Bored piles are a fairly simple technology that most often does not require special complex equipment. The essence of the method: drill a well and fill it with concrete. It happens that reinforcement is used for concreting. When constructing objects on unstable soils, formwork is installed. For large-scale construction, casing pipes are used.

In the article we will talk about the types of bored piles, the technologies for their construction, as well as the pros and cons of a pile foundation.

Areas of use

Bored piles are used in the construction of urban facilities. This is suitable if there is a building nearby that needs to be preserved (from other pile driving methods, dynamic vibrations may spread to neighboring buildings).

They are also used when constructing objects in wetlands or too weak soil.

During the construction of the Crimean Bridge in the Kerch Strait, bored piles were used.

In addition, if you need to build a house on steep terrain or large industrial facilities.

Advantages

- When building a foundation, there is no need to be afraid of damaging neighboring structures, since driving such piles does not have a dynamic effect on them.

- Piles are laid at the depth where the soil freezes.

- The installation technology does not harm the surrounding landscape; it can be installed on uneven ground.

- Can be used on poor soils.

- There is no need to import a large number of finished piles.

Pile classification

Bored piles vary in shape, material, manufacturing method and reinforcement technology.

- Piles can be in the form of a cylinder of the same section or of different ones, including with a widening of the lower end.

- Material - concrete, a mixture of concrete and reinforcing steel, a solution of cement and sand.

- According to the method of reinforcement, they come with reinforced frames along the entire length or part of it.

The manufacturing method will depend on the geological and hydrogeological conditions at the construction site. The choice of technology will also be affected by the type of working equipment.

The main methods for making piles can be identified:

- Arrangement of special fastenings for well walls.

- Arrangement of walls in such a way that protects them from collapse: most often, a clay solution or water under high pressure is used for this.

- Fastening the walls of the well using casing pipes: non-removable or inventory.

The Code of Rules called SP 50-102-2003 contains a complete classification of all types of bored piles. It describes how different types of foundations are designed, based on piles.

The decision to use one or another type of pile as a foundation or enclosing wall is made based on the results of geotechnical work carried out. The surveys will help determine the properties of the soil and the presence of groundwater.

Technological features

Typically, the diameter of bored piles does not go beyond 880-1200 mm. They can reach 35 m in length. In order for the piles to take shape, a cast concrete mixture is used.

To make different pile designs, four methods are used:

- Continuous screw technology. Inside it is a cavity for supplying concrete to the lowest point of the well.

- With casing pipe. It is immersed and removed using a vibratory driver. This way the walls are protected.

- With bentonite solution, which does not allow the walls to crumble.

- Technology with a casing pipe that is immersed using the rotation method.

Continuous screw technology

This technology is used in strong soils, most often in clayey soils.

The auger has a pipe to which a special spiral is welded, capable of removing soil. This is how a well is drilled into the ground. The auger rotates, the drilling part crushes the soil, and it is fed in a spiral to the surface.

At the end, the internal cavity is closed with a plug with a check valve function: it does not let the drilled soil into the cavity.

First, the desired depth is selected, the plug is opened, concrete is gradually supplied and the well is filled. When it is full, the auger is removed (by rotating or simply pulled out without rotating).

In order for the concrete to harden, the well is left with the solution for some time.

To install reinforced concrete piles, a frame made of reinforcement is lowered into the well with a vibrator.

Using this technology, it is possible to produce bored piles up to 30 m in length and with a diameter of 400-1200 mm. It is not recommended to use this technology in conditions of ground or industrial aggressive waters.

Casing technology

This method is used when the soil is landslide or unstable. The casing pipe is capable of protecting the well: it prevents the walls from collapsing during drilling, “holds” the layers of soil around the well so that they do not put pressure, and prevents the reinforcement cage from collapsing when it is inserted.

The technology process is as follows:

- You need to immerse the pipe in separate parts (you need to remove it in the same way).

- Immersion method: indentation, vibration or rotation. Afterwards you need to remove the drill and the remaining soil, fill the pipe with concrete or reinforcement cage.

The reinforcement is placed in the center of the well to obtain a protective layer of 60-70 mm. The next stage is pouring the concrete solution and compacting it. The well is filled with concrete and the casing is gradually removed.

When installing rack piles, to support them, you need to widen the bottom of the well. The soil must be removed to 1.5-3 well diameters. If the well is camouflaged, it can be sealed with an explosion.

In the mid-twentieth century, electric pulse multiple water hammer began to be used for this purpose.

Fundex casing technology

This method became popular several years ago thanks to the so-called gentle regime. The work takes place without shock and vibration, so there is no risk of damaging nearby structures. At the same time, the soil retains its physical and mechanical properties.

The diameter of products made using this technology is in the range of 450-600 mm. This technology is usually used in areas where seismic conditions are unstable.

The well is drilled with special conical rollers, which are installed on a common shaft. They drill simultaneously using the rotation and indentation method, which does not allow soil to reach the surface.

- The rolling tip is made of cast iron. It is screwed into the ground and left inside, it becomes a reliable support for the pile.

- The pipe is attached to the roller and checked to see if there is any water in the pipe. If not, you can install a frame made of reinforcement.

- Then the primer is applied. The special solution contains equal amounts of water, cement and sand. Therefore, it does not allow the concrete to delaminate.

- The pipe is then filled with plastic concrete and pulled out, while rotating back and forth.

The technology for constructing piles is selected based on the soil. In addition, the general financial component of a pile foundation also matters.

Usually casing is not left in the well.

By law, they can be left in place only in extreme cases. For example, if there are landslide soils on the slopes or the speed of underground flows is more than 200 meters per day. For each exceptional case, a technical justification must be drawn up.

Technologies for constructing bored piles

Depending on the construction technology, all bored piles are classified into three types:

- Supports formed without shell;

- Supports with removable and permanent shell

As a shell, casing pipes are used - cylindrical steel structures connected to each other by means of a threaded or anchor connection.

Drilling wells for piles without a shell is not accompanied by their use, which is only possible in stable conditions (not prone to landslides) with a minimum groundwater level. Important : if necessary, in the process of drilling without casing, a bentonite solution can be used, which is fed into the well being developed, washes out soil masses from it and settles on the walls of the cavity, forming a crust that prevents soil shedding.

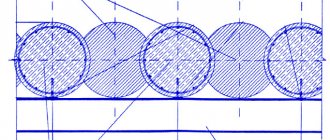

Fig : Casing pipes for drilling under piles

The technology for creating bored piles with a removable shell is implemented when working in problematic, moisture-saturated soils. The casing pipe, in this case, prevents the collapse of the well walls and isolates the cavity from groundwater. Dismantling of the casing occurs after filling the well with concrete. The creation of piles with a permanent shell is practiced when working in clayey soils, sands and sandy loams with a high level of groundwater, which can destroy the body of the pile at the stage of hardening of the concrete solution.

Types of bored pile foundations

The idea of a bored foundation is very simple: where it is impossible to get to dense soil, you can use piles. To connect them into a common structure, a grillage is used - a monolithic reinforced concrete strip that connects the piles.

Basic schemes of pile foundations

| Strip-pile foundation foundation. | Used for heavy brick and concrete buildings where the building has a high windage. |

| Bored pile foundation with a monolithic grillage. | Used for the construction of objects made of foam concrete, aerated concrete, logs and timber. |

| Slab-pile foundation. Can be done using shallow tape. But you also don’t have to use it. | They are used where the soil is completely unfavorable: viscous and marshy, saturated with swamp and river waters. |

Schemes using this type of piles are divided into two groups: structures in which the base and walls are raised above the ground and bases tied to the ground.

The advantage of a foundation foundation on piles: you can raise the structure above the ground, while maintaining the rigidity of the base foundation belt.

Thanks to this, piles can be used on unfavorable soils; they are able to protect the frame of the house from cold and ground moisture. And this is extremely important if the house is built from timber, logs or sip panels.

Foundation Stages

- The well is drilled using a hand-held motor drill or a powerful mobile unit.

- Install the casing pipe (if the soil is loose or damp).

- Install reinforcement cages.

- The well is concreted.

- A sand-crushed stone cushion 10-15 cm thick is poured for the grillage. It compensates for the rise of the soil as a result of frost heaving.

- The formwork is mounted above the ground, reinforcement is installed and a grillage is poured, which will connect the piles.

It is necessary to correctly calculate the weight of the building. The number of piles needed, their diameter and installation depth will depend on it. If the house is heavy, the piles need to be placed more tightly under the walls.

According to the standards, the distance between the centers of adjacent supports must be at least three times the diameter of the pile. If this distance is less, the load-bearing capacity of the racks may decrease.

Technology for installing bored piles with a grillage

The configuration of the grillage of bored supports is selected based on the arrangement of piles in the foundation:

- Tape grillage tying is used in a sequential arrangement scheme, which is used for arranging foundations for low-rise buildings (the supports are placed under the contour of the walls of the house);

- A slab grillage is used to tie the pile fields of the foundations of high-rise buildings, in which the piles are located along the entire perimeter of the structure.

Important : at the stage of forming bored piles, the supports are reinforced with a frame, the length of which is 30-50 cm longer than the length of the concrete body of the pile. The protrusions of the reinforcement are necessary for subsequent connection with the reinforcement frame of the harness.

Depending on the level of elevation above the ground, 3 types of grillages are classified:

- Low (lowered into the soil below its freezing level or so that the upper contour of the piping is flush with the ground);

- Elevated (laid on the ground surface);

- High (raised above the ground to a height of 20-30 cm).

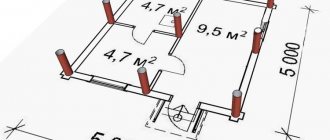

Fig : Types of bored pile grillages

The sequence of installation of the grillage of bored piles is as follows:

- A layer of sand and crushed stone bedding 20-30 cm thick is laid around the perimeter of the piping; if necessary, the soil level is lowered by digging;

- A formwork is formed on top of the bedding, made from planed boards. The formwork is fixed by means of side struts;

- The internal walls of the formwork are covered with waterproofing material (oilcloth, roofing felt);

- A reinforcement frame is assembled from reinforcing bars, which is placed in the formwork and welded to the protrusions of the reinforcement of bored piles;

- The grillage is filled with concrete. Filling the formwork is carried out simultaneously, without pauses. After pouring, the mixture is compacted by vibration.

Fig : The process of arranging a grillage of bored piles

Important : upon completion of installation of the grillage, a 30-day pause is maintained for the concrete to gain strength, after which time the foundation of bored piles becomes suitable for further construction.

Advantages of a foundation on bored piles

A foundation made from such piles has the following advantages:

- Versatile. Suitable for almost any soil, except very rocky ones.

- The unevenness of the site or its proximity to water is not at all an obstacle to a pile foundation. The level of the building is still determined directly by the location of the load-bearing supporting elements.

- Economical. Much less money is spent on the construction of such a foundation compared to other types.

- The work can be carried out at any time of the year, installation time is quite fast.

- There is no need to use special equipment; you can build such a foundation on your own, which once again speaks of its low cost.

- A pile foundation does not require large-scale excavation work, so unnecessary damage to the surrounding landscape design is excluded.

- Such foundations are resistant to vertical soil movement, since their base is located below the freezing point.

- High load-bearing capacity. The foundation holds the weight load even from a heavy building. A prerequisite is waterproofing between the strip element and the walls of the building. This way you can protect materials with different properties from destruction.

Disadvantages of pile foundations

- Poor floor insulation. Drafts and coolness may enter the house. It is recommended to install heated floors on the first floors of houses with such a foundation.

- It is not possible to install a basement in the house. But if there is such a foundation, for example at a bathhouse, then there is no need for a basement there.

- Concrete consumption is higher compared to driven piles. Since there is no compaction of the soil around the pile during its manufacture.

- The production of piles is difficult to control.

Calculation of a bored foundation

Preliminary values of the laying depth (rod length) and pile cross-section are taken from the recommendations of SNiP “Pile foundations”. Short piles (less than 3 meters) have a cross-section of 30 cm, etc.

The formula for calculating the bearing capacity is P = P1 + P2, where

- P1 – bearing capacity of the base;

- P2 – lateral surface.

Р1 = 0.7 x R x F, where

- R – standard bearing capacity (tabular value);

- 0.7 – tabular coefficient of soil homogeneity;

- F is the area of the pile base.

P2 = 0.8 x U x fxh, where

- f – standard wall resistance (from tables);

- h – thickness of the working layer;

- U – section perimeter;

- 0.8 – working conditions coefficient.

Load per p.m. foundation is determined by the formula Q = M/U, where

- M – sum of loads (see above);

- U is the perimeter of the house. If the house has internal walls with its own foundation, their length is added to the perimeter.

The pile installation step is determined as P/Q. The number of piles is the perimeter of the house divided by this figure. Then you can calculate the required amount of concrete and reinforcement. Calculations are performed several times, varying the length and cross-section of the pile.

Below is an example of calculating bored piles for given structure parameters.

About the distance between bored piles

Reinforced frames for bored piles

Bored piles using TISE technology