Features of reinforced concrete fences

Concrete structures perform a decorative function, which is combined with protecting the site from unauthorized entry. Part of the building structure is a metal frame, which ensures the reliability of the assembled elements. A reinforced concrete fence has a number of advantages, which include:

- resistance to fire;

- ease of installation;

- strength and reliability;

- low price.

Due to the monolithic design, protection from dust and wind is enhanced and noise pollution is reduced. The slabs are made by forming a concrete mixture consisting of sand, cement, crushed stone and additives that give the material plasticity and hydrophobicity.

Concrete fences are made from blocks, decorative elements, and monolithic structures. The technological production process is regulated by regulations and complies with GOST and technical specifications.

When manufacturing sections, molds are used into which a metal frame is placed. After pouring the mixture, it is compacted on vibrating tables. Structural elements are painted by adding mineral pigments to the working solution.

Such finished products have a higher cost and retain their original color when exposed to sunlight and precipitation. For the production of sections, pigmented concrete is used, products from which are more expensive and have a long service life.

Scope of application

Concrete fencing is the optimal solution for constructing a high-quality and reliable fence. Designs of this type are characterized by the best price-quality ratio, practical protection and decoration functions.

Reinforced concrete fences are often designed in exterior design systems. When planning, the type of product, the requirements of technical standards and the wishes of the customer are taken into account. Fences are used in civil engineering in the construction of country houses, arrangement of park areas, and children's institutions.

Massive structures are part of the system of security measures at sensitive facilities and areas with limited access. For example, a set fence PO-2, which consists of panels and foundation glasses, is intended for perimeter fencing:

- industrial and energy facilities;

- warehouses;

- residential and public buildings.

Self-standing fences are massive structures. Their surface can be smooth or have a relief, and the height can reach 4 m. Fences made of prefabricated panels are used to fence suburban areas. In this case, they are decorated and painted in different colors.

Advantages and disadvantages

Before choosing the type of structure for demarcating a site, it is recommended to consider the properties and installation features of each of them. Concrete fences are not demanding on the condition of the soil or the terrain of the area. Properly installed reinforced concrete fences are characterized by the following advantages:

- strength;

- resistance to deformation and mechanical loads;

- tolerate the influence of climatic factors;

- create a barrier to illegal entry.

No excavation work is required for the foundation. The speed of construction and dismantling is ensured by mechanizing the process and minimizing manual labor. In such places, when pouring the foundation, reinforced reinforcement and deep planting are required.

Concrete sections are manufactured in a wide range: stone-like, with imitation brickwork, balusters. The decorative concrete fence has an adjustable height and is easily transformed; if necessary, sectional elements can be dismantled and replaced with new panels.

The disadvantages of concrete structures are their high price. Installation of individual blocks will require the use of special equipment, and installation of heavy structures requires strip foundation equipment.

When installing monolithic blocks, the area is poorly ventilated. Moisture has a destructive effect on structures, so when choosing, pay attention to the surface of the blocks. High-quality products should not have defects or mechanical damage.

The main disadvantage of reinforced concrete fencing is its low decorative effect. Exterior finishing increases the cost and requires constant updating, so when choosing, you can pay attention to openwork elements and a European fence.

Types and characteristics of reinforced concrete fences

Depending on the design features, there are panel reinforced concrete fences equipped with legs, which are mounted in special foundation glasses. The advantage of this fence is the simplicity and time of construction.

Stacked fences have other design features. Rectangular slabs are installed in the grooves of pillars of various heights. The advantage of a reinforced concrete fence is the ability to reach a given height of up to 3.5 m.

By design, reinforced concrete fencing panels are rectangular in shape, slightly elongated horizontally. The width (length) of the fencing element is 2500 and 4000 mm.

Reinforced concrete slabs, the dimensions of which are indicated by the manufacturer in the specifications, are produced in accordance with the requirements of building codes. For example, the PO-2 fence element is made from heavy concrete grade M200 and can withstand 50 cycles (in terms of frost resistance). The front surface of the panels is made with a “diamond edge” pattern.

The panels are designed for strong wind loads, have a width of 250 mm, a length of 300 mm, a thickness of 15 mm, and a weight of 1450 kg. The cost of the product is 7800 rubles. Fence panels of this type can be manufactured with an apron (product marking PO-2m, weight - 1600 kg, cost 8 thousand rubles).

The PO-3 structural element has a mass of 1250 kg, width and length - 2500 mm, and is used for arranging the fence of sensitive enterprises. P-6v slabs are produced in heights of 2.5 m, lengths of 2.5 m and 4 m. The weight of the product is 1600 kg, the price is 9800 rubles.

The monolithic reinforced concrete panel of grade P-6m has a large weight (1800 kg), the design of which is designed for high dynamic loads. This type of fence is equipped with aprons and has a size of 4x2.5 m, which speeds up installation. Structural elements are intended for repeated use.

Sectional

This type of fencing is assembled from individual elements - panels. They can be equipped with supporting pillars and a foundation or installed between them during installation. Reinforced concrete sections are made smooth or with a pattern. Depending on the design, the panels are installed in the gaps of blocks that act as a base, or rest on pillars. The aesthetics of the fence is achieved through the geometric shapes of the elements.

Combined

Fencing can be installed using solid or patterned panels. In a combined version, the following is used for installation:

- corrugated sheeting;

- tree;

- metal elements (forging);

- concrete.

This type of fence is rarely used. Installing a fence around the perimeter of the territory using different materials reduces the aesthetic appeal of the structure. Combined options are used based on financial capabilities, but at the same time take into account the features of the landscape and the construction site.

Decorative

Fences that use panels imitating various materials and line patterns are distinguished by their aesthetics and attractive appearance. Decorative reinforced concrete fence is characterized by high cost, which is compensated by a number of advantages:

- ease of care;

- wide range;

- durability;

- chemical resistance;

- possibility of painting;

- no need to fill the foundation.

Fences are assembled according to the principle of a designer. For installation, you will need to decide on a location, install and concrete the support cups. The gaps between the slab and the pillar can be compensated for by a special type of installation, in which the work is carried out in stages.

Eurofence

Concrete fences are used in private construction and are made using vibration casting. This technology ensures high quality slabs, absence of defects, and hardening of the mixture without subsequent firing.

A prefabricated structure consists of stacked elements that differ in size and weight. You can do the installation yourself. The fencing panels are laid in supports. Which have special slots.

Self-standing reinforced concrete fence

The fence is used in enterprises and in the private sector when the groundwater level is high. Heavy concrete M20 is used for the manufacture of structures, which ensures resistance to changes in climatic conditions and temperature extremes. During the production process, reinforcement with metal or composite mesh is used.

The panels can have decorative patterns that enhance the integrity of the structure. For self-standing products intended for fencing (O), the following markings are used:

- EO - element;

- FO - foundation;

- Software - panel.

The fence is installed on a base consisting of a layer of crushed stone covered with sand. The stability of the fence is ensured by the center of gravity located closer to the ground and the expansion at the bottom. The slabs of the structure have a T-shaped configuration.

Restrictions on installing a fence of this type are determined by the weight and parameters of reinforced concrete products. The average weight of the panel is 1.5-2 tons. For this reason, self-standing fencing should not be installed on loose soil or areas with elevation changes, which can lead to subsidence or falling fragments.

On glasses

When installing slabs, reinforced concrete products in the shape of a truncated pyramid can be used. Special “glasses” make it possible to create a prefabricated base that compensates for minor differences in height of the fenced area. You can pour cement mortar into the recess of the “glass” to raise the slab horizontally.

Prefabricated structures are characterized by strength and quality. Fences of this type are installed using special equipment. The elements of each panel are connected by welding embedded parts.

Monolithic

The fence is constructed by filling voids in installed formwork made of lumber, plastic, and metal. The installation of monolithic slabs for a reinforced concrete fence is subject to a number of requirements to ensure the safety of the structure.

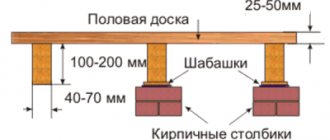

The width of the wall should be 10-20 cm, and the height of the fence should be 180 cm. Reinforcement with a diameter of 8 mm is used for strengthening. A monolithic structure can consist of panels, pillars, or be a monolithic wall.

Step-by-step installation of a concrete fence made of panels

Figure 3. Installation of a fence made of concrete panels

Installation of fences made of concrete panels is in most cases carried out independently. The following tools and materials are required for work:

- shovel, crowbar;

- device for compacting soil, sand mixture;

- level, building level;

- roulette;

- sand, screenings, crushed stone;

- cement;

- ladder;

- concrete plates;

- stakes or posts for fixing supports.

Often the master needs the help of several more people. There are 2 options for installing a fence. The first involves installing pillars at the same distance from each other, and the slabs are mounted in grooves. The supports are fixed every 2 m. They are installed in prepared holes and filled with large crushed stone. After this, the cement-sand mixture is poured. Installation of panels is allowed only after 3 days.

The second installation method involves alternate installation of pillars. After installing one of them, concrete sections are attached. Next, a second pillar is dug in and fits onto the panel with a groove.

Installation steps

The work of installing a fence involves the following steps:

- Marking the territory. For this purpose, stakes and rope are used. The procedure begins from the gate. In place of the future pillars, stakes are installed on which the cord is pulled.

- Preparing holes and installing pillars. Each fragment is checked by level. Even a slight distortion will lead to the fact that the plates will not fix properly.

- Installation of panels.

The progress of work is constantly monitored using a building level and level.

Basic installation rules

Reinforced concrete fencing is installed on a prepared and pre-marked site. Before starting work, an area will be equipped for storing fence elements. Site preparation includes clearing debris and leveling. Before installing reinforced concrete fences, markings are carried out.

To do this, find the corner points of the fence, stretch a rope between them and determine the installation location of the 1st support. The distance between the pillars is determined taking into account the parameters of the supports and the width of the panels.

The installation of the structure is carried out in accordance with the rules. Fencing on “glasses” is carried out according to markings, maintaining the fence line. The installation of blocks and panels is carried out as the supporting elements of the structure are fixed. To avoid errors when installing products, it is recommended to follow the instructions developed by the manufacturer.

Decor and painting

Concrete fences have a relief design that imitates tree branches, stone, logs, timber. Complex structures can consist of several types of blocks. At the top of the fence, an imitation of a lattice or baluster is often installed. The correct choice of texture and color allows you to emphasize the natural appearance of the fence and organically combine it with the landscape.

An original solution for decorating a fence is the use of openwork elements with a reliable imitation of weaving made of bamboo, wicker, and forged elements. Coloring can be done using high-quality mixtures. As decoration, artistic compositions, graffiti, and drawings with cartoon characters are applied to the surface.

Concrete fence as a decorative element

Figure 1. Fence made of concrete panels

A fence made of concrete slabs is often a decorative element. It can have different texture, height, color. You can purchase panels decorated with patterns that replicate the texture of stone and brick.

Such fences are installed not only near private houses, but also around offices, schools, and kindergartens. The design does not take up much space, looks aesthetically pleasing and beautiful. Concrete slabs for the fence can be purchased ready-made or made yourself.