Blitz tips

The device is very dangerous, so it is not recommended to use a voltage of 380 V, unless absolutely necessary.

In accordance with precautionary measures and safety precautions, it is necessary to additionally install grounding.

Monitor the thermal conditions of development. It is not inherent to it to work at idle speed

To reduce the thermal impact, you should select the capacitor well.

Correctly calculate the power of the electrical voltage produced. For example, when in a three-phase generator only one phase is functioning, it means that the power is 1/3 of the total, and if two phases are working, respectively, 2/3.

It is possible to indirectly control the frequency of intermittent current. When the device is idling, the output voltage begins to increase and exceeds industrial values (220/380V) by 4-6%. It's best to isolate development.

You should equip your homemade invention with a tachometer and voltmeter to record its operation.

It is advisable to provide special buttons to turn the mechanism on and off.

The efficiency level will decrease by 30-50%, this phenomenon is inevitable.

Possibility of control

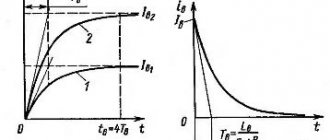

Another feature of a synchronous generator (as well as an asynchronous one) is that the frequency and amplitude of the EMF induced at the stator terminals significantly depends on the rotor rotation speed.

Important! As the active load connected to the generator changes, the frequency of rotation of the generator shaft also changes in proportion to it, which leads to a change in the characteristics of the EMF created in the stator. This drawback forces the installation of an electronic voltage and frequency regulator in synchronous and asynchronous devices, which ensures that these parameters are maintained at the proper level (the regulator diagram is given below)

This drawback forces the installation of an electronic voltage and frequency regulator in synchronous and asynchronous devices, which ensures that these parameters are maintained at the proper level (the regulator diagram is given below).

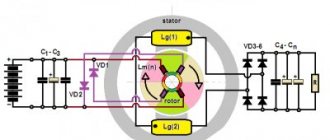

AG voltage regulator circuit

Since the asynchronous generator operates on the principle of mismatched rotation of the fields of the moving and stationary parts, it is not possible to regulate the output parameters within the system. This is explained by the impossibility of organizing instantaneous voltage feedback by supplying part of the output signal from the stator to the rotor (only external voltage stabilizers can be used in AG).

This is another difference between asynchronous units and their synchronous counterparts, which in all other characteristics are very similar to the former.

Reversibility effect

It is known that the operating principle of any device generating electric current is based on the conversion of one form of energy (heat, for example) into the form necessary to power the equipment. You can use so-called alternative (also called renewable) sources of energy supply, but this method is associated with even greater material and production costs.

It is much easier and more economical to make a homemade current generator by taking advantage of the potential capabilities of an old asynchronous electric motor at the user’s disposal.

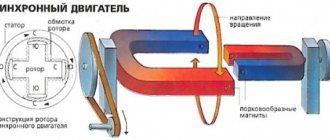

The basis for such production is the well-known principle in electrical engineering of the reversibility of the processes of interaction of electromagnetic fields, which is explained by the specifics of the electrical processes occurring in this case. If in an engine three-phase current energy is used to convert it into mechanical rotation of the shaft, then in a generator everything happens exactly the opposite. In these units, the forced rotation of the armature is transformed into an electric current flowing through the phase windings, the power of which is spent to serve the consumer (see the figure below).

Generator operating principle

Thus, before making a sample of a homemade electric generator from a used asynchronous motor, in the most general case, you need to do the following manipulations:

- The terminals to which three-phase (or single-phase - for collector product samples) voltage is supplied must be turned into the output contacts of the generator;

- The moving part of the generator from which this or that mechanism (a machine tool, for example) operated should be equipped with a drive from an external source of mechanical rotational impulse;

Additional Information. Any propulsion unit suitable for specific conditions, rotating under the influence of the energy of burning fuel (gasoline, gas or diesel fuel), can be used as such a source. If a private household has a windmill or a homemade water mill, solving the problem of the drive is significantly simplified.

Due to the high cost of gasoline in suburban conditions, the only acceptable option is to manufacture a small power plant powered by a diesel engine or gas.

In this case, the engine, running on relatively cheap fuel, is connected through a special drive coupling to the shaft of the structure being constructed, which, after minor modifications, turns into an alternating current generator.

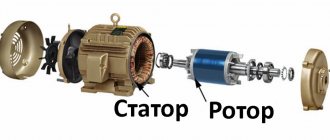

Asynchronous motor design

Just a few elements can be highlighted:

- Stator with winding.

- Front and rear covers with installed bearings.

- Rotor with short-circuited turns.

- Contacts for connecting to the electrical network.

If you think about it, it may seem that it is very simple to convert the engine into a generator, a photo of which you can examine in detail. But if you look more carefully, it turns out that not everything is so simple, there are plenty of pitfalls.

The stator consists of many metal plates pressed tightly together. They are also varnished; in some designs, to give strength, all plates are welded to each other. A wire is wound on the stator, it fits tightly to the core and is insulated from it using cardboard inserts. Bearings are located in the covers; with their help, not only does the rotor rotate more easily, but also its centering.

A rotating magnetic field is the basis of a generator circuit made from an asynchronous motor

In an electric machine, initially created as a generator, there are two active windings: the excitation winding, located on the armature, and the stator winding, in which the electric current arises.

The principle of its operation is based on the effect of electromagnetic induction: a rotating magnetic field generates an electric current in the winding that is under its influence. The magnetic field arises in the armature winding from the voltage usually supplied from the battery, and its rotation is provided by any physical device, even your personal muscular strength.

The design of an electric motor with a squirrel-cage rotor (this is 90 percent of all executive electric machines) does not provide for the possibility of supplying supply voltage to the armature winding. Therefore, no matter how much you rotate the motor shaft, no electric current will arise at its supply terminals. Those who want to convert an asynchronous motor into a generator must create a rotating magnetic field themselves.

Conversion

How to practically convert an asynchronous electric motor into a generator with your own hands?

To connect the capacitors, you need to unscrew the top cover of the boron (box), where the contact group is located, switching the contacts of the stator windings and the power wires of the asynchronous motor are connected.

Open boron with contact group

The stator windings can be connected in a “Star” or “Triangle” configuration.

Connection circuits "Star" and "Triangle"

The nameplate or product data sheet shows possible connection diagrams and motor parameters for various connections. Indicated:

- maximum currents;

- supply voltage;

- power consumption;

- number of revolutions per minute;

- Efficiency and other parameters.

Engine parameters indicated on the nameplate

In a three-phase generator from an asynchronous electric motor, which is made by hand, the capacitors are connected in a similar “Triangle” or “Star” circuit.

The connection option with a “Star” ensures the starting process of generating current at lower speeds than when connecting the circuit in a “Triangle”. In this case, the voltage at the generator output will be slightly lower. Delta connection provides a slight increase in output voltage, but requires higher rpm when starting the generator. In a single-phase asynchronous electric motor, one phase-shifting capacitor is connected.

Connection diagram of capacitors on a generator in a “Triangle”

Capacitors of the KBG-MN model or other brands of at least 400 V non-polar are used; bipolar electrolytic models are not suitable in this case.

What does a poleless capacitor of the KBG-MN brand look like?

Since in everyday life it is almost impossible to calculate the required capacitor capacity for the engine used, a table was compiled experimentally.

Calculation of capacitor capacity for the motor used

| Generator rated output power, kW | Estimated capacity in, µF |

| 2 | 60 |

| 3,5 | 100 |

| 5 | 138 |

| 7 | 182 |

| 10 | 245 |

| 15 | 342 |

In synchronous generators, the generation process is excited on the armature windings from the current source. 90% of asynchronous motors have squirrel-cage rotors, without winding; excitation is created by a residual static charge in the rotor. It is enough to create an EMF at the initial stage of rotation, which induces current and recharges the capacitors through the stator windings. Further recharging already comes from the generated current; the generation process will be continuous as long as the rotor rotates.

It is recommended to install the automatic load connection to the generator, sockets and capacitors in a separate closed panel. Lay the connecting wires from the boron generator to the switchboard in a separate insulated cable.

Even when the generator is not working, you must avoid touching the capacitor terminals of the socket contacts. The charge accumulated by the capacitor remains for a long time and can cause electric shock. Ground the housings of all units, motor, generator, control panel.

Scheme of work

An asynchronous generator is considered one of the simplest and most reliable in terms of operation. The work process looks like this:

- A magnetic field is created in the armature winding using the voltage coming from the battery.

- You can organize the rotation of field elements yourself or automate the process using a relay.

- The speed of the magnetic field allows the generation of electromagnetic induction, which provokes the generation of electricity.

Due to the presence of a squirrel-cage rotor inside the equipment, not all circuits have the ability to provide voltage to the winding. Therefore, even in the case of active rotation of the shaft, the terminals will be de-energized.

Components

It is not difficult to create a generator from a 220 V asynchronous motor with your own hands, but first you need to understand what parts are included in the mechanism. Even simple models require the right elements to recreate electricity. Standard induction motor includes :

- The stator is made from a network winding for three phases. They are placed on its working surface in the form of a winding.

- A winding resembling a star and consisting of slip rings that have access to the rotor.

- Brushes that do not actually do any work, but help turn on the rheostat. Such a device affects the functionality of the winding and changes its resistance parameters.

- Sometimes a special automatic short circuit may be built into the mechanism, which can short-circuit the winding and stop the rheostat element, even if the part is in operation.

At the stage of closing the brushes and slip rings, additional elements for their wiring can be included. Not all generators are equipped with such parts; the device can be seen on new models.

Secrets and subtleties

To make an asynchronous motor in generator mode, you need not only to study the device model, but also to select the necessary elements. Experts advise using non-polar capacitor-type batteries, since electrolytic elements do not fit into this circuit.

The three-phase type runs the capacitor parts using a star. This makes it possible to start the generative process with low rotor speeds, but this method negatively affects the voltage output.

You can create a generator using a single-phase mechanism, but this is only if there are squirrel-cage rotors. It is impossible to use commutator type engines for conversion to a generator, since their power is too high for such a mechanism. At home, it is impossible to find out about the capacity of a capacitor-type battery. This should be taken into account during the remodeling process.

You can find out whether a battery is suitable for a generator based on its weight. The weight of the part must be equal to the electric motor.

Types of asynchronous machines

Different types of AG may differ in the following performance characteristics:

- The type of rotating part of the generating device - its rotor;

- The number of output or stator windings in the generator (the number of operating phases);

- The connection diagram of the three-phase generator coils - triangle or star, as well as the method of their placement and laying on the stator poles (photo below);

Placement of stator windings

The presence or absence of a separate field winding.

In accordance with the first of these characteristics, all known types of AG are equipped with a squirrel-cage or phase-wound rotor. The first of them is made in the form of a one-piece cylindrical structure, consisting of individual pins with two rings closing them (of the “squirrel wheel” type).

The phase rotor, unlike its squirrel-cage counterpart, has an inductive winding made of insulated wire, which ensures the creation of a dynamic electromagnetic field. Due to the peculiarities of its design, such a rotor has a high manufacturing cost and requires specialized maintenance.

The output windings of the stator, like the entire generator, can be single-phase or three-phase, which is determined by the direct purpose of this unit (when a voltage source of 220 or 380 Volts is required). Regarding the first of these designs, everything is quite clear, but the three-phase modification of the AG has one more feature regarding the electrical circuit for switching on the windings.

It is known that to form any three-phase power supply network in electrical engineering, two types of connection of windings are used, shifted in vector representation one relative to the other by 120 degrees. This:

Star switching, when the beginnings of the coils are connected at one point, where a zero wire is formed, and their ends diverge along three power lines (together with the neutral wire, there are four of them, as shown in the photo below);

4-wire star connection

A “triangle” connection, in which the end of one coil is connected to the beginning of the second, and so on until the chain is completely closed. The second connection option is used in 3-wire power supply lines, since there is no neutral wire in this circuit.

In each AG product, the connection according to one scheme or another is implemented in very specific ways, allowing the wires of all stator windings to be placed between the poles of its core. They are wound in such a way that each section of phase coils A, B and C is offset along the circumference from each other by exactly 120 degrees.

In conclusion of the review of generator devices, let us pay attention to the possibility of manufacturing an AG from an asynchronous motor. Such a prospect appears thanks to the well-known principle of reversibility of the action of electrical machines, according to which the direction of energy conversion can be chosen arbitrarily

Asynchronous motor device

Depending on the design, all asynchronous motors can have a squirrel cage or wound rotor. In the first case, the main components of the engine are the stator, in the form of a stationary part, and the rotor, which rotates around a shaft mounted in bearings. Their cores include sheets of electrical steel insulated with each other. The rotor winding is short-circuited using jumpers in the form of rings, which is why this type of motor got its name.

The phase rotor differs from the first version in the winding laid in its slots. This type of winding is made in the same way as on the stator. Its ends are connected to slip rings fixed to the shaft. The brushes slide along these rings, connecting the winding and the adjustment or start rheostat. Devices with a wound rotor are more expensive and require qualified maintenance. Therefore, they are used much less frequently compared to conventional electric motor designs.

Generator with neodymium magnets

How to make a generator from an asynchronous electric motor?

This homemade generator eliminates the use of capacitor units. The source of the magnetic field, which induces EMF and creates current in the stator winding, is built on permanent neodymium magnets. In order to do this yourself, you must sequentially perform the following steps:

- Remove the front and rear covers of the asynchronous motor.

- Remove the rotor from the stator.

What does the rotor of an asynchronous motor look like?

- The rotor is ground, the top layer 2 mm larger than the thickness of the magnets is removed. In everyday conditions, it is not always possible to bore a rotor with your own hands, in the absence of turning equipment and skills. You need to contact specialists in turning workshops.

- A template is prepared on a sheet of plain paper for placing round magnets, Ø 10-20 mm, up to 10 mm thick, with an attractive force of 5-9 kg per sq/cm, the size depends on the size of the rotor. The template is glued to the surface of the rotor, the magnets are placed in strips at an angle of 15 - 20 degrees relative to the rotor axis, 8 pieces per strip. The figure below shows that on some rotors there are dark-light stripes of displacement of the magnetic field lines relative to its axis.

Installing magnets on the rotor

- The rotor on magnets is calculated so that there are four groups of strips, in a group of 5 strips, the distance between the groups is 2Ø of the magnet. The gaps in the group are 0.5-1Ø of the magnet, this arrangement reduces the force of sticking of the rotor to the stator; it must be rotated with the efforts of two fingers;

- The magnetic rotor, made according to a calculated template, is filled with epoxy resin. After it dries a little, the cylindrical part of the rotor is covered with a layer of fiberglass and again impregnated with epoxy resin. This will prevent the magnets from flying out when the rotor rotates. The top layer on the magnets should not exceed the original diameter of the rotor, which was before the groove. Otherwise, the rotor will not fall into place or will rub against the stator winding when rotating.

- After drying, the rotor can be put back in place and the lids closed;

- To test an electric generator, it is necessary to turn the rotor with an electric drill, measuring the voltage at the output. The number of revolutions when the desired voltage is reached is measured by a tachometer.

- Knowing the required number of generator revolutions, the belt drive is calculated according to the method described above.

An interesting application option is when an electric generator based on an asynchronous electric motor is used in a self-feeding electric motor-generator circuit. When part of the power generated by the generator goes to the electric motor, which spins it. The rest of the energy is spent on the payload. By implementing the principle of self-feeding, it is practically possible to provide the house with autonomous power supply for a long time.

Materials and tools

To make a wind generator, it is enough to have an asynchronous motor , which will have to be redone. At the same time, you will have to stock up on a number of materials:

- steel pipe, the minimum diameter of which must be 7 cm, used as material for the mast;

- PVC or metal pipe from which the blades will be made. An alternative to them can be a wooden board, a fiberglass profile, onto which epoxy resin or ready-made blades are applied;

- concrete will serve as a support material, although it can be replaced with wood and metal.

- drill with a set of drills;

- hacksaw, tape measure, adjustable and gas wrench;

- a steel frame with which the installation of blades and a generator with a rotating unit will be carried out;

- steel sheet, which will serve as material for the tail;

- a tool with which the necessary parts will be made;

- crutches and clamps - they will be used to install the braces;

- a metal cable, the cross-section of which should be 12 mm - on its basis the stretch marks will be made.

Benefits and Applications

The advantages of asynchronous generators include the following properties:

- AGs are resistant to overloads and short circuits, and also have a relatively simple design (this distinguishes them from more complex synchronous machines);

- The indicator of nonlinear distortion of a sinusoid does not exceed 2 percent (compare 15% for their synchronous analogues);

- Due to the low clear factor value, asynchronous devices guarantee high stability of the operation of the UPS and TV receivers connected to them;

- When powering welding equipment, they provide a significant improvement in welding quality;

- To stabilize the output voltage, they can use external automatic control devices;

- When rotating, AG rotors generate a limited amount of heat, which does not require powerful fan devices to compensate.

The latter property allows you to reliably seal the internal cavity of the unit, that is, protect it from the penetration of dust and dirt. Thanks to this circumstance, the scope of application of asynchronous machines capable of operating in conditions of great dust and high humidity is significantly expanding.

The possibility of sealing contributes to the fact that asynchronous type electric generators have a longer service life and can be operated at low temperatures. Let's add to this that it is allowed to connect loads of varying power to each of the phase windings of these units.

Additional Information. The permissible rate of unevenness of phase loads (the difference in the currents they consume) is about 70% for AG, which cannot be achieved when working with synchronous units.

A disadvantage that can be easily eliminated during operation is the rather “heavy” starting characteristics of the generator, which can be corrected by installing special starting amplifiers (figure below).

Starting generator circuit

These devices provide the ability to smoothly bring the generator into operating mode even with significant starting currents.

In all other respects, AGs have undeniable advantages over synchronous machines, some of the differences with which were discussed earlier. Due to these advantages, they are widely used as sources of electricity in the following economic areas:

- For power supply to equipment with rheostatic or regenerative braking mode (cranes, conveyors, etc.);

- In industrial equipment that does not require compensation for parasitic reactive power and does not have high requirements for the quality of supplied energy;

- In domestic and field conditions, where sources of cheap electricity with mechanical drive from a diesel engine are required;

- As a powerful charger that recharges batteries in car repair shops, for example.

In addition, they can be used as power sources to which welding units are connected, as well as to ensure uninterrupted power supply for critical healthcare facilities.

Asynchronous generator. Generator from an asynchronous motor.

General characteristics of the generator in asynchronous mode

An asynchronous generator (AG) is the most common AC electrical machine, used primarily as a motor.

Only low-voltage AGs (up to 500 V supply voltage) with a power of 0.12 to 400 kW consume more than 40% of all electricity generated in the world, and their annual output amounts to hundreds of millions, covering the most diverse needs of industrial and agricultural production, marine, aviation and transport systems, automation systems, military and special equipment.[ad#lowercase]

These engines are relatively simple in design, very reliable in operation, have fairly high energy performance and low cost. That is why the scope of use of asynchronous motors is continuously expanding, both in new areas of technology and as a replacement for more complex electrical machines of various designs.

Types of engine-based generators

Buying a standard ready-made electric generator is by no means a cheap pleasure and is unlikely to be affordable for the practical majority of our fellow citizens. A homemade generator can be an excellent alternative; it can be assembled with sufficient knowledge of electrical engineering and plumbing. The assembled device can be successfully used as:

- Self-powered electric generator. The user can obtain with his own hands a device for generating electricity with a long period of action due to self-recharge;

- Wind generator. A windmill, which rotates under the influence of the wind, is used as a propulsion device necessary to start the engine;

- Generator with neodymium magnets;

- Three-phase gas generator;

- Single-phase low-power generator for motors of electrical appliances, etc.

Converting a standard motor into a working generating device with your own hands is an exciting activity and obviously saves your budget. In this way, you can convert a regular windmill by connecting it to an engine for autonomous energy generation.

In electrical engineering, there is the so-called reversibility principle: any device that converts electrical energy into mechanical energy can also do the reverse work. It is based on the principle of operation of electric generators, the rotation of the rotors of which causes the appearance of electric current in the stator windings.

Theoretically, it is possible to convert and use any asynchronous motor as a generator, but for this it is necessary, firstly, to understand the physical principle, and secondly, to create conditions that ensure this transformation.

Generator circuit from an asynchronous motor

generator circuit based on an asynchronous motor

In virtually any electric-type machine, designed as a generator, there are 2 different active windings, without which the operation of the device is impossible:

- Excitation winding , which is located on a special armature.

- Stator winding , which is responsible for the generation of electric current, this process occurs inside it.

In order to visualize and more accurately understand all the processes occurring during the operation of the generator, the best option would be to take a closer look at its operation diagram:

- Voltage supplied from a battery or any other source creates a magnetic field in the armature winding.

- The rotation of the device elements together with the magnetic field can be realized in different ways, including manually.

- A magnetic field rotating at a certain speed generates electromagnetic induction, due to which an electric current appears in the winding.

- The vast majority of circuits used today do not have the ability to provide voltage to the armature winding; this is due to the presence of a squirrel-cage rotor in the design. Therefore, regardless of the speed and time of rotation of the shaft, the power terminals of the device will still be de-energized.

The positive qualities of the development include:

- Simple and quick assembly with the ability to avoid disassembling the electric motor and rewinding the winding.

- The ability to rotate electric current using a wind or hydraulic turbine.

- Use of the device in motor-generator systems to convert a single-phase network (220V) to a three-phase (380V).

- The ability to use development in places where there is no electricity, using an internal combustion engine for promotion.

Advantages and disadvantages of self-assembly

The positive aspects of making a homemade electric generator with your own hands include:

Increasing your own self-esteem, which is extremely important for men. A successfully assembled unit can become the subject of not only an alternative power source, but also pride

Significant financial savings. The ability to create a device that would meet all the stated requirements.

In addition, the process can become more complicated and have a lot of negative consequences:

It is possible that the unit will often break down, which is due to the impossibility of a hermetically sealed connection of all parts of the generator. Incorrect connection or power calculation will lead to generator malfunction and will also reduce its productivity by an order of magnitude

A certain skill in work is required, as well as caution, since all work is carried out with electricity, which, as you know, is not to be trifled with

Interesting option. Electric generator from a bicycle

How to choose an electric motor

To eliminate errors at the project stage, it is necessary to pay attention to the design of the purchased motor, as well as its electrical characteristics: power consumption, supply voltage, rotor speed. Asynchronous machines are reversible

They are able to operate in the following modes:

Asynchronous machines are reversible. They are able to operate in the following modes:

· electric motor when external voltage is applied to them;

· or a generator, if their rotor rotates a source of mechanical energy, for example, a water or wind wheel, an internal combustion engine.

We pay attention to the nameplate, the design of the rotor and stator. We take their features into account when creating a generator

What you need to know about stator design

It has three insulated windings wound on a common magnetic core for power supply from each voltage phase.

They are connected in one of two ways:

1. A star, when all the ends are collected at one point. Voltage is supplied to the 3 beginnings and the common terminal of the ends via four wires.

2. Triangle - the end of one winding is connected to the beginning of the other so that the circuit is assembled into a ring and only three wires come out of it.

This information is presented in more detail in the article on my website about connecting a three-phase motor to a single-phase household network.

Rotor design features

It also has a magnetic circuit and three windings. They are connected in one of two ways:

1. through the contact terminals of a motor with a wound rotor;

2. short-circuited with an aluminum insert into the squirrel wheel design - asynchronous machines.

We need a squirrel-cage rotor. All circuits are designed for him.

The wound rotor design can also be used as a generator. But it will have to be redone: we simply short-circuit all the outputs to each other.

How to take into account the electrical characteristics of the engine

The operation of the generator will be affected by:

1. Winding wire diameter. The heating of the structure and the amount of applied power directly depend on it.

2. The design speed of the rotor, indicated by the number of revolutions.

3. Method of connecting windings in a star or triangle.

4. The amount of energy loss determined by the efficiency and cosine φ.

We look at them on a plate or calculate them using indirect methods.

Connection diagram

Today, various variations of the asynchronous motor are produced. It can be single-phase or have three phases for connection. It may include several windings or upgrade the rotor design. However, in any case, the device connection diagrams remain unchanged.

Among the common schemes are the following.

"Star". In this case, it is necessary to take the ends of the stator windings and connect them at one point. The method is suitable primarily for three-phase generators that need to be connected to a three-phase line at a higher voltage.

Each generator is connected to the system through a specific circuit that determines how electricity is generated. Any of these methods involves the rational placement of the wires of the windings of a fixed element between the poles of its core, only in this case the connection of these wires is carried out in different ways.