Cast iron bathtub, porcelain, acrylic or ceramic – for a long time, buyers were faced with exactly this choice.

One was distinguished by its unbearable weight, the other by its fragility, the third by its limited model range. Today on the market you can find a fundamentally new, innovative offer - a bathtub made of quaril . What kind of material is this, what advantages and disadvantages it has - everything is in this article.

What it is?

Quaril is a modern material that contains acrylic and quartz sand . The mineral powder is sealed into a kind of capsules, connected by the same acrylic. Characterized by increased strength and wear resistance. The big advantage is that a product made from quaril does not require reinforcement or the use of any frame at all; it is completely self-sufficient.

The material has thermal conductivity properties that are comfortable for everyday life - the water in such a bath will not cool down for a long time. It suppresses noise. Increased impact resistance and wear resistance are associated with manufacturing technology. Quaril takes any shape and maintains the parameters specified in production.

Quaril content and features of its composition

The development of quaril is a new phase in the development of multicomponent materials used for the manufacture of household sanitary equipment. The end result was a composition that affected the quality of the goods produced. The main components of the new substance are:

- Acrylic resins. They contain about 60% per unit volume of mass. The composite acquires the properties of elasticity and flexibility at the stage of processing with this component. And these same components provide the strength and hardness of the finished quaril product.

- Patented modifiers. They perform the function of improving the positive characteristics of acrylic, which is a constituent unit of the composite. Quaril acquires additional shine, a uniform rich shade, it becomes more plastic, is endowed with increased sound insulation, products made from it have a smooth but also non-slip surface.

The material has passed excellent testing in terms of strength, anti-slip, noise and heat insulation qualities and the technical advice of TECH SÜD, which confirmed its suitability for use in domestic conditions. Quaryl fully meets European standards for environmental safety.

Advantages and disadvantages

Like any material, quaril has its positive and negative sides.

Therefore, before choosing models made from this material, you need to weigh the pros and cons . And find out what operational features you will have to face. This is what we will do below.

pros

Strength. The material, thanks to quartz, has increased impact resistance.

Manufacturers claim that in domestic conditions the bathtub is almost impossible to damage, split, and even quite difficult to scratch.

Special surface. Quaril can look as smooth and shiny as traditional acrylic products, but it also has a pleasant roughness. Therefore, the surface of the bathtub is non-slippery, which prevents falls.

Maintainability. The leading manufacturer of quarryl bathtubs, Villeroy&Boch, gives customers a ten-year guarantee, thereby emphasizing its durability. However, if the bathtub splits for some reason, the quaril can be restored.

For the restoration of the font, there are specialized workshops and even pastes that can be used to restore light damage to the font at home.

Beautiful appearance. The bathtub can be painted in various rich colors and shades. The classic white model has a special brightness. The color does not fade or change over time, and UV rays are not dangerous either. Easy to clean with household detergents.

Plastic. The ability to create various models with both right angles and amazing bends, which do not require additional supports.

Those who value style and modern design will be pleasantly surprised by the ductility and durability of quaril.

The manufacturer can make a bathtub with a wall thickness of only 8 mm, give it the actual rectangular or angular shape, and do not use any frames for weighting.

Noise insulation. Quaril absorbs noise. Thus, an open tap will not create virtually any inconvenience: it will not disturb neighbors at night and will not interfere with listening to the radio.

Thermal conductivity. It retains heat perfectly and helps maintain the required water temperature for a long time.

Hygiene. During the manufacturing process of the material, the manufacturer can add various impurities and chemical compounds that will help the coating become antibacterial and dust-repellent.

Minuses

High cost of restoration. If a crack or chip appears, repairs will require large financial investments. Of course, it is better to have the defects eliminated by professionals, but this will increase costs even more.

In the Russian Federation, the material remains quite new, few craftsmen will undertake such repairs, so specialists set high prices due to the absence of any competition.

High cost of the bath itself. Quartz is a natural material. In addition, the creation of quaril takes place using a certain new technology, and is so far only possible in Europe. Due to the lack of competition and exclusivity of the material, the manufacturer sets a high price.

It is difficult to choose the same plumbing ensemble. There is still no large selection of sanitary ware made from Quaril on the Russian market. You will have to spend time searching for the right toilet or sink to pair with the bathtub.

Types of plumbing range

Quaril baths come in a variety of sizes and shapes. The products also have different colors and textures.

Placement technique

Depending on the location and installation, the bowl can be:

- Wall. Suitable for small rooms.

- Separately standing. The design is appropriate in a spacious room. With this placement, the distance from the wall to the bowl should be at least 50 cm. A model located in the middle of the room looks good.

- Built-in. A bathtub designed in the same style as the walls or floor looks aesthetically pleasing.

The corner model will save free space.

Surface treatment

Villeroy&Boch produces 2 types of bowl surface coatings:

- ActiveCare. Ceramic enamel contains silver ions, due to which it has an antibacterial effect.

- Ceramic Plus. The coating is smooth, resulting in reduced dust and contamination on the surface.

In the store you can choose a design with the required coating.

Dimensions and shapes

Standard bowls are 150-180 cm long, 70-85 cm wide, 65 cm high. Dimensions may vary depending on the model.

The following forms of quaril products are sold in stores:

- oval;

- round;

- triangular;

- semi-oval;

- asymmetrical;

- polygonal.

The outer side of the products can be white, coral, yellow, black, blue, green. In addition, there are models with a gold or champagne-colored outline.

Quarryl, acrylic or cast iron, which is better?

Quarril bathtubs are often compared with products made from other materials, so let’s look at the main points and decide which is better, Quarril or acrylic, or maybe the good old cast iron bathtubs?

Strength. Acrylic is an inexpensive material that is familiar to everyone; it is often subject to mechanical scratching of the top layer, and also crumbles and cracks under strong impacts. Quaryl, according to manufacturers, is four times stronger. But the leader here is cast iron ; even with a strong desire, such a font is difficult to split.

Ergonomic surface. As noted above, the manufacturer of quaril, with the help of special impurities, achieves a special surface condition, which is called Soft touch. It is not slippery and pleasant to the touch, which models made of acrylic and cast iron cannot boast of.

Price. Here the leader with a minus sign is quaril. The price of bathtubs made of this material is several times higher than the price of models made of cast iron and acrylic:

- an ordinary acrylic bathtub costs about 10,000 rubles;

- cast iron - 14000;

- and quaryl as much as 50,000.

The noise insulation and thermal conductivity of the materials in question are at a decent level, but quaril still wins the debate .

The main advantages of quaril baths

While working on the material, the creators sought to neutralize the shortcomings of acrylic, while preserving and enhancing its positive aspects as much as possible. Thus, quartz introduced into the composition of quaril provides it with strength and resistance to chips and scratches. This also makes it possible to produce heavier bathtubs with thick walls. If acrylic products necessarily required the installation of a power frame, then the new material no longer needs this condition. A wide range of freestanding bathtubs are manufactured from quaril.

Important. The thickness of the material at the base of the bathtub reaches 25 mm, which guarantees its good stability and sufficient strength.

Plastic raw materials make it possible to produce products of traditional or non-standard design shapes. The following bath options are currently offered:

- rectangular;

Rectangular quaril bath

- round;

- oval;

- corner;

- with beveled side;

Quarril bathtub with sloping sides

- hexagonal.

A quaril bathtub has low thermal conductivity, which means the water in it cools slowly. The surface is always warm and pleasant to the touch. The products are distinguished by their brightness and color saturation. Specially developed technology provides anti-slip performance. The manufacturer guarantees impact resistance, durability, and insensitivity to scratches.

The bathtub is easy to clean and does not require any special care. We recommend gentle soapy cleaning products that do not contain abrasive particles. The creators claim that the surface has absolutely no pores and is as hard as crystal. Microcracks do not form on it, which means that pollution will not penetrate inside. The material is designed to be hygienic and UV resistant.

Quaril bathtubs are very easy to clean

The weight of the standard model is significantly less than cast iron, but heavier than acrylic. Is about 50 kg. The polymer product has excellent sound insulation. The noise of falling water from a tap will not irritate you, and even more so, your neighbors will not hear it. The design of the quaril bath allows the mixer to be mounted on board.

Leading manufacturer Villeroy Boch

Villeroy Boch is a company established in Germany. It is familiar to many primarily because of the production of first-class tableware. They also produce sanitary ware from various high-quality materials, such as porcelain. It was they who came up with the idea of creating bathtubs from quaril. Accordingly, they have the largest selection of such bathtubs.

The company introduces various nanotechnologies into production. For example, it achieves the formation of a surface on which dust cannot settle. The top layer of some models is enriched with microscopic silver ions, which prevents the formation of a bacterial environment. The photo shows the model that is most popular among consumers, villeroy boch oberon 170×70 . You can purchase it on our partners’ websites at the lowest price.

Conclusions and useful video on the topic

The video review shows several options for placing a quaril bowl and ways to harmoniously combine plumbing with the design of the bathroom:

The cost of innovative plumbing fixtures is high, and it is represented exclusively by European brands that guarantee the reliability and durability of their products. Quaril products have already occupied a certain niche in the group of goods, and will soon become more in demand due to a gradual reduction in price.

Please write comments in the block below. Share useful information on the topic of the article. Ask questions about unclear and controversial issues, post photographs.

Photo

Below are photographs of the most interesting models:

Comparison

If a bathtub made of acrylic is of high quality, then it is reliable and durable. These baths are lightweight and easy to use. They keep the temperature heated by water for a long time. Bathtubs of various configurations can be cast from acrylic. If the item is of poor quality, then it may lose its shape from hot water, since the material from which it is made belongs to the class of plastics, and they are prone to deformation at high temperatures. Therefore, these baths are reinforced with resins and fiberglass. It turns out that the quality of such baths depends on both the quality of the raw materials and the number of reinforcing layers.

In addition, acrylic is painted in such a way that it cannot be rubbed off with anything. The reason may be rust in water, faded colorful clothes soaked in the bath, etc. Therefore, it is better to buy from painted acrylic. Then the change in the shade of the bath will not be noticeable. There is another drawback to these baths. Acrylic is susceptible to mechanical damage. Any scratches on its surface are noticeable and cannot be easily removed. A good quality acrylic bathtub is not cheap.

The workers at Villeroy & Boch decided to use the much-loved acrylic to create a new material – quarryl. The technology for its production is as follows: grains of quartz sand are placed in acrylic capsules, and the same polymer - acrylic - is introduced into the resulting voids between them. Despite the fact that the composition of the new material is simple, the product has better characteristics compared to the original source. The strength of quartz allows you to avoid additional reinforcement of the product made from it, the enamel of the bathtubs is not subject to damage, the bathtub is filled almost silently, and due to the presence of quartz in the material, anti-slip surface treatment with a special coating is not required. The only drawback is the high price. But it will also pay for itself over the long service life of the bath.

Bottom line: if you are at a crossroads when replacing a bathtub: acrylic or quarrylic, then as a budget and long-term option it makes sense to go with the first, and expensive, unbreakable, and therefore long-lasting products belong to the second category. Naturally, when choosing such an important subject, personal preferences must be taken into account. But it would be better to carefully consider their technical and operational characteristics in order to decide on the model based on a comparative analysis, and so as not to be disappointed in it in the future.

Repair

If, for some reason, a crack or scratch appears on the bathtub, or worse, the font breaks, it can be repaired sooner. Although it won't be cheap. There are already workshops in Russia that can work with this material. Professionals can glue parts of the product, repair large gaps, and eliminate serious chips.

Villery Boch provides a ten-year guarantee on its products and repairs its products themselves in case of damage. Interestingly, it was Villery Bosh that used to repair many porcelain and ceramic products with quarry.

It should be noted that paste for correcting defects in quaril products is also sold in construction stores. Repair kits cannot be used for acrylic bathtubs.

It will help, if necessary, to correct a small defect - a scratch or abrasion. Even independent use at home is allowed.

You should not try to fix a serious defect in a quaril bath yourself. Firstly, you can violate the terms of the warranty in this way, and secondly, if the repair is incorrect, the bathtub may leak at the site of the chip.

Installation technology for quaril plumbing

The sequence of installation work is almost identical to the installation of bathtubs made of other materials. One of the important features of the quaril tank is the absence of an overflow or drain hole. This complicates the installation somewhat, but allows you to independently determine the location of the communications connection.

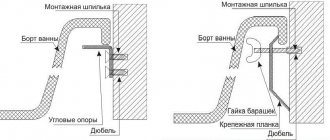

Installation of a built-in bathtub

The first stage, regardless of the placement method, is marking and preparing holes for drainage. Even at the planning stage, you should decide on the location of the bathtub, the point of supply to the sewer system, the placement of the mixer, handrails, nozzles and other equipment.

The holes in the quarry are drilled with a diamond bit of the appropriate diameter. It is better to entrust painstaking work to a professional - a minor mistake can ruin expensive plumbing equipment

Following actions:

- Place the bowl on a cleaned base.

- Adjust the horizontal position of the container by twisting and adjusting the height of the support legs.

- Install the faucet and install taps into the side of the bathtub or adjacent wall. An alternative option is to install the floor mixer separately from the bowl.

- Connect the siphon, connect the drainage system to the sewer pipe.

- Assess the quality of sealing of joints at joints. Fill the bowl with water and leave for a couple of hours. In case of leaks, eliminate the gaps.

- Install a decorative screen. If necessary, cover the front panel with finishing material.

The final stage is sealing the joints between the wall and the bathroom. One of the advantages of quaril models is their precise geometric shapes. Therefore, the seam between the edge of the plumbing and the tile will be minimal, provided the wall is even.

Placing a Freestanding Bowl

A separate bathtub is the absolute dominant feature of the room’s interior. To install it, it is advisable to choose a place so that the distance from the walls of the container to surrounding objects is at least 50 cm. It is important to adhere to an asymmetrical or axial interior composition.

A special feature of installing a free-standing type is the need to lay water supply and sewer pipes deep into the floor. There is little space under the bowl to connect the siphon and communication systems, as when installing traditional wall-mounted plumbing. Grooves are prepared in the floor screed and pipes are laid in the channels.

The water supply is carried out through a floor-mounted mixer - the pipes are connected to the rack. To discharge water into the sewer, a siphon is connected to the bathroom, which is connected to the sewer pipe using adapter fittings

Sequence of work:

- Lay the plumbing pipeline through the floor.

- Place the quaril bowl on supports, such as bars. Raising the bathtub will provide access to its base for connection work.

- After connecting the bowl to the communications, remove the stands and install it on hidden legs.

- Level the horizontal position of the bath.

- Test the tightness of the joints and install the front panels.

A rational way to install a quaril bathtub is to arrange a podium behind which all the plumbing equipment will be hidden. The solution will simplify repair work and effectively highlight the area where water treatments are performed.

How to install?

The installation of a quaril bathtub itself does not require any specific skills and is quite simple, as mentioned above - bathtubs made of this material do not require a frame, but one problem may arise. Manufacturers often do not make drain and overflow holes so that the user can choose where it is best for them to be when installing the bathtub.

Brief installation instructions:

- the font must be installed on a well-cleaned, level base;

- then, using an adjustable base and a building level, you need to align the edges of the bathtub to a strict horizon;

- drill holes for drainage and overflow and install a special siphon and connect to the sewer;

- if you plan to install the faucet on the bathtub, embed it into the side;

- fill the font with water and check the tightness

The video below shows the complete installation process.

What are the disadvantages of Quaryl composite?

The material demonstrates many positive characteristics, but is not without some disadvantages:

- High price. The novelty of quaril, the almost complete absence of competition, the rather expensive production process and the presence of characteristics superior to traditional materials were reflected in the final price.

- Relative strength. The composite is stronger than acrylic, but more fragile than steel and cast iron. A product made of quaril can only be damaged by a strong blow from a heavy object. This can only be done maliciously in everyday life.

- Instability to extreme high temperatures. Quaryl, like acrylic, can become deformed when exposed to boiling water. This occurs with prolonged and frequent use of very hot water.

- Limited availability of products. On sale you can only find quaril trays and bathtubs. It is not yet possible to select a complete set for bathroom furnishings made from one material.

There are models of acrylic bathtubs without overflow and drain holes, which come with a cutter attachment with a template for drilling. This expands the possibilities of bathroom planning, but complicates installation.

Cast marble baths

There are no names for such baths. On the Internet and in markets they can be found under the names: marble, stone, artificial stone, stone mass. But their production process is the same.

Making artificial stone baths can be compared to building a foundation for a building, only instead of crushed stone and sand, the composition includes ground natural marble or quartz sand, and instead of cement, polyester resin is used. The surface of the bathtub is covered with a layer of gelcoat, which, like armor, protects the bathtub from various types of damage. To understand the durability, I can say that yachts and boats, as well as billiard balls, are covered with a layer of gelcoat, and they usually get a lot of trouble.

How to determine the category and quality of a cast iron bathtub? Here are some pro tips:

| The first thing you should look at is the sides of the bathtub . They must be even, and the dimensions of the bathtub must correspond to the stated +/- 3mm. To check for evenness, you can take a long level and apply it to the side of the bathtub, and there should not be large gaps between the bathtub and the level. I have never seen a perfectly smooth cast iron bathtub, so I consider a gap of no more than 2 mm acceptable. |

| Next, you should pay attention to the enamel coating of the bathtub. It should be smooth and without sagging, without dark spots or visible pits. The enamel should be glossy, not matte, which can be checked by running your hand over it. |