What is a fluorescent lamp

The low efficiency of traditional incandescent lamps has long been a headache for electrical equipment manufacturers. The problem of saving energy became more and more urgent and in 1936 a solution was proposed. In Russia, special gas-discharge devices have appeared that can combine lighting with energy savings.

A fluorescent lamp is a structure made from a bulb with electrodes placed inside. The shape can be any; operation is affected only by the gas composition. After applying voltage between the electrodes, the process of electron emission starts, which creates radiation.

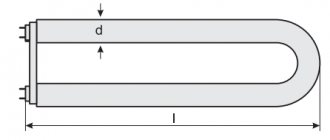

Figure 1. Fluorescent light source

However, the radiation received at this stage is in the ultraviolet range and is not visible to the human eye. To make the light visible, the top of the bulb is coated with a special compound - a phosphor.

Inside the flask there is an inert gas or mercury vapor to maintain a glow discharge between the electrodes. Inert gas is a safe option because it does not interact with the surrounding space in any way. But devices with mercury vapor are extremely dangerous. Devices with such contents must be disposed of according to all rules, and care must be taken when handling flasks.

Fluorescent lamp design

Before proceeding with the classification, you should consider the internal structure of the phosphor lamp, which serves as the structural basis for any devices belonging to this category.

These lighting devices are of the gas-discharge type. Fluorescent fluorescent lamps operate on electric current and have an extended service life. They are used in lighting networks of residential buildings, offices and shopping centers, and industrial production facilities. They are produced in various versions, differing in bases, shapes of glass bulbs, color radiation and other parameters.

Despite this diversity, each fluorescent lamp has common design elements. The basis is a glass tube or flask, sealed on both sides. Its length can be different, the inner surface is covered with a special substance - phosphor, and the space is filled with an inert gas, with the addition of a small amount of mercury. Along the edges there are cathodes coated with an active substance. Contact pins brought out are connected to them.

After applying voltage, an electrical discharge is formed between the electrodes. It acts on a mixture of gas and mercury vapor, resulting in ultraviolet radiation. In turn, it affects the phosphor and, interacting with it, turns into visible light. Adjustment of light shades is carried out using phosphors of various chemical compositions.

All these processes are carried out using special ballasts, without which the start-up and operation of a fluorescent lamp is impossible. This equipment is called ballast and is used to regulate electrical discharge.

The ballast can be electromagnetic, with a starter and choke, or electronic, based on a semiconductor circuit. The first option is considered an outdated model; it creates extraneous noise during operation and is large in size. More modern electronic devices are compact, operate quietly, with virtually no noise, and make all switches instantly.

Types of fluorescent lamps

All fluorescent lamps are usually divided into two large groups: high and low pressure devices.

High pressure devices are often used in street lamps. They are capable of producing a strong luminous flux, but the color rendering parameters are at a low level. On sale you can find lamps with different levels of light output and shades of glow. They are used for powerful lighting, as decorative lighting for buildings.

Figure 2. Types of LL

Low pressure LL is more common. They are widely used in everyday life and in production. Most often, the models look like small cylinders. Such electrical appliances have ballasts that reduce the pulsation coefficient and make the glow more uniform. The component is a small circuit housed in the base of a light bulb.

Parameters and technical specifications

Despite the variety of models and modifications, there are certain indicators that are characteristic of all fluorescent lamps. These include the following:

- Characteristics of the emitted light: brightness, luminous flux, color and spectral region, pulsations of the luminous flux.

- Electrical plan parameters related to power, supply current, operating voltage. The type of discharge and the glow area directly involved in the lighting process are taken into account.

- Performance qualities determined by the service life, luminous efficiency, size and configuration of fluorescent light bulbs. It should be noted that the first two groups of parameters largely depend on the supply voltage and external environmental conditions.

One of the main characteristics by which fluorescent lamps are distinguished is the combustion voltage, which is directly related to the discharge used.

They are divided as follows:

- Lamps up to 220 volts with arc discharge, with an oxide cathode that glows independently. It preheats, after which the lamp itself lights up.

- Lamps up to 750 volts with arc discharge. These devices do not require preheating of the cathodes, their power is over 60 W, and they are used mainly abroad.

- Glow discharge lamps. They use cold cathodes and operate on low currents, no more than 200 mA. Used in advertising and signal lighting.

In most areas and lighting systems, lamps of the first group are used. The power of fluorescent lamps of this type is 15-80 W, and the average service life is more than 12 thousand hours. In this case, each lamp must operate for a total of at least 4800-6000 hours. During this period, the permissible reduction in luminous flux is 40% or less of the original. The permissible temperature range is 5-55C, the most favorable operating conditions are at a temperature of 5-25C.

Markings and sizes

Each LL has its own technical characteristics that determine its use. Typically, all information about the device is encrypted in the labeling.

The designation begins with the letter L, which means lamp. Then comes the letter designation of the shade.

| Marking | Meaning |

| D | day glow |

| B | White light |

| HB | cool white |

| TB | warm white |

| E | natural light |

| HE | cool natural light |

| G, K, Z, F, R | various shades depending on the type of gas used and the phosphor used |

Sometimes in the marking you can find the designation Ts or TsTs, which indicates improved color rendering of the phosphor. For example, the designation LDC is typical for a fluorescent lamp with improved color rendering.

This is followed by digital designations that comply with global standards. These are three numbers, the first of which determines the quality of color rendering, and the rest indicate a specific color temperature. The larger the first number, the better the color rendering. An increase in the remaining numbers indicates a cooler glow.

Figure 3. Types of LL base

LL devices vary in size. The dimensions are indicated by the designation “TX”, where X is a specific size parameter. Specifically, T5 means 5/8 inch in diameter, and T8 means 8/8 inch in diameter.

The sockets can be pin or threaded. In the first case, the designation looks like G23, G24, G27 or G53. The number indicates the distance between the pins. Threaded sockets are available with markings E14, E27 and E40. Here the number determines the thread diameter.

Additionally, the lamp indicates the supply voltage and startup method. If the box has the designation RS, it means that no additional equipment is required for operation. All the necessary elements are already built into the base.

Latest events

06.01.2014

Decoding the markings of fluorescent lamps

The three-digit code on the lamp packaging usually contains information regarding the quality of light (color rendering index and color temperature).

The first number is the color rendering index of 1x10 Ra (compact fluorescent lamps have 60-98 Ra, so the higher the index, the more reliable the color rendering)

The second and third numbers indicate the color temperature of the lamp.

Thus, the marking “827” indicates a color rendering index of 80 Ra, and a color temperature of 2700 K (which corresponds to the color temperature of an incandescent lamp).

In addition, the color rendering index can be designated in accordance with DIN 5035, where the color rendering range of 20-100 Ra is divided into 6 parts - from 4 to 1A.

International markings for color rendering and color temperature

| Code | Definition | Peculiarities | Application |

| 530 | Basic warmweiß/warm white | Light of warm tones with poor color rendering. Objects appear brownish and have low contrast. Mediocre light output. | Garages, kitchens. Lately it has become less and less common. |

| 640/740 | Basic neutral white / cool white | “Cool” light with mediocre color rendering and light output | Very common, should be replaced by 840 |

| 765 | Basic Tageslicht/daylight | Bluish “daylight” light with mediocre color rendering and light output | Found in office spaces and for illuminating advertising structures (city lights) |

| 827 | Lumilux interna | Similar to incandescent light with good color rendering and luminous efficiency | Housing |

| 830 | Lumilux warmweiß / warm white | Similar to the light of a halogen lamp with good color rendering and luminous efficiency | Housing |

| 840 | Lumilux neutral white / cool white | White light for work surfaces with very good color rendering and luminous efficiency | Public areas, offices, bathrooms, kitchens. External lighting |

| 865 | Lumilux Tagslicht / daylight | “Daylight” light with good color rendering and mediocre light output | Public places, offices. External lighting |

| 880 | Lumilux skywhite | Daylight with good color rendering | External lighting |

| 930 | Lumilux Deluxe warmweiß/warm white | “Warm” light with excellent color rendering and poor light output | Housing |

| 940 | Lumilux Deluxe neutralweiß / cool white | “Cold” light with excellent color rendering and mediocre light output. | Museums, exhibition halls |

| 954, 965 | Lumilux Deluxe Tageslicht / daylight | “Daylight” light with a continuous spectrum of color rendering and mediocre light output | Exhibition halls, aquarium lighting |

Color rendering marking according to GOST 6825-91

In accordance with GOST 6825-91 (IEC 81-84) “Tubular fluorescent lamps for general lighting”, current, general purpose linear fluorescent lamps are marked as:

LB (white light)

LD (daylight)

LE (natural light)

LCB (cold white light)

LTB (warm white light)

Adding the letter C at the end means the use of a “de-luxe” phosphor with improved color rendering, and TsTs means the use of a “super deluxe” phosphor with high-quality color rendering.

Special purpose lamps are marked as:

LG, LC, LZ, LV, LR, LGR (colored lamps)

LUF (ultraviolet light lamps)

DB (ultraviolet light type C lamp)

LSR (blue light reflective)

The color rendering parameters of domestic lamps are given in the table:

| Abbreviation | Decoding | Color t-ra, K | Color rendition | Approximate equivalent according to international marking |

| Fluorescent lamps | ||||

| LDC, LDTS | Fluorescent lamps with improved color rendering; LDC - deluxe, LDTS - super deluxe | 6500 | Good (LDTS), excellent (LDTS) | 865 (LDTS), 965 (LDTS) |

| LD | Fluorescent lamps | 6500 | Acceptable | 765 |

| Natural light lamps | ||||

| LETZ, LETZ | Natural light lamps with improved color rendering; LETS - deluxe, LETS - super deluxe | 4 000 | Good (LEZZ), excellent (LEZZ) | 840 (LEZZ), 940 (LEZZ) |

| LE | Natural light lamps | 4 000 | Acceptable | 740 |

| Other lighting lamps | ||||

| LB | White light lamps | 3 500 | Unsatisfactory | 635 |

| LHB | Cool white lamps | 4 000 | Unsatisfactory | 640 |

| LTB | Warm white lamps | 3 000 | Relatively acceptable for warm tones, unsatisfactory for cold tones | 530, 630 |

| LTBCC | Warm white lamps with improved color rendering | 2 700, 3 000 | Acceptable for warm tones, less satisfactory for cool tones | 927, 930 |

| Special purpose lamps | ||||

| LG, LC, LZ, LV, LR, LGR | Lamps with colored phosphor | — | — | LH: 67, 18, BLUE LH: 60, 15, RED LH: 66, 17, GREEN LH: 62, 16, YELLOW[5] |

| LSR | Blue reflector lamps | — | — | — |

| LUF | Ultraviolet lamps | — | — | 08 |

Power and spectrum

In order for the lighting source to work normally, it must be connected to a 220 V network with a frequency of 50 Hz. Deviation may negatively affect the stability of lighting, significantly shortening the service life.

Voltage fluctuations can change the power of an electrical appliance, reducing its efficiency. Even the most powerful lamp will glow dimly if there is insufficient voltage.

Must watch: a ban on fluorescent lamps will come into force in 2021.

Modern LLs have almost any shade. The color temperature spectrum varies from classic warm to daylight. Each lamp is marked accordingly by shade.

Separately, it is worth considering lighting devices with ultraviolet glow. They are marked LUF, while reflective blue devices are marked LSR. UV lamps are used for bactericidal treatment of premises.

Most fluorescent lamps produce a flux similar in length to ordinary sunlight. You can see the similarities between the spectra in the picture below.

Figure 4. Comparison of the spectrum of sunlight and LL

The spectrum of sunlight is shown on the left; the spectrum of a high-quality fluorescent lamp is shown on the right. The light from the sun has a more even characteristic, but the similarities are definitely there. LL has a pronounced peak in the green region, while in the red region there is a decrease.

It has been scientifically proven that the closer the light from an artificial source is to natural light, the better it is for health. For this reason, fluorescent lamps are preferable to LED fixtures.

Types, principle of operation and use of fluorescent lamps

We have already familiarized ourselves with the superficial information, but now let’s look deeper at the structure of the lamps. We will define their main features and present a lot of interesting information, which, although not useful in practice, will be very useful for general development.

Principle of operation

Sectional view of a fluorescent lamp

Let's imagine that we have a lamp, it is turned on and working. What causes the glow? The fact is that at the opposite ends of the tube there are electrodes, between which an arc discharge burns (a physical phenomenon discovered in 1802 by the Russian physicist V. Petrov).

The internal volume of the lamp is filled with mercury vapor and inert gas (odorless and colorless monoatomic gases). Upon contact with electricity, a stream of ultraviolet non-thermal radiation is created.

As already mentioned, the inside of the flask is covered with a layer of phosphor, which has the property of absorbing ultraviolet radiation, converting it into visible light. The different composition of the phosphor allows you to adjust the light shade. Calcium-zinc orthophosphates and calcium halophosphates are used as spraying. The radiation intensity depends on the lamp power and the quality of the phosphor.

Petrov's electric arc, which is mistakenly attributed to the discoveries of Nikola Tesla

The arc discharge is maintained due to thermionic emission of charged electrons from the cathode surface (knocking electrons out of metals when exposed to high temperatures). Therefore, in order for the lamp to start, the cathodes need to be heated.

This is where the types of lamps begin to differ:

- The first are models with hot start (LD and DRL lamps). In them, the cathodes are heated by current passing through them. These lamps have a noticeable slow start (0.5 - 1 sec), which annoys many users. But it is worth noting that such lamps last much longer.

- The second are lamps with “cold” start. In them, the cathodes are heated by ion bombardment, which occurs in a high-voltage glow discharge. Such lamps turn on almost instantly, but their service life is reduced.

To start lamps, starting devices with electromagnetic and electronic ballast are used, but we will talk about them a little later.

Marking of fluorescent lamps

Lighting color temperature

Depending on how bright the lighting is, the human perception of color changes greatly. For example, blue color is more visible to us in low light, and red color becomes less noticeable. As a result, daylight at low intensities appears bluish.

Because of these features of our vision, standards have been developed for the illumination of various rooms: for a home, 75 lux (a unit of measurement of luminous intensity, according to SI) within one room is enough, and for industrial premises this value is 400 lux.

- In the first case, lighting with a color temperature of 3000K looks most natural.

- In the second - 4000-6000K, since the previous option will already appear yellow.

To avoid confusion in these parameters, manufacturers label their products. Labeling can be international or domestic.

International notation system

The international one includes a three-digit value, which, if correctly deciphered, can determine the parameters of the lamp.

An example of the use of international markings on fluorescent lamps

- The first digit in the code is the color rendering index. This number is multiplied by 10 Ra (a kind of indicator of the color level). The higher the value obtained, the more accurate the color rendering is considered. Compact lamps for home usually have this indicator of 60-98 Ra.

- The remaining two digits indicate the color temperature of the light emitted by the lamp.

That is, the marking on the 930 package indicates that the lamp has a color rendering index of 90 Ra and a color temperature of 3000 Kelvin.

In addition to the indicated marking, according to DIN 5035 (German equivalent of GOST), the color rendering range from 20 to 100 Ra is divided into 6 parts. We won’t go into details, but if anyone wants to enlighten themselves, we ask you to take a stroll through the Internet.

Domestic marking

Internal Russian markings are very different from those described above. It is regulated by GOST 6825-91 (IEC 81-84) and other regulatory documents.

Russian marking of fluorescent lamps

According to this marking, the following types of lamps are distinguished:

| Marking | Description | Temperature in K | International analogue |

| LB | White light. They are characterized by high light output and low-quality color reproduction. They are used primarily in administrative and industrial premises. | 3500 | 635 |

| LD | Daylight. Has a slight bluish tint. Color rendering is acceptable, combined with high light output. | 6500 | 765 |

| LHB | Cool white light. The shade is somewhat reminiscent of the sun. Color rendering is low. Like the previous options, it is suitable for production with low color rendering requirements. | 4000 | 640 |

| LTB | Warm white light. The white glow has a slightly pinkish tint. Used in catering establishments and grocery stores | 3000 | 530 — 630 |

| LE | Natural light. White light has no shades. It is characterized by high light output. | 4000 | 740 |

| LHE | Natural cold light. Similar to the previous one, but has a colder shade. | 6000 | 760 |

In the table we have listed the main types of lamps and their markings. In addition, the marking can be supplemented with the letter “C”, which means improved color rendition, or “TsTs” - high-quality color rendition.

That is, the LDCC marking will mean daylight with high color rendering. Such lamps are used in museums and exhibitions so as not to distort the perception of the efforts of artists.

The photo shows a special-purpose lamp

In addition to the options mentioned, there are many more lamps that have a specific purpose. These models also have their own markings.

- LZ, LG, LK, LR, LGR, LV - all these are colored lamps (p - pink, k - red, g - yellow, gr - purple, z - green, g - blue);

- LUF – ultraviolet lamps;

- DB – ultraviolet glow type “C”;

- LSR – blue light reflector lamps.

For more detailed information about the marking, please refer to GOST.

Electrical connection

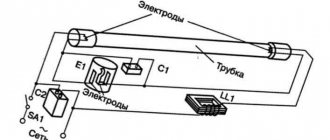

Starting control device

A significant disadvantage of fluorescent lamps is that they cannot be connected directly to the network, and there are two reasons for this.

- After a discharge occurs in the lamp, it acquires a negative differential resistance, which can cause a short circuit, unless, of course, resistance is included in the circuit.

- When turned off, a fluorescent lamp has high resistance, so it requires a high voltage pulse to form an electric arc.

To solve the described problems, starting devices are used. The most widely used are variations of electronic ballasts and electronic ballasts.

Electromagnetic ballast

Electromagnetic starting control device

An electromagnetic ballast or EMPA is a choke that has an inductive reactance of the required value and is connected in parallel with the lamp. Has a starter made from a capacitor and a new light bulb. The essence of this device is that when turned on, it generates a pulse of up to 1 kV due to self-induction, while it limits the current flowing through it due to its resistance.

The advantages of the scheme include reliability, durability and ease of execution. It has many more disadvantages:

- Long start – up to 3 seconds;

- High energy consumption by the throttle;

- Lower power factor;

- The presence of low-frequency hum with poor quality chokes;

- Double flickering of the lamp;

- Large dimensions of the structure;

- If the air temperature around the lamp is below zero, then the lamp may not start at all.

Electronic ballast

Electronic trigger control mechanism

Electronic ballast (EPG) powers the lamps with high-frequency current from 25 to 133 kHz, making the flickering of such lamps completely invisible to the human eye. There are many models of electronic ballasts that can be used for both hot and cold starting.

The difference with the electronic ballast is that the electronic ballast does not have a starter (a neon lamp with a capacitor), and it is capable of generating the required voltages itself. More often, an electronic ballast heats the cathodes to the required voltage temperature so that the lamp starts.

Depending on the model, electronic ballasts can ignite the lamp smoothly, gradually increasing the glow, or do it instantly.

“Cold” start is carried out due to the fact that the circuit into which the lamp is connected is, in fact, an oscillatory circuit, the parameters of which are selected so that in the absence of a discharge, the phenomenon of electrical resonance occurs in the circuit. This method is very popular among radio amateurs, as it allows you to start even lamps with burnt-out cathodes.

The lamp is broken

The lamp began to shine intermittently or went out completely

Why does a fluorescent lamp fail? If you did not break the lamp, then the reason most likely lies in the following. The ignition electrodes of the design are made of tungsten coated with an alkaline earth metal paste, which gradually falls off the cathodes during operation.

This process occurs especially intensely when the lamp is started due to the fact that the discharge begins to burn not over the entire area, but only on a certain area of the surface, causing local temperature changes. This results in darkening of the bulb around the edges, which becomes more noticeable towards the end of its service life.

Conclusion! The lifespan of a lamp directly depends on the quality of the electrodes installed in it.

Lamps on electronic ballasts and electronic ballasts burn out in different ways:

- In the first case, when one of the electrodes burns out, the voltage on the lamp increases to the value of the discharge in the starter. Because of this, it begins to constantly work and the well-known blinking of worn lamps occurs.

- When the starter is constantly activated, the electrodes begin to overheat, as a result, one of them burns out after a couple of days. In this case, the starter itself very often burns out, requiring replacement along with the lamp.

- The lamp may also fail due to a malfunction of the throttle and starter. In the first case, the current flowing through the lamp increases greatly, due to which the electrodes melt and the lamp instantly burns out. In the second, the lamp is shunted along the starter circuit, which is why only the lamp filaments begin to work. In this mode of operation they wear out many times faster.

- In electronic ballasts, after the filaments burn out and the voltage increases - if there is no protection system (poor quality ballasts) - the current increases, leading to the burnout of the ballast transistors.

- Low-quality electronic ballasts can also cause a breakdown, since the output capacitor, as the lamp ages, can break through, which will also cause the transistors to burn out.

There is no blinking in the electronic ballast when the lamp fails - it simply goes out. You can determine the cause of the breakdown with a regular multimeter by checking the filaments for resistance.

Varieties of execution options

Types of fluorescent lamps

In total, I distinguish two types of fluorescent lamps: linear and compact.

Linear fluorescent lamp

- The first option is a low-pressure mercury lamp, U-shaped or ring-shaped. According to GOST 6825-91, they are also called tubular, although this definition is today considered outdated.

- Essentially, it is a glass tube with two bases at the edges in which the legs of the electrodes are mounted. The tube itself is hermetically sealed to keep inert gas (Ne, Kr, Ar) and mercury vapor inside.

- These lamps vary in length, shape and thickness of the tube.

Compact fluorescent lamps

The second option has a curved tube, which can additionally be closed with rounded flasks. The main difference between them lies in the type of base used: 2D, G23, G27, G24 (with modifications ...Q1, Q1, Q3), G53. Because of this, the instructions for installing lamps may vary - study the annotations supplied with the device.

Standard versions of bases are also available, which we very often screw in with our own hands:

Small plinth

- E14 – the smallest base;

Base E27

- E27 – standard base, as on most incandescent lamps;

Base E40

- E40 – large base for street lamps.

This versatility has contributed to the rapid spread of energy-saving fluorescent lamps.

In what areas are they used?

With the help of fluorescent lamps, large areas can be effectively illuminated, while significantly improving indoor conditions, reducing energy costs, and also increasing the service life of the lighting system.

Devices with built-in electronic ballast and E27 or E14 screw threaded sockets are used in everyday life as an effective replacement for incandescent lamps. They are able to provide the necessary luminous flux, guarantee stability and absence of flicker. At the same time, there is no hum at all. They are used in apartments, houses, shopping centers, schools, hospitals, banks, etc.

Figure 5. LL in the interior

Specifications

The technical characteristics of a particular lighting device are encoded in the labeling and indicated on the packaging. This is information about the lamp power, base type, size, color temperature, service life.

Most modern fluorescent devices can operate for 8-12 thousand hours. The indicator depends on the type and size of the device.

Efficiency is expressed as 80 Lm/W, which is significantly more than traditional incandescent lamps. During operation, a moderate amount of heat is generated; the devices are resistant to wind and can operate stably at temperatures from +5 to +55 °C. If a heat-resistant coating is present, the device can be used at +60 °C.

Figure 6. Specifications

The color temperature is usually from 2700 to 6000 K. The efficiency can reach 75%.

The relevance of the use of fluorescent lamps

LL has become widespread due to many advantages, namely:

- high luminous efficiency (10 W LDS provides illumination comparable to a 50 W incandescent light bulb);

- large range of shades of emitted light;

- complete diffusion of light.

The guaranteed service life of LDS is from 2 thousand hours versus 1 thousand hours for incandescent lamps.

Disadvantages of fluorescent devices:

- chemical hazard (LDS contains up to 1 g of mercury);

- uneven spectrum that is unpleasant to the human eye;

- gradual destruction of the phosphor layer, leading to a decrease in illumination;

- lamp flickering at twice the mains frequency;

- the presence of a mechanism that regulates the start;

- LL power does not provide a high coefficient.

How the lamp works

The operating principle of any fluorescent lamp involves applying voltage to the electrodes located inside the bulb. A glow discharge occurs between the electrodes, which is supported by an inert gas or mercury vapor located inside the flask.

Figure 7. Operating principle

The glow discharge generates radiation in the ultraviolet range, which, through a phosphor applied to the flask, is converted into visible light of the desired shade.

To produce ultraviolet radiation, gas-discharge lamps are used. Ordinary glass does not transmit ultraviolet radiation, so special quartz glass is used to make the flask. There is no phosphor coating in this case. The devices are widely used in solariums and for disinfecting premises.

Why do you need a choke in a fluorescent lamp?

The standard connection diagram for a fluorescent lamp includes the light source itself, a starter and a choke.

The inductor is an inductor with a plate core. It plays the role of a ballast, stabilizing the voltage and preventing the lamp from quickly becoming unusable.

When turned on, the starter receives a significant voltage, several times higher than that required for the lamp. The choke reduces this voltage and only then supplies it to the contacts of the lighting device.

Figure 8. Connection diagram of the inductor to the lamp

The circuit can be supplemented with a capacitor connected in parallel to the power supply, which significantly improves system stability, extends service life and reduces flicker.

How to choose the right one

When choosing a fluorescent lamp, you need to pay attention to:

- temperature conditions of use;

- voltage;

- size;

- luminous flux strength;

- lighting temperature.

Devices with a threaded base and minimal flicker are effective in everyday life.

Figure 9. When purchasing, pay attention to the size of the base

Hallways need strong lighting, so choose lamps with an intense luminous flux. But in the bedroom or living room, compact devices with soft, dim light are appropriate.

In the kitchen it is better to use multi-level lighting, including general and local appliances. It is advisable to select warm shades with a power of at least 20 W.

It will be useful to read: Choosing fluorescent lamps for plants.

Lamp disposal

Fluorescent lamps contain substances harmful to the environment, so waste disposal must be handled as responsibly as possible.

One lamp can contain about 70 mg of mercury, which is quite dangerous. However, there are a lot of similar lamps in landfills, this is a serious problem.

If mercury enters the human or animal body, it quickly provokes poisoning. Storing faulty lamps in the house for a long time is prohibited due to the likelihood of mechanical damage to the bulb with subsequent leakage of harmful substances.

Figure 10. Designation of the place where disposal of devices is permitted

Disposal of devices:

- All lamps are collected and stored in special containers.

- Using a press, the devices are crushed.

- The resulting crumbs are sent to the heat treatment chamber.

- Harmful substances enter the filter, where they remain.

Sometimes gases are exposed to liquid nitrogen and become solid. The resulting mercury is reused.