Basic Concepts

To generate electrical current, special devices are used - generators. The device consists of a motor and an energy converter installed in a housing or on an open frame. The alternator is one of the main parts of the source, converting the mechanical movement of the shaft into electricity. The mechanism contains static and moving parts (stator, rotor).

Electric current generator Source chelyabinsk.mototech.ru

To activate an electromotive force on the insulation of a stationary part, a magnetic field is created. All types of equipment of this type use a rotating magnetized rotor. Based on design differences, alternators are divided into 2 types:

- Synchronous. In brush technology there is winding on a moving part.

- Asynchronous. The magnetized part has no insulation. The residual field is transmitted using a non-contact principle, which is why the equipment does not contain brushes.

The structure of the first type of alternators is more complex than the second. The synchronous one has windings and electric brushes (carbon, copper-graphite), which affects the cost. Such options last a long time and rarely break down radically. Elementary in structure, asynchronous does not contain many parts, so it is cheaper in price.

The generator winding is made of metal. If you need equipment for constant and active use with frequent overloads, then preference is given to durable copper. Aluminum models have maximum load restrictions, so they will quickly fail.

Differences in windings Source mototech.ru

Synchronous and asynchronous generator

Electricity is everywhere.

The day has already come when it is difficult to argue with this. Even where the centralized power grid does not reach, diesel and gasoline generators are widely used, which have become widespread not so long ago, despite their almost two-hundred-year history. Today, the range of generators is very large, and there are many ways to classify them, one of which is classification by degree of synchronization. In relation to electric generators, synchronization is the combination of the rotor speed and the stator magnetic field. Accordingly, if their rotation frequency coincides, such a generator will be called synchronous, and if not, then asynchronous.

Synchronous generator

As is known, in a diesel or gasoline generator, an electric current is generated after a rotating magnetic field passes through the winding. In this case, in a synchronous electric generator, the rotor is a permanent magnet or electromagnet. After starting the generator, it creates a weak magnetic field around itself, which becomes stronger as the speed increases. Ultimately, the rotor speed and magnetic field are synchronized, resulting in the most stable current output.

Unlike an asynchronous generator, a synchronous unit is vulnerable to overloads, since exceeding the permissible load can cause a large voltage surge in the rotor winding. On the other hand, an important advantage of a synchronous generator is its ability to briefly produce a current power 3-4 times higher than the rated one, which allows you to connect devices such as pumps, compressors, refrigerators, etc. to it. In other words, it is designed for electrical appliances with high starting currents. Despite their vulnerability, the cost of synchronous generators is higher than asynchronous devices.

Asynchronous generator

An asynchronous generator operates in braking mode: the rotor rotates in the same direction as the stator, but its rotation speed is initially higher. In this case, the frequency of rotation of the magnetic field always remains unchanged, and only the speed of rotation of the rotor can be adjusted. Such generators are less vulnerable to short circuits and are well protected from external influences (dust, low temperature, moisture, etc.).

Synchronous design

A generator (alternator) whose rotor speed coincides with the indications of the movement of the magnetic field is called synchronous. When operating autonomously, AC equipment can withstand any load. The equipment functions perfectly in conditions without centralized highways.

Principle of operation

A synchronous alternator operates on the principle of electromagnetic induction. During idle motion, the stator coil is open, and energy is generated in the rotor winding. The moving parts rotate from the motor. During the process, a constant frequency is generated inside, and a magnetic field is transferred through the parts and creates an electromotive force.

To form fields inside the structure, a winding is needed. The element allows you to reliably isolate metal plates from each other. If in a synchronous alternator the armature is set in motion by rotation, then the energy flow passes through the stator coils.

Operating principle of the equipment Source en.ppt-online.org

Brush structures operate in motor mode or to generate electricity. In models operating under high loads, cooling systems are additionally used. “Wings” are installed in the shaft, which blow on the rotor on both sides and reduce the temperature of the moving element. The stronger the oxygen flow, the better the procedure.

Design Features

The structure of a synchronous alternator is a typical representative of generators. A single-, two-, or three-phase winding is placed in the slots of the brush machine stator. The model differs from the brushless type in that it has a rotor, which functions as an electric magnet. The design contains poles (2 or more).

For high-speed generators, the number of pole pairs is 1. To obtain current, the synchronous alternator must be rotated at a certain frequency. Manufacturers create designs containing three-phase semiconductor elements inside. To generate energy, the method of rectifying variable currents is used.

Technical features of the species Source smolgelios.ru

The generator excitation system is equipment designed to produce current. Regulators are used to control electricity. Based on the type of action, there are 2 groups:

- Proportional. When one parameter deviates, the excitation current is uniformly transformed.

- Strong. Changes occur when several indicators diverge.

Excitation structures in a synchronous alternator ensure safe operation and braking of equipment at idle speed. The equipment operates according to a given program taking into account the loads. When parameters deviate, the device adapts to changes (voltage, speed).

DC generator Source arsvest.ru

Types of equipment

According to technical features, synchronous alternators are divided into 4 groups. In turbogenerators, energy arises from the movement of special elements. The speed of models often reaches 6000 rpm. Due to the absence of poles, hydraulic structures operate at low speeds.

Types of brush alternators Source en.ppt-online.org

Alternating current generators in transport

Car alternator.

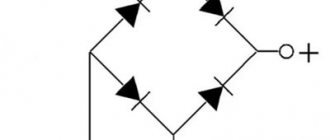

The drive belt has been removed. Three-phase alternating current generators with a built-in semiconductor bridge three-phase rectifier are used in modern cars to charge the car battery, as well as to power electrical consumers, such as the ignition system, car lighting, on-board computer, diagnostic system and others. Constant voltage in the on-board network is maintained by a specialized voltage regulator.

The use of automobile alternating current generators makes it possible to reduce the overall dimensions and weight of the generator, increase its reliability, while maintaining or even increasing its power compared to direct current generators[2].

For example, the G-12 direct current generator (GAZ-69 car) weighs 11 kg, the rated current is 20 amperes, and the G-250P2 alternating current generator (UAZ-469 car) with a weight of 5.2 kg produces a rated current of 28 amperes.

Alternating current generators are used in hybrid vehicles, which allow combining the thrust of an internal combustion engine and an electric motor. This allows you to avoid operating the internal combustion engine at low loads, and also to realize the recovery of kinetic energy, which increases the fuel efficiency of the power plant.

Diesel locomotives such as TE109, TE114, TE129, TEM7, TEM9, TERA1, TEP150, 2TE25K use AC-DC electrical transmission and install synchronous three-phase traction generators. DC traction motors, the electricity generated by the generator is rectified by a semiconductor rectifier unit. Replacing the DC generator with an AC generator made it possible to reduce the weight of electrical equipment; the reserve can be used to install a more powerful diesel engine. However, the traction alternator cannot be used as a starter for an internal combustion engine; the start is carried out by a direct current generator for control circuits.

The experimental diesel locomotive 2TE137 and the new Russian locomotives 2TE25A, TEM21 use alternating-alternating current electric transmission with asynchronous traction motors.

Asynchronous equipment

Designs operating on non-constant current are called asynchronous. The brushless alternator can be used both as a generator and as a motor. The functional apparatus quickly switches from engine mode to the schedule of an uninterruptible energy source.

Technical features

In an asynchronous alternator, the stator field rotates more slowly than in a synchronous alternator. To change the function of a motor to a generator, it is worth increasing the moving speed of the rotor. The rotating element stops following the magnetic field and changes direction.

The process occurs when a group of capacitors is connected to the network. The parts begin to charge and accumulate the energy of electric fields. The phase has a charge opposite to the source pole. The rotor slows down, which causes current to be produced.

Characteristics of equipment Source bijlibachao.com

Asynchronous designs consume power, which is needed to form a magnetic field. Electrical energy enters the engine and mechanical energy is output. The speed of transition from one mode to another depends on the characteristics of rotation or braking.

Due to the absence of brushes, the models are called brushless. The rotor of an asynchronous alternator is made in the shape of a “squirrel wheel”. The structure in the form of a solid lattice slows down the parts, creating a sliding effect. During a mechanical impulse, due to residual radiation in the elements, fields arise that dynamically interact.

Generator types

Asynchronous alternators are distinguished by operating parameters. The designs have phase or squirrel-cage rotors. Due to its complex structure, the first type is expensive to maintain. The second has moving parts in the shape of a cylinder consisting of sticks and rings, a bit like a squirrel wheel.

Alternator design Source dthy6505696.en.made-in-china.com

Transformation of a three-phase generator into a single-phase one

Quite often, the practical use of a low-power 3-phase generator to power a large number of single-phase consumers is associated with inconvenience. For example, with a station power of 30 kW, each phase is designed for 10 kW, respectively. If a load exceeding this value is connected to any phase, the automatic protection will work and the generator will turn off.

The use of single-phase generating units allows, when switching on consumers, not to calculate their distribution and power each time. A 1-phase generator can be obtained by simple transformation of a 3-phase one. To do this, you just need to switch the stator winding wires in a certain way and replace a number of components on the outlet electrical panel. The following pictures perfectly illustrate the process of converting a 3-phase generator into a 1-phase one. Let's take a closer look at them.

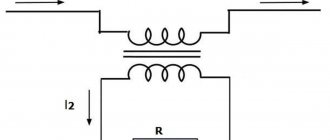

During the generation process, a voltage appears at the output of the 3-phase alternator, which is removed from 6 winding segments, which are connected mutually in the form of a “star” (see figure).

The rectangles are separate windings with a voltage of 110 V. If you connect them as shown in the following figure, the 3-phase alternator will become 1-phase.

Parallel connection of windings allows doubling the phase current. The maximum power value of a 3-phase alternator with a current in one winding of I A is calculated using the formula 3 (phase) × 220 V × I A. The maximum power of a 1-phase modification will be already 220 V × 2I (A). It should be taken into account that when transforming a 3-phase alternator into a 1-phase alternator, its active power (kVA) is limited by the diameter of the winding wires and amounts to 2/3 of the total power according to the device passport before the conversion. At the same time, the transformation of the electrical part of the generating set does not affect the power of its mechanical unit - the engine. It remains unchanged.

Which one is better to take

When faced with the task of which alternator to choose (synchronous or asynchronous), users must start from the requirements placed on the technology. Brushless models are a source of reactive energy that is not afraid of overloads from starting electrical equipment. The composition contains an automatic regulator that protects against unforeseen changes.

Brushless designs themselves are a consumer of electricity, and therefore depend on the characteristics and quality of the current. It is dangerous for the devices to operate under starting load. In professional equipment, capacitors are included to stabilize the current value.

How to choose the right source ladistributionltd.com

If you need to protect equipment from energy surges, then choose synchronous alternators. The equipment has high requirements for voltage stability, which will prevent possible problems. The devices are suitable for frequent overloads in transient mode, which occurs when connecting electrical users (equipment). The generator will protect all connected receivers.

An asynchronous alternator is used to operate equipment that does not have high requirements for current quality. The device works great in dusty places, and small debris or moisture will not damage the device. The model is suitable in cases where it is not possible to buy an expensive brush option or there is no qualified service. Equipment with additional starting capacitors can withstand transient overloads.

If you need to choose an alternator for your home, it is better to give preference to a synchronous model. Brush equipment with AVR (voltage regulation) function is suitable for PCs and household appliances. The generator will protect sensitive devices from energy surges and failure. The device is suitable for:

- offices;

- medical clinics;

- research laboratories.

If you need a device for construction, then they give it to the asynchronous model. Brushless generators function perfectly in the fresh air, on the street. The design is not afraid of dust in the production workshop. Due to its resistance to short circuits, the equipment does not break during welding, and its compactness adds mobility to the unit (easy to carry).

When choosing power, add up the sum of all connected consumers. To avoid unforeseen situations, models are taken with a reserve of capacity. The generator must be checked in the on mode. During operation, the measuring instruments are always stable, and the exhaust sounds smoothly, without jerking.

How to choose a generator Source sogaenergyteam.com

Before choosing equipment, pay attention to the type of fuel. The indicator affects the cost of the device and subsequent maintenance. If you plan to operate the generator periodically or at sub-zero temperatures, then they give preference to a cheap gasoline one. When working around the clock in a private home or office, it is better to take a diesel one. A one-time overpayment will save money on power plant maintenance.