For many years now we have been using conventional incandescent lamps to illuminate our homes, apartments, offices or industrial plants. However, every day electricity prices are rapidly rising, which forces us to give preference to more energy-efficient devices that have high efficiency, long service life and are capable of creating the necessary luminous flux at minimal cost. These devices include 220-volt LED lamps, the advantages of which we will try to fully reveal in this article.

Attention! This publication provides examples of circuits powered by a life-threatening voltage of 220V. Only persons with the necessary education and permits are allowed to assemble and test such circuits!

The simplest scheme

A 220 V LED lamp is one of the types of lighting lamps in which the luminous flux is created by converting electrical energy into luminous flux using an LED crystal. To operate LEDs from a stationary household 220 V network, you need to assemble the simplest circuit shown in the figure below.

The circuit of a 220-volt LED lamp consists of an alternating voltage source of 220–240 V, a rectifier bridge for converting alternating current into direct current, a limiting capacitor C1, a capacitor for smoothing ripples C2 and LEDs connected in series from 1 to 80 pieces.

Principle of operation

When an alternating voltage of 220 V of variable frequency (50 Hz) is supplied to the LED lamp driver, it passes through the current-limiting capacitor C1 to a rectifier bridge assembled from 4 diodes.

After this, at the output of the bridge we receive a constant rectified voltage required for the operation of the LEDs. However, to obtain a continuous light output, it is necessary to add an electrolytic capacitor C2 to the driver to smooth out the ripples that occur when rectifying the alternating voltage.

Looking at the design of a 220-volt LED lamp, we see that there are resistances R1 and R2. Resistor R2 is used to discharge the capacitor to protect against breakdown when the power is turned off, and R1 is used to limit the current supplied to the LED bridge when turned on.

Making a 220V LED driver with your own hands

The 220 volt ice driver circuit is nothing more than a switching power supply.

As a homemade LED driver from a 220V network, we will consider the simplest switching power supply without galvanic isolation. The main advantage of such schemes is simplicity and reliability. But be careful when assembling, since this circuit has no current limit. The LEDs will draw their required one and a half amperes, but if you touch the bare wires with your hand, the current will reach tens of amperes, and such a shock of current is very noticeable.

The simplest driver circuit for 220V LEDs consists of three main stages:

- Capacitive voltage divider;

- diode bridge;

- voltage stabilization cascade.

The first stage is capacitance on capacitor C1 with a resistor. The resistor is necessary for self-discharge of the capacitor and does not affect the operation of the circuit itself. Its rating is not particularly critical and can be from 100 kOhm to 1 Mohm with a power of 0.5-1 W. The capacitor is necessarily non-electrolytic at 400-500V (effective peak voltage of the network).

When a half-wave of voltage passes through a capacitor, it passes current until the plates are charged. The smaller its capacity, the faster the full charge occurs. With a capacity of 0.3-0.4 μF, the charging time is 1/10 of the half-wave period of the mains voltage. In simple terms, only a tenth of the incoming voltage will pass through the capacitor.

The second stage is a diode bridge. It converts alternating voltage to direct voltage. After cutting off most of the half-wave voltage with a capacitor, we get about 20-24V DC at the output of the diode bridge.

The third stage is a smoothing stabilizing filter.

A capacitor with a diode bridge acts as a voltage divider. When the voltage in the network changes, the amplitude at the output of the diode bridge will also change.

To smooth out the voltage ripple, we connect an electrolytic capacitor in parallel to the circuit. Its capacity depends on the power of our load.

In the driver circuit, the supply voltage for the LEDs should not exceed 12V. The common element L7812 can be used as a stabilizer.

The assembled circuit of a 220-volt LED lamp begins to work immediately, but before connecting it to the network, carefully insulate all exposed wires and soldering points of circuit elements.

Circuit with active current limiter

In this version of the circuit, the current-limiting element is resistance R1. Such a circuit will have a power factor or cos φ close to unity, unlike previous options with a current-limiting capacitor, which are a reactive load. The disadvantage of this option is the need to dissipate a significant amount of heat on resistor R1.

To discharge the residual voltage of capacitor C1 to zero, resistor R2 is used in the circuit.

Installation of LED lamps for 220V AC circuits

LED light bulbs consist of the following components:

- Base (E27, E14, E40 and so on) for screwing into the socket of a lamp, sconce or chandelier;

- Dielectric gasket between the base and the housing;

- A driver on which a circuit is assembled to convert alternating voltage into a constant voltage of the required value;

- A radiator that serves to remove heat from the LEDs;

- A printed circuit board onto which LEDs are soldered (sizes SMD5050, SMD3528, and so on);

- Resistors (chips) to protect LEDs from pulsating current;

- Light diffuser to create a uniform light flux.

LED lamp device

Diode lamp models began to replace standard ones. They are expensive, but their technical parameters are significantly superior to outdated models. To understand how they work, you need to know the design of an LED lamp.

It consists of 5 elements that are connected in one housing:

- The base is an element that is screwed into the socket of a chandelier or other lamp. Produced for: household use screw type E27 and E14, made of brass with nickel anti-corrosion coating;

- For other needs, light sources with a pin base are available.

- microcircuits;

- A radiator is an element that removes heat and provides the LEDs with an optimal operating temperature. It usually makes up the visible part of the body.

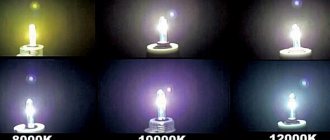

- A diffuser is a transparent “cap” that helps distribute light in space. It is made in the form of a hemisphere for dispersing light beams at a wide angle. The material used is polycarbonate or plastic. Prevents dust and moisture from entering the housing. To soften the harshness of the light and reduce the irritating effect on the eyes, this element is coated from the inside with a phosphor. This achieves a color temperature similar to natural light.

- LEDs are the main working element of the lamp, due to which the glow appears. There are 4 main chip assembly technologies: SMD technology is the most common in everyday life. The crystal is placed on the surface of the light device;

- DIP - the light element consists of 1 powerful crystal, on top of which a lens is attached;

- Piranha - favorites of the automotive industry, there are 4 contacts;

- COB technology is an advanced connection scheme for LED crystals, the most protected option from overheating and oxidation.

Inexpensive products may not have a driver; instead, they install a power supply that does not provide either current or voltage stabilization.

How to connect 220 volt LED lamps

The biggest trick when connecting 220 V LED lamps is that there is no trick. The connection is exactly the same as you did with incandescent lamps or compact fluorescent lamps (CFLs). To do this: turn off the power to the base, and then screw the lamp into it. When installing, never touch the metal parts of the lamp: remember that sometimes careless electricians can pass zero through the switch instead of a phase. In this case, phase voltage will never be removed from the base.

Manufacturers have released LED analogues of all previously produced types of lamps with a variety of sockets: E27, E14, GU5.3 and so on. The installation principle for them remains the same.

If you bought an LED light bulb designed for 12 or 24 Volts, then you cannot do without a power supply. The light sources are connected in parallel: all the “pluses” of the light bulbs together to the positive output of the power supply, and all the “minuses” together to the “minus” of the power supply.

In this case, it is important to maintain polarity (“plus” to “plus”, “minus” to “minus”), since the LEDs will only emit light if the polarity is correct! Some products may fail if polarity is reversed.

Attention! Do not confuse a DC power supply (power supply) with a transformer. The transformer produces an alternating voltage output, while the power source produces a constant voltage.

For example, you have furniture lighting in the kitchen, wardrobe or other place, made up of 4 halogen lamps with a power of 40 W and a voltage of 12 V, powered from a transformer. You decide to replace these lamps with 4 LED lamps of 4–5 W each.

Attention! In this case, it is necessary to replace the previously used transformer with a 12 V DC source with a power of at least 16–20 W.

Sometimes such LED lamps for spotlights are in most cases equipped with a power supply at the factory. When purchasing such lamps, you should also consider purchasing a power source.

Design diagram: device features

In appearance, ice bulbs are similar to light sources of all other types; they are available with various bases in the shape of a ball, candle, or pear.

LEDs intended for lamps are also different:

- ordinary ones on a plastic case (powerful “corns”);

- unframed;

- diode COB assemblies;

- threads on a sapphire, glass or metal strip (filament);

- diodes on transparent ceramics (Crystal Ceramic MCOB).

LED sources are available that support indicator switches and dimming.

Structural design of 220V LED lamps:

- frame;

- reflector;

- light diffuser;

- power supply (printed circuit board with soldered radio elements).

Filament light bulbs differ in design. There is no board in them, it is replaced by rods, the driver is also in the base. The rod is a tube made of sapphire or glass with a cross-section of 2 mm and a length of about 3 cm. Miniature LEDs are located on the rod.

Important! The power of these lamps is from 1 kW.

How to make a simple LED light bulb

In order to assemble an LED lamp, we need an old fluorescent lamp, or rather its base with a base, a long piece of 12 V LED strip,

and an empty aluminum 330 ml can

To power such a lamp, you will need a 12 V DC source of such a size that it can fit inside the can without any problems.

So, now the production itself:

- Wrap the ribbon around the jar as shown in the picture.

- Solder the wires from the LED strip to the output of the power supply (PS).

- Solder the IP input with wires to the base of the lamp base.

- Securely secure the source itself inside the jar, having previously cut a hole large enough to allow the power source to pass inside.

- Glue the can with tape to the base of the body with the base and the lamp is ready.

Of course, such a lamp is not a masterpiece of design art, but it is made with your own hands!

Types of LED light sources

All LEDs can be divided into two large categories: indicator and lighting. The first type is used in electrical engineering for illuminating instrument panels, displays, signal indications, as well as in other devices that do not require a large luminous flux.

And lighting LEDs are used just in household LED lamps. Such lamps can be classified according to their purpose, external structure and type of radiation sources.

By area of use

LED lamps are capturing more and more technological niches. They are used in consumer electronics, industrial and commercial equipment.

LED spotlights for street lighting are made mainly on the basis of one large LED, so it is not possible to adjust their brightness

The main areas of application of LED lamps are:

- Street lighting.

- High performance floodlights.

- Lighting of industrial premises and apartments.

- Agriculture. Lamps with a radiation spectrum capable of initiating photosynthesis are used.

- Car lights.

- Illumination of products in shop windows.

- Space lighting in explosive environments.

A large number of areas of use of LED lighting are due to differences in the characteristics of LEDs and the spectrum they emit. Innovative types of lamps are constantly being developed to fill new market niches.

By appearance

One of the reasons for the prevalence of LED lamps is the minimal size of their semiconductor crystals. Thanks to this, lamps can take on a wide variety of shapes.

It is not recommended to install high-power LED devices in places with limited air circulation - this may cause the LED to overheat

The main designs of LED lamps are:

- Classic design like an incandescent lamp with a base. Such lamps usually contain several multi-directional LEDs.

- "Corn". This lamp looks like a cylinder covered on all sides with LEDs.

- Ribbon-shaped LED lamps in which individual crystals are arranged in series on a narrow, thin substrate.

- Spotlights with one large luminous crystal.

- Spot ceiling lights.

- Flat LED panels of round, rectangular or arbitrary shape.

The small size and unpretentiousness of LEDs to the installation site allows them to be used to produce designer lamps of unusual shapes. And the low heating of LED lamps does not prevent their placement near plasterboard and plastic surfaces.

By LED type

Lighting LEDs are divided according to their physical structure into several types, each of which has its own characteristics and predominant areas of application.

LED lamps are manufactured in three main types:

- SMD (surface mount LEDs).

- COB (device on a chip).

- Filament (LED filament).

Surface-mount LEDs have low luminosity, but they can be independently soldered to any surface without fear of overheating.

Therefore, they are often used in the manufacture of LED strips and portable lights. The radiation angle of SMD LEDs is 90-130 degrees, so to illuminate the entire room around the lamp, a radial arrangement of crystals on the base is necessary.

The power of an LED lamp with LED filaments depends on the number of glass fibers, their length and the characteristics of the crystals placed on them

COB LEDs are high-luminosity crystals placed on a metal substrate. It is designed to remove heat generated during operation.

The emission angle of on-chip devices approaches 180 degrees, making them poorly suited for highly targeted lighting. COB is used in the production of floodlights and premium lamps.

LED filaments are a series of miniature crystals placed in series on a glass fiber. Sometimes other transparent materials are used instead of glass. This structure allows for uniform circular lighting.

The main problem with high-power small LEDs is overheating, which reduces their service life and luminous flux levels.

The main malfunctions of 220 volt LED lamps

Based on many years of experience, if a 220 V LED lamp does not light, then the reasons may be as follows:

Failure of LEDs

Since in an LED lamp all the LEDs are connected in series, if at least one of them goes out, the entire lamp stops lighting due to an open circuit. In most cases, LEDs in 220 lamps are used in 2 sizes: SMD5050 and SMD3528.

To eliminate this reason, you need to find the failed LED and replace it with another one, or install a jumper (it is better not to abuse jumpers - as they can increase the current through the LEDs in some circuits). When solving the problem using the second method, the luminous flux will decrease slightly, but the light bulb will begin to shine again.

To find a damaged LED, we need a low current power supply (20 mA) or a multimeter.

To do this, we apply “+” to the anode and “–” to the cathode. If the LED does not light up, it means it is faulty. Thus, you need to check each of the lamp LEDs. Also, a failed LED can be identified visually; it looks something like this:

The cause of this failure in most cases is the lack of any protection for the LED.

Failure of the diode bridge

In most cases, with such a malfunction, the main reason is a manufacturing defect. And in this case, the LEDs often “fly out”. To solve this problem, you need to replace the diode bridge (or bridge diodes) and check all the LEDs.

To check the diode bridge you need a multimeter. It is necessary to apply an alternating voltage of 220 V to the bridge input and check the voltage at the output. If it remains variable at the output, then the diode bridge has failed.

If the diode bridge is assembled on separate diodes, they can be unsoldered one by one and checked with a device. A diode must pass current in only one direction. If it does not pass current at all or does pass it when a positive half-wave is applied to the cathode, then it is out of order and requires replacement.

Poor soldering of lead ends

In this case, we will need a multimeter. You need to understand the circuit of the LED lamp and then check all the points, starting with the input voltage of 220 V and ending with the LED outputs. Based on experience, this problem is inherent in cheap LED lamps and to eliminate it, it is enough to additionally solder all the parts and components with a soldering iron.

Where to buy a lamp

You can resolve the issue as quickly as possible in the nearest specialized store. The optimal option, in terms of price-quality ratio, remains purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| Nieuwe MR16 GU5.3 High Power LED Flood Light 6W 9W 12W | LED lamp Ampoule, E14, E27, GU10 | LED lamp with Bluetooth, E27, E14, GU10, RGB |

| LED spotlight E27, GU10, E14 | LED lamp for home | LED chandelier with a unique design |