Determining the thickness of load-bearing walls

The size of wood concrete blocks is standardized by GOST; the thickness of the block is constant - 300 mm. Other sizes vary for different series. The width and thickness of the wood concrete block, as well as their height, come in the following sizes: 500x300x200 mm, 500x300x250 mm, 500x250x200 mm, 500x250x150 mm.

The thickness of the walls depends on many factors. Each building material has certain characteristics. We list the most important ones:

- Thermal conductivity.

- Strength against loads.

- Frost resistance.

Thermal conductivity determines the ability of a material to conduct heat. This value indicates the thermal conductivity coefficient. The lower its value, the worse the structure will transmit heat to the outside. This means that to preserve heat in the house, you can make the walls thinner.

Load-bearing enclosing structures not only serve to protect against external cold, but also provide support for the roof and other elements. Depending on the current load, the minimum thickness of the wood concrete wall is determined. This indicator is also affected by the number of floors in the house.

It should be remembered that in buildings up to three floors it is necessary to use blocks measuring 500x300x250 mm, for two-story houses - 500x250x200 mm.

If we are building a bathhouse from wood concrete, the wall thickness will be sufficient 250 mm. The thermal conductivity for such a width will be sufficient, and the block will withstand the load of a one-story building.

An accurate calculation of load-bearing structures, depending on the region of construction and permissible loads, should be made by a design specialist at the design stage.

There is an opinion that the thickness of monolithic walls made of wood concrete may be less than that of blocks. If high-quality, even blocks are used for masonry, or perlite mixture or adhesive for cellular concrete is used for bonding, then there will be no difference between these structures.

The design and composition of external walls made of wood concrete, thickness can be different. Sometimes they include brick cladding. The brickwork is fastened using metal loops, which are placed in every 5th row in increments of 500 mm.

No. 1. Wood concrete composition

Arbolite is one of the varieties of lightweight concrete. The name of the material has French roots: arbre is translated from French as “tree”. If you know this fact alone, you can guess what basic materials are included in the composition of wood concrete. So this is:

- wood chips (up to 80-90% of volume);

- cement;

- water;

- chemical additives to improve strength and increase adhesion of chips to cement.

It is clear that the characteristics of the finished material depend on the quality of the raw materials. Since there is the most wood chips in a wood concrete block, it is given the greatest importance. The composition should consist of wood chips - not sawdust, hay, tyrsa or shavings (otherwise it will be sawdust concrete). The strength of the material depends on the caliber of the chips. According to standards, the length of the chips can be up to 40 mm, width – 5-10 mm, thickness – 3-5 mm. It is desirable that the block contains only wood chips without any impurities, although a small amount of bark (up to 10%) has virtually no effect on the strength of the products. The type of wood is not so important, but pine or spruce are usually used, and larch is used much less frequently, since more additives will need to be used due to the characteristics of the wood.

Cement is used no lower than grade M400, but since it has the ability to quickly lose strength properties during storage, it is better to use grade M500 cement in the production of structural arbolite blocks.

It is impossible to do without chemical additives in the production of wood concrete - the sugars contained in wood are to blame, which prevent normal adhesion. Therefore, well-dried wood is used in production, but this does not help. The surface of the chips is mineralized with lime, calcium chloride, liquid glass or alumina sulfate.

The ratio of components is regulated by GOST. If, for example, you exceed the water content, then you may end up with a block of insufficient strength, and there will be more problems with its production.

Arbolite is produced in several types:

- masonry blocks;

- hollow blocks;

- thermal insulation boards;

- panels;

- mortar for creating monolithic structures and pouring in place (similar to expanded clay concrete and polystyrene concrete).

Since arbolite blocks have found the greatest application, today they are meant by arbolite. As a rule, they are made in dimensions of 500*250*200 mm, but products with other parameters may be found.

Required thickness of partitions

The thickness of internal partitions made of arbolite blocks does not depend on loads, since in this case they are absent. Their thermal conductivity and sound insulation are important here. If they are not load-bearing, they can be kept minimal. For partitions, narrow blocks measuring 500x250x150 mm are produced.

Wood concrete has good soundproofing properties (0.17–0.6 units at a sound frequency of 135–2000 Hz), so such a wall will ensure silence in individual rooms.

Wall thickness for different regions

In different regions of Russia, the dimensions of external walls made of wood concrete may vary. This depends on the temperature of the outside air. For example, the thickness of wood concrete walls for Siberia will require at least 40 cm.

Here you need to consider concepts such as recommended and permissible thickness. The recommended thickness indicates the value at which the room will always be warm, regardless of whether the other structures of the house are heat-intensive enough.

Acceptable means that in order to obtain a comfortable temperature in the rooms, additional measures must be taken to eliminate heat loss through other structural elements - floors, windows, ceilings.

It is necessary to distinguish between such concepts as operating conditions. They depend on the humidity conditions in the room. They are distinguished by classes A and B. The type of premises is also important, 1 is residential premises, 2 is non-residential.

The album of technical solutions presents recommendations for the design and construction of external walls and partitions of low-rise residential and public buildings made of blocks. Here you can find a table containing information for calculating walls. For your reference, we present data for some Russian cities.

Table 1. Thermal requirements and thickness of wood concrete walls

| City | terms of Use | Room type | Degree days (GSOP) | Calculation based on standard value | Calculation of permissible wall thickness | |

| R0mp | Recommended wall thickness, m | Permissible wall thickness, m | ||||

| Arkhangelsk | B | 1 | 6172 | 3.57 | 0.423 | 0.267 |

| 2 | 5672 | 3.37 | 0.401 | 0.251 | ||

| Vologda | B | 1 | 5573 | 3.36 | 0.396 | 0.248 |

| 2 | 5104 | 3.2 | 0.373 | 0.236 | ||

| Krasnodar | A | 1 | 2681 | 2.35 | 0.265 | 0.167 |

| 2 | 2382 | 2.24 | 0.251 | 0.158 | ||

| Moscow | B | 1 | 4941 | 3.14 | 0.367 | 0.232 |

| 2 | 4524 | 2.97 | 0.348 | 0.218 | ||

| Saint Petersburg | B | 1 | 4802 | 3.09 | 0.361 | 0.226 |

| 2 | 4361 | 2.92 | 0.339 | 0.215 | ||

| Tyumen | A | 1 | 6121 | 3.55 | 0.420 | 0.264 |

| 2 | 5672 | 3.39 | 0.401 | 0.253 | ||

Reviews from builders about wood concrete blocks

When choosing a material for the exterior walls of a house, one of the indicators is its cost in relation to its quality characteristics. Some builders believe that walls made of wood concrete 300 mm thick are quite acceptable for different climatic regions. To do this, consider the following:

- The cost of energy in a given area. At the same time, the price of gas or electricity is calculated, depending on what is used to heat the room.

- Reduce heat loss from other structures of the house as much as possible - use double-glazed windows for windows, provide sufficient insulation of the ceiling. It is good for this to make a high base of the building and insulate the floors.

Here are reviews from builders who have repeatedly used wood concrete blocks in construction.

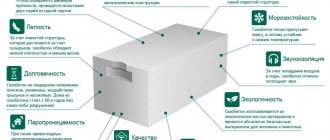

Positive characteristics:

- The material is fire-resistant, although it contains wood chips, the resulting fire is not supported, and no fire occurs from them.

- Arbolite is not subject to destruction from fungus, mold, and harmful bugs.

- It is easy to work with, easy to cut, and light in weight.

- It has low thermal conductivity and does not require an additional layer of insulation.

- This is a breathable, environmentally friendly material.

- It has high sound insulation characteristics.

- The surface of the block has good adhesion to plaster and other finishing materials, which allows saving on additional reinforcement.

- It has a shrinkage after construction of the building of 0.4%, this reduces the period of final shrinkage of the walls.

This material also has disadvantages. It cannot be used in damp areas. The humidity in them should not exceed 60%. For large values, a vapor barrier should be used on the surface of the structures. Cannot be used for plinths and foundations, basement walls.

Wood concrete blocks do not have a high enough load-bearing capacity, which makes it impossible to use them for the construction of multi-story buildings. It is acceptable to use for two to three storey buildings.

Decorating a house from wood concrete

With a small percentage of house shrinkage (0.4%), you can immediately begin finishing the house. Arbolite blocks with decorative finishing are available for sale. Using them during construction, you can get rid of finishing work. The following finishing materials are used for external finishing of wood concrete walls: You should select a material with the same vapor permeability as wood concrete. The plaster coating protects the structure well.

To do this, apply a rough layer, on top of which a plaster mesh is fixed. A protective layer of plaster, resistant to frost and moisture, is laid on top of it with a layer of 5 mm. The facade can be painted with textured paint. The inside of the building can be finished with any material, as long as the humidity does not exceed 75%. A house made of wood concrete has a number of positive characteristics: construction is carried out with a minimum amount of costs, the house has good heat-insulating properties, fire resistance due to the property of wood concrete to withstand high temperatures for a long time without fire, good sound-absorbing properties, resistance to various types of fungi and mold.

A house made of arbolite blocks has a low cost. One cubic meter of building material costs 3.9 thousand rubles. An arbolite house, built in compliance with technology, will delight its owners with comfort and warmth for a long time.

Residents respond positively to good heat retention, which reduces heating costs.