The need for a smooth start

In order to provide the necessary starting power, the rated power of the supply network must be increased. For this reason, equipment may become significantly more expensive. Moreover, the excessive consumption of electricity is also obvious.

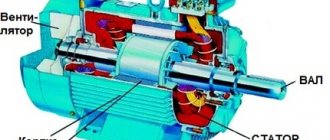

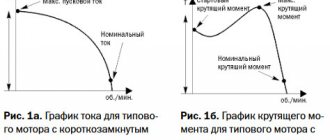

One of the disadvantages of an asynchronous electric motor is the high starting current. It exceeds the nominal value by 5 - 10 times. High surge current can also occur when the engine is braking or reversing. This leads to heating of the stator windings, as well as too much electrodynamic forces in the stator and rotor parts.

If, as a result of an emergency, the engine overheats and fails, the possibility of repairing it is always considered. But after overheating, the parameters of transformer steel change. The repaired electric motor has a rated power that is 30% less than it previously had.

In order to limit the current, starting reactors, autotransformers, resistors and soft starters are used.

Options for soft start systems for electric motors

Star-delta system

One of the most widely used starting systems for industrial asynchronous motors. Its main advantage is simplicity. The engine starts when the windings of the star system are switched, after which, when the normal speed is reached, it automatically switches to delta switching. This starting option allows you to achieve a current that is almost a third lower than when starting the electric motor directly.

However, this method is not suitable for mechanisms with low rotational inertia. These, for example, include fans and small pumps, due to the small size and weight of their turbines. At the moment of transition from the “star” to the “triangle” configuration, they will sharply reduce the speed or stop altogether. As a result, after switching, the electric motor essentially starts again. That is, in the end, you will not only not achieve savings in engine life, but also, most likely, you will end up with excessive energy consumption.

Video: Connecting a three-phase asynchronous electric motor with a star or triangle

Electronic motor soft start system

A smooth start of the engine can be done using triacs connected to the control circuit. There are three schemes for such connection: single-phase, two-phase and three-phase. Each of them differs in its functionality and final cost, respectively.

Using such circuits, it is usually possible to reduce the starting current to two to three rated ones. In addition, it is possible to reduce the significant heating inherent in the aforementioned star-delta system, which helps to increase the service life of electric motors. Due to the fact that the engine starting is controlled by reducing the voltage, the rotor accelerates smoothly and not abruptly, as with other circuits.

In general, engine soft start systems are assigned several key tasks:

- the main one is to reduce the starting current to three to four rated ones;

- reducing the motor supply voltage, if appropriate power and wiring are available;

- improvement of starting and braking parameters;

- emergency network protection against current overloads.

Single-phase starting circuit

This circuit is designed to start electric motors with a power of no more than eleven kilowatts. This option is used if it is necessary to soften the shock at start-up, but braking, soft starting and reducing the starting current do not matter. Primarily due to the impossibility of organizing the latter in such a scheme. But due to the cheaper production of semiconductors, including triacs, they have been discontinued and are rarely seen;

Two-phase starting circuit

This circuit is designed to regulate and start motors with a power of up to two hundred and fifty watts. Such soft start systems are sometimes equipped with a bypass contactor to reduce the cost of the device, however, this does not solve the problem of phase supply asymmetry, which can lead to overheating;

Three-phase starting circuit

This circuit is the most reliable and universal soft start system for electric motors. The maximum power of motors controlled by such a device is limited solely by the maximum temperature and electrical endurance of the triacs used. Its versatility allows you to implement a lot of functions , such as: dynamic brake, reverse pickup or balancing of magnetic field and current limitation.

An important element of the last of the mentioned circuits is the bypass contactor, which was mentioned earlier. It allows you to ensure the correct thermal conditions of the electric motor soft start system , after the engine reaches normal operating speed, preventing it from overheating.

The soft start devices for electric motors that exist today, in addition to the above properties, are designed to work together with various controllers and automation systems. They have the ability to be activated by command from the operator or the global control system. Under such circumstances, when the loads are turned on, interference may appear that can lead to malfunctions in the automation, and therefore it is worth paying attention to protection systems. The use of soft start circuits can significantly reduce their influence.

Direct launch

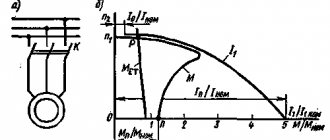

In a direct start electrical circuit, the machine is directly connected to the mains supply voltage.

The diagram above shows the inrush current characteristic for direct starting. With this connection, the temperature increase in the windings of the machine is minimal.

The connection is made using a contactor (starter). The circuit uses an overload relay to protect the electric motor. However, this method is applicable when there are no current restrictions.

During the start of the machine, the starting torque is limited in order to smooth out a sharp jerk, as a result of which the mechanical parts of the drive and connected mechanisms may fail.

For this reason, manufacturers of large electric motors prohibit direct starting.

Disadvantages of angle grinders without soft start

Cordless angle grinder Metabo W 18 LTX 125 602174850 with soft start. Photo VseInstruments.ru

In addition to providing comfortable working conditions for the user, the angle grinder with soft start has a number of other advantages.

- The absence of a large starting current during the soft start of the angle grinder , which is several times higher than the nominal value of this parameter during operation, increases the reliability of the electrical part of the power tool. In this case, the winding wires do not experience overloads and do not crack, the commutator lamellas and brushes are not subject to wear from increased sparking, and processes that worsen the connection do not occur at the contact points.

- During a uniform increase in the speed to the nominal value, the angle grinder with a soft start does not experience increased dynamic loads that arise in its absence. An instantaneous acceleration of 6000 rpm or more does not leave its mark on the gear transmission and bearing units . They fail faster, so angle grinders without such a device are more often repaired.

Star-delta connection

One of the main ways to start a machine is with a star-delta circuit. Such a start is possible for engines in which all the beginnings and ends of the windings are removed.

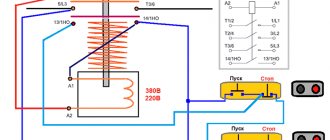

The start control according to this scheme consists of three contactors, an overload relay and a time relay that controls the contactors.

Initially, switching with the network occurs according to the “star” scheme. Contactors K1 and K3 are closed. Then, after a certain time, the windings switch automatically to the delta circuit. Contacts K3 open, and contacts K2, on the contrary, close. The time relay in the electrical circuit serves to control their switching. It sets the engine acceleration time. At the same time, starting currents are significantly reduced.

This method is effective, but it is not always used.

Start via autotransformer

This method is used by using an autotransformer in the electrical circuit, which is connected in series to the machine. It serves to ensure that startup occurs at a voltage reduced by 50 - 80% of the rated voltage. As a result, the starting current and starting torque will decrease. The time interval for switching from low to full voltage is adjusted.

However, there is a drawback here. During operation, the machine switches to mains voltage, which leads to a sharp jump in current.

Starting overloads of electric motors

What is the launch moment? This is, in fact, the beginning of rotation of the motor shaft, which is connected to transmission mechanisms (gearboxes, a block of pulleys or sprockets). In this case, the torque of the rotor is very unstable. Moreover, the shaft begins to rotate under the load from the transmission mechanisms. Such instability leads to shock loads, which negatively affects transmission mechanisms, especially the keys on the motor shaft and gearbox shaft.

The soft starter reduces starting loads. The rotation of the shaft begins at low speeds, and the speed increases gradually. That is, there are no impacts, and, therefore, no loads on the transmission elements. This is the principle of soft starting of an electric motor.

It should be noted that soft starters produced in production are multifunctional devices that can be used for different purposes. This includes the smooth start of the motor, its smooth braking, protection of the network and equipment from overloads, and so on. Each consumer will find the necessary device for their specific needs. True, these devices have one significant drawback - their high price. And if it is possible to assemble it yourself, while spending a minimum of time and parts, then is it worth buying a factory version?

Soft starters

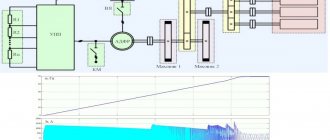

Under conditions of a smooth start of an asynchronous machine using thyristors in the electrical circuit of the power unit, a non-sinusoidal current is supplied. Acceleration and braking occur in a short period of time. Many people assemble a soft starter with their own hands. This greatly reduces its price.

In this circuit, the thyristors are connected in parallel in a circuit based on the counter principle. A control voltage is supplied to the common electrode. Such a device is usually called a triac. In the case of a three-phase system, it is present in each wire.

In order to remove the heat generated when semiconductors are heated, radiators are used. The dimensions, weight and price of devices increase.

There is another option to solve the heating problem. A shunt contact is connected to the circuit. After the start, the contacts close. In this case, a parallel circuit appears, the resistance of which is less than the resistance of semiconductors. And current, as you know, chooses the path of least resistance. While this process is happening, the triacs are cooling down. An example of such a connection is shown in the figure below.

Manufacturing a soft start socket

The most important requirement for such an outlet is its mobility. Therefore, you will need a carrier.

With its help, you can smoothly launch the tool anywhere - in the garage, at the dacha, during the construction of your house in different areas of the construction site.

The first step is to disassemble the carrier.

The main power wires in it can be either soldered or connected to screw terminals.

Depending on this, your additional outlet will also be connected. This should be an additional socket near the carrying case in order to be able to simultaneously connect the instrument in different modes.

By the way, if you mistakenly turn on an angle grinder or circular saw that has a factory built-in soft start into an outlet that is also equipped with such a soft starter, then surprisingly everything will work. The only thing is that there will be a delay in starting the saw or turning the disk for a couple of seconds, which is not very convenient to use and can be puzzling if you don’t get used to it.

Here are real tests of such a connection, carried out by one master from YouTube BaRmAgLoT777. His comment after such tests on a Dremel type engraver, a Bosch drill, a Makita router, and an Interskol circular saw:

Next, to assemble the socket, take a stranded copper wire with a cross-section of 2.5 mm2 and strip its ends.

Then you need to tin the contact pad on the carrier where this wire will be soldered.

Securely solder the cable cores to these pads.

Carefully lay out the wires and close the extension cord.

Take a square external socket for installation on the outer surface of the walls, and try on a soft starter unit in its housing. Since it has compact rectangular dimensions, it should fit there without any problems.

Mount and secure the socket body on the same platform as the extension cord.

The PP block is connected to the gap of any wire, phase or neutral. Do not confuse it, phase and zero are not supplied to it at the same time, i.e. 220V.

It is installed on one of the wires.

Also for this BPP, there is no difference on which side to make the entrance and on which side to make the exit. The twists are soldered and insulated with heat shrink.

After that, all the insides of the socket are assembled into a housing and all that remains is to close the entire structure with a lid.

At this point, the entire reworking of the carrying case and the manufacture of the socket can be considered complete. It will take you no more than 15 minutes.

We advise you to study Battery Restoration

Types of soft start devices

They can be divided into four categories.

- Regulating starting torque. Their operating principle is such that they control one phase. But when controlling a soft start, the starting currents are not reduced. Therefore, their range of applications is limited.

- Regulating voltage with no feedback signal. They work according to a given program and are among the most common in use.

- Regulating voltage with feedback signal. Their operating principle is the ability to change the voltage and regulate the current within a given range.

- Regulating current with the presence of a feedback signal. They are the most modern of all devices of this type. Provide the greatest control accuracy.