Varieties

Electrical insulating casings can be made of different materials. The most common are PVC based due to their low cost and ease of use. This is not a disposable item, it can be reused.

Insulating tubes with different parameters

The following types of isolation are available to users:

- heat resistant;

- heat shrinkable;

- cotton.

Heat resistant insulation

In the production of this type of insulation, fiberglass materials are used. They are resistant to high temperatures that occur during short circuiting. They do not burn, do not corrode and retain their shape under strong physical impact. Heat-resistant tubes are impregnated with resins and polymers. Operating temperature - from -60 to +530 degrees.

Heat-resistant cambrics include tubes with solder. The inner part is made of heat-resistant plastic. Inside there is a solder ring, which melts under the influence of temperatures and envelops the wires at the point of twisting. They should be tinned first. Such rings protect the tube from involuntary movements.

You may be interested in this Features of cable ties

Heat-resistant type of insulation for wires

Main characteristics:

- does not conduct electric current at all;

- the wall thickness reaches 3 mm, which prevents the passage of current and complicates the work a little;

- does not melt or burn;

- the internal diameter is quite large - from 10 to 150 mm;

- the operating temperature is set at -60 to 530 degrees;

- does not change properties when exposed to cold.

Heat shrink sleeves

The use of insulating tubing in electrical applications has been simplified thanks to heat-shrinkable tubes. They reduce the diameter of the pipe at the heating site. This property allows the use of insulating tubes with a reserve diameter. Wires, terminals and solders easily fit into them and, when the temperature rises, they take the necessary shape to protect the assembly. Polyethylene, polymers (PET, PVDF, PTFE), rubber and PVC are used in production. What these materials have in common is that they stretch when heated and contract when the temperature drops. Capable of tightly fitting the insulation area and the contact plate.

Heat shrink type of insulation

The diameter of the tube can be 2 times the diameter of the wire. This gives superiority to heat-shrinkable tubing compared to PVC and heat-resistant tubing.

Advantages:

- the temperature range allows the tube to be used in electrical installations;

- release of fewer harmful substances during heat shrinking;

- long service life compared to electrical tape;

- immunity to corrosion;

- does not react with chemicals.

Important! Before heating, the thermal casing should slide and not dangle. If all rules are followed, the result should be moisture-proof insulation.

You can understand what heat shrink casing is and how to use it by reading above.

Available colors of heat shrink tubing

Structure

The color marking of cambrics is developed and produces models with more than 100 shades. You can also order a color of your choice. Clear tubes available. Designed for more careful installation. They are easy to label. They have poor heat resistance.

You may be interested in Checking the cable cross-section

The manufacture of cambrics occurs using polymers such as:

- Latex rubber;

- Fluorine rubber;

- PTFE;

- PVDF;

- PET;

- cross-linked polyethylene.

Insulating tubes with markings

The main advantages of using cambric

Cambric is a universal material that is suitable for all types of connections, as well as for exposed parts of cables and wires. What are the advantages of this type of insulation:

- Low cost, which makes it quite popular. But gradually more modern consumables are pushing these products out of the market.

- Versatility. It is enough to choose the correct diameter, and you can mount the cambric on any open current-carrying part.

- Long service life. If the connection of the wires (for example, by crimping with sleeves) is made correctly and there is no excessive heating of the conductors, then the cambric will last quite a long time.

- Reusable. For example, when dismantling an old shield, you can remove the cambrics and use them for their intended purpose in another place.

- Strength. The cambrics are quite durable, this allows you to put them on joints without worrying about the safety of the material.

- Can be used as a basis for marking conductors. To do this, you need to choose a light cambric, put it on the wire or cable, and sign it. Helps restore markings that have faded over time or been damaged during work.

Cambrides are a multifunctional consumable material for wires; due to the difference in diameters, they can be used not only for connecting conductors, but also for laying telephone lines and signal networks, where currents and voltages are small.

CAMBRICK is... What is CAMBRICK?

- CAMBRICK - husband. English, thin paper fabric, cambric decos. Dahl's Explanatory Dictionary. IN AND. Dahl. 1863 1866 ... Dahl's Explanatory Dictionary

- cambric - noun, number of synonyms: 2 • cambric (3) • fabric (474) ASIS Dictionary of Synonyms. V.N. Trishin. 2013 ... Dictionary of synonyms

- cambric - - [Ya.N.Luginsky, M.S.Fezi Zhilinskaya, Yu.S.Kabirov. English-Russian dictionary of electrical engineering and power engineering, Moscow, 1999] Topics of electrical engineering, basic concepts EN cambricvarnished cambric ... Technical Translator's Guide

- cambric - CAMBRAI or CAMBREZ, CAMBRICK, CAMBRAI cambrai m. The type of linen is linen, white, pure and thin... These linens got their name from the province of Camberz and the capital city of Cambrai. Sl. comm. 1790 3 34. Cambric, cambrai, light, ... ... Historical Dictionary of Gallicisms of the Russian Language

- cambric - cambric, from English. cambric cambric from Cambrai in Flanders (lat. Camaracus), French. toile de Cambrai; see Matzenauer 201; LF 8, 42; Strekel 44 et seq. ... Etymological Dictionary of the Russian Language by Max Vasmer

- Cambric - see Cotton fabrics... Encyclopedic Dictionary F.A. Brockhaus and I.A. Efron

- Cambric - French. thin linen fabric. Originally manufactured in Cambrai, France. (Encyclopedia of fashion. Andreeva R., 1997) ... Encyclopedia of fashion and clothing

- Cotton fabrics - The vast majority of fabrics made from cotton are the simplest and cheapest products for the household use of the poorer classes of the population. The predominant weaves (see the corresponding article) are simple, shaped and complex-patterned fabrics... ... Encyclopedic Dictionary of F.A. Brockhaus and I.A. Efron

- A float is a fishing device on the line of a float rod that allows the fisherman to notice a bite. Floats A float is a body of rotation mounted on a rod. The working position of the float is vertical, in which a part of the body with ... ... Wikipedia is above the water

- Fishing float - This term has other meanings, see Float (meanings). Floats ... Wikipedia

dic.academic.ru

General information and areas of application

Heat shrink tubing is a plastic structure used to insulate electrical connections. Heat shrinking is used to restore the damaged insulating layer of cables, as well as to prevent their mechanical damage in the future.

The tubes are made from nylon or polyolefins, that is, thermopolymers that change size due to heating. The polymer is heated using hot water, air or an open flame.

Heat shrink acts as a crimping element of the structure. Due to the peculiarity of the technology, channels appear between the stretched insulation and the unevenness of the object being pressed, making the connections insufficiently tight. To achieve high-quality insulation, tubes with glue are used. During heating, the glue, turning into a liquid state, levels out all irregularities.

Heat-shrinkable tubes are characterized by a higher transverse compression ratio compared to the longitudinal compression ratio. As a result, the diameter of the tube can be reduced several times, and the length - by only 20%. High-quality heat shrinks shrink in length even less - no more than 10%.

Due to temperature effects, only the heated part of the tube increases. Its other end retains its original dimensions. As the diameter of the heat shrink decreases, the thickness of its walls increases proportionally, which gives the product insulating qualities.

Heat shrink tubing helps achieve the following tasks:

- They create a reliable insulating layer that protects against electric shock.

- Protect connections from mechanical damage.

- Thermal tubes are used as cambrics (when desoldering connectors), which makes it possible to mark cables and wires.

- Thermal insulation prevents the development of corrosion.

- Act as a barrier between compounds and aggressive environments.

- In the automotive industry, heat shrinks are used to protect brake hoses and fuel lines.

Scope of application

The main task of cambrics is protection against corrosion, additional fixation, and insulation of connections made by welding, soldering, crimping, screws, twisting (the latter option is not recommended by the PUE). Wires with terminal lugs also require insulation. Sections of dielectric material mask connection points and add aesthetics. They strengthen the shell, protect it from ruptures and mechanical damage. Heat shrink sleeves are used to restore insulation sections of AC/DC wiring. Another function of cambrics is wire marking. The necessary data is applied to them manually or using an industrial printer.

Criterias of choice

When choosing, you should pay attention to the internal diameter of the products. It should not exceed one and a half to two diameters of the wire (core)

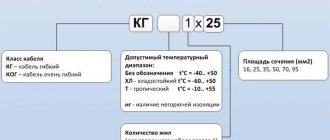

More precisely, the parameters of the tube can be determined by the manufacturer’s marking: he indicates the diameter before shrinkage (numerator) and after shrinkage (denominator) as a fraction.

It is important that after shrinkage the diameter of the tube decreases to a size that is smaller than the diameter of the insulating layer of the wire (cores together with insulation)

Some manufacturers indicate the diameter and shrinkage factor when labeling their products. For example: 20 mm: 1.5:1. Here 20 mm is the initial diameter, and 1.5:1 indicates the range of polymer reduction (in this case, one and a half times). Dimensions may be indicated in inches.

Let's present the main characteristics of the most common heat-shrinkable casings in the form of a table:

Table 1. Main characteristics of heat-shrinkable tubes (HERE)

| product name | Tube diameter, mm | Wall thickness in mm after shrinkage | Shrinkage range, mm | Maximum reduction in length, percentage | |

| Before shrinkage | After shrinkage | ||||

| TUTng-2/1 | 2.0 | 1.0 | 1.8 – 1.2 | 1.8 – 1.2 | 5 |

| TUTng-3/15 | 3.0 | 1.5 | 2.7 – 1.8 | 2.7 – 1.8 | 5 |

| TUTng-4/2 | 4.0 | 2.0 | 3.6 – 2.4 | 3.6 – 2.4 | 5 |

| TUTng-5/2.5 | 5.0 | 2.5 | 4.5 – 3.0 | 4.5 – 3.0 | 5 |

| TUTng-6/3 | 6.0 | 3.0 | 5.4 – 3.6 | 5.4 – 3.6 | 5 |

| TUTng-8/4 | 8.0 | 4.0 | 7.2 – 4.8 | 7.2 – 4.8 | 5 |

| TUTng-10/5 | 10.0 | 5.0 | 9.0 – 6.0 | 9.0 – 6.0 | 5 |

| TUTng-12/6 | 12.0 | 6.0 | 10.8 – 7.2 | 10.8 – 7.2 | 5 |

| TUTng-16/8 | 16.0 | 8.0 | 14.4 – 9.6 | 14.4 – 9.6 | 5 |

| TUTng-20/10 | 20.0 | 10.0 | 18.0 – 12.0 | 18.0 – 12.0 | 5 |

| TUTng-25/12.5 | 25.0 | 12.5 | 22.5 – 15.0 | 22.5 – 15.0 | 5 |

| TUTng-30/15 | 30.0 | 15.0 | 27.0 – 18.0 | 27.0 – 18.0 | 10 |

| TUTng-40/20 | 40.0 | 20.0 | 36.0 – 24.0 | 36.0 – 24.0 | 15 |

| TUTng-50/25 | 50.0 | 25.0 | 45.0 – 30.0 | 45.0 – 30.0 | 15 |

| TUTng-60/30 | 60.0 | 30.0 | 54.0 – 36.0 | 54.0 – 36.0 | 15 |

| TUTng-80/40 | 80.0 | 40.0 | 72.0 – 48.0 | 72.0 – 48.0 | 15 |

| TUTng-100/50 | 100.0 | 50.0 | 90.0 – 60.0 | 90.0 – 60.0 | 15 |

| TUTng-120/60 | 120.0 | 60.0 | 108.0 – 72.0 | 108.0 – 72.0 | 15 |

Please note that in the table the diameters before and after shrinkage repeat the fractional numbers in the product name. You can also find products made from tarred cotton fabrics on sale.

Tubes made from such materials are very durable and provide excellent wire insulation. Cambrics reinforced with cotton fabric, although inferior in hardness to fiberglass tubes, do not collapse under deformation or mechanical stress. The tubes fix the position of the wire well

On sale you can also find products made from tarred cotton fabrics. Tubes made from such materials are very durable and provide excellent wire insulation. Cambrics reinforced with cotton fabric, although inferior in hardness to fiberglass tubes, do not collapse under deformation or mechanical stress. The tubes fix the position of the wire well.

By material

Several types of materials are used to produce heat-resistant cambrics with electrical insulating properties.

There are polyolefin heat-resistant tubes made from so-called “cross-linked” polyethylene with the addition of a number of plasticizers and dyes that prevent the spread of combustion. The overwhelming majority of heat-resistant cambrics are produced using this technology.

The temperature at which they can be used without any restrictions ranges from -50 to +125 degrees. By adding special plasticizers to the material, the temperature range can be expanded to 150 degrees. This also increases its resistance to benzene and other oxidizing agents.

They produce cambrics based on synthetic rubber, which are characterized by increased resistance to high temperatures (up to 175 degrees) and chemically active substances such as lubricants and oils. They have a relatively high price and limited demand.

Heat-sensitive cambrics are produced from thermoplastic polyvinyl chloride. Products made from this material have excellent insulating characteristics, but at the same time have a limited temperature range (from -20 to +80 degrees). The presence of toxic emissions generated during ignition, harmful to health, sharply limits the demand for this type of product.

Features and Properties

Previously, only heat-resistant solid cambrics were used, which were sections of PVC pipes of different diameters. This material practically does not stretch (it cracks under strong tension), so you need to select consumables individually (according to the diameter of the wire/cable). The edges are often wrapped with electrical tape for additional fixation.

Currently, heat-shrinkable cambrics, which shrink when heated, have become much more widespread. Thanks to this, they fit tightly around the joint. Additional fixation of the edges with electrical tape is not required. They are made from cross-linked polyethylene (ethylene polymerized under pressure), as well as from other polymers (PTFE, PVDF, PET) and silicone rubber. They:

- practically not exposed to aggressive factors;

- provide long-term high-quality insulation (including sections of connections with differences in size, which arise, for example, when using non-insulated sleeves for crimping);

- can be operated in a wide temperature range (depending on the type: from -55 to +125 °C, from -55 to +105 °C, from -65 to +260 °C);

- When heated, they do not emit hazardous substances.

The shrinkage coefficient is different: 2 to 1, 3 to 1, 4 to 1, 6 to 1. This indicator indicates how many times the original internal diameter will decrease. Both diameters (before/after) must be indicated in the name (for example, TUTng 40/20). The length of the segment does not change.

The color differs - the tubes are:

- colored (green, red, yellow cambrics are used to indicate phases);

- transparent - most often they are used to mark cable ends.

The diameter is selected individually - after shrinking, it should become smaller than the diameter of the insulated area so that the fit is as tight as possible. The tubes are sold in the form of individual lengths or in coils. The length in the latter case often depends on the diameter:

- 1-3.5 mm – 200 m;

- 6 mm – 100 m;

- over 8 mm – 50 m.

To change the diameter of the tube, a hot air gun is used, and if it is not available, a soldering iron or lighter is used. The optimal temperature can be seen in the specifications or checked with the seller.

It is not advisable to exceed the recommended temperature.

Fiberglass heat-resistant cambric has improved electrical characteristics, such as:

- non-flammability;

- optimal thermal conductivity;

- high-quality electrical insulation (dielectric density - 800-1200 V);

- increased strength.

This insulation is used to protect joint areas when exposed to high temperatures (up to +400°C). During manufacturing, the fiberglass braid is subjected to heat treatment and impregnated with silicone varnish. This tube is used to insulate connections of heating elements and devices, electrothermal equipment, and heat-resistant cables. The internal diameter varies widely (3-150 mm). The wall thickness is 2.5-3 mm.

Types of cambrics

There are two main types of cambrics: cambrics made of PVC and heat-shrinkable tubing. In turn, the latter are divided into:

- high-voltage - have high resistance, are used at high voltage;

- fluorescent - have a glow, used in buildings with limited lighting;

- with a corrugated surface - used where slipping needs to be eliminated;

- Teflon - expensive consumables, used at high temperatures, resistant to combustion and chemical environments.

Cambrics made from polyvinyl chloride do not expand either in width or in length. When choosing this type of product, you must carefully select the diameter corresponding to the cross-section of the wire. Otherwise, when insulating a wire with a large cross-section, the cambric may simply burst.

In addition, this type has its positive qualities: the possibility of reuse, endurance of chemical environments, resistance to various temperature conditions, durability in use, and the product has a low cost.

When choosing heat shrink tubes, you need to pay attention to the shrinkage coefficient. Frequently occurring tubes have a ratio of 1:2, 1:3, 1:4

This means that they have the ability to shrink two, three or four times. A distinctive feature of this type is the provision of electrical network contacts with reliable insulation and durable fastening.

When using them, there is no need to purchase tubes with the exact diameter. This type is endowed with such qualities as protection against corrosion and moisture. The inner side of the heat shrink is covered with an adhesive layer. During the shrinking process, the glue evenly fills all the irregularities.

Heat resistant insulation

These tubes are made from fiberglass. They are able to withstand temperatures from -60 to +150 degrees. For better efficiency, the tubes are impregnated with varnish. They are mounted on the wires of internal connections. This method is suitable for household appliances: heaters, electric kettles, electric stoves.

Heat shrink sleeves

These types, unlike other cambrics, are made of polyethylene or other polymers. When heated, such tubes can shrink by half. With this positive point, it is allowed to use the same size for a larger wire diameter.

When using cambric as insulation, it is possible to insulate various terminals and connections, since the shape does not affect the properties of the covering. The shrink sleeve will copy and cut for different contour.

In addition, heat shrink is highly stretchable, but this must be done with caution. If you do not have the required diameter at hand, the tube may be pulled over terminals and cables of a larger size

Also, this type of cambric is available in colored and transparent versions, this allows you to sort the wires according to their intended purpose.

Heat-shrinkable tubes have a number of positive qualities: when ignited, heat-shrinkable tubes practically do not release harmful toxic substances; ability to withstand high temperatures; do not interact with chemicals; unlike electrical tape, they have a long service life; eliminate corrosion and oxidation of contacts.

Heat-shrinkable casings are in demand among specialists, and purchasing them is not difficult.

When exposed to hot air, it shrinks well to the necessary connections in the electrical circuit. This can be done using a hair dryer, matches or a lighter.

You can also use a soldering iron, but this must be done with caution so as not to damage the tool.

What is cambric and heat shrink cambric?

In short, cambrics are small insulators made from various materials. There are two types of cambrics: regular and heat-shrinkable. Conventional cambrics are made primarily from flexible multi-colored polyvinyl chloride and are called PVC cambrics. There are also other specialized types of cambrics made from resin-impregnated cotton fabric or fiberglass fabric coated with layers of various polymers. Heat-shrinkable casings are made from cross-linked polyethylene and other specific polymers (PET, PVDF, PTFE, silicone rubber, etc.).

Heat-shrinkable (heat-shrinkable) cambric is a piece of heat-shrinkable tube used as electrical insulation for various conductive elements of electrical equipment, usually designed for a voltage of no more than 1000 volts DC, but more often in low-voltage equipment.

Most often, cambrics are used to restore the insulating sheath of wires or individual cable cores at the point of their connection (soldering) with contact plates in various electrical connectors and connectors. The cambric can be used to insulate and protect passive elements of printed circuit boards (resistors, capacitors, etc.) or their current-carrying parts from contact with each other and the printed circuit board itself. The cambric can also act as a mechanical protection, protecting wires, cables, contacts, connecting units from corrosion, kinks and damage. Additionally, cambrics can perform a marking function, designating different conductors and contacts in different colors (see photo). Also, with the help of special printers, various inscriptions and drawings can be applied to regular and heat-shrinkable cambrics, which allows you to mark a large number of conductors in more detail.

Cambrics can be used to secure objects in various devices. For these purposes, cambrics (both regular and heat-shrinkable) are very popular among fishermen to make various fishing accessories, using them to secure floats and hooks on a fishing line. What hooks are there! Fishermen manage to catch fish using ordinary multi-colored cambers, imitating worms and other edible animals!

Although both types of cambrics are used for similar purposes, there are some differences in their properties and applications. The simplest, ordinary cambric, which is a PVC plastic tube cut into pieces of the required length, has a fixed diameter, which means it requires careful selection of the diameter. If, for example, the thickness of the conductor soldered to the contact is significantly less than the thickness of the contact, then the casing cannot be placed on the soldering unit. Although such a cambric can be slightly stretched in width by forcefully pulling it onto the contact, its stretch margin is very limited. The casing may not fit onto the contact or may burst.

Heat-shrinkable cambric has an advantage over PVC cambric, since its diameter tolerances are incomparably greater. After all, as soon as you heat it up, it will shrink to the desired size, similar to a heat-shrinkable tube, tightly crimping both the contact point and the wire. Not only will the heat-shrinkable casing provide reliable electrical insulation of the assembly, but it will also be firmly attached to the insulated assembly. This eliminates the need for very precise initial adjustment of diameters. The diameter difference between the contact and the cable core can be up to 1.7-1.8 times! Additional advantages of heat-shrinkable casings include a wider range of operating temperatures, less toxicity in case of equipment fire, resistance to corrosion and aggressive liquids, long service life, the ability to use heat-shrinkable casings with an adhesive sealing layer, etc.

But regular cambric also has its advantages. First of all, this is its low cost and the possibility of repeated use. After shrinking, the heat-shrinkable casing cannot be removed from the product without damaging either the casing itself or the equipment elements. This can be done easily with a regular cambric. Just don’t forget that heat-shrinkable cambric can be used for its intended purpose without mandatory thermal shrinkage, in a “reusable” mode, simply as an insulating tube.

www.gradiant.ru

How to use cambric

Ideally, shrinking should be done with a stream of hot air. Any hair dryer is suitable for this. But more often it happens that it is not at hand or there is nothing to connect it to.

The second option is a soldering iron. Walk the heating element casing over the surface of the tube and it will shrink. The stinger does not need to do this for three reasons:

- Too high a temperature can melt the cambric.

- The sting leaves traces of soot.

- So as not to spoil the sting.

The third option is to use fire sources. This could be matches or a lighter. Keep the flame a couple of centimeters from the heat shrink, so as not to damage it, walk with quick and short movements on all sides to achieve uniform contraction of the insulating layer. For a quick effect, you can do this directly with the flame, then the movements should be even faster, and you should be more attentive. The disadvantage of this method is that traces of burning may remain on the cambric. Turbo lighters do not have this drawback, but the flame temperature is very high and it is easy to burn the pipe, so keep the flame stream away so that only streams of hot air hit it.

The video example clearly shows how to use casings for wires:

Characteristics and differences

What types of heat shrinks are there and how do they differ from each other?

Diameter before and after

The heat-shrinkable tube changes diameter when heated. Therefore, the name should always include the size BEFORE and AFTER shrinkage.

For example, tube HERE NG 40/20

- internal diameter 40mm - BEFORE

- diameter of full shrinkage 20mm - AFTER

Shrinkage coefficient

The next criterion is the shrinkage coefficient. What it is? This is the ratio of the original diameter to the diameter after the shrinkage process. That is, depending on the coefficient, the tube is reduced several times. There are odds:

- 2 to 1

- 3 to 1

- 4 to 1

- 6 to 1

The larger it is, the more difficult the product is to manufacture. Accordingly, their prices differ significantly. However, 4 to 1 tubes are considered more versatile than 2 to 1. If you connect two wires of different sections and different thicknesses, without heat shrink with large coefficients. you can't get by.

Wall thickness

Thermal tubes can have different wall thicknesses. According to this criterion they are divided into:

- thin-walled

- mid-range

- thick-walled

In addition, the thermotube can be adhesive - brand TTk. This is the one that has a layer of hot-melt adhesive applied to the inner surface. When heated, the glue melts and fills all microvoids, thereby ensuring complete sealing.

The walls stick to almost any surface. Excess glue should protrude around the edges.

It will not be possible to replace such hot-melt adhesive by first coating the inner walls of a simple tube. It is applied precisely during its manufacture. In addition, the adhesive coefficient of heat shrinkage is greater than that of a regular one - 3 * 1 or 4 * 1 versus 2 to 1. It can also be designed for greater stress due to the thickness of the walls.

Non-flammable

The material from which the product is made is of great importance. It is thanks to the composition of this material that the necessary properties are set in advance. If, for example, fire retardants are added to the composition, the tube acquires self-extinguishing properties and is designated by the NG index.

This does not mean that it does not burn at all. But in the absence of an external source of flame, it will quickly go out. This is achieved by preventing the flow of oxygen to the fire site with fire retardants.

In this case, you can no longer use the usual cheaper option.

Color

Heat shrink tubing comes in a variety of colors, including clear ones. They are mainly used for marking.

They are very convenient for marking the ends of the cable, if you adhere to the old rules of color designation of phases. It is enough to place individual pieces on the end of the core.

For phases A-B-C, buy J (yellow) - G (green) - K (red).

But according to the new GOST, fA-fV-fS correspond to the colors K (brown) - CH (black) - S- (gray). Here you will have to use transparent tubes, or buy them to order.

There is also an original solution using multi-colored tape, on top of which a transparent thermal tube is applied. So the phases will be marked according to the new rules.

If you do not need color designation of phases, then take black ones. They are cheaper, and the quality of insulation is the same.

This is due to the specifics of the technological process. After each run of the same color, the auger is cleaned of old material. And this is precisely what affects the cost.

There are also two-tone yellow-green products. They are intended for grounding wires.

When you want to see and control the contacts after installation, a transparent tube will help you in this matter. Just be careful. Transparent ones will no longer be non-flammable products. Since the addition of fire retardants always leads to a change in color.

True, in this case it is better to heat the transparent heat shrink with a hairdryer rather than with a torch. Otherwise, you may accidentally damage the inscription itself.

There are also semiconducting heat shrinks and equalizing electric field strengths.

But still, the usual electrical insulating ones are most often used. They use a material with high electrical insulating properties and have high electrical strength. Moreover, the higher this electrical strength, the higher the voltage class they are designed for: up to 1 kV-10 kV-35 kV.

Despite the fact that heat-shrinkable tubing was invented in the last century, it still remains an innovative product in the electrical market. You can select and order your own sets of thermal tubes here.

Heat-shrinkable tubes - shrink when heated

Although a heat-shrinkable tube or cambric performs the same tasks, it differs from the usual one both in the method of application and in the material from which it is made. Typically these are polyethylene and other polymers.

Heat shrinkage when heated can decrease by half. This advantage allows the same tube size to be used for a much larger range of wire sizes. This gives a definite advantage when used as insulation for various kinds of terminals and connections, because the shape of the terminal strip does not affect the quality of the covering. The heat shrink will shrink and follow any contours.

Heat shrinkage stretches well, up to 1.5-2 times its original value, but this must be done carefully, ensuring the integrity of the surface. This way you can stretch heat shrink onto wires and terminals if you don't have the size you need.

The next difference from heat-shrinkable PVC tubes is their appearance - they are sold in any color, including completely transparent or with color. This opens up even more conveniences for marking, for example, the wires of one group are divided by color and labeled by contact. Like regular cambrics, these products are inexpensive, but they can be found in every electrical or household goods store.

Which type of cambric is better?

When going to a specialized electrical goods department, many consumers often ask the question: “Which wire casings are best to use?” The right choice largely depends on what type of insulation you plan to perform. For example, in order to prevent short circuits on electrical boards, it is necessary to choose heat-shrinkable material. It tightly fixes the area of interaction of parts.

When exposed to high temperatures, it begins to melt, thereby creating resistance in the area of open sections of the conductor circuit. The diameter of the heat shrink tube should be 2 mm larger than the thickness of the wire.

For electrical appliances with high temperature conditions, it is necessary to choose heat-resistant insulators. They have thermal protection and high-quality insulation.

The advantages of consumable thermal material include:

- wide temperature range. These products can be used at different levels of an electrical circuit;

- safe composition. During the heating process of the plastic surface, no toxic substances are released that negatively affect human health;

- long service life;

- does not come into contact with chemical components. As a result, the risk of premature equipment failure is reduced;

- Excellent resistance to corrosion of parts and oxidation of metal surfaces.

Modern models of heat shrink material have an additional substance in the inside of the tube. When heated, it increases the adhesive ability of the plastic. Thanks to this, the connection point has a good seal. The heating temperature of the insulator surface is 60°C.

Ordinary cambric also has good electrical insulating ability. To do this, you need to choose the right size and diameter of the rubber tube. The main advantage of this product is its repeated use. If a crack appears on the surface of the product, its further use is prohibited. In addition, it has a low cost.

Heat-resistant insulators are often used in the design of an induction furnace, oven or drying chamber. It protects the place where semiconductors are fixed in the electrical circuit and reduces the impact of high temperature on device parts. You can mark adhesions on its surface.

Technical characteristics of heat-resistant material include:

- electrical impermeability. This type of insulator practically does not conduct electric current;

- The wall thickness of the product reaches from 2 to 2.5 mm. This makes it possible to create a strong barrier on the electrical circuit;

- fire resistance;

- large selection of tube diameters;

- high level of temperature exposure. It is used in areas of the electrical circuit with temperatures from -55 to 600 °C. The photo of cambrics shows models of insulating material.

Cambric is... What is Cambric?

fashion.academic.ru

Purpose of products

The main purpose of heat shrink is to insulate current-carrying conductors. Due to the electrical insulating properties and ease of installation of the product, they are increasingly replacing conventional electrical tape.

Today, similar products used to protect the switching of conductors can be easily found on the shelves of electrical goods stores. The demand for thermocambrics as an insulation material lies in the ability to reduce their size under the influence of heat. The required shrinkage temperature is no more than 120 °C. However, in order to do the job correctly, you need to know how to use heat shrink tubing. When exposed to high temperatures, the product is tightly and securely fixed to the conductor, providing insulation and mechanical protection.

Today, manufacturers provide a wide range of colors and sizes of heat shrink tubing. Due to this, they are used not only for insulation, but also for accurately determining in the future the purpose of the insulated conductor.

Thus, when processing DC conductors, many electricians use red tubes for the positive and black tubes for the negative. The five-core electrical cable is marked as follows:

- black, brown, and white - phase conductors;

- blue - 0;

- yellow or green - grounding.

Using a heat-shrinkable tube to mark the conductors is very convenient, because it does not need to be placed along the entire length of the conductor. You only need to pull a small piece of the product over the insulating layer onto the end of the wire. This material is very reliable, resistant to external influences and temperature changes. The service life of a thermotube is at least 20 years. These are durable, budget-friendly and easy-to-use products.

PVC pipes and cambrics - application, advantages of use

Quite often, when installing electrical wiring, smooth rigid PVC electrical pipes and cambrics are used as elements of cable support systems, in addition to plastic and metal boxes or corrugated pipes.

PVC pipes

. They are a “hard” version of corrugated pipe. From the name it is easy to understand that they are made from polyvinyl chloride. The material composition of most of these products includes additives that prevent the spread of combustion.

The main purpose of electrical PVC pipes is to lay cables and wires in them. In addition, the manufacturing material and its rigidity impart a certain strength and localization properties to the products, which, in some cases, allows them to be considered as protection for wires and cables.

They can be laid under a layer of plaster or self-leveling floors, which can be convenient for their further maintenance; In this case, the wires are hidden and for repair (replacement) you just need to pull them out from one side of the pipe.

Thus, by using them when installing hidden electrical wiring in premises, it is possible to achieve compliance with the requirements of the Rules on its replacement (PUE-7 clause 7.1.37).

In the case of open electrical wiring, the use of PVC pipes increases the level of fire and electrical safety, significantly reducing the possibility of exposure to electric current to a person in case of possible insulation failure.

The most common form of product release is 3-meter sections with an outer diameter from 16 to 63 mm. Small-diameter pipes bend relatively well, which cannot be said about products with a diameter of more than 25 mm or more.

The rigid structure due to the strength of the material and the thickness of the walls does not allow them to be given the required shape by bending without damage, therefore, various components are used for routing and turning: swivel units, tees, plugs and couplings.

Special plastic clips can be used for fastening. Thanks to them, the installation of electrical pipes is a fairly quick and uncomplicated process: fixation occurs by simply snapping the pipe into clips fixed to the wall surface.

And with the help of plastic clamps (or “ties”) or dowel clamps, you can fasten the pipes, as they say, in a hurry. In addition, this mounting method is cheap and simple. When laying hidden wiring, no additional fasteners are required.

Cambrics

. This type of electrical installation products are essentially covers, flexible hoses made of polyvinyl chloride or polypropylene - materials with excellent dielectric properties that can be placed on wires and cables over the sheath or insulation.

The insulating properties of cambrics are successfully used to restore damaged sheathing of wires or insulation at the point of their contact connections. Quite often, labeled cambrics are used to identify a large number of wires with single-color insulation in the absence of factory markers.

The use of this product can also be justified if it is necessary to give a cable or wire a more aesthetic appearance, enhance its protection, or combine several conductors into one backbone.

These electrical products complement the already rich set of modern means of laying cables and wires, expanding the possibilities for installing electrical wiring.

CAMBRICK is... What is CAMBRICK?

dic.academic.ru

Selecting Heat Shrink

When choosing a heat shrink tube, the following parameters are considered essential:

- initial diameter and the same characteristic after shrinkage;

- type of material, its resistance to chemical environments, as well as flammability;

- shrinkage factor;

- wall thickness;

- presence or absence of an adhesive layer;

- heat shrink color or transparent version.

It is recommended to pay special attention to the possibility of interaction of heat shrinkage with fuels and lubricants. If such contact is planned, the product must be oil and gasoline resistant

Insulation of high-voltage cables must be carried out with tubes specially adapted for this purpose. They are capable of performing their functions at voltages up to 1000 V.

When choosing the diameter of heat shrink, you should proceed from the “10.20” principle. This rule means that the minimum shrinkage should not be less than 10% of the original diameter, and the maximum should not be more than 20%. An example of the implementation of this rule is shown in the figure below.

Note! Heat shrink tube gives longitudinal shrinkage

What is cambric used for in electrics?

The main task is to insulate electrical cables, but people have come up with a lot of other uses, from the role of covers for screwdrivers and awls, to use in fishing gear. Connecting cables by twisting (already prohibited by the PUE), soldering, welding, bolts, sleeves, as well as wires terminated terminal lugs, need to be insulated. Most of these connections can be fitted with a cambric. For additional fixation and protection from moisture, the edges are fixed with electrical tape, and if one of the edges is free, it is heated with a lighter and squeezed with pliers.

In addition to insulating the connections, you can restore the insulating layer of the wire using cambric, securing its edges with electrical tape so that it does not move. This type of insulation is suitable for DC and AC circuits up to 1000 V.

An additional function is marking. A black felt-tip pen or marker is clearly visible on light cambric. In any circuits, both power and signal and communication lines, a casing with the wire marking is placed at the ends of the cable near the terminal.

Cambrides come in different sizes; select products that are a couple of millimeters larger than the diameter of the cable, otherwise it will constantly fall off or not fit. If you try to stretch it to the required diameter, it may burst, because... There is almost no size reserve for this product. Heat-shrinkable tubes do not have this disadvantage. In addition, PVC pipes dry out and crack when heated, and become very hard in cold weather.

Products TKR, TKSP (selection order)

For the manufacture of flexible heat-resistant tubes of the TKR-M brand, organosilicon mixtures are used that meet the requirements of GOST 17675. They are usually chosen when it is necessary to obtain reliable electrical insulating protection of the joints formed during installation. To increase it, special reinforced products of the TTSP-SV or TKSP brands are used.

The latter are made in the form of a special stocking made of tightly woven cord (glass thread), impregnated with varnish based on organosilicon compounds and coated with rubber of the same class.

All of the listed types of heat-resistant tubes can be purchased at any retail outlet that has electrical installation products in its assortment. Using heat shrink casings is very simple.

You need to put them on the wire, place them in the required place and heat them with a lighter, match or hot air gun. Heating is carried out from the center to the edge or from one edge to the other. When the material has shrunk and cooled, the insulation process is complete.

Types of pipes

Heat shrinks are usually classified according to a number of characteristics. First of all, the tubes are divided according to the type of material from which they are made:

- Polyolefin. This material is based on polyethylene, cross-linked using chemical or radiation technology. The product also contains dyes, plasticizers, flame retardants and a number of other substances. Polyolefin tubing operates in a temperature range from 50 degrees below zero to 125 degrees above zero. Some modifications with special additives are able to maintain performance at 150 degrees. Polyolefin is highly resistant to benzene and strong oxidizing agents. Polyolefin tubes are not resistant to prolonged contact with fuels and lubricants.

- Synthetic rubber elastomers. The main feature of the material is the ability to maintain functionality at elevated temperatures (up to 175 degrees). Elastomers are used when constant interaction with fuels and lubricants is necessary. The main disadvantage of elastomers is their high cost. In this regard, elastomers are rarely used and only in cases where there is nothing to replace heat shrinks from this material.

- Polyvinyl chloride. Thermoplastic PVC is used for the production of heat shrinks. The material has high insulating characteristics. Its main drawback is its small temperature range (from 20 degrees below zero to 80 degrees above zero). In addition, polyvinyl chloride is toxic when burned.

- Polyester. It is considered a more successful material compared to polyvinyl chloride. It has greater strength and resistance to aggressive chemical environments.

- Fluoropolymers. Modern developments in the field of materials science have made it possible to create heat shrinks with excellent characteristics. We are talking primarily about the ability of fluoropolymers to maintain performance characteristics under extreme temperature conditions. The widespread use of fluoropolymers is hampered by their high cost.

- Silicone. Heat shrinks made from silicone are characterized by plasticity and the absence of toxic emissions. The material is characterized by high chemical inertness and electrical strength. The disadvantage of silicone is its low resistance to the destructive effects of organic solvents. Therefore, such heat shrinks are not suitable for contacts with fuels and lubricants.

Heat-shrinkable tubes are classified according to other characteristics:

Heat shrinks with additional capabilities are available for special needs. For example, there are heat-shrinkable tubes of increased diameters, with a corrugated coating, fluorescent additions, and increased electrical density.

An important parameter of heat shrinkage is its ability to withstand external influences. In accordance with this indicator, it is customary to distinguish the following properties of heat shrinkage:

- oil resistance;

- inertness to chemical media;

- high voltage (some tubes can withstand voltages up to 1000 V);

- light-stabilizing qualities (resistance to solar radiation);

- heat resistance (lack of flammability).

Heat-shrinkable tubes come in round, oval and flattened shapes. This parameter does not affect the performance of heat shrink in any way. The shape of the tube only affects the method of its transportation.

Related Posts

- Heat shrink tube: dimensions, characteristics, rules of use

- Cable current cross-section

- Pugnp and punp wires: characteristics, differences, prohibition of use

- Using PVC wire according to the characteristics and description

- Wire cross-section for home wiring: how to calculate correctly

- Connecting wires: how to connect wires together, what kind of terminal blocks there are, mounting options with and without soldering

- Technical parameters and scope of application of heat-resistant wire RKGM

- Repair of electrical equipment on ships - cable termination

- Wire pv-1: description and characteristics

- How to glue fiberglass correctly?

- Wood screws: table with dimensions, features of choice and nuances of use

- What color is phase and zero in electrical engineering?

- Copper pipes and their use in air conditioners

- Pvs cable. pugsp, pugnp: alphanumeric marking and decoding

- Triple socket in one socket

- Wiring diagram and installation of electrical wiring in the kitchen

- Options for making shelves for the garage with your own hands

- Baseboard and floor electrical sockets. device and installation

- Connecting sleeves for crimping wires: types, features, crimping tools

- Overview of electrical wire connectors

- Calculation of well volume

- Disadvantages of polypropylene pipes in home heating

- Which pipes are best to choose for a water well?

- Benefits of using a duct extension for radiators

- How to check grounding

Read with this

- Heat shrink tube: dimensions, characteristics, rules of use

- Cable current cross-section

- Pugnp and punp wires: characteristics, differences, prohibition of use

- Using PVC wire according to the characteristics and description

- Wire cross-section for home wiring: how to calculate correctly

- Connecting wires: how to connect wires together, what kind of terminal blocks there are, mounting options with and without soldering

- Technical parameters and scope of application of heat-resistant wire RKGM

- Repair of electrical equipment on ships - cable termination

- Wire pv-1: description and characteristics

- How to glue fiberglass correctly?