Conductive glue is a handy adhesive for many cars and radio enthusiasts. It is used to repair glass heating filaments in cars, to seal wiring, and to solder contacts in keyboards, remote controls, household appliances, and other devices. An adhesive that does not conduct current may impair the performance of the equipment being repaired.

Features and Properties

The first electrically conductive compound was developed by Germany at the beginning of World War II. Initially it was used only in mechanical engineering. Over time it became universal. Now it is used as a solder when laying heated floors and heating systems, which is due to the ability of the adhesive solution to withstand high temperatures.

- It dries quickly, so gluing must be carried out without interruption.

- It has a high viscosity, which prevents the mixture from flowing into the boards.

- High adhesive characteristics ensure reliable adhesion to the surfaces being processed; it is well fixed on glass, plastic, etc.

- After drying, it can withstand temperatures up to +160 °C while maintaining its structure.

- Safe for humans and nature.

- The elasticity of the composition allows for spot application.

The conductive composition has low electrical resistance. Its use helps protect parts from damage, shock and vibration loads. Thanks to the conductor adhesive, the boards will not react to temperature changes.

Before use, you need to carefully study the composition of the glue and do not use products containing water. The composition and instructions for use are indicated on the original packaging of the glue. For microcircuits, wire contacts, cables, and other electrical elements, the water base is destructive. This composition will take a very long time to dry.

The current-carrying component in the adhesive is often graphite or nickel powder, silver or any other metal. The higher the content of the electrically conductive component, the worse the adhesion of the glue to the surface.

Purpose:

- you can repair computer cables and microcircuits;

- used when installing heating baseboards;

- used as linoleum adhesive when laying antistatic flooring;

- Defects in car electrical systems are eliminated, rear window heating is repaired;

- piezoelements are fastened in radio equipment;

- used when replacing the soldering of light-emitting diodes.

Work with conductive mixtures takes place indoors to minimize environmental pollution.

What is Conductive Adhesive

Glue is a viscous substance that is used to join a variety of materials. There are many types of adhesives, each of them has its own characteristics and properties. Among the most popular are stationery (PVC for papers), linoleum (for flooring), conductive (for various electrical circuits and mechanisms).

Photo - Conductive glue

A conductive two-component adhesive must have the following features:

- Dry quickly, this is necessary for speed of work;

- Have a knitting consistency so that parts of the pattern that do not need to be glued are not damaged during processing;

- Have high adhesion and resistance;

- If you want to use a soldering compound, then you need to choose a heat-resistant glue;

- Be safe for the environment and workers.

This substance is necessary for repairing electrical circuits (keyboards, consumer electronics), constructing various heating mechanisms, floor coverings (warm floors, tiles, glass), etc.

Photo – Elast

You can buy conductive glue without any problems at any construction or electrical store, the average price is from 100 rubles per 25 grams. At the same time, taking into account the consumption, we see the following picture:

- For PVC coatings, the consumption is approximately 250 grams per square meter;

- Non-PVC (textiles, metal) – 400 grams.

It is much cheaper to prepare conductive glue yourself, especially since the components can be bought at any radio store. Let's look at the most popular recipes.

Choosing glue in the store

Construction and hardware stores have a very wide selection of factory-made electrically conductive glue.

Contactol

Produced in Germany by the Keller concern. 3 products in this series have become famous.

- "Single-component contactol." It is possible to organize or restore a conductive connection on dielectrics (glass, polymers, textolite, etc.). Contains silver and synthetic resins. Has high adhesion and moisture resistance.

- "Kontaktol Radio". The base is graphite powder. The properties are similar to the previous composition, but the price is two times lower.

- "Kontaktol conductive marker". The basis is silver powder, palladium, and PVC resins. It has a convenient release form, you can glue parts in hard-to-reach places. Repair jumpers and conductive paths.

Contactol sets quickly. Complete polymerization of the seam in 6-7 hours. To speed up the final gluing, heat the treated area with warm air.

Permatex

Permatex glue (Permatex) is a two-component composition for the restoration of heating contacts. The connection made is resistant to vibration loads, not subject to ultraviolet radiation and temperature changes. It is better to work with glue at an ambient temperature of at least 10 °C.

TPK-E

It glues carbon fiber, aluminum and stainless steel, and any combination of materials can be used. On the treated area, you can create an electrical connection with a transition resistance. The composition and thickness of TPK-E allows static charges to be removed from the processed part.

Forbo 615 eurostar lino el

Floor coverings (linoleum, carpet) are “slung” onto Forbo electrically conductive glue. This is a translucent composition without a characteristic odor.

Done deal

Done Deal glue is made in the USA and has a polymer-silver composition. Used to restore contacts in cars and to restore heating filaments on windows. High quality adhesive with excellent adhesive properties.

Homakoll

It was developed specifically for gluing floor coverings that are produced in rolls and have a fabric or fleecy backing.

- The composition contains no toxic or volatile components.

- Minimum water content.

- Does not shrink after complete drying.

- After initial adhesion to the surface, the likelihood of shifting and peeling is minimal.

- Easy to apply with a notched trowel.

- Incombustible.

Mastix

Mastix adhesive based on nickel powder. It is used for the restoration of rear window heating threads in cars, filling gaps, cracks and holes, and gluing metal. The characteristics are similar to cold welding.

It is permissible to work at low and high temperatures. The quality of the connection in both cases does not decrease.

VolgaKhimProm

Restoration and reinforcing composition. Complete hardening, depending on the thickness of the applied layer, occurs in a maximum of an hour. Used in everyday life and industry. The glue is safe, without harmful effects on human skin, respiratory tract and mucous membranes.

Other brands

- Conductive adhesive Abro Masters. Produced in the United States of America. Repairing the rear window heating filaments.

- Forbo 523 adhesive for gluing linoleum and other floor coverings. Refers to dispersion compositions, frost-resistant, odorless, does not contain solvents.

- Baku BK 426 is an electrically conductive paste for restoring traces on microcircuits.

- Astrohim. Used in repairing glass heating filaments.

- Irpol 5. Elastic composition based on polyurethane components. Bonds antistatic floor coverings.

- Elekont. Epoxy resin based adhesive. Used when repairing a car. Ineffective, sometimes the application has to be repeated.

Areas of application

The scope of application of such glue is truly wide. Let's say, where working with a soldering iron is impossible, due to the too small size of the parts or their sensitivity to high temperatures, it is simply irreplaceable .

The most popular areas of application of electrically conductive adhesives and varnishes:

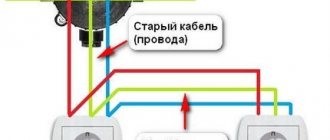

- Gluing and restoration of heating filaments on car windows;

- In radio devices - connection of piezoceramic parts;

- For connecting dielectrics through which electrical communications must pass;

- For connecting conductors of too small a cross-section, where hot soldering is simply impossible;

- For “cold” soldering;

- Restoring broken tracks in various devices: keyboards, remote controls, printed circuit boards, etc.;

- Used in the repair of high-tech devices: phones, e-books, computers, etc., for attaching microcircuits and crystals to boards;

- Acts as a base for enamel or paint with conductive properties;

- Restores current conductivity in damaged areas of various devices;

- Used in the installation and repair of electrical heating systems and “warm” floors.

Of course, the possibilities of adhesives and varnishes capable of conducting current are much wider, but the above list is quite capable of impressing with the scope of the capabilities of such a composition.

DIY conductive glue

Conductive mixtures can be made based on graphite, silver and aluminum.

Graphite based

The easiest way to make conductive glue at home is from graphite. Its main components are pencil lead and nail polish.

You can take the cheapest varnish, it is important that it is transparent, since colored varnishes contain paint that can disrupt the electrical conductivity of the glue. A paste or liquid for gluing false nails is suitable; you can buy the cheapest quick-drying glue, such as “Moment”, “Second”, “Elephant”.

The graphite composition is prepared as follows:

- if you are using nail glue rather than polish, unroll the foil of the tube from the back side;

- remove the lead from a simple pencil, the pencil should be soft (M2, M4);

- grind the lead into a fine powder;

- pour the powder into a tube or bottle;

- mix the ingredients thoroughly with a toothpick;

- Close the tube with the graphite composition again, and clamp the edge with pliers.

If the tube is not closed tightly, the contents may dry out prematurely. Avoid getting air inside. If the resulting glue accidentally spills or is applied unsuccessfully, remove the excess with acetone or nail polish remover.

Graphite can be obtained not only from a pencil. It is found in copper-graphite brushes or salt batteries. You can use sandpaper or a needle file to transform the graphite into powder. The extracted powder can be mixed in a 1:1 ratio with tsaponlak until a creamy mass is formed. An adhesive mixture based on graphite from brushes will be more effective, since it contains an admixture of copper, which increases the electrical conductivity of the product.

Silver based

To make conductive silver-based adhesive, the following components are needed:

- formalin 1%;

- silver nitrate or nitric acid;

- ammonia 5%.

Silver and formaldehyde are mixed in equal parts, and then diluted with a few drops of ammonia. After a couple of minutes, a reaction will occur and silver powder will settle to the bottom of the container. To extract it, the liquid is filtered. The resulting powder is dried at a temperature of 120-150 °C.

To make glue, silver powder is added to varnish or glue, as in the instructions for making graphite glue. Before mixing the components, a little alcohol is dripped into the adhesive solution to slightly dilute it.

There are several more recipes.

- Combine 0.13 kg of silver powder and 12 g of graphite. 8 g of nitrocellulose, 0.05 kg of acetone and 3 g of rosin are mixed into them. If the mass is too thick, dilute it with acetone. The product can be used immediately after preparation, but for the most part not for gluing parts, but as an electrically conductive primer.

- 0.03 kg of graphite is mixed with 0.07 kg of silver powder, 0.07 liters of acetone and 0.06 kg of vinyl acetate are poured into the mixture. After mixing the components, an electrically conductive syrup is obtained, which can be used to coat other adhesives, for example, BF.

Aluminum glue

To create it, aluminum powder is added to epoxy glue or resin.

Epoxy polymerizes quickly when a hardener is added, so aluminum powder must be added to the resin before the liquid component is added.

Aluminum and epoxy are mixed until creamy, then a portion of the homogeneous mixture is measured and combined with a hardener in a ratio of 1:10.

Conductive glue and varnish at home

Now we’ll find out how you can make conductive glue with your own hands without overpaying in electronics stores. There are several methods, differing in preparation methods and basics, we present them.

Epoxy-aluminum composition

Required:

- any two-component epoxy solution, up to the simplest and cheapest EDP-20;

- aluminum powder (it’s easier to use silver paint than to grind sawdust or old pans).

Mix the resin without hardener and aluminum powder in the required proportion until the consistency resembles sour cream. Pour into a glass or plastic resealable jar, before use mix with the hardener in the proportion specified in the instructions, most often it is 1:10, but you can slightly reduce the amount of hardener to improve elasticity, but you need to be careful, the resin can remain sticky for a long time if if there is too little hardener.

This composition has a long hardening time, but can be used when it is not critical. The main advantage is that you can make quite a lot of it; aluminum powder can be bought ready-made. In addition, you can vary the electrical conductivity and elasticity by decreasing or increasing the amount of powder (more metal means more conductivity and less elasticity, and vice versa), but in general, the composition is characterized by low elasticity and high strength.

Graphite and instant adhesive mixture

We will need:

- any quick-hardening adhesive solution (for example, super glue “Second 505” or “Moment”), the main thing is that the hardening speed is such that you have time to apply and mix it before the composition hardens, but not too long so that the prepared paste does not spread ;

- graphite pencil (not colored).

Let's describe the cooking method. A sufficient amount of glue based on Secunda cyanoacrylate glue. We grind a whole pencil lead on a sheet of paper to a dust state; the finer it is crushed, the more homogeneous the final mass will be and the better the conductivity and elasticity will be.

We open the tube or jar of glue to pour the conductive composition (our crushed rod) into it. Mix quickly and seal so that the mixture does not start to harden.

Specifics of using homemade glue

If you need to repair expensive electronics, it is better not to save money and buy high-quality store-bought glue, or even give the equipment into the hands of a specialist. If you need to repair the remote control or have a simpler task, you can prepare a homemade mixture according to the recipes above. This will save you money on buying a ready-made product. The only problem that is typical for all homemade adhesives is that they have a limited shelf life. You need to prepare a small portion, which is used at a time.

Selecting Factory Conductive Adhesive

It is absolutely clear that making glue yourself is much more profitable, especially if a large amount is needed. On the other hand, a solution created independently may not always have all the required properties. You can make a mistake in the ratios of components or simply the resulting consistency will not have all the necessary qualities .

In this case, you should still pay attention to factory analogues. For example, try the most popular Kontaktol glue.

The consistency of this glue is similar to a paste, which contains a mixture of polyester, epoxy and some other resins. And electrical conductivity is provided by gold, silver or palladium powders. Conductive glue Kontaktol will cope with its task perfectly and is quite affordable. However, recently Kontaktol conductive adhesive of poor quality has begun to appear on the shelves. Therefore, it is preferable to contact a seller who provides guarantees.

How to Make Conductive Silver Based Adhesive

To avoid these problems when working with non-ferrous metals, you can make conductive cream on silver, but this is much more difficult than working with pencil lead. Before starting work, you need to acquire silver nitrate, but this may be more difficult than replacing it with nitric acid; it also conducts electricity.

At the pharmacy you need to buy a 1% formaldehyde solution and a bottle of ammonia (ammonia).

Having carefully measured equal proportions, you first need to mix formalin and silver nitrate, then add a couple of drops of ammonia to the resulting mixture.

If the actions were carried out without errors, after some time a black precipitate will form in the resulting composition - silver powder, which must be removed from the liquid (distilled water or a filter can be used) and used for electrical conductivity purposes. This is followed by drying of the sediment extracted from the liquid at a high temperature of 105-150 degrees Celsius. The resulting dried black powder must be added to any quick-drying glue similar to the previous recipe. Professionals advise first mixing the glue with a small amount of alcohol. Due to the high drying rate of the composition, it requires periodic stirring.

There are a huge number of similar recipes, but they are all based on the same processes. It is enough to remember the chemistry or physics lessons at school to identify which elements conduct current, and later, based on them, prepare the ideal adhesive paste for the product.

Reply to reader

Hello Dmitry! We have the answer to your question, but first, for those readers who do not know what such glue is for, we will give a little introductory information.

Purpose of conductive glue

So, conductive glue is required mainly for radio amateurs and craftsmen who professionally repair household electronics. Very often, for various reasons, breaks form on contacts or conductive paths, which is why the equipment loses some functionality or stops working altogether.

To quickly repair such faults, conductive glue is used for cables. That is, it is applied to the damaged area in a thin strip, without touching adjacent contacts, and after drying, it begins to conduct electricity through the restored circuit.

If you have a radio store within walking distance, then purchasing such a miracle will not be difficult, and the price does not exceed 200 rubles. Among the most popular brands are: Elekont, Kontaktol, Elast (varnish) and others.

But when there are no such stores nearby, finding the compounds becomes problematic. So let's now figure out how to make conductive glue at home with your own hands. The procedure will not take much time and will not require you to use extremely rare components.

Features of conductive adhesive

Before we begin analyzing the recipe, let's figure out what quality the composition should be and what properties it should have.

- The conductive base of such adhesives, which ensures normal current conductivity, consists of the following substances: graphite (the most common pencil), some polymers, nickel powder, silver powder (the best conductivity). To implement the idea, any of these materials in powder form will be suitable, but most likely it will be graphite, since it is the most affordable.

- The final mixture must have low resistivity so that the tracks do not heat up during operation, and its consistency must be elastic so that it does not spread and is convenient to work with.

- It is very important to maintain the correct ratio between the liquid and powder components. For example, if you overdo it with graphite, the glue may begin to poorly adhere to various types of surfaces, and conversely, an insufficient amount of it will lead to an increase in resistance, and as a result, heating of a given point, which is extremely undesirable.

- The next important property that homemade conductive glue should have is fast drying time. The speed of your work will entirely depend on this parameter. Therefore, to make the mixture, it is better to prepare any quick-drying glue or varnish.

Production of conductive glue from graphite

As we have already said, the most accessible conductive dry component is graphite. Therefore, let's figure out how glue is made based on it.

- To work we need only two components. Actually, the graphite itself and the binder.

- We take a simple pencil (preferably a construction pencil, since its core is very thick and soft, which is what we need), split it with a knife and a hammer, placing the blade parallel, and remove the core. The cost of the solution will be from 10 to 20 rubles.

- Grind the graphite rod into powder. To do this, you can use a stationery knife or a fine abrasive, for example, zero-grit sandpaper.

- Take a tube of super glue (let's use it as a base, since it dries very quickly) and carefully unfold the bottom of the tube. If the bottom is sealed or pressed in too well, you can use tin snips to open the tube from that side.

Advice! Wear medical rubber gloves, as glue that gets on your skin is very difficult to remove!

- Pour the prepared powder inside, making a one to one ratio by eye.

- Stir the contents thoroughly using a toothpick or any other suitable object.

- Carefully roll the metal back and, in principle, that’s it - the glue is ready for use. This mixture will dry very quickly, which will undoubtedly increase your productivity.

Read also: How to set up satellite channels on your TV

If you don’t have a pencil on hand, but you have worn copper-graphite brushes, you can safely grind them into powder. Moreover, the electrical conductivity of such a solution will be even better.

It is more difficult to grind the brush, so use a fine file or sandpaper for this. Another excellent alternative option would be a salt battery rod.

Where can the resulting composition be applied?

Yes, the same place as the one you buy in stores. It can be useful for an ordinary person (not a radio technician) for minor repairs of devices where it is impossible to use a soldering iron, for example, tracks on a remote control or on a keyboard. Also, such compositions are in demand by car enthusiasts when repairing contacts of the rear window heating system.

That's all, you can of course look for more recipes based on other components, but this composition will be sufficient in most cases. At the same time, the manufacturing instructions are extremely simple and everything for this can be purchased at your nearest store.

In general, which conductive glue to choose, decide for yourself, Dmitry. In addition, we recommend watching a video that will complement our short material.

Currently, every apartment has devices that run on electricity. There are large household appliances, and there are very small ones like a TV remote control or a clock. All of them have long become part of everyday life, and without them it is difficult to imagine the usual state of affairs in everyday life. Every device can break. After all, nothing lasts forever and everything has its service life. You should have on hand the tools and supplies that may be needed in the process of repairing devices.

Many radio amateurs, and even ordinary users of electrical appliances, in the process of repairing devices are faced with the need for conductive glue, varnish, gel or lubricant for contacts. In principle, electrically conductive glue can be purchased at radio electronics stores; experts already know about the presence of the so-called contactor . At the same time, it is not so easy to find. Sometimes you have to search for a long time and in vain, which costs nerves and effort.

such conductive glue, varnish, gel or lubricant yourself . How to make it at home? The main thing is that there is nothing complicated about it. You should be aware that most of these adhesives contain certain binders. These include the following: polyurethane, polyester, epoxy and others. Conductive metal powders are added to these substances: silver-plated, silver, gold.

When preparing conductive glue with your own hands, you can adjust its consistency. This is achieved by adding certain solvents to the glue composition - isopropyl alcohol, acetone, ethyl cellosolve. And also to create such an adhesive substance, you can watch various videos for a better understanding.

How to make conductive glue: step-by-step instructions

Now let's move on to the main thing, making conductive glue with your own hands at home. Follow these recommendations, they are simple:

- We clean the pencil and break off a small part of the lead.

- Place the lead on paper and use a hammer or other blunt object to grind it into dust.

- Unscrew the tube of glue.

- Pour all the lead there, the ratio with glue should be 50 to 50%.

- Stir the lead with a needle until a homogeneous mass is obtained.

- We close the glue, do it well, otherwise it will dry out quickly.

- We use it for its intended purpose.

This is how you can make conductive varnish with your own hands, we found this video for you. Also find out how to unscrew a lamp if it has burst.

This is interesting: Resonance of currents and voltages - conditions of occurrence and application