List of tools

Basic accessories and tools required by an electrician:

- Drill;

- Drills and nozzles;

- Screwdriver;

- Pliers;

- Wire cutters;

- Nylon ties;

- Calipers;

- Indicator screwdrivers;

- Spanners;

- Screwdriver Set;

- Set of crowns;

- Multimeters;

- Latex gloves.

And this is not the entire list of accessories used by electricians.

Tools for stripping wires

A real electrician's kit must have an item for cleaning insulation from wires; it is needed for stripping conductors when connecting sockets, cables, cutting wiring, and so on. You will also need such a tool for household use if you need to carry out home repairs.

You may be interested in Checking the network voltage

Wire crimping tool

Note! An electrician's knife is mainly needed for cleaning flat cables. Experienced specialists will easily strip the insulation from other types of wires, but the practicality of use will be less.

A knife is the most common tool for stripping cables, making the work process as easy as possible. This type of device has a large number of models, so everyone can choose something for themselves.

The operating principle is based on processing the wire with two movable blades that have a rounded appearance.

Dielectric gloves

When working with elements that are under electrical voltage, use rubber gloves for insulation.

Before you start using gloves, you need to make sure there are no flaws on them.

When purchasing gloves, you need to check them for quality and durability by filling them with air and clamping the hole intended for putting your hand in. If air escapes, then you need to discard them.

Low voltage indicator

When studying what electrician's tools are needed for what , you must remember that electrical voltage is a very dangerous factor, and you cannot ignore safety rules when working with electricity. Any tension is dangerous. If you hear the terms “low voltage equipment” or “low voltage indicator”, this means that it is designed for 220 V. And this is a deadly level, working with which requires special approvals.

Checking with a screwdriver indicator may not give an accurate answer as to whether there is dangerous voltage in the network. As already mentioned, the light bulb can also glow from the induced current in the adjacent wire. To verify whether there really is a voltage of 220 V in the network, use a professional indicator TIN-1. This is a device of two probes connected by a cable to a lamp. When the neutral and phase wires are connected, the lamp lights up, indicating the presence of current. The cable and probes are reliably insulated and protected from breakdown, and the lamp is covered with a durable transparent screen.

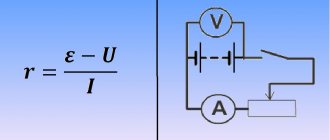

Multimeter

If the INN-1 device only answers the question “is there current in the network or not,” then the multimeter shows all the parameters of the network - voltage, current, polarity, circuit resistance. Multimeters are divided into household and professional, with extended functionality. Modern digital instruments show current parameters with high accuracy, sufficient for a complete analysis of the processes occurring in the network.

But you need to know how to use a multimeter. If you confuse direct and alternating currents, set the measurement range incorrectly, or insert probes into the wrong sockets, troubles will inevitably arise. The easiest outcome is damage to the device. The most severe is electric shock. When working at the household level, it is best to use an indicator screwdriver, or INN-1. A multimeter is a tool for professionals.

Screwdrivers

Often, an electrician needs different types of screwdrivers for work. They are needed for:

- tightening and loosening contact terminals;

- tightening and unscrewing bolts and screws;

- dismantling broken equipment, etc.

To carry out work, it is better to purchase insulated screwdrivers with long working parts.

Electrician hand tools

The master’s set of tools directly depends on the level of professionalism and the intended purpose. For home work with voltages up to 1000 V, the list will be more narrowly focused. But in general, the entire set of tools can be divided into hand tools, voltage measuring instruments and power tools.

Set of screwdrivers of different types and sizes

A screwdriver is the most commonly used tool in work. They are used for tightening contact terminals, tightening and fixing bolts and screws, or when dismantling outdated equipment. Flat and Phillips slots are considered the most basic; it is better to purchase insulated screwdrivers with a long handle in two or three sizes, depending on the purpose and complexity of the work being performed.

It will also be useful to purchase a universal set, which contains various nozzles of different shapes and sizes. But this is necessary for more complex and specific work; a beginner does not need such a set.

Hammer

This tool, like a screwdriver, is probably in every home. But rarely does anyone understand what kind of hammer it is and what it is needed for. It is more correct when there is more than one, but ideally when there are at least three of them with different weights of the striker: 600, 300 and 150 g. The smallest one is designed for driving small nails for fastening an electric mounting bracket. It is better to look for a medium hammer that also includes a nail puller. It is also useful to have a tool such as a mallet, either wooden or rubber, which will be needed when working with a chisel.

A set of keys

When connecting wiring using bolts and nuts or clamps, as well as when unscrewing connections in electrical devices, this tool is indispensable. The most successful would be to have a set with small dimensions up to 24 mm. Large keys are rarely needed in the work of beginners, only if at a high level of professionalism and when working with high-voltage equipment. Today, sets of wrenches consisting of multiple attachments and one handle are very relevant and practical to use.

Pliers

Pliers or pliers are also considered one of the most necessary tools in an electrician's arsenal, which are responsible for twisting wires, making the necessary bends on the wire, and holding when connecting the wire. It’s also convenient that the pliers often have sharpened blades that help you cut through the wire at the right time. However, wire cutters (side cutters) are more often used, because the quality of the cut with pliers is quite low and the edge of the wire is compressed, which is undesirable. The blades of the wire cutters are more suitable because they have a specially sharpened shape, which results in a high-quality cut of the wire without compression or deformation of the cable edge.

Round nose pliers

They are not used as often as pliers, but they have their place and value in the work process. The purpose of this tool is to shape the end of the wire and form a complex bend for connecting certain types of contacts.

Assembly knife

Without this tool, it is very difficult to carry out any installation work. A knife and a set of blades must be kept in an electrician’s drawer, as they are used to remove insulation from the wires. But the use of this tool by a beginner is not advisable, since due to the lack of experience and practice, a cable core or several cores at the same time can be easily damaged if it is a multi-core cable, which will lead to a decrease in the reliability of the entire electrical installation being mounted. A prerequisite when purchasing this tool is the presence of an insulating handle.

Chisel

With the help of this electrician's tool, holes or grooves are created in stone or metal by scoring the surface in problem areas when the electric tool cannot reach the required depth. Usually, the chisel comes with a rubber plate that fits over the chisel and protects your hands when the hammer comes into contact with the chisel.

File

A cutting tool for processing metal by removing it layer by layer. Files come in different shapes and sizes, and also differ in cut.

Hacksaw for metal

A type of saw for cutting metal workpieces. The tool consists of a handle and a frame on which a hacksaw blade is stretched.

Chisel-chisel

A carpentry tool used for the purpose of digging out a hole or socket in wood. The difference between chisels is the shape of the cutting edge. The work is done with a hammer or mallet, or completely by hand.

Crimping pliers

Crimping is the process of creating the desired shape or permanent connection between the connection element and the conductor. This is achieved using special precision debugging equipment, resulting in high-quality electrical or mechanical safe communication. The presence of such an electrician’s tool will increase the speed of work and improve its quality.

Stripping pliers

The main task when removing insulation from wires is the integrity of the conductor itself and the insulation in the place where it should remain, as well as following electrical safety rules. The principle of operation of such a tool is simple - using a screw, the pliers are adjusted to the required diameter of the conductor, taking into account a small margin so as not to damage the conductor itself during removal, then the wire is grasped and the claws are rotated in a circle to cut the insulation. After that, slightly pull the claws towards you, and the insulation is easily removed.

Plastic ties

This is a product that acts as a fastener for bundling electrical wiring and cables into a single bundle. It is a flexible strip of polymer. The wider the screed, the greater the load that can be withstood. There are reusable and disposable zip ties. As an alternative to banding ties, tapes are used, which are also made of plastic.

Calipers

This tool is used when there is no external marking on the wire and in the case when you need to determine the cross-section of the wire, or more precisely, know the diameter of the core. If such a tool is not available, a regular ruler is often used, but the accuracy of the data in this case is lower.

Wire Connection Tool

When connecting conductors, electrical contact and its mechanical strength are made in the following ways: using soldering, crimping, twisting or welding. To make wires twisted together more reliable, a crimping tool using special sleeves is used. This equipment is also used to connect various lugs and terminals to wires.

Roulette

Used to measure length. It is a tape, metal or plastic, with marked divisions, which is wound on a reel and enclosed in a housing, which is equipped with a mechanism for winding the tape when the trigger is pressed.

Tool belt

Since electrical installation work is often carried out in hard-to-reach places or at heights, and the tool must be at hand and easily accessible, it is convenient to use a tool belt. Which will allow you not to hold tools in your teeth, hands or anywhere else, limiting your legal capacity. The mounting belt is attached to the belt, has a large number of different pockets, as well as loops in which you can place all the necessary tools and materials at hand. Moreover, today there is a large abundance of different modifications.

Insulating tape

A consumable material that is necessary to ensure hermetic isolation of objects and parts from the effects of certain external factors, such as sun rays, humidity, weak salt solutions and solvents.

Dielectric gloves

When performing any work with electrical voltage, you must use dielectric rubber gloves. Before each use, it is mandatory to check them for holes, cuts, cracks or punctures. You can purchase this product in any store specializing in electrical equipment and electrical goods. When choosing gloves, you need to pay attention to the quality of the material, density, and also how durable the material is.

Screwdriver

It is used for many jobs. Use this tool to make holes in shields and wire junction boxes.

Instead, you can use a battery-powered screwdriver. The best option would be to purchase it complete with the largest number of attachments, so that the necessary accessories will be at hand at any time.

How to choose a phase meter - review, purpose, principle of operation, scope of application + instructions for use with photosHow to make a transformer with your own hands - step-by-step instructions, diagram, drawings, list of materials + photo of a finished homemade transformer

Which hidden wiring detector is better? TOP 10 best manufacturers with photos and descriptions

Hand tool

Slotted and flat screwdrivers.

A common tool for an electrician is a screwdriver. Screwdrivers can be slotted, flat-tipped, or with different attachments. Screwdrivers with an elongated, insulated blade and a magnetized tip are used in places where access is difficult. They are used for repair, installation, dismantling of wiring and electrical devices: switches, sockets, lamps. It is recommended to make the connection not with twists, but with bolts on the terminal blocks.

Screwdrivers

When performing installation and repair work, it is much more convenient to use a screwdriver with different attachments. They can also make small holes in boxes and walls. Electricians mainly use this tool when installing distribution boards.

Pliers, side cutters, round nose pliers

The second most popular tools are pliers, side cutters and round nose pliers. If pliers were previously used for various purposes, now in most cases, only for their intended purpose - for twisting wires.

Round nose pliers are used for various profile formations of wires. Side cutters are convenient for cutting off cords and also for stripping insulation, although a stripper is designed for this. It is very convenient for them to expose the core from the insulation without damaging it. In the tool kit, an electrician also needs a stripper.

Stripper

Wires are often connected in sleeves. And for high-quality crimping, crimping pliers or crimpers .

An electrician has to install not only wiring, but also all kinds of electrical devices:

- distribution boards;

- machine guns;

- sockets;

- switches;

- lamps.

To do this, you need to have hand tools not only the above items, but also wrenches, a hammer, a chisel, a chisel, and a knife . An electrician may need wrenches for nuts ranging from the smallest 6 mm to 32 mm, so it is advisable to have a set of such tools. A chisel and hammer are used when cutting grooves for cables; sometimes they are used to make holes in concrete walls (if it is not possible to connect a power tool).

Chisels are used to form grooves for cords in wooden products. The knife is used to remove insulating material, stripping and cutting cables and must have a handle with insulating material. This tool is used mainly by professionals, since a beginner can damage the core when working. There is a special tool for beginners - a stripper.

This entire tool is in demand from time to time, and therefore it can rather be classified as an additional tool.

Side cutters

In order to cut wires evenly and easily, you need a device such as wire cutters.

Thanks to the special sharpening of the tool's cutters, they cut through the wire without flattening its edges.

Nylon clamps

To connect several wires into one bundle, ties of various lengths and widths are used. The required clamp size depends on the thickness of the harness.

Technological maps in construction - what is it?- How to fix a laptop that won't charge

Insulated dielectric screwdrivers up to 1000V - tips on how to choose the best manufacturer

Using these clamps you can attach wires to anything.

Electric tool

During installation and repair, a power tool is a necessary “attribute” for an electrician. It is needed for drilling holes in walls of different diameters, for the manufacture and fastening of distribution boards, boxes and other devices.

Drill

The drill occupies a leading place among other power tools and is indispensable when drilling and fastening in concrete walls, especially various electrical devices. Nowadays, many drills are equipped with a perforating device; with its help, it is quite possible to drill holes d up to 12 mm.

And if you need to drill holes of larger diameter for sockets and switches, as well as through holes in the wall larger than 12 mm, then it is better to use a hammer drill .

Using such a crown, you can drill holes to the required depth or through them in the wall for a pipe or cable.

Strippers

These are devices for stripping wires. However, various tools can be used for this:

- knife;

- pliers;

- wire cutters, etc.

But to use such items you need to have experience.

Tinning

To ensure protection of the ends of the wires, tinning is carried out using solder. Soldering irons are used for this. They can be of different powers.

Dielectric insulated tool for work - which one is better to choose? Review of manufacturers, photos + video- Properties, scope of application of Paroc basalt insulation

- Mitsubishi Electric: company history

Soldering iron

Such a device is very necessary for working with electricity, however, it is difficult for them to process very thick wires.

For such purposes, a soldering bath is used; it is extremely rare to purchase, as it belongs to the category of professional equipment.

Therefore, they are used only by large organizations and specialists with extensive experience. In the photo you can see what this tool looks like for an electrician.

Indicator screwdrivers

Such screwdrivers are used to determine the phase and check the presence of power supply. Any electrician, even a beginner, cannot do without this device.

Its operation is that when a phase is touched, the lamp in the indicator lights up, but when the neutral wire is touched, it does not.

Changes regarding tools and equipment

- A new clause has been added stating that hand tools must comply with the requirements of the technical regulations of the Customs Union “On the safety of machinery and equipment” (TR CU 010/2011) and the technical regulations of the Customs Union “On the safety of low-voltage equipment” (TR CU 004/2011).

- Simplified requirements for workbenches. Now its dimensions can be any at the discretion of the employer, and the installation of a foot grate on the floor in front of the workbench will depend on the procedures of the occupational safety management system.

- Periodic technical inspection of jacks should no longer be carried out once every 12 months, as before, but only after repair or replacement of parts in accordance with the manufacturer’s documentation.

- Simplified work with grinding and cutting wheels. It is no longer necessary to carry out mechanical strength tests and make a note of the tests performed before putting them into operation. Now, before starting to use them, you just need to carry out a visual inspection, and after chemical treatment or mechanical alteration, there is no longer a need to re-test for mechanical strength. Accordingly, maintaining a log of test results for grinding and cutting wheels is also no longer required.

- It is now always necessary to work with a grinding tool using personal protective equipment for the eyes and face, regardless of the diameter of the grinding head and the presence or absence of a protective casing.

- When working with pneumatic tools, it is now necessary to connect hoses only in accordance with the technical documentation of the manufacturer.

- Technical inspection of pneumatic tools now needs to be carried out not once every six months as before, but in accordance with the manufacturer’s recommendations.

This article discusses only the most interesting and most popular changes to the Labor Safety Rules, which are most often found at production sites. Therefore, if your enterprise actively uses hand tools and devices, you definitely need to familiarize yourself with the new Labor Safety Rules in more detail and update the internal local documents of the enterprise in accordance with changes in processes affecting your organization.

Do not forget that when regulations change, it is necessary to conduct an extraordinary test of knowledge of labor protection requirements for employees and managers (to the extent of the changes), as well as conduct an extraordinary on-the-job briefing for employees.

TIN-1

In order to determine low voltage in the electrical network, this device is used.

It has two probes connected by a wire; one of the probes is equipped with a warning light.

Multimeter

This measuring device is considered the most reliable for determining voltage.

Currently, there are digital versions of these instruments that measure:

- resistance;

- voltage;

- current strength.

For electricians with little experience, an inexpensive model will be enough, but for professionals it is better to have a model with wide functionality.

Low voltage indication

The expediency of its use is determined mainly by the fact that electric current cannot be seen with the eyes - its presence can only be understood by whether the device connected to the outlet is functioning or not.

Voltage indicator

Passive screwdriver. This is a simple household phase indicator that performs one single option - it indicates the presence or absence of voltage in a certain place in the electrical circuit.

Experienced craftsmen do not use passive screwdrivers because they have too few functions, but they are great for home use.

You might be interested in High voltage indicator

Universal active screwdriver

This tool will be an excellent variant of the previous model - it has a switch, you can control the sensitivity of the screwdriver, and also use it in contact and non-contact mode.

Electric drill

It can be said to be a universal tool for an electrician. When working with it, you may need various attachments and drills.

It is advisable that it be equipped with a hammer drill; this is necessary for drilling holes in concrete walls for branch boxes, sockets, and switches.

It would take a long time to list the electrician's accessories, but the main ones are those described above.

Tools required for installation work

Let's move on to the tool that an electrician will need for laying and installing electrical circuits.

So, a hammer drill with drills allows you to make holes in the walls of a building for pulling wires.

The same device, but with crowns, makes recesses in the walls for installing sockets, switches, and junction boxes.

A screwdriver will be needed to quickly tighten all kinds of screws during installation work, for example, to secure tunnels into which wiring will be laid. Also, when working at a distance from the industrial network source, it is convenient to use special battery-powered tools.

Using a wall chaser, small recesses are made in the walls for laying wiring in them - grooves.

Without this device, an electrician will have to make grooves either with a hammer drill or an angle grinder with a diamond wheel, which is very inconvenient and labor-intensive.

A press wrench is used by electricians to compress special copper caps on wire strands. The use of this key allows you to strengthen the connection of twisted wires.

A hammer is a universal tool that is needed not only by electricians. And when installing the wiring, he will have enough work.

An electrician may need open-end wrenches when performing industrial installation work.

For some electrical devices that operate with high power parameters, the wiring to them is secured using bolted connections, which is why keys are needed.

Measuring instruments such as a tape measure and a level are mostly needed for preparatory work.

The tape measure is used for correct measurements when punching grooves, measuring the length of wiring, etc. A level will be needed to secure sockets and switches evenly.

Also, during installation, an electrician may need a wide variety of tools.

For example, the internal partitions of a building are made of wood, then to make holes you will need a drill with different drills, and for grooves - chisels.

In some cases, reciprocating saws may come in handy.

Photo of electrician's tools

Did you like the article? Share

0