvanized cable made of steel. Due to the double weaving of the cable, the device has good strength and resistance to stress.

Several cable stockings

A triple-type device is used to grasp three electrical wires at once, having a cross-section from 10 to 65 mm. In this case, the capture occurs from the end during the production of a robot for laying power lines in wells, boreholes, and cable alarm pipes.

This mechanism has three single stockings grouped by one pull cable. The gut of the device is made of galvanized cable made of double braided steel, this gives the mechanism the necessary flexibility in production and tightening when stretched.

Also, thanks to these design features, triple stockings have great wear resistance and can withstand heavy loads when breaking.

Additional varieties

This category of electrical devices includes stockings used to solve specific problems. Such equipment is much less common than the main types.

The transit mounting stocking is used to replace old power wires with new ones. It is noteworthy that the old wiring serves as a broach for the new one. The sleeve on the transit stocking is open at both ends. One part of the stocking is attached to the end of the old cable, the other to the end (if you want, the beginning) of the new one. In fact, the product temporarily connects two cables together. A characteristic distinctive feature of the transit device is the long length of the hose (almost always over 1 m), since this product is used for large-diameter cables.

The triple cable stocking is used in the process of group cable laying with your own hands. Unlike the usual design, the product contains three sleeves made of flexible materials, which are fixed to a common eyelet. The main advantage of the stocking is a more uniform distribution of force along the pulled cables.

Support components must be used in one of two cases:

- In the process of laying wiring through trenches in order to suspend the cable above the level of its bottom.

- For hanging wires under the ceiling or roof.

Often these products consist of two loops.

The small cable stocking is made from dense steel braiding with wire of a smaller section. They are used for laying fiber optic, coaxial and other cable systems. The main feature is a large group of products with different fasteners (for example, threaded bushings).

Additional types of cable stockings

Additional varieties include those stockings that are used to solve specific problems and are quite rare in practice.

Two-loop version of a standard cable stocking

Transit cable stockings are used when replacing an existing cable with a new one. In this case, the cable being replaced performs the functions of pulling for the newly laid one. The sleeve of the transit stocking is open at both ends. Once the stocking is installed on both ends of the cable, they are actually connected to each other in a temporary manner. A characteristic distinguishing feature of this type of stocking is the long length of its sleeves, in most cases exceeding 1 m. In addition, such products are designed for a cable of no more than an average diameter.

Triple cable stockings are used for group installation. They differ from ordinary ones in that they contain three flexible braided sleeves, which are attached to one common loop. The strength of this design is the uniform distribution of the pulling force over the individual cables.

Triple cable stocking

So-called support cable stockings are used in two main cases:

- when laying in trenches in order to hang the cable above the level of the bottom of the trench;

- as a means of temporarily suspending cables from the ceiling or roof.

Taking into account the characteristics of the focal areas of application, stockings of this variety quite often have a two-loop design.

Small cable stockings are made on the basis of a dense steel mesh made of small-diameter wire and are designed to work with cables of relatively small diameter (fiber optic, coaxial and similar). A special feature of small cable stockings is that there is a fairly large supply of products of this variety, in which the loop is replaced with a threaded bushing, which makes it possible to reduce the midsection of the element as a whole.

Features of choice

When choosing a stocking, you should focus on the characteristics of the wire, the features of the cable route and how much it is filled with other structures. The values of the laid conductors are indicated in millimeters. Typically the markings are applied to the ring sleeve. The operating range error from the nominal value is +/- 15-20%.

Stockings are produced in regular or elongated versions. For production, wire of different diameters is taken. As the length of the hose and the diameter of the wire used increase, the permissible pulling force increases.

Important. When choosing a stocking, you need to ensure that the diameter of the cable and the sleeve match. If you break the rule, serious problems will arise during the installation process or the risk of the stocking coming off will increase.

Instructions for use

Despite the simplicity of the design of cable stockings, during their operation some features and tricks should be taken into account. On the one hand, the conductor is easily and simply pulled through the stocking, on the other hand, it will be difficult to pull it out. To understand the principle of operation, take a look at the distribution of forces in the picture below:

The arrow pointing to the right indicates the pulling force that occurs during the cable pulling process. The wires that make up the braid are compressed when pulled. Small vertical arrows indicate this process. Compression is carried out over the entire surface of the circle.

With an excessively large pulling force, the deformation of the outer sheath on the electrical wiring increases, but the core is not damaged, and the product is almost impossible to tear. The higher the force, the stronger the compression. To prevent the sleeve from tearing, the loop is made less strong, so if you tighten the stocking, the device will remain intact, and only the eye will tear.

There is a fixing tie in the tail part of the device. There is no load on it during cable pulling. If you need to pull out a cable route, the tie will perform an important function: it tightens itself when laying the cable and unclenches when removing the conductors. If the tie was not clamped or is missing from the device, then when you try to pull out the cable, the stocking freely jumps off the wire.

Types of cable stockings

Cable tester

Depending on the task at hand and the location of the work, the most optimal material option is selected, which will allow not only to efficiently fulfill the goal, but also to realize it in the shortest possible time with a minimum of effort.

The main types of cable stockings can be distinguished:

- The simplest option, designed for laying communication lines in the forward direction, is a stocking with one loop, it is also called standard, another name is assembly. This type of product is used for quick permanent or non-permanent fixation of communication networks in wells, trenches, pipelines, and sewer systems. The entire load during the installation process is evenly distributed over the route. Accordingly, the cables are not pinched, eliminating any possibility of physical damage. Cable stockings of this type securely fix the wires and do not slip. Manufacturers offer a wide range of models, depending on the diameter of the power line, which is available in sizes from 10 mm to 180 mm.

The following devices with one loop can be distinguished, such as:

- Cable stockings with one elastic loop with supporting properties, made of zinc-based cable, the main purpose of which is to hang any number of wires on a special support or holder. They are designed for cable diameters from 6 mm to 95 mm;

- Cable stockings with one loop, called extended, are designed for different cable diameters: from 10 mm to 180 mm;

- A cable stocking with one loop, called a triple one, allows for permanent or temporary fixation of 3 cables. This system provides a uniform load on the entire network, regardless of its length, thereby eliminating damage to the insulation or conductive conductor. The most commonly used material of manufacture is steel cable. The system is usually designed for wire diameters from 2 mm to 65 mm;

- Detachable (pass-through) cable stockings with one loop were designed specifically for non-permanent fixation of communications from wires in any place, prevent the violation of the integrity of networks, thereby ensuring a uniform load on the route throughout its entire length. Suitable for areas where there is free passage to networks, they can also be used as an auxiliary component when pulling the communication system to the desired location;

- Cable stockings with one loop for side gripping are called side ones; they are used for short-term gripping of communication networks from the end part, while the entire installation process is quite quick and simple. The system ensures an even load throughout the entire route, thereby maintaining its integrity. The sleeve is designed using standard technology from galvanized material; gripping and fixing is carried out by pulling the loop;

- Mounting cable stockings for SIP systems with one loop. SIP is a self-supporting insulated wire used to supply electricity outside the premises; current supply is carried out both by the air method on special poles and directly to the building. Cable stockings can be produced specifically for SIP 2, 3, 4 or more on an individual order. They are manufactured for cable diameters ranging from 10 mm to 65 mm;

- A stocking clamp for temporary gripping of overhead electrical networks called a head clamp is most often used during repair work. This type of stocking is conventionally divided into several types of weaving: single, double and triple. Thanks to these weaves, a uniform load on the power line is ensured without damaging them. Can be produced for cable diameters of 8 mm or more.

Cable stockings with one loop

- The Double Loop Cable Suspender (Standard) was designed for the non-permanent fixation of various cables from the end or beginning of a route. This model is characterized by the presence of 2 loops, and the sleeve is a special weave based on a steel cable. This contributes to the excellent flexibility and elasticity of this model during the fixation process, while cable communications are not damaged, and the work of pulling the sleeve of the product does not take a long period of time. The size of the mounting cable stocking with two loops can vary for cable diameters from 10 mm to 180 mm.

Classic cable stocking with two loops

Products are manufactured with two loops of various modifications:

- A cable stocking with two loops called extended is suitable for cable diameters from 10 mm to 180 mm;

- A detachable (pass-through) cable stocking with two loops provides temporary fixation of electrical wires at any location along the route along its entire length. Fixes perfectly without adding unnecessary weight to the system. Ideal when you need to tighten the cable system to a certain point. The hose is usually made of steel cable, additionally galvanized for reliability, which is quite soft and elastic, accordingly, damage to the insulation or conductive wires is completely eliminated, and is made for cable diameters from 10 mm to 180 mm;

Pass-through cable sleeve with 2 loops

- Detachable (pass-through) cable stockings with two elongated loops are also designed for core diameters from 10 mm to 180 mm;

- The main purpose of supporting cable stockings with 2 loops and a detachable mechanism is to fix any routes to special supports. Moreover, this model can be fixed along the entire length of the wires. They are produced to suit the diameter of electrical conductors from 10 mm to 95 mm.

Support cable stocking with 2 loops

- When carrying out repair work related to partial or complete replacement of the route, transit cable stockings, also called connecting stockings, are used. New wires are fixed to ground using a transit (connecting) sleeve, and when the old wire is pulled out, a new wire is automatically pulled. Moreover, all work is completed quite quickly and easily. This system is used in the case of dismantling and installing new cables at cranes or funiculars. The system is designed for cable diameters from 10 mm to 95 mm. The total length of the stocking can reach about 12 m;

- The stocking with a double clamp allows for temporary fixation of air communications and is a weave, which consists of 3 types, provides reliable fixation and the necessary flexibility, suitable for cables with a diameter of 8 mm to 17 mm;

- Cable stockings for wiring with a low total weight secure electrical communications, fiber optic cables indoors, and are also ideal for networks in moving parts of the premises, for example, in elevator shafts. On request they can be produced with 1 or 2 loops. Additionally, lightweight cable stockings can be manufactured. They are produced from stainless steel. Cable stockings can be produced specifically for optical cables with 1 or 2 loops at the request of the customer;

- For laying cable systems underground, special cable stockings with one or two loops were produced. They are made from a very strong steel cable consisting of 19 strands; they can withstand a lot of weight, but at the same time have the necessary flexibility. Can be through or triple with one loop;

- A special series of cable stockings was developed for laying the intra-house cable system. Their distinctive feature is the presence of an M5 threaded connection.

Weaving cable stocking

There are many more varieties of these products. Today, any self-respecting company produces a wide range of cable stockings for every taste and produces models according to all customer requests and criteria. When working with any volume of various power and other cables, these products are simply irreplaceable and really speed up the work process, without compromising quality.

Common mistakes

There are three main mistakes to watch out for:

- If the edge of the cable is not fully inserted into the sleeve of the stocking, then a breakdown may occur during installation. It is also possible that the wire will become damaged.

- Make sure the diameter of the cable and the stocking match. It is strictly forbidden to increase the diameter of the laid wire using a piece of hose or adhesive tape.

- If a stocking is used on an aluminum sheathed cable, the surface must be protected by a feed tube.

Thus, the process of laying cables underground requires skills and special tools. You can simplify the task as much as possible by using a cable stocking, which is used for the rapid installation of high-voltage lines or as a mechanism for gripping wires. Although it is considered the main device necessary for laying a cable line, a number of other mechanisms must be used in conjunction with the stocking.

Typical mistakes when working with cable stockings

- Incomplete advancement of the cable end into the sleeve is accompanied by the risk of the stocking being torn off and the cable being damaged.

- The cable sleeve must only be installed on cables with a suitable diameter. It is not allowed to increase the diameter of the cable being pulled by using a piece of hose or wrapping it with adhesive tape due to the danger of these elements breaking off when high pulling forces occur.

- When using a stocking, the surface of cables with an aluminum sheath must be protected with a special feed tube.

Rate the quality of the article: