Home |Blocks and floors |What are blocks for internal partitions?

Date: November 21, 2018

Comments: 0

When planning to build a house, remodel an old apartment, or improve housing in a new building, owners are faced with the task of dividing the premises into functional zones. To ensure comfortable conditions, it is important to clearly define your personal plans and choose the right material for the construction of load-bearing walls of buildings and internal partitions. Often, to break up the internal space, partition blocks made of lightweight and durable masonry building material - foam concrete, as well as tongue-and-groove blocks and plasterboard are used.

Partition and wall blocks for internal partitions made of foam concrete

Among the types of construction used, block construction is the most common. Foamed concrete building blocks are made by pouring them into special molds.

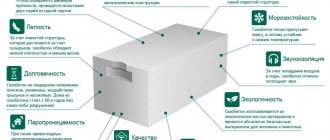

Foam blocks have a wide range of advantages compared to other materials:

- increased strength. The properties of the material allow the construction of buildings whose height reaches 10 meters. Foam concrete blocks are also used to construct walls in high-rise buildings, the load-bearing part of which is made using the method of monolithic concreting. Foam concrete is resistant to compressive loads and is able to maintain integrity under pressure up to 5 MPa;

This phrase means a special material that is necessary for the construction of partitions

- high thermal insulation characteristics. The thermal insulation properties of foam blocks used for wall laying are more than 3 times higher compared to the level of thermal insulation provided by brick walls. A foam block building does not require large wall thicknesses, since the porous material, which has a reduced density, reliably retains heat indoors and allows saving on heating costs;

- resistance to low temperatures and open fire. With repeated cyclic freezing followed by settling, foam concrete retains its cellular structure and does not crack. The blocks are also used in rooms with a high fire hazard, due to their ability not to collapse for up to 6 hours under the influence of temperature and open fire.

When planning to use foam blocks for the construction of walls and internal partitions, you also need to know about other advantages:

- ease of use. Thanks to the light weight of the products, which is 10-12 kg, high construction speed is achieved. The increased dimensions of the blocks allow the construction of foam block slabs, partitions and walls of buildings at an accelerated pace;

- environmental safety and biological resistance. Blocks for internal partitions do not have a negative impact on human health and are characterized by increased resistance to rotting;

- ease of machining. Using a standard set of tools, it is easy to shape foam blocks into the required shape, as well as cut the material or make a hole in it. Adjusting the dimensions of pliable foam blocks does not require special preparation;

- expanded area of use of foam blocks. Depending on the specific gravity, thermal insulating, structural, as well as structural and thermal insulating foam blocks with a density of 500 to 1200 kg/m³ are produced.

They make interior work much easier

Distinctive characteristics of foam concrete:

- the ability to freely pass steam from the room. The cellular structure of the material allows you to provide comfortable humidity in the room;

- long period of use. Foamed concrete blocks do not crack and retain their properties for decades;

- increased sound insulation properties. The cellular structure of foam concrete delays the penetration of external sounds into the room;

- acceptable price level. The use of inexpensive foam blocks reduces the total cost.

It is necessary to pay attention to the weaknesses that the material also has:

- increased hygroscopicity. Finishing of foam blocks on the outside and inside protects the building material from moisture absorption;

- the need to use a special adhesive mixture. It replaces masonry mortar and avoids cold bridges;

- unpresentable appearance. Foam blocks that are used for walls and partitions require mandatory decorative finishing.

For the construction of walls and the construction of internal partitions, it is also advisable to use polystyrene concrete blocks, the thermal insulation characteristics of which are not inferior to foam blocks.

Aerated block partitions: compliance with requirements

The properties of aerated concrete blocks make it possible to successfully use them as a building material for interior partitions. Partitions in a house made of aerated concrete meet all the listed requirements and also have other advantages:

- Ease of construction . Gas blocks are easy to machine (even with hand tools). The block can be given the desired shape using a hand saw. It also doesn’t cause any difficulties when cutting walls (punching furrows for laying communications).

Ease of working with gas blocks Source rmnt.ru

- Construction speed . The work does not require mechanization due to the small mass of the products. The size of the blocks and simple installation speed up the process of constructing partitions; labor and time costs are reduced.

- Accuracy of construction . Aerated concrete blocks have precise factory dimensions, which allows the construction of perfectly smooth wall structures. The impeccable geometry of the blocks allows the use not of sand-cement masonry mortar, but of a special adhesive mixture; The thickness of the seams does not exceed 1-3 mm.

- Performance properties . Due to the low density of the material, aerated concrete walls have decent thermal insulation.

- Environmental friendliness and safety . The composition of aerated concrete includes cement, sand and gas-forming agents (usually aluminum-based), which are inert at any temperature. Therefore, aerated concrete partitions do not emit toxic substances and do not burn (with prolonged exposure to flame, more than an hour and a half, the surface layer begins to collapse).

The geometry of the blocks allows you to build neat partitions Source ok-berta.ru

See also: Catalog of companies that specialize in internal redevelopment.

We use plasterboard for the construction of interior partitions

Some developers believe that it is better to use sheets of plasterboard for the construction of partitions.

The main advantages of using the material:

- reducing the duration of construction activities. The material is easily cut into pieces of the required sizes and attached to a pre-installed frame. In addition, lightweight sheets are easy to transport;

Plasterboard partitions are fundamentally different in construction technology

- rational use of free space in the room. The thickness of plasterboard structures assembled on a metal frame does not exceed 50 mm;

- increased level of sound insulation. Despite their small thickness, plasterboard sheets have high sound insulation characteristics;

- increased functionality and practicality. Electrical networks, water pipes and ventilation ducts can be placed inside wall cavities.

Along with its advantages, drywall also has its weaknesses:

- insufficient safety margin. The material is susceptible to deformation, bending loads and requires careful handling;

- increased sensitivity to moisture. Plasterboard slabs should only be used in rooms with normal humidity;

- small thickness, making it difficult to fix interior items. Special fasteners are used for drywall.

Various materials are used for decorative finishing, including paint, wallpaper and plaster. The use of plasterboard for the construction of internal partitions is a budget solution.

When giving preference to plasterboard sheets, pay attention to the strength properties, specifics of fastening, level of sound insulation and cost.

Types of interior partitions

To achieve comfort in their apartment, the owners are trying to deal with unusual room shapes, low lighting, and small space. Using transformable partitions (sliding, sliding, folding, folding) to zone a room will allow you to change the room beyond recognition. Lightweight structures are used, for example, to separate the kitchen from the dining room, the hallway from the living room. The options for interior partitions existing on the market will help you choose the most suitable rack.

Partition-rack

They can become both a piece of furniture and a decorative element. You can purchase a ready-made shelving partition, or you can order it in accordance with the dimensions of your room. When you decide to buy such a cabinet, think about whether it will really fit into your interior.

Positive aspects of the purchase:

- versatility (the ability to install in any room and choose any design);

- variations of materials (metal, wood, plastic);

- ease of installation (anyone can do it);

- mobility (can be moved from place to place);

- functionality (as a partition, interior element, storage system);

- aesthetics (can be decorated in the same color scheme as the interior);

- Duration of operation (high-quality materials will last for many years).

The following are noted as the disadvantages of the partition-rack:

- poor stability (if the floor is uneven, you will need to attach the structure to the wall or floor);

- increased dust collection (dust accumulates heavily on open shelves).

Partition screen

This is a stationary structure of several supports on which material is attached like a screen. The construction is not strong - it will only withstand wall decor. They can easily cut off access to light or cold air flows from the air conditioner.

Interior fireplace partition

Fireplaces are perceived as sources of heat. However, you can install a fireplace as a room divider. Lightweight false fireplaces running on gas or biofuel will decorate any room. Figurines or flowers can easily be placed on it. Such a fireplace, even if only slightly heating, will help save money on heating.

Rotating and sliding partitions

These partitions are made from several materials, combining them. You can order transparent or solid. They will complement any interior and solve the issue of room zoning. They work on the principle of curtain-blinds: panels mounted on a rotating mechanism rotate, allowing air and light to pass through.

When closed, they represent a single wall panel. Usually they are very thin, which does not take up space, and can be easily moved around the apartment if necessary. The most important advantage is that their installation does not require permission from the BTI for redevelopment. The disadvantages are the lack of sound insulation and fragility (you can’t hang anything on it).

Support partitions

This version of partitions is used as a support for stairs, countertops, and storage systems. Most often, such supports are made of wood or metal. Installed in a room as a shelving unit or a decorative element, it always looks original and functional.

Partition - decorative element

Sometimes a partition is used in a space not as a fence, but as a decorative object. By using a screen partition made of carved wood to zone the space, we add solidity to the interior.

Partitions made of plastic or decorative glass become art objects, the center of the entire living space. You can take several partitions, which, when placed one after another, add uniqueness and a feeling of expanding the space.

We use tongue-and-groove blocks for partitions

Blocks of a tongue-and-groove design are also widely used for the construction of partitions indoors. Structurally, the tongue-and-groove slab is a monolithic block in the shape of a parallelepiped. The end surfaces of the tongue-and-groove plate have protrusions and grooves of appropriate sizes.

Blocks for interior work made from gypsum have gained enormous popularity.

Various types of products are used:

- standard, intended for use in dry rooms with humidity levels up to 60%;

- moisture-resistant, intended for use in bathrooms and toilets, where the moisture concentration is more than 60%.

Tongue and tongue blocks also differ in design features:

- solid products have increased strength and allow you to securely fix furniture and attachments;

- Hollow slabs are almost as good as solid slabs in terms of strength, are lightweight and reduce the load on the foundation.

Tongue-and-groove blocks allow you to construct partitions of various designs:

- single, with reduced thickness and low weight;

- box-shaped, allowing you to place engineering communications inside.

Blocks have a number of advantages:

- reduced thermal conductivity. The material provides a high level of thermal insulation and allows you to save on heating costs;

- simplicity and speed of installation. Thanks to special protrusions and grooves, products of standard sizes can be quickly installed;

- ease of finishing. After installing the blocks, the surface does not need to be plastered. It should be primed, after which you can glue wallpaper or tiles.

In rooms where there is constantly high humidity, for example, in the bathroom, use a hollow tongue-and-groove comb

Other advantages include:

- environmental cleanliness;

- fire safety;

- vapor permeability;

- ease of processing;

- affordable price.

Disadvantages of blocks:

- impossibility of application for main walls and load-bearing partitions;

- violation of the integrity of tongue-and-groove blocks during shrinkage of the building.

Correct laying of the first row guarantees the stability of partitions made from tongue-and-groove blocks.

Foam concrete blocks

Foam concrete is a material that is quite light in weight, especially compared to brick. Of course, depending on the brand, the weight may vary. It varies from three hundred to one thousand two hundred kilograms per cubic meter. The structure of foam concrete blocks has a large number of closed pores. Nowadays, foam concrete blocks are actively used not only in the construction of interior partitions, but also in the construction of entire low-rise buildings. It is because of this that different brands of material have such different densities, because different construction situations require different weights. The less the material weighs, the better quality of sound insulation it creates from airborne noise. However, foam concrete blocks are inferior to other materials, since the sound insulation of a foam concrete partition, with a standard thickness of one hundred millimeters, reaches a normal acceptable value only if a ten-millimeter layer of plaster is applied on both sides. So low density protects well from airborne noise, but very poorly neutralizes structural noise. In addition, the low density of the material does not allow anything more or less heavy to be attached to the partition. Of course, you can hang a picture or a clock, but you will have to forget about shelves and, especially, additional structures.

Among the advantages of foam concrete blocks are their significantly larger size compared to brick. The standard size of a foam concrete block for walls is three hundred by six hundred millimeters with a thickness of two hundred millimeters, and for partitions - one hundred. In addition, creating a partition from foam concrete blocks is a much easier process, although here you will need to apply basic construction skills. The thickness of a regular foam concrete block is twenty centimeters. This means that such a partition will take up more space in the room. Like a brick partition, foam concrete will have to be plastered before finishing.

Construction of walls in an apartment or house - important points

When planning the construction of walls and partitions, pay attention to the following points:

- horizontal floor surface and absence of defects. The floor should be cleared of any remaining construction debris and any uneven areas and cracks should be carefully sealed. Installation of the first row of blocks is carried out only on a pre-planned surface;

- preliminary calculation of material requirements. Before starting work, it is important to calculate the number of blocks, the need for an adhesive mixture, taking into account the size of the walls and the volume of masonry. Using a calculator posted on professional websites, it is easy to quickly perform calculations;

- performing markings that meet the requirements of the project. The outline of the future wall or partition should be marked on the floor. Laying and fixing the steel profile on the floor will allow you to clearly determine the location of the masonry and will facilitate further construction operations;

- locations of future openings. Interior openings are formed during the process of laying blocks and reinforced with steel reinforcement placed in a pre-made groove. Situations arise when the location of the opening changes. For such openings it is worth using a reciprocating saw.

Foam concrete blocks are placed on glue or cement mortar

Before starting work, carefully study the technology of laying blocks and purchase materials in the required quantity.

How to strengthen walls made of foam concrete blocks

There are various methods for strengthening foam block walls:

- interior. It is implemented by laying reinforcing bars at intervals through four levels of foam concrete masonry;

- external. It is produced by decorative surface finishing or by applying a protective plaster layer.

Options for external wall reinforcement:

- using a plaster compound. This is a simple, but not reliable enough method, since the plaster may peel off as a result of shrinkage;

- using drywall. Finishing foam block walls with plasterboard sheets will increase the strength of the structure;

- using wood. The use of wooden lining or particle boards allows you to decorate partitions and walls.

Please note that it is easy to glue wallpaper or install ceramic tiles onto a plasterboard surface.

Construction of insulated walls

Insulated partition

We will consider in more detail the methods of constructing insulated walls, for example, internal partitions made of foam blocks or expanded clay blocks in order to obtain a private space. But first of all, it should be noted that according to generally accepted standards, blind partitions can only be installed in rooms with several sources of natural light, that is, in which there are two or more windows. If the partition is erected in other places, then permission from the BTI and the drawing up of a new project will be required. Therefore, the first thing we will consider is the conditions for installing partitions in the apartment.

Studio apartment - partition options

The area of the apartment does not always allow the use of building blocks for partitions.

To divide the space into zones in a studio apartment, various types of partitions are used:

Apartments with an open plan have become very popular.

- stationary;

- sliding

The construction of sliding partitions, functioning similarly to wardrobe doors, allows for rational use of space and the implementation of original design solutions.

The following materials are used for the manufacture of sliding partitions:

- glass;

- mirrors;

- plastic.

The main advantages of plastic and glass partitions:

- expanded color range;

- versatility;

- compactness;

- rational use of space.

A significant advantage is the feeling of increased volume when using mirror partitions. The disadvantages include the high cost of the material, as well as the ability to perform work only by professional builders.