A modern concrete fence has high performance qualities and can satisfy the most demanding needs. Such fencing has a wide range of applications; they amaze with their diversity not only in design, but also in appearance. It is customary to distinguish the following types of concrete fences:

- monolithic self-standing fencing;

- decorative one- and two-sided concrete fences;

- typesetting with the possibility of final decorative finishing;

- combined.

A self-standing fence is made from monolithic sections; it is distinguished by its laconic design, reliability and durability. Individual blocks are heavy, their dimensions depend on the installation location. Installation requires a pre-prepared foundation; fencing is usually used for production areas, warehouses, parking lots, and country houses.

A decorative fence can be one- or two-sided; it has a wide variety of shapes and designs; it is usually made up of separate small sections that can be mounted without a special foundation. The textured surface of the concrete section can imitate brick, natural stone or wood. Fences of this type are used for private homes, public buildings, and schools.

After installation, stacked sections reinforced with steel rods can be painted in any color or any type of tile can be used for finishing, which makes the fence more attractive.

Composite fencing typically combines concrete and wrought iron elements to create a custom design. Most often, such fences are used for country houses, giving the site a solid appearance and harmonizing with the landscape design.

self-sufficient

decorative

combined

Types of concrete fences also include the following groups:

- solid sections, can be of greater height, are usually used for areas where maximum protection from visibility from the street is required;

- decorative openwork and partially openwork designs, excellent for country houses, have decorative permeable inserts that provide ventilation of the area and partial visibility.

Advantages of the design

A reliable and attractive fence made of concrete sections has many advantages, including:

- Weather resistance . Structures in the form of concrete sections are resistant to frost, precipitation, sudden temperature changes, and high humidity. The appearance and condition of the fence are not affected by factors such as frequent rains, snow loads, salty sea air or fogs. Such fences can be safely used in regions with a high degree of air pollution, in climatically unfavorable areas, for example, in the north.

- Durability . The estimated service life is 40-50 years, but with proper care the fence will last much longer without requiring repair or replacement. The use of vibration casting during the manufacture of sections makes it possible to remove air from the mixture as much as possible. This ensures increased density of the structure, increasing its frost resistance and stability in high humidity. Such fencing is guaranteed to withstand up to 350 freeze-thaw cycles, but only if all the conditions of the section manufacturing technology are met.

- High strength . During the manufacture of sections, reinforcement is used using smooth or corrugated steel rods. This makes it possible to increase resistance to mechanical loads and increase the durability of the structure.

- Mobility . The structure is collapsible; if necessary, it can be removed and moved to a new location, for example, when expanding the site.

- Enhanced aesthetics . The peculiarity of manufacturing sections allows you to produce sections of any size and shape, simulating the surface of stone, brick, wood. Adding pigments to the solution allows you to give the fence an individual, very attractive appearance.

- Quick installation . This type of fencing is installed very quickly; when using small sections, the use of heavy construction equipment is not required.

- Geometry of sizes . The use of special shapes in the production of sections ensures the stability of the geometric dimensions of each element. This makes it possible to quickly and efficiently perform installation using standard supports with grooves.

Sectional concrete fence: design features

An important point in arranging a site on which a summer cottage for seasonal recreation or a private residential house may be located is the construction of a fence. The main requirements are durability and a pleasant appearance of the fence. A sectional concrete fence combines many useful qualities; the structures also do not require the use of special equipment for installation.

Modern sectional fences

Unlike monolithic reinforced concrete slabs, the new concrete fences consist of supports with grooves for sections, including no more than four slabs weighing up to 70 kg, so two workers can handle the installation.

Vibratory casting technology involves the creation of steel reinforcement, which improves strength characteristics. The slab contains plasticizers and fiber - a material that is synthetic fibers that make concrete abrasion-resistant, frost-resistant and waterproof. In addition, this makes it possible to use any type of decor.

An improved concrete fence can be one-sided, having design elements only on its outer side, or double-sided, equipped with a pattern or bas-relief. The texture can be different; the most popular are imitations of wood, stone, and brick.

Today, the construction market offers a wide range of such products, differing in size, shape and color. Concrete can be given any color during the process of creating the slab by adding special coloring pigments, most of which are acidic components. They are resistant to ultraviolet radiation, chemical and thermal influences, and corrosion.

Despite the fact that such fencing elements can be created independently, it is quite expensive and difficult if there is no experience in such work. But there is always the opportunity to purchase a high-quality finished product, based on your preferences.

Advantages

The sections are produced at the factory using special technologies and high quality materials. This allows us to produce products for long-term and successful operation.

Eurofence has the following positive characteristics:

- Increased strength of concrete - such a fence can be used for about 40-50 years. Thanks to its dense structure and reinforcement with steel rods, the structure is resistant to any climatic and weather conditions.

- Reinforced concrete fence is not subject to rotting and corrosion. The product is fire resistant.

- The structure can be installed without a strip foundation. With proper concreting, the slabs can be installed on any type of soil and remain stable even on water-saturated soils - quicksand.

- Simple and quick installation of finished products is noted. The prefabricated structure is erected with the help of two or three people and does not require professional equipment.

- Concrete fences are suitable for different types of landscapes, since they are varied in their texture and shape, can have different patterns, imitate any natural materials, and recreate a particular style.

- The surface of the fence does not require special care during operation. If sections of unpainted concrete are initially purchased, they can be optimized using inexpensive oil-based exterior formulations.

- Despite the variety of products, there are established slab sizes. Thanks to this, assembly is carried out without distortions and gaps.

Types of concrete fencing

A sectional fence may include transparent segments cast in open molds. They are decorative openwork slabs, the creation of which uses a specific design. However, blind structures are also produced that are not visible.

You can choose a glossy or matte finish. If desired, products with a one-sided or double-sided pattern or bas-relief are installed.

The traditional parameters of one prefabricated fence block are 50 cm wide and 200 cm long. A feature of the one-piece structure is the presence of support posts that support the fence.

They also have standard sizes:

- for single-block fencing, supports are designed with a height of 120 cm, while they go 70 cm into the ground,

- with two-block sections, products with a height of 170 cm are used (100 cm remains above the ground),

- for three, four and five sections, columns of 220, 280 and 350 cm are required. In this case, it is calculated that 150, 200 and 250 cm will remain above the soil surface.

These characteristics are important for quick and error-free installation. In order to create a blank, impregnable wall and hide the courtyard, concrete fences are often installed in two or three rows. Even four-row fences are built stone by stone.

Tools for creating and constructing blocks

Making sections of a prefabricated fence with your own hands is quite possible, but such work makes sense if there is a need to fencing an area of 7-8 acres (about 120 meters).

Creating fence components

The design of sectional concrete includes:

- sections of different shapes and sizes;

- support posts (it is recommended to use special supports with grooves to facilitate installation);

- foundation (depending on the characteristics of the fence, it can be strip or point for supports);

- gate and wicket.

During installation, the foundation is laid first and the supports are installed. Sections can be purchased ready-made or made yourself. But this will require special equipment and materials, and some work skills.

How to make and install concrete fences from sections

Structurally, an assembled concrete sectional fence is a system of specially shaped load-bearing pillars and concrete sheets installed between them, the number of which is determined by the design features and the height of the fence. As a rule, the section fabric is chosen as a composite type, so it is easier to install and it is easier to give the fence an original design.

The pillar is a reinforced concrete product with a U-shaped recess for installing a slab, which is located on both sides of the pillar. At the same time, the lower plate of the canvas rests on the post itself, so the fence does not require a foundation and can be installed with a gap between the canvas and the ground.

The function of the foundation is performed by the pillar itself, which, due to the fairly high load, is usually concreted to a depth of 1.2-1.5 m, depending on the nature of the soil and the depth of freezing. The concrete pad for such a support should be below the freezing depth of the soil to avoid pushing the pillar upward.

Therefore, the quality and reliability of installing a fence made of concrete sections depends on the reliability of the installation of load-bearing pillars, maintaining the exact distance between them and a strictly vertical position. Sections for such fences are either used as standard ones from the existing range, or are manufactured according to an individually developed project.

In both cases, concrete is poured into a mold under vibration, which allows for maximum strength of the finished product.

When you contact a company that installs concrete fences, the work is usually carried out according to the following scheme:

- The site is studied in detail, the perimeter of the fence is measured, the installation locations for wickets and gates are determined, the soil is examined, the desired shape of the canvas and the height of the fence are selected.

- Design documentation is developed, an estimate is drawn up, which is finally agreed upon with the customer.

- Sections and load-bearing pillars are manufactured or purchased for the future structure.

- Everything you need is delivered to the site.

- Work is being carried out to install the supporting structure, usually using concreting and support pillars.

- After the solution has hardened, the sections are carefully lowered into the grooves of the pillars and, thus, the entire fence is assembled.

- After completion of the work, a certificate of completion is signed, and warranty documents are transferred to the customer.

The longest stage of installing a concrete sectional fence is the installation of pillars, since it requires the preparation of holes and the completion of the concrete hardening process. After this, the sections are installed quite quickly, and usually fencing a small area of a private house takes about 1 week from the start of work.

Stages of installation of a concrete sectional fence

Installation of a concrete sectional fence usually requires preliminary preparation of the base in the form of a shallowly buried strip. To do this, it is necessary to mark the perimeter of the site, dig a trench with a sand cushion and formwork. Next, the supporting elements are installed and the concrete mixture is poured. Since the dimensions of a monolithic reinforced concrete fence slab are quite large, installation may require a crane or other equipment that will help install each section strictly in place.

marking

sand cushion

formwork

Installation of a decorative fence with small sections can be carried out without the use of construction equipment. But it is recommended to involve 3-4 people in the work to install supports and sections. If large sections will be used during installation, a crane may be required for the work.

The installation process of sectional fencing includes the following steps:

- the territory is marked around the perimeter (the distance between the supports should be about 2 meters);

- foundation work is being carried out;

- support pillars are mounted, for which it is recommended to use a building level to check verticality;

- Concrete slabs are fastened into place, after which final decorative work is carried out if necessary

- To install gates and wickets, separate posts are mounted to which metal inserts for the doors are welded.

Sectional concrete fence: pros and cons

Owners of private houses do not have to think long about choosing a fence. Often preference is given to reinforced concrete structures: they are durable, aesthetically pleasing and are in an acceptable price category. They are used in factories and other industrial facilities.

Reinforced concrete fences come in different designs and with different purposes. Monolithic varieties are the strongest of all types of concrete fences. They are made from massive slabs and installed on a foundation. Often practiced in industrial areas. Monolithic fences also include types of self-standing fencing that do not require a foundation.

Self-standing fences are the most powerful. One element weighs up to two tons, so installation is impossible without special equipment. They are expanded at the bottom and are installed stably without a foundation. This makes it possible to install fences even in places with high groundwater levels. They look boring, but they are durable and reliable, they are used in industrial areas.

Stacked (sectional fences) consist of individual slabs 50 x 200 cm. They are laid between supports from 2 to 4 pieces to achieve the desired height. A wide variety of sections allows you to choose the material, suitable texture and pattern. Most often, the upper part of the fence consists of decorative sections, while the lower part looks simpler.

Sectional fencing is:

- Decorative - differ from homogeneous slabs in a variety of textures (stone, brick, wood and other decor), can be colored or contain images.

- One-sided - only one side contains decor, the other is flat (this side of the fence is turned towards the yard).

- Double-sided – the decor contains both planes; this section looks complete on both sides and is more expensive.

- Blind fences are assembled from four sections; they look impressive and reliable.

- Open openwork sections rise above the ground on posts and create an impression of openness and grace.

Fences look interesting when the design is made up of four independent elements (50-60 kg each), into which the section is divided. Due to the lightness of the material, such a fence is easier to install.

Sections for collecting fencing are available in matte and glossy.

Advantages and disadvantages

People call sectional concrete fencing “Eurofence” for its beautiful appearance and excellent qualities. To evaluate this material, you need to find out all its advantages:

- Strength. It is guaranteed by a metal base hidden in layers of concrete. This fence can withstand heavy mechanical loads.

- Weather resistance. Reinforced concrete is well compacted, it is as air-free as possible, which makes it particularly resistant to aggressive weather conditions. It is frost-resistant, not subject to rotting and corrosion.

- Appearance. The fence is beautiful, neat, some openwork types are especially attractive. A variety of decor inspired by wild stone, wood, stucco, weaving and forging can satisfy every taste. Color, pattern, surface texture - everything works for aesthetics.

- The fence, consisting of sections, is easy to install. Even monolithic blocks, which require special equipment for assembly, are not difficult to install. Some types of fences do not require a linear foundation.

- Any soil and any soil surface (even slopes) are suitable for installing a concrete fence.

- It is fire resistant.

- The variety of products makes the choice easier.

- Due to its strength, it reliably protects against penetrations.

- The sections are mobile, this facilitates transportation and assembly, and makes it possible, if necessary, to disassemble the fence and move it to another location.

- The advantages include the compatibility of such fencing with other finishing materials.

- You can choose your own type of fence for any yard design.

- The sectional structure of the structure allows it to avoid gaps.

- The fence is easy to maintain; occasionally it should be treated with concrete water repellents. But many don't do this either.

Flaws

There are few disadvantages to such a fence. High fencing is considered airtight and harms nearby plants. You can use openwork material, fewer rows of sections, raise the fence above the ground and solve this problem. The disadvantages include the large weight of monolithic slabs, but this is what gives the fence its special strength.

Features and Specifications

Vibratory casting technology is used in the production of concrete sections. Special forms are filled with a mixture of cement (grades M500, M600), sand, granite filler and water. Then the solution is compacted. Reinforcement with high quality steel occurs. The result is a particularly durable and beautiful product.

Design ideas are embodied in several hundred types of these products. The sections come out with a pattern and are solid. They can be with through holes, like a mesh or weaving. This design makes them graceful and airy. The sections are of a standard type: length is 2 meters, height – 50 cm, thickness – 5 cm.

As for monolithic panels, their thickness is at least 15 cm. Based on the two-meter length of the module, the distance between the supports should be calculated. When purchasing poles, you need to make sure the quality of the grooves (5 cm), otherwise problems may arise with the installation of sections. The upper part of the fence is made with especially beautiful decorative elements; the lower the sections are installed, the simpler they are. If the fence plays a protective function, its assembly height should be at least three modules. For decorative purposes, a light fence in 1-2 sections is sufficient.

Installation work

To carry out installation work, supports and sections are needed. Decorative modules are all the same size. There are two types of pillars: solid and prefabricated. Before constructing the fence, it is necessary to prepare wells. Installation should begin from the corner (install a solid support to a depth of more than half a meter and secure with supports).

During any work, it is necessary to accurately set dimensions and levels. After making sure that the post is vertical, you can pour the concrete. A second pole is mounted at a distance from the length of the section. The module fits into special grooves. The second element should not be installed immediately (misalignment may occur). The structure must be strengthened. There is no need to rush in the construction of a fence; everything is done gradually and carefully (support by support, section by section).

If the fence is built on prefabricated posts, you should prepare a base for them. The width of the hole should exceed the block by 5 - 7 cm. The reinforcement is inserted into the well so that its height coincides with the top of the fence. Check the level of verticality of the support, then concrete it. All elements of the pillar are gradually exposed and filled with concrete. And then, as in the case of solid supports, the sections are mounted between the pillars using grooves.

Tools for work

To install a concrete fence, you will need the following materials and equipment:

- Portland cement M400-500;

- sifted river sand;

- crushed stone;

- pure water;

- pigment (if sections of a certain shade are required);

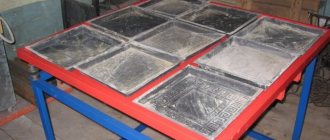

- silicone or plastic molds for pouring;

- machine oil for lubricating molds;

- vibrating table;

- electric concrete mixer;

- shovel;

- pegs for marking;

- building level, plumb line;

- ready-made supports with grooves.

If one section is heavy, lifting equipment will be required, but usually a sectional fence can be installed by 3-4 people.

Calculation of the number of sections

When planning the installation of a concrete fence, it is necessary to pay great attention to calculating the size of one section and the total number of elements. The standard dimensions of one section of the fence are 2 meters wide and 1.5-2 meters high. When calculating the number of sections. It must be taken into account that the total length of the section is 2.06 meters (2 meters is the working width), to this value it is necessary to add the cross-section of the support column and the presence of technological gaps.

When making calculations, the perimeter of the fence is first calculated, and the width of the gate and supports for the doors is subtracted from the resulting value. Next, the number of supports is calculated, and two pillars are dug in at once in the corner parts of the fence, that is, their cross-section is doubled. The remaining value is divided by the total width of one section, allowing you to obtain the number of slabs for installation.

How to correctly determine the quality of panels

If you are planning to install a concrete fence, you need to carefully assess the quality of its structural elements. A fence made of concrete sections must meet the following requirements:

- The grade of cement for the production of concrete fence panels must be at least M500. Visually, this can be determined by the light gray color of the unpainted sections. This color indicates the use of high quality concrete.

- A high-quality fence should not have pores or cracks on the surface, since any voids are a danger of moisture entering, which will gradually destroy the structure.

- The accuracy of manufacturing support pillars for concrete fences plays an important role. The panels should fit freely into the grooves of the supports, but not jump out of them. The standard dimensions of the sections are 2000*500*45 mm, so the depth of the grooves must be maintained at 50 mm.

It is better to order a concrete fence from large companies specializing in the production of reinforced concrete products. It is advisable to simultaneously purchase a complete set of decorative elements of the same series as the panels. If desired, you can immediately order concrete coloring in bulk.

Solutions for concrete fence

One of the most important steps in the manufacture of concrete sections is the correct choice of solution and its proportions. It is on this that parameters such as strength, durability of the structure, and resistance to loads will depend.

The basis of the solution is cement; experts recommend taking M400 or M500, which have the necessary qualities. Screened river sand without clay inclusions is used as filler. Before mixing, it is recommended to sift the sand mixture again.

When choosing the proportion of the solution, you need to focus on the brand of concrete; among the recommended proportions are the following:

- Portland cement M400 B30 is used for mixing. The proportion of the solution is 1:1.2:2.7 (cement, sand mixture and granite crushed stone, respectively). The volumetric composition for 10 liters of cement will be 11 liters of sand and 22 liters of crushed stone. The yield of concrete per 10 liters of cement will be 31 liters of finished solution.

- When using Portland cement M450, the following proportion is observed: 1:1.1:2.5 (cement, sand, crushed stone, respectively). The volumetric composition is 10: 22 (sand mixture to crushed stone), the amount of the finished solution will be 29 liters per 10 liters of dry cement.

An electric concrete mixer is used to mix the solution (a manual one may not produce the required quality). Water is added gradually, the finished consistency should resemble thick sour cream.

If you want to obtain colored sections, then special pigments are added to the solution during mixing. Their quantity is indicated by the manufacturer, the substances themselves are distinguished by rich shades, they do not fade in the bright sun, and do not wash out. Such a fence does not require additional painting after installation.

Video: proportions and composition of concrete

Types of concrete fences

Gray simple spans of concrete fences are a thing of the past. Manufacturers produce concrete sections that can successfully imitate brick, natural stone, wood and even marble. The upper part of a concrete fence is often decorated with a curved decorative section.

Longitudinal seams have also been learned to be hidden well. To do this, they try to place the seam along uneven joints of supposedly masonry. The result is a decorative fence, as if made of natural stone. Concrete pillars are also decorated by casting them in the form of various figures.

Nowadays concrete sections are decorated not only from the outside, but also from the inside. Therefore, the fence looks great both from the street and from inside the yard.

The technology of manufacturing concrete fence sections to look like “marble made of concrete” has become quite popular. The sections are strong, without pores or cracks. And the paint applied throughout the entire mass of the product provides a smooth glossy or matte surface. The fence retains its marble texture and color throughout its entire lifespan, without additional maintenance.

The process of pouring concrete mixture into a finished mold

After mixing, the concrete mixture is carefully poured into molds. For the manufacture of sections, two methods are used - instant formwork and exposure. Both are based on vibration casting, that is, it is necessary to use a vibrating table and special molds.

The mixture is poured into fiberglass molds and placed on a vibrating table to compact the solution. In the first case, the form is removed immediately after the concrete compaction process is completed. In the second case, the solution remains in the formwork used until it gains strength.

To make the fencing sections more reliable and resistant to mechanical and other loads, it is recommended to use smooth or corrugated metal rods. Reinforcement is performed at the pouring stage; such a simple technology allows you to correctly distribute the loads on the fence sections and increase their resistance to external loads.

When choosing a production method, the operating features of the fence are taken into account. Products made using the exposure method are distinguished by greater strength, complete absence of defects and improved aesthetics. Products made using the instant formwork method are used for industrial areas, warehouses, and car parks. They do not have such high aesthetics; minor defects are possible on their surface. But the performance characteristics remain just as high.